Pipe fittings, whatever they may be, are an integral part of any engineering solution, even the most seemingly simple one. With the help of fittings, you can solder, twist and press in any strapping pattern you need.

The choice of fittings is yours. It will be a cheaper option, for example polypropylene, or a more expensive and reliable one, like a press. In any of the types of fittings there are all kinds of bends, American joints and connections, which gives you limitless possibilities for your solutions. Fittings are an integral part of the pipeline.

Its main task is to connect pipes at turns, branches and when moving from one diameter to another, as well as to connect identical pipes. A fitting is an indispensable part of the entire pipeline system, allowing the entire structure to be hermetically mounted, significantly simplifying the entire installation process. Fittings are used during the installation of all plumbing, heating, sewerage systems, in municipal and industrial production. Since pipes are made of different materials, fittings are selected accordingly. According to the raw materials from which they are made, pipe fittings are divided into: polypropylene fittings; steel fittings; cast iron fittings; brass fittings; copper fittings; stainless steel fittings; Widely on the market began to use polypropylene fittings because of its strength and ductility, their use in water supply systems, namely cold, hot, and also in heating systems.

Manufactured from the latest material which has made it more resistant to thermal and physical irritants. This allowed the polypropylene fitting and pipes to transport a more aggressive chemical environment that is heated to one hundred degrees. They are leak-proof, have a long service life, and are completely environmentally friendly.

Corrosion-resistant and completely rust-free, fittings and pipes can last from 25 to 50 years without repair or replacement. The simplest installation and tightness of the connection allows the consumer to carry out the installation himself without any effort. The lightness of the pipes and fittings makes it possible to transport them effortlessly from the point of departure to the point of arrival.

Therefore, many European countries stratify and use this material for water supply and heating. For steel and cast iron systems, threaded fittings made of similar metal are used, which are rapidly developing in the direction of metal connections of any kind. At the present time, it is difficult to imagine repairing or replacing parts in the pipeline that was originally laid as a metal water supply system. A cast iron fitting is used when moving a pipe from one diameter to another, when turning or branching, dismantling in case of repair or replacing necessary parts.

Cast iron fittings are produced directly by casting the part. The steel fitting is intended for threaded and welded connections of the structure, as well as couplings and locknuts on the outlet. A steel fitting is made from a pipe blank on lathes and can be used exclusively for your sewerage and water supply systems. Copper fittings are non-corrosive, long-lasting, and can withstand temperatures from 200 below zero to 250 above zero Celsius.

It is used in water supply systems and sewerage technologies. Having proven itself, the copper fitting has become a convenient solution for communication systems, gas pipelines and heating systems. Copper fittings are often used due to its quick installation - its flexibility, smoothness and heat permeability.

Resistance to various external irritants and unfavorable conditions makes copper fitting an integral part for your sewer system. For the installation of plumbing systems, an integral part is a brass fitting that connects the entire water supply system together into one whole system. The brass fitting has such advantages as – long-term operational life of at least 10 years. The special coating does not allow corrosion to take hold and oxidize by passing large amounts of liquid through it.

Eliminates sudden drips at the joints due to its design, which can be considered special. The brass fitting is installed in water pipe branches, at bends and hard-to-reach places, and at changes in pipe diameter. A brass fitting will make your plumbing system strong and reliable. HDPE fittings are used in various systems of polyethylene pipes - as a crimping device for joining an entire plumbing system and other structures.

Fittings are produced by monolithic casting from polypropylene copolymer, for different purposes, diameters and sizes with both internal and external threads, for any type of installation. HDPE fitting is used in all pipeline systems. Resistance to unfavorable conditions and its sealing makes it possible to use it in water supply systems.

Intended use: Couplings. The simplest fitting that is used to connect two straight pipes.

Using direct couplings, you can replace damaged or unusable parts of the pipe, or connect it to something (shut-off valves, regulators, rotameters, other structures). Straight fittings are used to connect pipes of different diameters and materials. Their main task is hermetic and reliable installation of the structure.

Angular (bends).

The most popular fittings. They are used when there is a need to change the flow in the pipeline by several degrees (45,90,120). The main advantage of this type is that there is no need to weld pipes.

And this greatly simplifies the installation process; you just need to select the right corner. For complex structures, specialized angles are used. They are used less frequently, mainly in highly specialized industries.

Tees .

Used when branching the main pipe in two directions, when connecting three pipes, including those of different diameters. As a rule, tees are installed when it is necessary to separate pipes from each other at an angle of 45 or 90 degrees. Cross. Connect four pipes at the same time. Fastening occurs in one plane and at an angle of 90 degrees. In complex structures, two-plane crosses are also used, but they are often found for industrial purposes. Plug (stopper, cap). Designed for hermetically sealing holes at the end of a pipeline. For high temperatures in the working area, steel plugs using a flange method of fixation are used (their

used in chemical and oil and gas pipeline systems).

For lower temperatures - flat plugs, welded or elliptical type. For each plug, the conditional pressure and permeability are determined. By connection method: Crimping (compression).

Used for connecting metal-polymer pipes, as well as installing these pipes to pipeline fittings based on polyethylene (regular, cross-linked, heat-resistant). Compression fittings are in demand due to their ease of installation. They eliminate the use of welding and threading, as they have special crimping

rings. A special feature of compression fittings is the possibility of their dismantling and reuse, which does not affect the reliability of the system sealing. Operating temperature - 115

degrees.

Nominal pressure - 25 bar. Press fittings. The connection of a pipe with a press fitting is considered more reliable than others. Therefore, they are used for hidden systems that are hidden in walls and floors (for example, installation of heated floors, in hot and cold water supply, heating systems).

But it is worth noting that these fittings are frost-resistant, so they are not recommended for use on structures outside buildings. Installation is done using a press machine and the press fitting is used only once. Threaded. This is one of the main types of connection.

Threaded fittings connect parts of a pipeline using threads, internal or external. Their use can be repeated, therefore the application is different (connecting pipes, appliances, plumbing). The range of threaded fittings is large both in terms of purpose and material of manufacture. Sewer.

These fittings are made from polypropylene because they are resistant to oxygen diffusion and are not subject to corrosion and sudden temperature changes, which ensures their durability. Sewer fittings greatly simplify the design of a complex pipeline system for the entire sewer system. Pipe joining occurs with

using rubber seals; also, for reliability, silicone sealants are used. Polypropylene. Fittings are made from a material that is appreciated for its physical and thermal properties.

Environmentally friendly, sealed, chemically resistant, long-lasting in use.

Polypropylene fittings are universal and certified. They are used in all pipeline systems: hot and cold water supply, heating, sewerage, drainage. Fittings are an integral part of all systems that unite, fasten, solder and even plug the pipeline junction. Fittings, which have a very huge selection, will help you do this.

You will definitely find your fitting that will help solve the problem or in laying a new heating system, water supply system, drainage system, gas pipeline and much more. Stainless steel fittings are an alternative to copper fittings in the construction of heating systems and boiler rooms. Buy fittings for pipes in Kiev, with delivery to your home. The highest selection of steel radiators only in .Read »"Expanses of Ukraine" is one of the leading companies in the plumbing market.Read »ScrollAdd to bookmarksPrint versionFittings for metal-plastic pipes play the role of connecting elements, thanks to which you can quickly install pipelines fittings, connect taps or control devices, etc. Note that welded fittings are gradually being forced out of the market.

Types of connecting elements

Depending on the purpose, fittings may vary in shape; the figure below shows the most common options.

Photo: various forms of connecting elements (fittings)

The figure shows the following forms:

- A, B, C - straight, as a rule, they are used to connect pipes to each other; D, E, F - angular, allow you to connect at an angle; G, H, I - tees, used for complex wiring, or for connecting control devices , for example, determining the pressure of the working medium in the pipeline; J - crosspiece, as well as tees, are used for complex pipeline wiring; K, L - water sockets, used to connect mixers.

In addition to the shape, the connecting elements of metal-plastic pipes are usually divided into types according to the method of fastening: threaded (crimp or collet), as well as Push and press fittings. It makes sense to talk in more detail about each of these types.

Types of fittings by production material

Connecting fittings are made of plastic and metal alloys. The material of the fittings is selected according to the type of pipes, installation method, and operating conditions.

Depending on the material, there are the following main types of fittings:

- Plastic. Made from polypropylene, PVC, polyethylene. Used for laying plastic pipelines. Performance qualities depend on the type of polymer material. Thus, polypropylene fittings are characterized by increased resistance to high temperatures. Connectors and products made of polyethylene and PVC are characterized by increased resistance to ultraviolet radiation. Plastic fittings are chemically resistant and are not susceptible to corrosion.

- Steel. They are used when laying water pipes, gas pipelines, and other networks of steel pipes. Threads are used to make connections. Corrosion protection is provided by zinc or nickel coating. Steel connecting parts are characterized by increased strength, their service life reaches 20 years.

- Brass. A popular type of metal connectors used in modern engineering plumbing. Brass is a material that combines strength with ductility and corrosion resistance. The alloy is suitable for thread cutting and gives parts resistance to water hammer. The service life of brass fittings, depending on the operating conditions of use, can be 50 years.

- Copper fittings. Used when laying copper pipelines, for example, in a water heated floor system. They are characterized by increased durability. Given the softness of the metal, threaded copper parts are not available. The connection to the pipes is made by capillary soldering.

- Combined. Connectors of this type consist of a plastic body into which a metal pipe with a union nut or a threaded part is soldered. Metal-plastic fittings are used to connect plastic pipes with metal ones, to connect plumbing fixtures, household appliances, metering devices, and other equipment to the water supply system.

Rarely used connectors include cast iron and bronze parts, which today are almost never used when installing water pipes.

Cast iron does not meet technological requirements. Bronze is not used due to its significant cost with properties similar to brass. Date: September 25, 2021

Threaded fittings

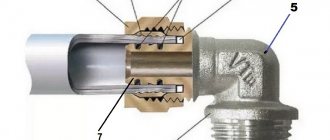

The tightness of the connection in this type of device is ensured by the expansion ring, on which pressure is exerted by the nut when it is tightened. The design of similar connectors is shown in the figure.

Angle threaded device

The figure shows:

- A – ferrules; B – rubber seal (gasket); C – device body; D – clamp nuts.

The advantages that this type has include:

- simple installation that does not require specialized tools and certain skills in working with them, a sufficient ordinary adjustable wrench; after the fitting has been dismantled, it can be reinstalled; collet fittings used for connecting metal-plastic pipes have a fairly low price.

Features of threaded fittings that create certain inconveniences:

- Compression couplings require a relatively lengthy installation procedure; the joint must not be covered and maintenance may always be required, for example if the joint has become loose and needs to be “tightened”. Because of this feature, devices of this type are not installed on a heating system such as “Warm Floor”.

Differences from compression analogues

Due to inexperience and ignorance of all the nuances of installing metal-plastic pipes, press fittings can be confused with compression fittings. They also have a fitting and a sleeve. Only the latter is crimped not with a tool, but using the union nut included in the design.

The main difference between these parts is the different type of connection resulting from installation. The compression version can be disassembled if necessary, but this cannot be done with a pressed version. The press fitting can only be cut off from the pipe to be replaced with a new one.

If a leak develops at the connection point, the nut of the compression fitting can be tightened, but the maintenance-free press fitting will have to be completely removed (+)

However, the likelihood of a leak in the press connection is practically zero. It is not for nothing that this installation method is recommended for use when installing heated floors under screed and when embedding pipelines into the wall.

Cases when such fittings begin to leak in concrete occur extremely rarely in the practice of plumbers. This is more of an exception to the rule.

On the other hand, installation of both types of press fittings requires specialized tools. And to tighten the nuts of compression products, you only need a pair of wrenches.

As a result, on one side of the scale there is “expensive tools + higher reliability of the joint”, and on the other “no extra expenses + a slightly higher risk of leaks”. The choice here is only up to the master and the owner of the house where the pipeline is being laid.

Crimping connection method

Press fittings for connecting metal-plastic pipes are quite easy to use; their design is shown in the figure.

Valtec press fitting device for metal-plastic pipes

Explanation of symbols in the figure:

- a – a fitting, for its manufacture, as a rule, brass alloys are used; b – dielectric plastic rings; c – a sealing gasket made in the form of a ring; d, f – crimp sleeves; e – metal-plastic pipe; g – fitting shank (inserted into the pipe ).

The crimping method has its undeniable advantages, the main of which are:

- a high-quality connection is ensured; installation in a “Warm Floor” heating system is allowed, and hidden placement in the walls is also allowed; installation is carried out within a few minutes.

Crimping has its drawbacks, including:

- the mandatory presence of a press machine, it can be manual or mechanically driven;

Crimping tool set

- the device cannot be reused; after dismantling, they are thrown away along with the piece of pipe.

Before you buy press fittings used to connect metal-plastic pipes, make sure of their quality; Chinese analogues are much cheaper than products produced by such manufacturers as: Henco, Far, Ltm, Pexal, Valsir, Tiemme, but are inferior to them in reliability.

Manufacturers and technical specifications

Italian polypropylene pipes and fittings Valtec (“Valtek”) are produced in three categories: conventional thin-walled, reinforced with fiberglass and foil. At the same time, the manufacturer states that the foil contains 99.4% aluminum. The layers are glued together using adhesives from Japan and the USA, which give a layer strength of 70 N/10 mm at a rate of 15 N/10 mm. The company makes fittings from PP-R 100, which guarantees its durability. There are some design features of Valtec fittings: their sockets are conical in shape, and no bead of molten material is formed during welding. Another nuance: combination fittings (with metal threads) have an octagonal outer shape, which allows you to use standard wrenches when working with them.

Valtec polypropylene pipes and fittings

The German company Banninger Kunststoff-Produkte GmbH also produces pipes and fittings from random copolymer polypropylene. This raw material is chemically neutral and allows the use of pipelines from this company to supply drinking water. It is worth remembering that Germany has adopted the most stringent safety standards for building materials in the European Union. So, if the Germans are ready to use them to supply drinking water, then there is no doubt about their safety. The only drawback of Banninger polypropylene pipes and fittings may be their rather high price.

Banninger polypropylene pipes and fittings

The products of the Czech company Wavin Ecoplastic have an impeccable reputation. This is exactly the “eco-plastic” that is of excellent quality, and not fake. Before purchasing what sellers call “eco-plastic”, check the country of origin of the product. If this is not the Czech Republic, then this is one of the crafts, the quality of which is difficult to vouch for. Why are Ecoplastic polypropylene pipes and fittings so good? Because the manufacturer guarantees that they will withstand 20 atmospheres, and only high-quality materials are used for manufacturing. Ekoplastik Stabi - foil-reinforced pipes, Ekoplastik Fiber and Basalt+ are reinforced with basalt fiber. The rest are unsuitable for hot water supply or heating, but are very good for cold water.

Polypropylene pipes and fittings Wavin Ecoplastic

Polypropylene fittings and Turkish pipes have fairly good reviews on the forums. They have good quality and low prices. Available:

- Simple pipe PN10 and PN16.

- With fiberglass reinforcement (fiber) Kalde PN16.

- Superpipe Kalde - pipes with aluminum reinforcement, but the foil is not solid, but perforated. Therefore, when welding, it does not require stripping or trimming. The manufacturer says that at an ambient temperature of no more than 70°C, the service life of a pipeline made from such elements will be 50 years. For hotter environments the period is reduced.

Naturally, a set of fittings are produced for each type of pipe.

Polypropylene pipes from the Turkish company Kalde with perforated aluminum

Another Turkish manufacturer is Tebo. Polypropylene pipes and fittings of this brand are made from a resistant new polymer Polypropylene Random Copolymer (“Random copolymer” PPR type 3)

This company pays great attention to certification: there are documents of compliance with GOST, DIN and TSE. Product diameters from 20 to 160mm, product types - PN10, PN20, PN25

Solid foil is used for reinforcement, therefore stripping when welding PN25 pipes is required.

Polypropylene pipes and fittings Tebo

There is another Turkish company SPK on the market. Its products are of fairly high quality, and prices for some products are 50% lower than those of European manufacturers. In this case, raw materials are used from Holland, and the equipment at the factories is German. The quality of SPK pipes and fittings is high: they can withstand operation in Siberian conditions, which is a fairly compelling argument in favor of this campaign.

Polypropylene pipes and fittings SPK

These are not all manufacturers, but they are the most frequently used and have decent quality.

Instructions on how to make the connection

The connection of metal-plastic pipes with press fittings must be performed in the following order:

- using scissors, cut the pipe to the required length; next, it is necessary to remove the chamfer inside and outside the pipe, for this a calibrator is used; the device is disassembled to check the condition of the gaskets, rings and sleeves; if their integrity is not compromised, reassembly is performed; at the next stage, the pipe is reassembled; the shank is inserted, this will require a certain force; after the shank is installed, the sleeve is inserted, after which crimping is performed.

Video: Installation of fittings for VALTEC metal-plastic pipes.

Repair

Metal-plastic fittings of sewer pipes periodically require repair. Even if you did all the operations correctly, after a few years the connections may weaken from the effects of differences in temperature, pressure, or simply time.

Since the pipe itself is monolithic, it means that repairs of metal-plastic pipes are carried out at the points of their connection - fittings.

The very first thing to do is simply tighten the connection. This must be done carefully. If the leak does not stop, then you will have to disassemble the connection.

Possible causes of leakage:

- The rubber O-rings are damaged. They need to be replaced.

- The pipe has an uneven cut. Align and calibrate the cut.

- The brass body of the fitting burst. Replace the entire fitting.

Tip: some craftsmen lubricate the joint with silicone, which provides additional waterproofing.

It is worth saying that metal-plastic pipes are produced not only for hot and cold water supply. There are also pipes for heating and sewerage. These types of metal-plastic pipes differ in that they contain not food-grade polyethylene inside, but technical plastic. Therefore, the cost of such a pipe is much lower.

If you still want to make the pipeline maintenance-free, then you need to use not the compression fitting we discussed in the article, but a press fitting.

This pipeline assembly involves creating permanent pipe connections using special press machines. There is no point in buying this expensive equipment for installing several meters of pipe, so in this case it is better to use the services of professionals. And you can fill the pipe with concrete. In this case, the question “how to repair a metal-plastic pipe” disappears by itself.

Source: kanalizaciyadoma.ru

Connecting elements PUSH type

To install a PUSH type fitting for metal-plastic pipes, unlike the crimping method, no special tool is required; it is easy to do it yourself. The figure below shows the design of this device

Design of "PUSH" type fittings

The figure shows:

- A – ring with a double seal; B – holding legs, usually made of stainless steel; C – inspection windows, allow you to check that the pipe is completely inserted; D – pipe to be connected; E – sleeve made of durable material; F – device body.

Among the advantages of this type of connection are the following:

- the connection can be made without the use of special tools; installation work is carried out quickly; the reliability of the connection allows you to hide it inside the wall, that is, you can install a heated floor in this way.

There are two significant disadvantages of this type:

- relatively high price level for Push fittings; after the fitting is installed, it will take at least three hours for the rings, acting as a seal, to take the desired shape.

Features to pay attention to:

The edges of the cut pipes should not contain burrs or other irregularities, since this poses a high risk of cutting through the gasket. That is, if a hacksaw was used to cut pipes, the edges of the cut must be processed.

How to connect metal-plastic pipes

Now about the direct connection of the pipe and fitting. To begin with, you need to put a nut on the end of the pipe to be connected and then tighten the brass ferrule ring.

In different models of metal-plastic pipes, the crimp ring can be made in different ways - some manufacturers make it a cone, while others make it straight with large chamfers. Those with chamfers can be installed on either side, and those made with a cone are put on the pipe with the thin side away from the fitting.

Have you put it on? Now, the evenly cut edge needs to be calibrated. As a rule, the internal diameter of metal-plastic pipes is slightly smaller than the fitting fitting - this is done in order to achieve a high crimp density.

In normal conditions, it is quite difficult to pull the pipe onto the fitting. We insert the gauge into the inner hole of the pipe and, turning it in different directions, immerse it a couple of centimeters deep.

Some craftsmen use the handle of an adjustable wrench instead of a calibrator - this is incorrect and can lead to unpleasant consequences in the form of deformation of the end of the pipe and, as a result, leakage of the connection.

Working with metal-plastic pipes - calibration

Lightly moisten the fitting fitting with water and place the pipe on it. You need to pull it until the very end, until the pipe rests against a small white ring. If you do not insert the pipe all the way, the chances that it will be torn off during operation increase several times. At this stage, you should check the evenness of the cut - if the pipe rests against the white ring evenly on all sides, then everything is in order.

If there is a gap of more than a millimeter on either side, then it is better to remove the pipe and cut its end again, since such a connection can lead to a leak.

Connection of metal-plastic pipe and fitting

If everything is connected normally, then you can move the nut as close to the fitting as possible and, using adjustable wrenches, tighten it with all the force until a characteristic creak or squeak appears.

Don’t be afraid to pull - if the fitting is of high quality, the nut will withstand any load. If it bursts, that's even better. You will get rid of low-quality spare parts, the operation of which could lead to a flood.

Estimated cost

The sale of these products is organized in almost every city; the cost of the devices is affected by the type, size and characteristics, they are determined by the corresponding GOST. To estimate the estimated cost, the price level for the direct press fitting NTM 26x26x3 was analyzed.

CityCost ($)CityCost ($)Novosibirsk3.5Samara3.3Minsk3.0St. Petersburg2.8Ekaterinburg3.1Perm3.1

As you can see, prices for fittings for metal-plastic pipes are approximately the same, both in Minsk, Perm, and Samara.

Due to their performance characteristics, metal-plastic pipes are ideal for creating water supply and heating systems. According to the installation rules, to connect individual fragments it is necessary to use fittings for metal-plastic pipes; other options are not suitable.

Let's consider the types of fittings and methods of their installation, so that in the future you will not make a mistake when purchasing fittings and can handle the installation of the system yourself.

Types of joints used for iron pipes

In order to install metal pipes, many connecting elements are required, each of them has a specific purpose, so it is recommended that you familiarize yourself with these types.

Table No. 1. Types of fittings for iron pipes.

| View | Purpose |

| Fittings | Connecting elements for flexible pipes. |

| Gags | Required for fixation at the ends of the pipeline. |

| Adapters | Allows joining of pipeline parts of different diameters. |

| Crosspieces | Required in order to direct bends in different directions. |

| Collectors | Allows you to make a branch from the beginning of the stream. |

| Couplings | Required in order to increase the length of the pipeline in a certain location. In addition, using these parts, it will be possible to repair the pipe. |

| Corners | Used to guide the pipeline at an angle. The use of such parts will eliminate the need for welding. |

Metal fittings

In the manufacture of fittings, various metals and alloys are used. If it is necessary to install flexible leads, PVC elements are used.

There are also differences between the fittings in the connection method:

- welded;

- threaded;

- crimping

When installing plumbing structures, all of the above types of connections are used. The choice of elements is influenced by the load and the characteristics of the pipe cross-section.

Threaded fittings are used when there is a pipeline with a high load. Therefore, high-strength steel products are connected in this way. Such elements are made of durable alloys, and threads are applied to their surface.

To ensure reliable connection of such elements, linen thread treated with drying oil is often used. To do this, you will need to select the optimal thickness of the thread, and then cut the desired length. However, now another method of hermetic connection is increasingly used - fluoroplastic sealant (FUM tape).

Technical characteristics of fluoroplastic

For a hermetic connection, fluoroplastic tape is used

Most often, connecting parts of this type are made of steel or cast iron. At the same time, they are tested for strength during production. In addition, there should be no various defects or sagging on the surface of the product.

On average, the diameter of the elements ranges from 1 to 10 centimeters. They can withstand temperatures up to 165 degrees and a load of 1.5 MPa.

Pipeline made of metal pipes

A distinctive feature of threaded elements is that they can be disassembled at any time. This means that a pipe cutter is not used during the installation process. In addition, if the connections are intact, then they can be used for re-installation.

Most often, such elements are mounted if welding is impossible. This is relevant in the presence of the following types of premises:

- country houses;

- garden plots;

- agricultural buildings.

Compression fittings have a long service life compared to other elements, so they are often used not only when laying pipelines inside a residential building, but also outside. Even experienced craftsmen prefer such details.

Crimp metal connections

Quite often, the use of compression fittings is the only possible connection option. After all, it can be difficult to connect risers of different sections, as well as from different materials, using another method.

Important! Despite their reliability, compression fittings can be disassembled and then reassembled when performing repair work or changing the method of pipe routing. Such communication will be protected from leakage and the penetration of contaminants inside.

Pipe connections are used not only for water supply or sewer systems, but also for gas pipelines.

Compression fittings are also divided into types:

- press;

- with a detail for fixing.

The connection method using press elements involves the use of welding at the joints. When dismantling, such an element is removed and then another is installed. This option is used when it is not possible to make another connection.

Fitting with crimp ring

Compression fittings are also classified as crimp elements. Most often they are used when it is necessary to lay a pipeline in outdoor conditions. Only this type of connection can be installed with two keys, so you don’t have to purchase a special device. A distinctive feature of the elements is the presence of a crimp ring, which is tightly fixed when the nut is tightened. The result is a strong connection that is protected from leakage even in the presence of high pressure and water hammer.

The use of crimp elements in the presence of metal pipes has several obvious advantages:

- reliable connection without additional fixation;

- the ability to use parts several times;

- durability of the connection, regardless of the type of material.

Due to the above positive qualities, crimp elements are successfully used in the presence of compression systems. After all, such equipment assumes the presence of maximum pressure.

Prices for metal pipe fittings

Metal pipe fittings

Video - Connections for metal pipes

Pros and cons of metal-plastic products

Metal-plastic has characteristics that make it possible to create reliable systems with a service life of 15 to 50 years. The outer diameter of the products is 16-63 mm. The fittings must fully match the diameter of the pipes, while the wall thickness (2-3 mm) must also be taken into account.

For internal wiring, the most optimal diameter is 32 mm. Water is supplied to heating devices most often through narrower products - from 22 mm to 24 mm.

The joining of two metal-plastic pipes occurs through fittings, which also have different diameters, differ in installation method, purpose and configuration. Material of manufacture – stainless steel and brass

Metal-plastic pipelines can withstand temperatures up to +95ºС (with interval increases up to +110ºС), therefore they are used for assembling heating systems.

There is a threshold at which pipes freeze - this is -40ºС. Working pressure – 1 kPa. When the temperature decreases, the pressure can increase without the risk of system destruction up to 2.5 kPa.

Advantages of metal-plastic pipelines (when compared with analogues made of metal, PVC and polypropylene):

- Quick installation. To connect individual sections, no welding or soldering is required; keys or a special crimping tool are sufficient. No need to be coated with protective paint with an anti-corrosion compound. Systems with permanent connections are designed for installation in a screed or in walls. The weight of pipes and fittings is low, which also facilitates installation in various ways .During installation, a minimum of waste is obtained. They are protected from stray currents. Pipelines with detachable connections are easy to repair and replace fittings. They have the ability to connect additional devices without disassembling the entire system. Using special fittings, they are combined with metal pipes.

There are also disadvantages, and they must be taken into account when installing the wiring yourself. The cost of MP pipes is quite high, and accordingly, fittings are more expensive.

If the temperature of the liquid in the heating pipeline is constantly maintained at the maximum (+95ºС), the service life of the pipeline is reduced by half.

The polymer layer is destroyed by sunlight, therefore, the pipes should not be in the area exposed to ultraviolet radiation.

Pipe soldering

Let's consider connecting pipes using the soldering method:

- Using a hacksaw or sharp scissors that do not deform the plastic, cut the pipes at an angle of 90°. If you don't know how to cut a pipe at an angle, you need to read more information.

- If there are burrs on the end, carefully clean them off.

- Mark the depth of the soldering, i.e. measure a section of a certain length on the pipe to fit into the coupling or tee and draw a line with a marker. Remember that the length of immersion into the connecting element is directly dependent on the diameter of the products. The larger the pipes, the greater the soldering depth.

The algorithm of actions will change slightly if the pipes are reinforced. Then, before the soldering process, it is necessary to process the top layer of the tubular product, including aluminum foil, basalt or nylon fiber. Using a special tool, the required layer size can be easily removed

You need to pay special attention to carefully remove the foil. Even a slight excess of it on the pipe will negatively affect the tightness of the solder joint.

Further steps in the soldering process:

- Place a soldering iron with nozzles that are pre-selected according to the diameter of the pipes on a smooth and reliable surface.

- At the same time, a pipe and fitting are placed on the hot nozzle on both sides, moving it to the marking made with a marker.

- Heat the plastic for a certain time, which depends on the diametrical size of the pipes. For example, if the cross-section of the product is 20 mm, then 6 seconds are enough to heat up; if 32 mm - 8 sec.

- Then the elements are removed from the nozzle and ensure a strong fixation into each other. Never make any turning movements.

- To ensure strong adhesion of the joint, you need to wait 4-10 seconds. This time will be enough for the polypropylene to harden properly and obtain a permanent connection.

Classification of fittings by purpose

Its shape (straight, angular, cross-shaped) depends on the purpose of the part. Let's look at the main types using the example of VALTEC products, which are often preferred to other brands due to their good price/quality ratio:

In addition to the listed elements, plugs, fittings, adapters for pipes of other diameters, and water sockets are used.

The strength of the parts is given by high-strength brass, which makes up the body, and stainless steel for the press sleeves. The maximum operating temperature for which they are designed is +115ºС

To find out exactly what fittings are required to assemble communications, you need to draw up a general diagram and count the number of connections, corners, intersections, etc.

Fitting device for metal-plastic pipes

High-quality installation is impossible without the correct connection of the pipe with the fitting. To understand the principle of their connection, it is necessary to study the design of the compression fitting.

It consists of three parts - a body (on one side of which there is either a threaded connection or a fitting, and on the other there is a fitting with rubber ring seals), a ferrule nut and a cone ring.

It is these three elements that ensure the tightness of the connection. This connector works quite simply - as the nut is tightened, the ferrule compresses the pipe, forcing it to tightly and forcefully fit the fitting with the rubber seal.

Classification by connection method

You can often find a classification in which fittings for metal-plastic pipes are divided into three groups: threaded, compression, press fittings. This is an incorrect division, since the threaded type presupposes the presence of factory or self-made internal or external threads on the pipe and fitting.

Metal-plastic pipes, unlike metal ones, are not cut at the ends before crimping, so it is correct to consider two categories of fittings:

- compression (collet, crimp); press fittings.

The type of part is selected depending on the installation scheme and the need for monolithic or prefabricated wiring.

Basic rules for installing metal-plastic pipes

Metal-plastic pipes are highly sensitive to mechanical damage, temperature influences, and do not tolerate direct exposure to ultraviolet rays. Therefore, open laying of metal-polymer pipes is possible only in those places where the presence of these factors is excluded.

In order to easily repair concealed metal-plastic pipes with screw fittings, it is necessary to provide inspection hatches at the joints. These elements should not have sharp edges.

Metal-plastic pipes are laid through building structures using sleeves. There should be a gap of 3-5 mm between the inner surface of the sleeve and the outer side of the pipe, which is created using a soft, non-flammable material that allows longitudinal movement of the pipe.

At all stages of pipe laying, it is necessary to remember that the formation of cracks, cuts and scratches on the surface is unacceptable.

Therefore, sharp objects should not be used when unpacking pipes. Marks can only be drawn with a marker or pencil.

For the installation of press fittings, reliable equipment is used, which eliminates the creation of poor-quality connections.

Installation of metal-plastic pipes - video materials will help you cope with this process - should be carried out using hangers and supports offered by pipe manufacturers. When using metal fasteners, the pipe is protected with gaskets made of soft materials.

To solve the question of how to repair a metal-plastic pipe, you can choose one of the options:

- to eliminate a leak, it is necessary to cut out a piece of pipe and install a new one using a connecting fitting;

- if the leakage area is small, you can install only a connecting fitting without buying a new pipe;

- The leak can be sealed by installing a flange with a gasket or sealed with epoxy glue or sealant.

Metal-plastic pipes are the most versatile among polymer pipes; they are reliable in operation, easy to install and have an aesthetically attractive appearance. It is these properties that explain the growth of their popularity.

Source: canalizator-pro.ru

Option #1 - compression fittings

The crimp connection is used quite often, especially in open sections of the pipeline.

The crimping process is as follows. When tightening the union nut (put on the pipe from the outside), the split ring (collet) presses on the outer surface of the pipe, as a result of which the inner surface of the pipe is pressed tightly against the fitting. As a result, a conditionally detachable connection is formed, which is strong, but requires tightening from time to time.

Compression fitting diagram. Before the fitting is placed in the pipe, first a union nut is put on it, then a split ring. During the crimping process, all elements are tightly adjacent to one another, forming a hermetic bundle

It is worth knowing that there are two types of compression fittings:

With integrated fitting. The fitting and body are an indivisible part.

When crimping, the fitting is inserted inside the pipe, the body remains outside. The body is usually made of brass, sometimes nickel-plated. With a threaded adapter. Differs in the push-in type of fitting. It has a specific purpose - they act as terminal connectors when installing radiators, manifolds, and pipe fittings.

The dimensions of the adapters depend on the diameter and thickness of the machined pipe. Adapters also differ in the size and shape of the ferrule nut, and the shape of the seal (flat or conical).

A sample of an adapter, the fitting of which has a slightly elongated cone seal narrowed on one side (Eurocone). Material of manufacture: nickel-plated brass. Technical characteristics: diameter – 20 mm, maximum operating temperature – +95ºС, pressure – 10 bar

No special tool is needed for crimping. Usually open-end or adjustable wrenches are used.

Advantages and disadvantages of PPR pipes

A variety of fittings make it quite easy to assemble any pipeline that can work with almost any environment, since the material is chemically neutral. Everything is connected together using a welding machine, you can master the welding technique in a few tens of minutes - everything is simple and accessible

It is very important that polypropylene is not afraid of defrosting - when it freezes, it expands slightly, and when thawed, it returns to its size. It can withstand light loads quite well, but for long-term operation, it is better to protect the pipeline from mechanical stress and ultraviolet radiation (it becomes fragile when exposed to direct sunlight for a long time)

The inner surface of the pipes is nasty, deposits and sediments do not accumulate on it, so normal permeability is maintained for many years, which allows you to use pipes of smaller diameter and pay less for them. It is also important that the cost of such a pipeline is lower than a similar metal-plastic one.

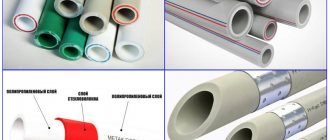

Glass fiber reinforced polypropylene pipes and fittings for them

There are two serious shortcomings. First: large thermal expansion (5 cm per 1 meter of pipe), so to level out changes in linear dimensions, compensators (of any shape) are required. The second is high oxygen permeability. For water supply systems this is not very bad, but for normal operation of the heating system it is advisable to take pipes with solid aluminum reinforcement, which have an almost 75% lower coefficient of thermal expansion and significantly reduce oxygen conductivity, and can withstand high temperatures quite well (up to 95° WITH).

Option #2 – press fittings

Connecting elements of the second type differ from compression analogues in design and crimping results.

The design of the radial press fitting is based on three components: a brass body, a steel press sleeve and a plastic ring for fixation. A correctly installed connecting element is as strong as the pipe material

Brass is recognized as the ideal body material, but some manufacturers also use bronze. Both materials perform well without additional coating, but tin-plated and nickel-plated parts are also very popular. Along with brass, PPSU and PVDF polymers are used - cheaper, more durable and not subject to corrosion.

The best material for the press sleeve is AISI 304 stainless steel. It is stronger and more stable than aluminum, which is used much less frequently. Some liners have inspection holes necessary to control crimping.

O-rings (gaskets) are made of EPDM or NBR. Options with two seals are more common than with one.

Plastic thrust rings are located between the sleeve and the body.

They protect metal parts from electrical damage. Some manufacturers paint the plastic in different colors to make it easier to determine the diameter. Sometimes the rings are equipped with a small protrusion for precise installation of the crimping tool.

Installation of press fittings is carried out using a special tool - press pliers. Hobbyists usually use manual modification; professionals find it more convenient to work with hydraulic and electromechanical devices that simplify the crimping process.

Press pliers are a universal tool, as they have a set of replaceable attachments. The choice of a specific standard size of equipment is made based on the diameter of the MP pipe and the shape of the profile. Popular sizes – 16, 20, 26, 32 mm

O-rings on fittings from different manufacturers are located in different places. During the crimping process, the tool presses the sleeve as tightly as possible, and the location of the rings plays a crucial role. For this reason, it is strongly recommended to use press fittings and crimping tools from the same manufacturer, otherwise the connection technology will be disrupted.

The exception is the products of companies that prudently produce universal systems.

Popular makes and models

Banninger brand products

The Germans are considered one of the most popular manufacturers of fittings. These include companies:

- Banninger - pipes and connections made from environmentally friendly materials that do not change the taste of water and its chemical properties. All products have the necessary strength and lightness, do not rust or become clogged during operation, do not transmit vibration and do not break when frozen.

- Aquatherm – German quality and full compliance with certificates. The connections of this company have a wide range of applications; they can be used in heating, any water supply and even in shipbuilding.

- Wefatherm - pipes and connections fully satisfy all the requirements for pipelines for a wide variety of purposes. This company produces products from new generation materials, for example, glass fiber reinforced polypropylene. Such pipes and fittings have minimal thermal expansion; no stripping is required during assembly (reduces installation costs).

- Ecoplastic is a Czech company that sets a quality standard. Its products are not inferior to German ones, and prices are much lower. The declared service life of pipes and fittings is 50 years.

- TEVO, a Turkish manufacturer of polypropylene products, has been competing in the market with the Czechs and even the Germans for several years. Large range of pipes and connections for them.

- BLUE OCEAN and Dyzain are Chinese in the polypropylene products market. In general, the quality of manufacturers from this country is not very high, but these two have proven themselves well. Their products have the necessary characteristics. A special advantage is the low cost. Among the disadvantages, there are some difficulties during installation.

- PRO AQUA, RBK, Santrade, Heisskraft, Polytek are domestic manufacturers of polypropylene products, the quality of which is not inferior to foreign ones. The main advantage of Russian companies is that only their products can withstand a pressure of 70 atm; accordingly, they will have the longest service life.

Compression fitting installation technology

When you have the right tool at hand, the process of crimping a compression fitting is quick and easy. After two dozen procedures, the hand becomes full, and every movement is brought to automaticity. Perhaps for this reason, pipelines assembled by professional plumbers last about 7 years even without additional twisting (although it is recommended).

So, to install a compression fitting on a metal-plastic pipe you will need scissors (pipe cutter), a calibrator, and open-end wrenches to size. Manually straighten the piece of pipe to be crimped and follow the following instructions:

As a result of crimping, the union nut should not “walk” along the pipe, even if you try to move it by hand.

A few professional tips will help you avoid mistakes when installing a compression fitting:

Before installing the fitting into the pipe, be sure to check the presence of o-rings: they must be in the grooves intended for them. To prevent the rings from moving out of place during installation, some craftsmen lubricate the fitting with a soap solution. If the fitting does not fit into the pipe, and the sealing rings are pulled off during installation, it is necessary to perform flaring with a calibrator.

If you don’t have a special tool at hand, use the end of a wrench. When tightening the union nut, control the effort: excessive effort can lead to damage to the edges and deformation of parts of the fitting. During installation, two wrenches are used: hold the fitting with one, and tighten the nut with the other. It is better to select the sizes in advance, as they are most often non-standard. If you don't have the right size, an adjustable wrench will help.

A properly installed compression fitting will maintain system pressure even when the compressor or pump is running. Approximately once a year it is necessary to carry out an inspection, and if digging is detected, it is recommended to tighten the nuts.

General provisions

So, you thought about it and decided to install the pipeline yourself. And rightly so, with attentive and diligent attitude, any business can be resolved. Where to start?

Take a sheet of paper and draw a plan of the premises where we will install the pipeline. It should look like a top view. As a rule, all the pipes in the apartment/house are replaced at once, and this is, first of all, the kitchen, bathroom and toilet. Carefully measure future pipe passage locations.

Tip: Ideally, draw straight lines with a pencil directly on the walls where the pipe will go and measure them with a tape measure.

Installing a water supply system from metal-plastic pipes is probably the most affordable way to replace pipes without proper qualifications. Feel free to get to work.

Do not forget that there is a double pipe: cold and hot, but there are a number of places where only the cold pipe passes. This is the wiring near the toilet, the supply to the washing machine, dishwasher, etc.

At this stage you already know how much pipe you need. Now carefully consider how many connections of pipes, tees, mixers and other installation units you plan to make.

Some fitting options for a metal-plastic pipe

Advice: it is very advisable that at the stage of compiling a list of components, one of the experienced people will help you. The choice of the type of fitting in a particular location is important and is selected optimally.

Do-it-yourself pipe installation also implies the presence of a certain set of tools.

Let's make a list of what you need:

- Scissors for cutting pipes. This is a necessary device, don’t skimp, be sure to buy it, otherwise you risk ruining the pipe. Cutting with other tools can cause burrs, irregularities, and damage to the protective layer of the pipe, which will subsequently lead to leaks.

Pipe cutting shears

- Calibrator. It is also necessary because after cutting the pipe is concave a little inward, but on the contrary, you need to flare it a little so as not to damage the rubber seals.

Pipe calibrator

- Adjustable wrench, open-end wrenches of the required sizes, pliers, drill.

Tip: you can purchase the necessary tool for installing metal-plastic pipes along with the pipe and fitting, and you will even receive a rightful discount.

So, everything is ready to go. Now it is necessary to dismantle the old pipe, and with it the old valves at the entrance to the home.

If you live in a private house, then you simply shut off the central water supply to the house, and if you live in an apartment, then you will have to call a plumber to shut off the hot and cold water supply in your driveway riser.

Advice: it would be logical to entrust the work of replacing the valves at the entrance to the apartment to a local plumber, who will shut off the water. Otherwise, nothing will happen to him, and you will wait for him for a long time.

It is worth noting separately that the valves at the entrance to the home should only be of high quality. Choose taps that can withstand a pressure of 60 atmospheres and a temperature of 150 degrees.

Do not skimp on such valves, because in the event of an accident they are the only gate into the house.

How to install a press fitting

Press fittings differ in design and, accordingly, installation method. Before installing the connector, you need to carefully inspect the fittings for metal-plastic pipes (sleeve, seals) and prepare press pliers that are suitable in profile and size (ideally from the same manufacturer).

We prepare the pipe in the same way as for a compression fitting - we straighten it, mark it, and carefully cut it with a pipe cutter. It is important to process the end part: remove burrs, make the rim smooth and even. We install the fitting in the following order:

When working with hand tools, you need to remember one subtlety of crimping: it must be done twice. That is, after the first clamp, it is necessary to loosen the fixation, rotate the pliers along the axis by approximately 30º and repeat the procedure.

Do-it-yourself installation of metal-plastic pipes: where to start

Let's start learning how to work with metal-plastic pipes by learning how to cut them correctly. The fact is that this type of pipe itself is a relatively soft material - incorrect or careless pressure with scissors can simply flatten the end of the pipe. A deformed pipe, even if straightened, crimps much worse, therefore, the likelihood of a leak increases.

Do-it-yourself installation of metal-plastic pipes - trimming

The process of cutting metal-plastic pipes looks something like this: first, with light pressure, you need to make a small cut half the diameter of the pipe, after which, turning the scissors in a circle, we cut the pipe to the end. In this way, a smooth and uncrumpled edge of the pipe is obtained.

What you need to know about the difference in methods

Before choosing the type of fittings installed on a water supply or heating system, you need to become familiar with the differences between two different crimping methods:

- The pipeline with compression fittings is serviceable (needs tightening the nuts approximately once a year), and the system with press fittings is monolithic, maintenance-free. To install compression parts, available tools are sufficient; to install the press sleeve, special press pliers are required. A system with compression fittings can be disassembled at any time to replace parts or repairs; if a pipeline with press fittings has to be changed, it must be completely replaced. The dismountable system must be visible (for regular maintenance), monolithic connections can be filled with screed and masked in the walls.

If the cost of a set of connecting elements is important, then keep in mind that press fittings are approximately 1.5 times cheaper than their crimp counterparts.

Recommendations for selection

When choosing press fittings for working with metal-plastic and deciding which one is good and which one is not of very high quality, you can adhere to the following recommendations.

- Since the body of a high-quality press fitting is made primarily from brass, which is a fairly heavy metal, you should evaluate the weight of the selected products: they should not be too light.

- The body parts of press fittings must have markings, which, if such products are of high quality, should be clearly legible.

- The appearance of the sleeve is another parameter that you should pay attention to when choosing a press fitting. In low-quality products, the sleeve may be made of thin metal and will look different from the entire fitting. It will not be possible to obtain a reliable connection if the press fitting is equipped with such a sleeve, since it will not be evenly pressed around the surface of the metal-plastic pipes being connected.

Thus, in order for the press fitting to efficiently compress metal-plastic pipes, the choice of such a product should be approached responsibly and competently.

To control the correctness of crimping, there are special templates, the use of which significantly reduces the likelihood of leaks in fitting connections.