The ideal operation of a gas boiler is considered to be a mode when the main burner burns stably with the flame as low as possible, i.e. The heat transfer from such combustion corresponds to the needs of the heated house. Otherwise, when a gas boiler is often turned on and off, its wear increases and gas consumption increases, since it is greater at the time of startup.

It is impossible to determine exactly why constant clocking occurs without seeing the boiler and the heating system diagram. However, we will consider all possible reasons for the frequent switching on and off of a gas boiler in descending order of their frequency, and we will give recommendations for solving the problem.

Main causes of breakdowns

To repair a gas boiler yourself, you need to understand the cause of the breakdown.

Problems are caused by the main factors:

- atmospheric conditions;

- electricity;

- water;

- incorrect installation.

Adverse weather conditions can cause some problems. When there is severe frost in the house, the AOGV is turned on at full power, which reduces the pressure in the heating system. Because of this, boilers cannot reach their full potential.

Therefore, in winter, it is better to install an additional floor-mounted or wall-mounted boiler that will run on a different type of fuel - coal, wood or sawdust.

Modern boilers have different automation systems. Some units are powered by electricity. Although new technologies make it possible to use alternative energy sources, power grids still experience power outages. This problem is especially acute in small cities, towns and villages. Therefore, it is worth purchasing a high-quality stabilizer , and you need to choose expensive models. Cheap ones will not be able to ensure stable operation of the boiler during voltage surges.

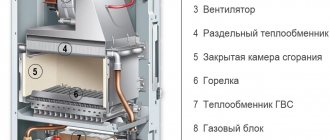

Wall-mounted units are designed not only for heating the room, but also for heating water. The design of the unit includes a flow-through heat exchanger. It can fail for a long time due to the use of hard water or liquids with various chemical impurities. To keep the boiler in good condition, special filters are used. A unit using purified water will last longer, and it is healthier for human health.

The boiler should only be installed by a specialist , since the smallest errors during installation can lead to serious consequences.

For example, a cast-iron Navien gas boiler, if the piping is incorrectly performed, can crack under the influence of low temperatures. If the owner of the house has never dealt with units, then he definitely needs to turn to professionals for help.

Excessive power as the most common cause

In a simplified form, the required boiler power is calculated based on experience: for every 10 m2 of an average house with 2 bricks and a ceiling height of no more than 2.7 m, 1 kW of thermal power of heating equipment is required. It is also recommended to take into account a reserve of 15-20% so that the boiler does not work at the limit or the heat transfer is sufficient during the most severe frosts in the region.

This calculation method is sufficient for any typical private home. For example, for a house with an area of 200 m2, a boiler unit with a capacity of 22-24 kW is required.

How to calculate the required boiler power Individual calculation, formula and correction factors

If, with insufficient power, everything is clear - the boiler simply cannot provide heat transfer corresponding to the heat loss of the house in cold weather, then according to practice, owners often do not take into account that excess power is also bad, especially if the boiler has primitive automation and one- or two-stage burners. Most often this happens to owners of small houses (60-100 m2), who purchase boiler units with a capacity of 14.16 or even 20 kW.

The boiler lights the main burners, which quickly, in 2-5 minutes, heat up the missing few degrees of coolant temperature and turn off. And since modulation (power adjustment) of the flame is not provided for by the design of the burners, nothing can be done at the level of boiler settings.

One of the simplest mechanical room thermostats.

However, there is another fairly simple solution - installing a room thermostat, which will regulate the boiler’s operating mode depending on the room temperature, and not the constantly changing temperature of the coolant. The thermostat will block the ignition of the boiler until the room temperature drops below a predetermined critical level, thereby extending the ignition and extinguishing cycles to 1-2 cycles per hour. The cost of the cheapest room thermostats, and this will be quite enough to solve the problem, starts from 800 rubles.

If the boiler is a double-circuit boiler, it is necessary to install the thermostat exclusively according to the instructions, otherwise incorrect operation may occur both in the heating mode and in the hot water supply heating mode.

Do-it-yourself boiler repairs

A gas boiler is a very complex and dangerous heating system. If installed incorrectly, there is a risk of the unit exploding. Failure to correct problems in a timely manner or improper maintenance will lead to the release of carbon monoxide and combustion products into the room, which is very dangerous to the health and life of humans and pets.

Built-in automatic devices are responsible for the operation of the boiler. They are not easy to understand. And if the automation turns out to be faulty, then you should not repair it yourself . It is better to call a specialist to troubleshoot problems in the automatic system. With your own hands, it is only possible to remove all contaminants in the chimney, pipe and other parts of the boiler, as well as correct visible damage to the unit.

Checking the heating system: pipes, radiators, circulation pump

Simplified diagram of CO with a circulation pump at the boiler supply.

If the boiler power meets the requirements, you should pay attention to the elements of the heating system (all valves and thermostats, radiators, pipes); perhaps something is blocking or slowing down the movement of the coolant, make sure there is no air.

In systems with forced circulation, the cause may be the circulation pump. Firstly, in order to operate the boiler in vacuum mode, it is recommended to install it on the supply side (provided that the pump is designed for a temperature of 110-115°C). Secondly, it is worth trying to increase its speed; perhaps the speed of movement of the coolant is not enough and it lingers for a long time in the boiler heat exchanger.

Typical problems

There are several typical problems with gas boilers that you can deal with yourself.

These include:

- the smell of carbon monoxide;

- malfunction of the combustion sensor;

- unit overheating;

- breakdown of the boost fan;

- difficulties with the chimney;

- periodic shutdown of the structure.

Before the technician arrives, you can protect yourself by eliminating these problems. In some cases, in the room where the boiler is located, you can smell a persistent smell of gas. This indicates that a valve in the system has become faulty.

The unit must be turned off immediately and the room must be ventilated. There should be no people or animals in it, and under no circumstances should you light matches or fire.

After this, a qualified technician is invited, since it is very difficult to identify the location of a gas leak on your own.

When repairing double-circuit boilers, you can repair the combustion sensor yourself. If it breaks down or there is a problem in the gas supply pipe, the unit is turned off. You need to close all the valves and give the structure time to cool completely. The room is ventilated, then returned to it and checked for the presence of escaped gas. If there is draft, then you need to reconnect the boiler . If the smell of gas persists or there is a leak, you need to call a specialist.

The most common problem with modern devices is overheating.

The main cause of the problem is a clogged heat exchanger or a malfunction of the automation system. The boiler is usually equipped with parts made of stainless steel or copper; they can be easily cleaned at home. In the instructions for the unit, manufacturers indicate the frequency of cleaning the heat exchanger from soot deposits and other combustion products. For example, when repairing an Immergaz boiler with your own hands, the part is removed and cleaned with a metal brush. Copper parts are cleaned with a dishwashing sponge.

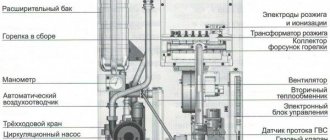

The problem areas can be boost fans, or more precisely, their bearings. If the part has stopped rotating as before, then this problem must be corrected as soon as possible . The rear part of the fan is removed, the stator is removed and the bearings are lubricated. To do this, use machine oil or a special carbon composition with heat-resistant components.

If the problem is an interturn short circuit, then you need to seek help from a professional. It is necessary to replace the winding in the stator or buy a new part instead.

Sometimes the main cause of unit failure is a clogged chimney. It must be removed and thoroughly cleaned of soot. The chimney is installed back, which will not only restore the previous efficiency of the boiler, but also increase its efficiency. When turning off the boiler yourself, the main problem is contamination of the pipe. It needs to be removed, rinsed under running water and cleaned with a cotton swab. The pipe is returned to its place and the boiler is turned on. If it turns off again, then the problem is a broken combustion sensor. A specialist is called in to repair it.

Features of ignition of gas heating boilers

Each heating device is equipped with automation. The ignition procedure depends on its design and features. Modern boilers are equipped with piezo ignition or automatic start. Rarely in villages, there are still old KST boilers that can operate on solid fuel and gas. During the conversion, the heating devices were equipped with primitive automation, where the igniter was ignited with matches. Features of ignition depend on the automation of the gas boiler. Regardless of the model of the boiler and its automation, preparatory measures are carried out before ignition:

- Before the first start after the summer season, all components of the gas supply line and automation are checked for the absence of gas leaks. This can be done easily with soapy water. If a thread or connection is gassed, soap bubbles will appear.

- It’s a good idea to check the heating system itself for leaks. Make sure there is enough coolant. To do this, in a closed system, the pressure is checked on a pressure gauge. If the heating is gravity-fed, make sure the expansion tank is filled with water.

- After renovations, a lot of dust is generated in the house. With the help of draft, it partially enters the boiler furnace and settles on the burners. A similar situation occurs if the heating device at the dacha has been idle for a long time. Before ignition, try to clean all burner units with a vacuum cleaner or other devices.

- Immediately before starting ignition, check the presence of draft. This can be easily done with a strip of paper. If it is pulled inside the firebox, then there is a draft.

After the preparatory activities, they move on to the process of igniting the boiler. To properly ignite a gas appliance, you need to know the features of the automation. The ignition process begins by opening the gas supply tap to the boiler from the main line. If the heating is equipped with a circulation pump, be sure to put it into operation. Further actions depend on the features of the automation:

- Old KST with ancient automatic equipment are lit manually. First, a burning match or splinter is inserted into the window and gas is supplied with the regulator. After igniting the igniter, allow it to warm up for a couple of minutes. The regulator lever is moved to the next position. The main burners are ignited.

- Modern budget boilers are also started manually, but with the help of a piezoelectric element. Press the flame regulator with one hand. Continuing to hold it, press the piezoelectric element button with the other hand. With each action, a click occurs and a spark is formed near the igniter on the electrodes. The action continues until the flame appears. After the pilot light ignites, the regulator is held for about 30 seconds to allow the thermocouple to heat up. Now you can release it and turn it to light the main burner.

- Expensive gas boilers are equipped with electronic start. There are even models that are controlled from a remote control. Ignition of such devices is carried out with one click of the “Start” button. Then the automation will do everything itself. It is only important not to forget to connect the unit to the electrical network.

Setting up the automation is trusted only to a specialist. Each gas automation has its own characteristics. The regulators are marked with numbers, stars, and circles. They indicate different positions at which a spark is supplied, the burner is ignited, and the temperature is set. All the nuances of a particular model are described in the manufacturer’s instructions. It must be studied before starting ignition.

From it, a signal about the presence of a flame is sent to the control board, which confirms the correct functioning of the Ariston boiler; if not present, the work is blocked. In some models, the sensor and control electrode are separated, but the meaning of the flame failure error does not change.

Preventive measures

To prevent damage to any boiler parts, special preventive measures are taken. Before the start of the heating season and after it, the unit must be serviced in a special way. If possible, it is disassembled and all components of the spare part are carefully inspected for damage. All faults must be eliminated, broken parts replaced with new ones or repaired.

The instructions for the device always include a list of preventive measures. must be strictly followed . The instructions for do-it-yourself repair of a Navien or Oasis mounted boiler contain information that you need to promptly remove all contaminants from the internal surfaces.

Due to the danger of gas boilers, you should not deal with problems yourself if you do not have any experience in repairing units. It is better to entrust the repair of the device to a specialist who will accurately identify broken parts and repair or replace them with new ones. During operation and maintenance, you must follow the manufacturer's instructions.

Geysers Ariston - Malfunctions and repairs

- Ariston gas water heaters - Characteristics and features

- Types of geysers

An Ariston Fast 11 CF gas water heater has been installed and connected. This is a battery operated model. The problem is that it comes on and then goes out after a couple of seconds. Most often, this problem occurs at night, after the device has been left idle for some time. Moreover, if it heats the water periodically, it does not turn off. At first I thought that the ionization sensor was broken. Changed the battery. But it did not help. The error began to appear even faster. If you click the microswitch for a long time, the unit lights up and works without problems for several days. What could it be? You don't need to flip the microswitch, you just need to install a new one. The fact that such manipulations have to be done means that it is faulty. The principle of operation is approximately this: first, a spark appears and goes to the igniter. There is an ionization signal, the gas supply to the main burner is turned on, a flame appears, and ionization is constantly monitored. If there is no signal that the pilot burner is working, then the main burner will not start either. But it happens that the signal comes from the igniter, but the main burner does not work. It tries to ignite, but since there is no signal, the gas supply stops. You should clean the electrode and its insulation. There may be problems because of this. There is a malfunction in the Ariston Marco Polo M2 10L FF geyser. After the water heater is turned on, the control panel begins to light up. When this happens, a beep sounds repeatedly and the display goes off. The unit does not want to work, I cannot light the display by pressing a button. I tried turning the plug over in the socket to change the phasing. It did not help. Has anyone encountered this? You need to make sure that the connectors and wires with the controller are in order. And that he sees the control panel or the main gas valve. This sometimes happens if a transformer or diodes have burned out. There may also be no voltage supplied to the board. Or maybe you should just move the contacts. Please tell me, who knows how to convert the Ariston Next Evo SFT 11 dispenser to propane. I ordered a Gi7S, but they delivered this one. It seems like Gi7S was discontinued, and SFT 11 is being released instead. Maybe there is a service manual? To convert to propane, you will need 10 nozzles with a hole diameter of 1.1 mm and a gas pressure gauge. You need to: enter the service mode (+ and - simultaneously for 3 seconds), change the first parameter in section L0 from 6 to 15, set the minimum pressure in front of the burner to 3.9 mbar, the maximum to 7.3 mbar, ignition pressure to 7.6 mbar . We connected an Ariston Fast Evo 11b gas water heater for heating. Recently there was a problem with the ignition. An electronics unit PAT 1180 97 is installed on it. If you look at the electrical diagram, RL20 is marked there. This instantaneous water heater was installed 3 years ago, and the problems appeared quite recently. When a request for hot water is made, the wick ignites. It lights up, and the flame presence sensor supplies 0.5-0.8 Volts to the electronics unit. Then the pilot light goes out and the column tries to start again. So two, three attempts. After that she starts working. I can't figure out why the candle flame doesn't ignite the main burner. What could it be? Now the device works on this principle. A spark appears. She lights the fuse. The spark stops. The wick works for a few seconds and goes out. The unit produces a spark again. The wick lights up again. The spark disappears. After some time, the main burner ignites. Most likely you have problems with the ionization sensor. You need to look at it first. It would be better, of course, to install a new one, but if this is not possible, it can be cleaned with sandpaper. It is also necessary to clean the burner using a wire brush. Particular attention should be paid to dirt under the sensor. Next, it is important to make sure that the wick burns with a blue flame and not a yellow one. The fire must reach the ionization sensor. If necessary, you need to clean the wick. Make sure that the contacts between the wire and the sensor are good. And it happens that re-hardening the sensor can solve the problem. In any case, it is much cheaper to repair the sensor than to install a new control unit. Please note that the draft sensor will not signal the wick to ignite. In your case, your wick is burning, which means there is a problem with the electronics. She doesn't see him. We put into operation the Ariston Fast Evo 14 b gas water heater. Lately it hasn't been working correctly. The smoke exhaust protection is triggered. I read in the instructions that after 15 minutes of stopping, it should start working again. But in reality everything happens differently. The device starts up after 6-8 hours, and sometimes you have to wait a day. After that it turns on itself. I changed the batteries and unplugged the unit, but it didn’t help. What could it be? A smoke exhaust sensor is essentially a thermostat. Apparently, the “frog” takes a very long time to cool down. And in the room where the instantaneous water heater is installed, the air temperature should not exceed 30 degrees. If this condition is violated, your problem may arise. The recovery speed of the sensor depends on several reasons: the draft in the chimney and the air temperature in the room. In any case, you need to make sure that everything is in order with the chimney. Since the sensor is triggered, it means that the upper part of the device is overheating, and the draft is accordingly impaired. The sensor is inexpensive, and you will always have time to change it, but perhaps the problem is not in it, but in the chimney. It may simply be clogged, or it may be an incorrectly designed design. In any case, the unit will only work if there is good traction. I have a double-circuit boiler installed. One circuit operates on DHW. I additionally want to connect an Ariston Fast Evo 11b gas water heater. How to do this correctly? Maybe there is some kind of connection diagram? You need to disconnect the DHW pipes for water supply and outlet from the second circuit of the boiler and connect it to a water heater installed nearby. Also, do not forget to connect gas and water supply, as well as electricity. It is also necessary to mount a separate tap and an insulating coupling and install them on the gas pipe in front of the heater. Don't forget about grounding. The Ariston Marco Polo GI7s 11L FFI column is in use. There are no problems with the gas part, except for one. It always starts only on the second try. That is, after opening the hot water tap, the device starts working and stops due to error E1. After I close the tap and open it again, the error is reset and the unit starts working as expected. Although there are some things that light up the first time. Natural gas from a cylinder is used for operation. Could this be because I physically turn off the gas valve every time after use? The problem you described sometimes happens during a cold start. You need to clearly understand how much you need to open the tap so that the device starts without problems. Ignition without error occurs only if the water flow is at a certain pressure. If it is more or less than required, error E1 may appear. After the unit has been in operation for some time, this problem no longer arises. As I understand it, on the Ariston Next Evo SFT 11 NG EXP column, the pressure is regulated from the panel using buttons (menu L2, L3, L6), and not by resistors on the board. And it is controlled on the valve. And also, shouldn’t we touch any switches on the board, if they are there? Are there flanges or strips in front of the injectors? Pressures are set only by parameters in the service menu. The pressure at the valve outlet is controlled. The control points and methods are in your instructions. Next Evo can operate on 4 types of gas. The gas pressures on the burner are close, after replacing the nozzles and setting the LO parameter to 15, you can try to start the device on propane, monitoring the state of the flame. There may be no need to adjust anything else. The gas inlet pressure should be 30 mbar. This needs to be measured before connecting. Please tell me, I converted the Ariston Marco Polo gas instantaneous water heater to propane: I changed the nozzles, set L0 to 16, and turned it on. When the temperature was set to 70, the entire burner was burning, but the water temperature was low. In the service menu L3 set parameter 19 (it was like 0 or 1, I don’t remember). The burning became more fun, the water started getting hot. I didn’t control the pressure on the valve, but I understand that the maximum amount of gas is flowing. The launch was confident, parameter L2 was not touched, L6 was slightly raised. Inlet 30 mbar. If you set it to 45-50, only a third of the burner works, and the water is generally cold. You have shifted the adjustment range, and there is a risk that it may not work normally at low power. The pressure on the burner must be checked and set using a pressure gauge. In theory, it turns on parts of the burner in series - 1/3 - 2/3 - full. In general, you need to check it at low power, if it works, you can leave it. The main thing is that the flame is normal, blue, without yellow and white borders on top in all operating modes from minimum to maximum. If the combustion is even slightly incomplete, you cannot leave it like that, the heat exchanger will become clogged with soot. The Fast Evo 11 b column is in operation. The second part of the injectors has stopped working, that is, only the right part is burning. Does the board need to be changed? First, measure the voltage on the solenoid valve of the second group with a large flow of water, when the entire burner should burn. If there is voltage, ring the EMC winding; if the winding is normal, disassemble it and eliminate the jamming of the valve. If the winding is broken, change/rewind. If there is no voltage, the controller board is to blame. Please tell me how the anti-freeze system (resistors on the heat exchanger) works in the Ariston Fast Evo 11c column: you just need to plug it in or you need to turn it on. press to light up the temperature readings. And at what temperature does it turn on (water or air)? It always works, turns on at temperatures below +5 degrees. Ariston Next Evo SFT 11 NG EXP on bottled gas, changed the nozzles, everything worked without errors, I didn’t use it often for a year, and then it stopped turning on, and when the hot water is opened, nothing happens - neither the fan starts, nor a spark, nor an error. Although the button is on. lights up and shows the temperature. At first I thought that the gas in the cylinder had run out, I refilled it, but nothing changed. Look at the flow sensor. Perhaps it got stuck due to sand in the water. The Ariston Marco Polo column broke. Operation for 2 years, and now error E1 appears. In this case, the device cannot ignite. I observed, there is a spark, there is a click, but there is no fire. Immediately after this, error E1 appears. Most likely you will need to either repair or change the power controller, and you will also have to change the electrolytes. This information will be useful to all those who often experience E1 and E2 errors. And at the same time, the installed Marco Polo gas water heaters do not light up. I recently installed a GOK 50 mbar mega reducer. After this modernization, the device began to work very poorly. The ignition did not happen the first time. After studying the instructions, I found out that for correct operation, you need to install a pressure gauge that will control the pressure at the outlet of the gas valve. I will roughly describe the principle of operation. It is necessary to remove the casing, but do not disconnect it from the payment. On the board you need to find two buttons and two variable resistors. After this, the device must be connected to the network, and with the button located on the front front panel, set the default mode to 42C. Next, water is supplied for analysis from the tap, and you need to wait until the column flares up. This may not happen on the first try. You need to press button 1, after which the unit emits a sound signal and goes into minimum flame mode. Resistor “1” must be adjusted so that the minimum flame is stable. It should be tight and without coming off the burner. Then you need to press the “2” button. After the sound signal, the water heater will operate in the maximum flame setting mode. Make similar adjustments to the flame in maximum condition. It should be large, but not have yellow tongues. The state of the flame can be assessed through special windows. After this, the column can be turned off using a special button on the control panel; it is important to wait until the fan stops. Turn on the device again and set the temperature you require. You need to check the ignition. Most likely there will be normal stable work. If not, then you need to repeat the minimum and maximum flame settings again. There was a problem with the Marco Polo M2 11 l gas water heater. Error E3 appears. Moreover, the device shows it immediately after the hot water supply tap opens. As soon as the fan starts working, a fault is immediately displayed. I looked at the instructions to see that it means “overheating/working without water.” To resolve this, I checked the temperature sensor, but it works and opens the contacts when necessary. I also checked the water flow sensor, it is not dirty, but just in case I blew it out. The blades can be heard rotating freely. What else should I check? Maybe a transformer or control panel? You need to check all components from the sensor to the board. Please tell me what is the fundamental difference between the GI7s 11L and M2 10L FF speakers, besides the fact that they have a different method of air intake and different power. The difference in price is quite large, up to 30%, so I would like to understand which one to buy. Also, as I understand, the M2 10L FF model comes with a chimney included, but the GI7s 11L will have to be purchased separately. And it is coaxial, which makes it expensive. As I also understand, M2 takes air from the room, and GI7s uses a chimney from the street. Can I buy an M2 column to organize air supply from the street, for example, by making a hole in the wall? Air enters M2 from all slots. If during the winter period cold air gets into the inside of the device, then a problem with condensation will immediately arise on all parts. The housing will also be covered in condensation. Whereas when moving along a coaxial cable, the air has time to heat up, and such a problem does not arise. In addition, it will be supplied directly to the turbine, without passing through the internal parts of the unit. Therefore, there is no need to come up with a new design; work as provided by the manufacturer. Tell me, is it possible to convert the Ariston Fast R OMN 14 NG dispenser to propane? How to do it? To convert to propane, you will need 10 injectors installed, a 1.1mm hole diameter, and a gas gauge installed. For further settings, you will need to go into service mode (press and hold “+” and “-” at the same time for 3 seconds). You will need to change the first parameter in section L0 from 6 to 15. And also set the minimum pressure in front of the burner to 3.9 mbar, the maximum should be 7.3 mbar, ignition pressure 7.6 mbar. But the injectors most likely will not need to be changed. I noticed that recently Ariston gas water heaters with a liquid crystal display have appeared on sale, on which you can see the water temperature. I'm wondering if their design is the same as conventional devices, or if there is some special electronics that works with feedback. For example, a sensor measures the temperature of water, and thereby automatically supplies the required amount of gas to the device. Full feedback only works in turbocharged water heaters. This is due to the fact that this design runs on mains power and not on batteries. If the device runs on batteries, then the control is discrete using a special rubber membrane and small valves, which often break. This scheme has many disadvantages, such as low performance and reliability. And in the case of turbocharged models, the power comes from the network, and a more advanced controller with a PID regulator is installed there, and there is also modulation of the gas supply using a valve servo valve. Stepwise regulation of the combustion area through separate valves is also used. This allows you to expand the range of regulation, as well as speed. This type of device does not have rubber membranes. Electrolux geyser I have an Electrolux GWH 275 SRN installed. The apartment is rented and when I moved in, the renovations had not yet been completed. I had to complete it. During repairs... Ariston geysers On top, the Ariston geyser has an outlet for connection to the chimney system to ensure the mandatory removal of combustion products outside the home. The main task...

What to do if the boiler turns off

Let's look at typical problems and ways to solve them.

Unsuitable power

If the boiler switches on and off frequently, it is due to excess power. Yes, yes, excess is the same problem as lack. A powerful device in a small room quickly warms up the area. Frequent shutdowns lead to wear of components, parts and rapid breakdown.

Before purchasing equipment, consider the following factors:

- climatic conditions;

- square;

- quality of insulation;

- number of windows and doors;

- purpose of adjacent rooms.

For large areas and private houses, floor equipment “Baxi” (Baxi), “Navien”, “Lemax”, “Danko” are suitable. Wall-mounted units will fit into a small apartment space. These are models “Bosch”, “Ariston”, “Visman”, Beretta, Vaillant.

But what to do if the boiler has already been purchased and installed? Don't go to the store for new equipment. Adequate solutions are needed:

- Installation of four-way valves in a hydraulic system.

- Modulation of the burner flame to minimum mode.

- Inclusion in the boiler circuit. This way the equipment will work not only for heating, but also to provide you with hot water.

Low pressure in the gas line

The problem is caused by problems with the common line or frequent interruptions in the fuel supply.

- Gas meter is clogged or broken. You may hear noise or other sounds. A working meter should change readings. If this does not happen, contact a specialist. You are not allowed to fix the problem yourself.

- The protective sensors have activated. Modern equipment is equipped with gas control and temperature sensors. If a fuel leak is detected in the system, the operation of the boiler is blocked on its own. Apply a soap solution to the connections to locate the leak. If bubbles appear, turn off the gas supply and open the windows for ventilation. Call the gas service immediately.

- Gas filter clogged. Clean.

Before the heating season, services check the condition of the mains. They also calculate the gas supply. If your home is constantly experiencing power outages, notify your gas utility.

Chimney problems

Problems with the presence of draft occur during the operation of turbocharged and atmospheric boilers. In the first and second cases, freezing of the outer part of the chimney is typical. Along with the removal of combustion products, hot steam also comes out. It settles into condensation, which freezes outside. This blocks the flow of air, so the device turns on and turns off immediately.

Way out: remove ice and insulate the chimney pipe. Then the drops will drain and not freeze.

To check for draft, light a match and bring it to the control window. If the flame deviates to the side - there is draft, if it burns evenly - no.

Facts about blocked chimneys:

- The mine can become clogged with construction waste. These are pieces of pipe that break off under the influence of condensation.

- Insulated sandwich pipes are susceptible to peeling of the zinc coating. It looks like a film blocking the passage.

- The mine becomes clogged with soot, soot, garbage from the street, and leaves.

- There have been cases when birds built nests on the chimney heads.

For cleaning, it is better to contact utility services. If the reason for the lack of draft is frosting, then you will have to insulate the pipe. In winter, this is difficult to do, so you can temporarily install a gas burner for heating.

There is a reverse thrust

Then the flame is blown out by the wind, causing the automation to turn off.

The situation is dangerous. New boilers are equipped with control sensors that turn off operation, while in old boilers carbon monoxide can enter the room.

How to fix the situation:

- Checking the chimney installation. If the height is insufficient, there will be poor traction and wind blowing. Increasing the height 50 cm above the roof ridge will help.

- It is recommended to install fungi on the top of the pipe to avoid clogging. This is effective for solid fuel boilers. In the case of gas appliances, this is prohibited.

- Burnout or damage to the pipe also leads to blowing. Repair or replacement will help.

- The lack of normal ventilation contributes to extinguishing the flame in atmospheric burners. Open the window to allow air to flow normally into the dual-circuit unit.

The principle of operation of a gas burner

It consists of the following: air and fuel are mixed, and the combustion products must go through the entire combustion process.

We can conditionally distinguish three tasks in the operation of this element of the system:

- preparing air and fuel for combustion by determining temperature, speed and direction;

- mixing these elements;

- combustion, that is, oxidation of combustible elements with the help of oxygen, combustion due to the nozzle at the end point of the tube.

The reasons that the burner does not light up must be sought in the principle of its operation.

The burner itself is essentially a metal tube that is hollow inside and has several holes called nozzles. The gas burns in it, heading towards the combustion chamber. The mixture of combustion products is discharged outside. And if the air is collected by natural injection, then the gas is distributed and directed inside thanks to the system of indicated holes.

If the gas boiler does not ignite, it means that the combustion conditions are not met: there is no gas, no air is supplied, and combustion products do not come out. Understanding the cause of problems allows you to eliminate them in a timely manner and restore system operation. When lighting a gas boiler, be careful. This equipment requires special care.

Why doesn't the boiler start?

Often problems are shown as an error code on the display. All modern models Vaillant (“Valiant”), Baxi (“Baxi”), Ferroli (“Ferroli”) are equipped with a self-diagnosis system. Each brand has its own codes and their meanings. If the display does not show symbols, then you need to look for the cause of the problem yourself.

Problems with wall and floor units can be caused by external and internal factors.

External ones include:

- Insufficient gas pressure in the main;

- Chimney problems;

- Power surges in the network;

- Draft, low temperature in the room/boiler room.

Internal factors include breakdowns of electronics - sensors, wiring, as well as individual components - pump, heat exchanger.

Localizing the problem of boiler malfunction

With the development of modern low-rise construction and gas networks, the boiler has become a common household appliance in every house or apartment. Basically, after installation, the boiler does not cause users any trouble. Modern boilers operate completely autonomously and require only regular maintenance or inspection. In our opinion, the average operating time of units before the first breakdown is from 4 to 6 years. Some users encounter problems even after 9 years, and some, on the contrary, earlier. In this material I will tell you what can be done if the boiler simply does not turn on, and I will also consider the most common malfunctions of gas boilers. The concept of “does not turn on” can mean completely different problems:

- There is no indication (the display is not lit)

- The boiler does not light up

- The boiler does not operate in any particular mode

Therefore, these different situations should be considered separately in detail. Please note that to eliminate some malfunctions, user intervention is sufficient, but in some cases it is necessary to call a qualified specialist.