Maintenance of country houses requires a large amount of water. The liquid is consumed by showers, dishwashers and washing machines. Previously used water sources do not satisfy the needs of owners of modern cottages. In this case, it may be necessary to drill a well in the well.

A large amount of silt and water with impurities are the most common reasons for upgrading a well by drilling wells to aquifers.

Reasons for modernization

A decrease in well productivity is caused by the following reasons:

- Sludge formation. If the source has not been used for a long time, a coating forms on the bottom and walls, deteriorating the quality of the extracted resource.

- Damage to casing elements. Occurs when the ground freezes or moves. Soil particles penetrate through the resulting defects and pollute the water.

- The appearance of harmful impurities in the produced liquid. Well water rises from a depth of 5-10 m. It comes from streams originating on the surface of the earth. Precipitation is filtered by a sand layer and penetrates into the aquifer of the soil. At these stages, the water is saturated with harmful impurities contained in the air and soil. Nitrates and heavy metal salts make the liquid unsuitable for consumption.

It is recommended to extract water by drilling a mine to deep aquifers. A budget option is to install a well in an existing well.

Drilling a well next to a well is a more affordable solution than upgrading an existing well.

External water supply

When installing a water supply system for a private house from a well with a hydraulic accumulator, it is important to correctly lay the pipes outside. Products made from HDPE are considered the best options. Low-density polyethylene withstands temperature changes well, is easy to install, and is resistant to deformation

Low-density polyethylene withstands temperature changes well, is easy to install, and is resistant to deformation.

For laying pipes, you need to dig a trench from the caisson to the foundation of a cottage, swimming pool, etc. The depth of the channel is below the freezing level of the soil. This parameter is often 0.8-1.5 m depending on the region.

The pipes are joined using special electric couplings. When heated, they melt the HDPE material and make the joints airtight.

It is better to enter the line into the house through the foundation. Here you should use a hammer drill bit to make a hole. It is reinforced with a steel sleeve. The water supply to the house from the well is hermetically sealed, and all gaps are additionally coated with bitumen mastic.

Well inside a well

This method of water extraction does not always help save money. It is more profitable to drill a well nearby. The power of professional equipment allows you to complete the work in a short time.

Therefore, most specialized companies prefer to develop water sources on flat areas. The depth of the mine is measured from ground level. This option is also beneficial for the customer. A well installed in a new location is easy to maintain and operate.

Private teams using low-power drilling rigs undertake the deepening of existing wells on the site. In this case, it is necessary to strengthen the walls of the shaft, build rigid frames, and secure casing rings and pipes. By using an existing mine, drilling costs can be reduced.

Choosing a location for a water source

The well must be located at a distance of at least 30 meters from sources of dirt (manure heaps, toilets, cesspools, bathhouses). If a well is installed, the distance can be reduced to 15 meters. It is not recommended to build a well on the slope of a ravine or on the bank of a river, since in this case the main source will be dirty groundwater.

Whatever water extraction system is chosen, it is necessary to ensure the passage and placement of the contractor's equipment and machines, as well as the availability of space for materials on the site. In the case of wells, additional territory is required for disposal of the excavated soil. If a house has not yet been built on the site, you can cut a well directly in the building area. This will significantly reduce the cost of pipelines and caissons, but can become a problem when carrying out well repairs.

In what cases is it necessary to make a deepening?

To understand whether it is worth deepening a well, you need to study the structure of the soil layers.

Cloudiness of water and harmful impurities are usually associated with insufficient depth of the well or well.

They are arranged in this order:

- Fertile layer. Located on the surface, covered with vegetation.

- Clay and loamy layers. These rocks do not pass water well. Such formations may contain sand inclusions from underground streams.

- Sandstone layer. The layer covered with a clay crust contains a large amount of water. Sand moves with the liquid, forming quicksand.

- Clay with granite and boulders.

- Aquiferous sand layer. The layer lies on the surface of porous limestones, in the thickness of which lies artesian water.

Simple wells receive only surface or groundwater. The watershed may be limited by quicksand that are impossible to see. With frequent mining of a resource, a pocket is formed in the sand, containing a certain amount of liquid. This volume is sufficient to meet minimum needs.

But this amount is not enough to service a private home. A slight increase in the depth of the well does not eliminate the problem, so the owner decides to drill a well. The process does not cause difficulties if the drill does not rest against the granite layer.

When repairing a concrete well shaft, special attention is paid to sealing the gaps between the rings.

Financial side of the issue

When carrying out excavation work, the cost directly depends on how deep the shaft will be. The shallower its depth, the cheaper the device will cost the site owner. From this point on, the cost of a well will be less than that of a well.

The cost of installing the latter is influenced by the topography of the site, the type of soil, the depth at which the aquifer lies, etc.

If the water is at a depth of up to 16 m, and the terrain does not create difficulties, then the cost of the device will be comparable to the cost of a well, and maintaining the well will be even cheaper. You need to consider the costs not only of drilling a well or shaft and installing a pump, but also of water filtration and disinfection.

Comparative cost of water intake

For many owners, the question of choosing which is better, a well or a well, is far from idle. After all, it is he who determines the cost of construction and maintenance of water production facilities.

When calculating the estimated cost of water intake, a number of parameters should be taken into account:

- excavation work based on each linear meter in depth;

- volume of materials to strengthen the walls of the penetration;

- frequency of maintenance of the structure.

Due to the low cost of excavation work, which can be performed without the use of heavy special equipment, many summer residents, gardeners and villagers can afford to install a well.

The estimated cost of completing a well varies from 30 to 40 thousand rubles.

It includes:

- Installation of a bottom filter (4-5 thousand rubles).

- Filtration gravel filling (1-1.5 thousand rubles).

- External house for the head (from 7 thousand rubles).

- Submersible pump with installation (15 + 7 = 22 thousand rubles).

Construction of a well without taking into account the laying of communications from the point of water intake to the points of consumption will cost about 100 thousand rubles. The cost depends on the time of year, drilling depth and equipment used. We examined in more detail the main factors influencing the final cost of constructing a well in this article.

The well package includes many components, including a pump, caisson, control devices and a hydraulic accumulator, the cost of which amounts to tens of thousands of rubles

The price of a pump for a mine well is also much cheaper in comparison with the pumping equipment required when constructing a well.

In which well can a well be made?

There are no regulatory documents regulating the construction of wells in wells. Before starting drilling, make sure that the work will not cause the collapse of the casing structure and will not affect the properties of water.

The existing structure is inspected for visible and possible defects. Cracks and chips are eliminated, the casing elements are given the correct position. Log structures are strengthened and tied.

Durable concrete products also require inspection. The casing must have no gaps or moving parts. The mine is given a strictly vertical location.

The displacement of the rings indicates the mobility of the soil layers. In this case, the drilled well will cause rapid flows of water to enter, destroying the casing.

Typically, when drilling wells in wells, auger drills are used, but if necessary, other options with a larger diameter can be selected.

Scope of application of core drilling

Core drilling is a method that makes it possible to determine with the greatest accuracy the depth of the roof and base of soil layers, as well as the depth level of the groundwater table.

Core drilling technology is widely used in the following industries:

- Water supply in industrial and private spheres. Drilling wells for private water supply, organizing water intake for entire villages or city blocks is effectively carried out by core drilling due to the fact that the drill easily penetrates to great depths. The core tool is capable of lifting almost any destroyed rock except for water-saturated and loose, non-cohesive soils (sand, gravel, pebbles);

- Geological exploration in the mining industry. When rock passes, a point effect on the ground occurs along the radius of rotation. In other words, with a projectile that is structurally reminiscent of a pipe, a solid mass of rocks is drilled out without disturbing their structure and condition.

- Construction. Conducting geotechnical research to study the physical and mechanical properties of soils and the condition of rocks. Core technology makes it possible to accurately identify ground water and take water samples to study their aggressiveness towards concrete.

During core drilling, a core is extracted - a column of soil or adjacent soil layers. The core is characterized by a solid natural structure, which ensures a comprehensive analysis of the studied rock. Drilling with a core pipe allows you to determine with the highest accuracy the depth of rock for study purposes.

Core drilling ensures the integrity of the extracted core, which contributes to high-quality study of the rock. At the same time, the highest quality cleaning of the face from destroyed rock is carried out

The use of a core drill in construction significantly facilitates and speeds up the processes. A pile is easily driven into the hole prepared with a core drill or a ready-made reinforced concrete structure is mounted. Core drilling allows you to create cylindrical holes in brick and concrete structures.

Strengthening and reinforcing structures

Strengthen the following structural elements with your own hands:

- Casing string. Strengthening a concrete structure is easier. To do this, anchor bolts are driven into the walls of the lower, middle and upper rings. Vertical beams made of profiles are attached to them. Edging rods are welded to the parts, forming a square. Reinforcing bars are placed in the corners of the resulting figure.

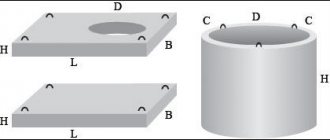

- Conductor. To begin, select the point at which drilling will begin. A pipe is driven into the bottom of the well, around which corners are placed. Metal elements are welded together. If the casing string was previously tied, the structures are combined. Drilling equipment with a gate block is installed above the well. Concrete slabs are placed under the legs of the apparatus.

Time to make a well

It is recommended to carry out the work in August-September. During this period, aquifers contain the least amount of resource. When performing work in winter, the water is frozen. To do this, a borehole pump is inserted into the well, which is attached to a conductor pipe and supplies cold air currents. The liquid freezes in 3-7 days.

The drilling technology is no different from that in the summer. The height of the conductor must reach ground level. The pipe must be buried below the sandstone layer. If necessary, the height of the conductor is increased by screwing on the couplings. After completion of the work, the free space is filled up, which protects the well from wastewater.

The procedure for performing earthworks

A water well can be made almost anywhere. But it’s better to spend a little time and choose the most suitable site. In this case, the most suitable one will be the one located at the shortest distance from the house. Be sure to take into account the fact that for the installation of a caisson you need to allocate at least 4 m² of area.

A short distance from the house will allow you to significantly save on consumables and reduce the amount of excavation work. In addition, in such a situation it will be possible to equip a water well using a cheaper pump. If a long line is made, the pump will need to not only lift water, but also “push” it further through the system. This will require the use of a more powerful and, of course, expensive model.

Scheme of manual drilling of a well.

Drilling can be done in different ways. Some people find it more convenient to do this with a hand drill, others prefer to use the impact method or an electric motor complete with a tripod, etc.

When choosing the type of tool, it is necessary to take into account the characteristics of the earth. If you really want to, using a hand drill you can “overcome” up to 15 m of land. But this is very labor-intensive and time-consuming work.