One fine day you discovered that the well is not able to operate as usual? It’s a pity that there are no “eternal” sources for water supply, isn’t it? Do you suspect that it has become mechanically clogged over time and want to fix the problem on your own, but don’t know where to start or which option to choose?

We will help you cope with the problem that has arisen and settle on the most optimal option. Let us tell you what other methods of self-cleaning there are - the article discusses the best methods applicable at home, both for clearing blockages in an equipped well and in a mine.

After all, troubles can lurk at the drilling stage. Until the casing pipe (work string) is installed, soil can fall into the excavation, clogging it.

We have also selected photographs demonstrating the procedure and tools for doing the cleaning yourself. For clarity, expert video recommendations are attached - so cleaning the well with your own hands will be within your power.

How to prevent clogging of a well?

There are no “eternal” wells for water supply. Unfortunately, sooner or later, the owner of an individual water source will face problems. It’s bad if the aquifer has dried up, you’ll have to drill again or deepen the existing excavation. This is difficult and very expensive.

It’s a different matter if a well becomes clogged—it’s easier and cheaper to prevent it than to “treat it.”

Extending the service life of the source is facilitated by following several operating rules:

- Strictly adhere to the selected drilling technology . Carefully monitor the tightness of the casing pipe and the integrity of the filter.

- Immediately after completion of drilling work, flush the source until clean water appears.

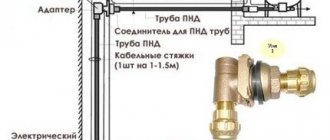

- Protect the well from the penetration of surface water and pollution by installing a caisson and cap. As a temporary solution, simply seal the top of the casing.

- Before starting operation, select the correct submersible pump and install it at the required height , always taking into account the flow rate of the well.

- It is advisable not to use a vibration pump to supply water . Vibrating in the casing, depending on the type of soil, it, to a greater or lesser extent, provokes the penetration of sand into the well or contributes to siltation of the adjacent soil. A cheap and simple vibration generator can be used for a short time; for continuous operation you need a centrifugal pump.

- The well should not stand idle without drawing water . The ideal operating mode is daily pumping of several tens or hundreds of liters of water. It is provided if people live in the house permanently. If this is not possible, you should regularly, at least once every 2 months, pump out at least 100 liters of water from the well.

Following these recommendations, of course, will not avoid clogging of the well in the future. However, it will delay this trouble by ensuring the maximum possible resource for efficient operation for a given source.

Proper construction of a well is the key to its longevity. It is necessary to install a special head on the casing pipe, which seals it and serves for reliable installation of equipment

Cleaning a well using a homemade bailer

How to properly install a well adapter with your own hands: the best alternative to a caisson

In order to always have clean and usable water in the well, it is necessary to carry out cleaning work. Some owners of summer cottages of private houses do not always maintain the well in working condition and solve the issue of cleaning it when it is in a rather neglected state. You should always remember the main rule when operating wells: the less they use it, the faster it silts up. Modern methods of cleaning wells using special machines, pumps and injection guns are quite expensive. In this regard, many owners perform well cleaning on their own. One of the DIY cleaning methods is using a bailer.

For a more detailed look, click on the picture.

This method is very reliable, but quite labor-intensive. It allows you to clean a well that has not worked for a long time. By removing coarse sand, silt, and small stones, it is possible to bring it to its original state. The bailer can be made independently and sized according to the diameter of your well. The main rule is that the outer diameter of the bailer should be 2 cm less than the internal dimensions of the narrowest part of the well. To make a bailer of standard sizes, you must have a pipe measuring 50 mm. 60 cm, a metal ball with a diameter of 40 mm and a thick washer. The upper plane of the washer is made in a funnel shape, and the hole is the size of the ball. The bottom of the washer can be flat or in the shape of a reverse funnel. The washer is welded to the bottom of the pipe, and a thick wire grid is attached to the top so that the ball cannot fly out of it. Next, a handle is arranged to which a thin metal cable or nylon cord will be attached. For the most efficient work

With a bailer, a bottom with 2-4 strong metal teeth is inserted into the pipe from below to loosen sand and silt. To clean a well, a bailer on a nylon cord or metal cable is lowered to the bottom of the well, then raised by 30-50 cm and sharply lowered to the bottom. With this lowering, the ball remains in place, and its lower hole opens. It receives water with silt and sand.

The bailer is filled approximately halfway after 3-4 movements. Then, smoothly, without sudden movements, the bailer is raised to the surface, and water with sand and silt pours out of it. In one lift, she can lift about 250-500 grams. sand and silt, not taking into account the volume of water. This is about 3 cm of silt layer in a well with a pipe diameter of 108 mm. To facilitate the process, tripod gates are sometimes used to lift the bailer.

To completely clean the well in the future, the sludge layer is determined and the required cleaning frequency is calculated to maintain the well in working condition.

Dear readers, comment on the article, ask questions, subscribe to new publications - we are interested in your opinion :)

Cleaning and repairing wells is an important problem for homeowners. Before starting the operation, it is necessary to identify and eliminate the causes of contamination and then select the optimal cleaning option. To do this, you should familiarize yourself with its design, calculate the cost of cleaning the wells, and the timing of the work.

To do this, you should familiarize yourself with its design, calculate the cost of cleaning the wells, and the timing of the work.

Possible causes of blockage

It is worth mentioning the types of well clogging; this will help identify the causes of the problems and determine how to properly clean the well with your own hands.

No. 1 - penetration of sand into the casing pipe

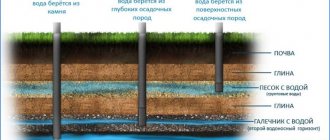

“Sanding” is a problem encountered in shallow sand wells where the aquifer is located in a sand and gravel layer. In a well-constructed well, sand penetrates into the casing in small quantities.

If the productivity of the source decreases, and grains of sand appear in the water, one of the following happens:

- Sand penetrates from the surface - the head and caisson are not sealed.

- The filter is not chosen rationally; the cells are too large.

- The integrity of the filter is compromised.

- The tightness between the casing sections is broken. The thread is not fully tightened, the welding is performed poorly, corrosion has “eaten” a hole in the steel casing pipe, mechanical damage to the plastic one.

It is not possible to eliminate leaks that appear inside the well. Fine sand constantly makes its way through the filter, but it is easier to remove it; it is partially washed out when the water rises.

Worse, if coarse sand penetrates into the well, over time the source may “float.” That is why special attention should be paid to the quality of installation of casing elements and selection of filters.

Installing a sand separator in the casing significantly reduces sand buildup in the filter and extends the service life of the sand well.

No. 2 - silting of an unexploited well

Over time, tiny particles of clay, rust, calcium deposits, and sediment accumulate in the soil in the filter area.

When their number becomes too large, the pores in the aquifer and the cells of the mesh (perforated, slotted) filter become clogged, and it becomes more difficult for water to penetrate through the mine shaft.

The well's flow rate drops, and it becomes “silted” until the water completely disappears. In a source that is used regularly, the process occurs slowly, stretching over decades. Without regular pumping, a well can become silted in a year or two.

If the well is cleared of silt in a timely manner, without waiting for it to completely dry up, there is a high probability of giving the source a “second life”. Water will be supplied in a volume sufficient to supply water to a private home.

The water entering the well through the filter carries with it small particles of silt. The soil near the filter becomes silted. Calcium salts also accumulate in the suction zone if the water hardness is high

Main signs of water pollution

Tests of water from a well should be carried out annually, since its composition in an underground source, depending on seasonal changes and other external factors, can change constantly.

This is especially important if the source is used only in the summer. A number of signs will indicate the need to purify water from a well.

Water turbidity and sedimentation

The opacity of the water indicates that too many silty small particles and suspended dust grains have accumulated inside the walls of the structure. This happens if the well rings have lost their tightness due to erosion of the seams or when the elements are displaced relative to each other.

A clear sign of a violation of the tightness of the walls of the structure is cloudiness of the water after heavy rainfall. Mechanical cleaning of the shaft, supplemented by work on sealing seams and sealing joints, helps eliminate the deficiency.

Subsequently, to prevent contamination, cartridge or mesh filters are installed that will trap and accumulate foreign particles at the bottom of the structure

The appearance of an oil film over the water surface indicates the presence of petroleum products. This may occur due to depressurization of the mine. Or for the banal reason of improper cleanliness during the operation of a hydraulic structure.

Natural color change

The color of the water in the well depends on the type of pollution. A change in color to green indicates a bloom in the water. The reason for this may be direct sunlight entering the mine.

Under the influence of sunlight, microorganisms and algae begin to actively multiply, forming numerous colonies

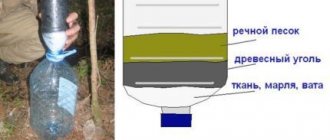

The problem is solved by disinfecting water using chemicals and then installing carbon filters.

Brown and yellow shades indicate that the water has a high iron content. Disinfection in this case is not effective. Only the arrangement of a water treatment system and the installation of additional filters will help solve the problem.

Water acquires a black color due to organic contaminants, which infect it during the process of decomposition and rotting. To eliminate decaying organic matter, simply disinfecting the source is no longer sufficient. To obtain water that can be consumed, you will have to perform multi-stage purification.

Appearance of a strange odor

The clayey or earthy odor is due to the presence of organic natural compounds in the liquid such as 2-methylisoborneol and geosmin. They are formed during the life of soil bacteria and blue-green algae present in water.

Mechanical cleaning of the structure, followed by the installation of household reverse osmosis and the installation of filters equipped with activated carbon, helps eliminate the cause.

Water containing sulfur bacteria has the smell of rotten eggs. They produce hydrogen sulfide.

These bacteria can be removed by disinfecting water using potassium permanganate or chlorine and then installing a filter unit

The smell of phenol and other unnatural aromas indicate that sewage and other human products likely entered the well shaft through underground aquifers. The problem can be solved by mechanical cleaning and installing a carbon filter.

Unusual taste of water

The salty taste appears due to the increased content of salts: NaSO4, NaCl, MgSO4. It can be removed by performing additional water purification by passing it through household reverse osmosis.

A metallic taste indicates the presence of iron in the water. Iron removal methods help correct the situation. For example, installing a compressor that will saturate the water with oxygen, a circulation pump and an iron removal filter.

The sour taste of water, which has a blue-green tint, indicates a high content of carbon dioxide. This phenomenon occurs due to the reaction of water upon contact with copper and bronze elements of the system.

Increased hardness indicates the presence of calcium and magnesium salts in the liquid. Stiffness is not a constant value. It fluctuates depending on the season and reaches its peak in the summer.

The cause of hardness can be salts of alkaline earth metals, which are often found in limestone and dolomite deposits.

The situation can be corrected by installing softening systems. Reagent and reagent-free complex purification filters are capable of demineralizing and softening water.

How to choose the right cleaning option?

It can be difficult even for a specialist to determine exactly why a well’s production rate has dropped. As a rule, pollution is complex. If the pump “drives” sand with water, this does not mean that the soil is not silted.

When cleaning a well with your own hands, you should be patient. You may have to apply several methods in succession and try hard before obtaining a satisfactory result.

We recommend starting with the simplest: pumping with a vibration pump. If pumping does not help, move on to flushing. We start with washing if the source has almost dried up. If there is a lot of sand at the bottom, a bailer will help to scoop out sand.

But it cannot be used for plastic casings, only for steel ones. For polymer barrels we use only bubbling. If there is neither sand nor water in the steel casing, we move on to water hammer technology.

This is, of course, if the aquifer itself has not dried up. Renting a washing machine, of course, costs a pretty penny, but the cleaning efficiency is noticeably higher than when using homemade methods.

Fighting oil film with biological products

Nature has a solution for oily water pollution. These are special microorganisms that process oil, breaking it down into less toxic substances. Based on them, preparations are produced for the purification of water bodies, land plots and industrial wastewater.

At home, the drug is applied to the surface of the water in the form of a suspension. The temperature of the environment is from 5 to 40 C. After absorption of substances that caused the appearance of an oil film, bacterial proteins and non-toxic waste are released. Compared to mechanical methods, which cannot completely remove the oil film, microorganisms win by a large margin.

We also suggest that you read the article on well disinfection here.

Conclusions and useful video on the topic

In conclusion, here is a useful video that shows step by step the available method for flushing a clogged well:

Note that cleaning a well from sand and silt can be a very difficult task. And it’s not a fact that you can do this on your own. And by carelessly wielding mechanical projectiles, you can generally cause significant damage to a water source .

At the same time, there is a special technique that very effectively and to a large extent restores the characteristics of wells.

Do you have personal experience in cleaning wells on site? Do you want to share effective methods or ask questions on the topic? Please leave comments - the feedback form is located below.

Cleaning water wells using the hydrodynamic method

Top 10 ways to clean water from a well from iron impurities with your own hands

The most common and reliable method of cleaning a well is the hydrodynamic method, which is based on the use of a high-pressure water jet. Water is supplied through a special nozzle into the well, effectively cleaning the filter walls, removing silt, sand and other impurities that impede the flow of water.

Compared to other, more aggressive methods of well flushing, the hydrodynamic method has a number of advantages:

- High efficiency.

- Environmental Safety.

- High performance.

- Possibility of use in small wells.

- Avoiding damage to filters and other well elements.

- Wide range of applications: cleaning containers and pipelines from deposits and rust.

Our company has high professional skills and modern installations that allow us to clean a well using the hydrodynamic method efficiently and quickly.

What to do if the water has a white sediment after boiling?

The preference for a specific softening water treatment technology should be given based on whether you want to solve this problem locally or on a large scale:

- If you only need soft drinking water, the filter jug we are all familiar with is quite sufficient. True, your home appliances will still work with water of increased hardness.

- Once you decide to take care of the long-term performance of household appliances, a good solution would be to buy special tablets or powders that soften water. This is an excellent option for dishwashers and washing machines, which, however, is completely unsuitable for treating drinking water if a white precipitate forms when the water is boiled.

- But let’s say you still approach the issue globally. Then we recommend that you think about installing reverse osmosis filters. They will soften all the water that comes to you from the taps, and you will not have to worry about your health or the condition of your appliances.

What can you do if there is a white sediment in your well water?

If you can afford a filter or more efficient systems with an aeration column, ion exchange resins, etc., the problem disappears by itself. But if this is not possible, the algorithm below for purifying water in a well will help you. So, you need to carry out the following procedures:

- Carrying out inspection, waterproofing of seams between the rings and insertion of the pipe into the well.

- Formation of a waterproofing layer on the upper rings.

- Carrying out forced drying of the inside of the rings, removing silt and deposits on the walls.

- Cleaning or construction of a bottom sand-crushed stone filter.

- Creation of a shungite bottom filter layer.

- Disinfecting the walls of the well using a solution of a chlorine-containing product like “Belizna” (0.5 liters of product per bucket of water).

- Disinfection of contained water using a chlorine-containing agent.

- A device for aerating water in a well.

- Choosing a good well cover.