Beton-House.com

Website about concrete: construction, characteristics, design. We combine the experience of professionals and private craftsmen in one place

Garage made of foam concrete block with a seating area

A garage made of foam concrete can be found in probably every tenth car owner in our country. Many people were prompted to choose the main wall material by the comparative cheapness of the project and the speed of construction. But is it really profitable to build such a building from foam concrete, or are these only apparent advantages?

What is foam concrete

Foam concrete is a type of cellular concrete. Used as the main wall material in low-rise construction. Its production is based on adding a foaming agent to the concrete mixture. Blocks made by forming foamed mortar in special molds have smooth edges and surfaces.

The main distinctive features of foam concrete, like any cellular concrete, are low thermal conductivity, low weight and ease of use. According to its characteristics, foam concrete is very similar to natural stone. It is environmentally friendly, since the raw material mixture for its production includes only natural ingredients. Moreover, its shelf life is practically unlimited. It does not rot and cannot be destroyed by insects or fungi. At the same time, foam concrete is much lighter than stone, so it can be used for the construction of buildings in areas with weak soil, with high groundwater levels and on a lightweight foundation.

Foam concrete building block Source domozavr.pro

Another significant difference from stone is vapor permeability. Thanks to this property, a garage made of blocks has the ability to self-ventilate. This does not eliminate the need to install a ventilation system, but “breathable” foam concrete walls help create a favorable microclimate in the room with an optimal level of humidity. But this is only provided that the exterior and interior decoration of the garage is also vapor-permeable.

Building with foam concrete is quite easy. This does not require special equipment or complex expensive tools. The blocks are produced in large sizes. But due to their porous structure, they do not weigh much. They can be laid by hand. As a masonry mixture, you can use a special adhesive composition, which allows you to build with masonry joints of minimal thickness. And the thinner the seams, the lower the heat loss from the walls.

An important advantage of foam concrete as a material for constructing a garage is that it belongs to the first degree of fire resistance. Another significant difference is that foam blocks can be easily processed using hand tools. They can be sawed without any problems into the desired shape.

Hacksaw for cutting foam blocks Source martand.ru

Project No. 5. Project of a small garage with an attic

This project can be considered a classic for small areas. Despite its modest size, the building can accommodate enough useful areas. Among the features of the project, we note:

- the garage is designed for one car, its advantages include the presence of several windows, as well as an additional entrance;

- on the ground floor there is a small utility room that can be used as a workshop or storage room. There are also windows here;

- The spacious attic floor can be used at your discretion. It is appropriate to organize a storage area there or create an area for entertainment. Fans of a healthy lifestyle will appreciate the idea of creating a small gym in the attic. The project provides for the presence of skylights, so there will be no problems with natural light.

The total area of the garage is 71 m². An excellent solution for any site.

Choosing a location on the site

The initial stage of building a garage is choosing a suitable location on the site for it. Typically, garages are located next to the house or near the entrance to the site. Moreover, the second option is often used in cases where the garage building is planned to be built from cheap and not very aesthetic material. However, foam concrete garages fit perfectly into the overall architectural composition of any cottage. They look good next to the main building.

There must be a minimum distance from the garage to the entrance to the site. The longer the path from the entrance to the garage, the less space there is left on the site for a recreation area, lawn, garden and other landscaping elements. In addition, long paths with turns are inconvenient.

The location planned for the garage should not be located in a low area or above laid communication lines. And, if communications can be moved if necessary, then nothing can be done about the humidity that inevitably forms in the lowlands. And for the construction of a garage made of foam blocks, the humidity factor is especially important, since this porous material can become saturated with moisture.

Porous structure of foam concrete Source daewoocenter.ru

It is advisable to build a garage in a place where there is space not only for the garage itself, but also for open parking in front of it. Outdoor parking is very convenient. It is useful for washing, inspecting and repairing a car. It is also irreplaceable in cases where guests come to the house in their own transport.

Recently, garages are increasingly being built as extensions to the house. If there is such an opportunity, it is worth taking advantage of it, since an extension garage has many advantages. Its entrance can be under one canopy into the house, which is very convenient in bad weather. It may have internal communication with the house. In addition, it is easier to connect all communications to the attached garage and make it heated.

Heating in a garage made of foam blocks Source kamtehnopark.ru

See also: Catalog of projects for garages made of foam concrete blocks presented at the exhibition “Low-Rise Country”.

Features of the garage layout

When arranging a garage, it is important to think about everything that should be located in this room. It is necessary to place not only the car, but also furniture, organize space for storing things and tools.

If a car owner wants to actively work in the garage, for example, repairing furniture, garden equipment, cars, then arrange things so that there is a working corner, an area for tools and cabinets. You can also create a separate workshop in the room and a place to do what you love.

You can build a garage as a separate plot or make it part of a country house

Design

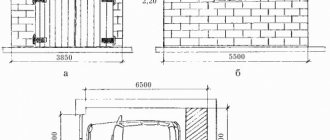

Despite the fact that a garage is a fairly simple building, it must be designed by a specialist. During the design process, all structural elements are calculated, the layout is thought out, and the consumption of materials is calculated. Projects for garages made of foam blocks vary in type of layout. They come in the following varieties:

- attached and detached;

- for 1 or several cars;

- with utility unit;

- with terrace;

- with parking canopy;

- with inspection hole.

An attached garage is more difficult to design than a detached garage. It must structurally fit into the overall architecture of the house, and at the same time have additional insulating protection. An extension garage can have several exits, for example, to the street, to the house and to the courtyard. In order to create maximum protection of the house from the car room, a buffer zone in the form of a vestibule, technical room or corridor is usually planned between the garage and the residential part of the building.

Project of a house with an attached garage Source zen.yandex.tm

The terrace and utility block can be located differently relative to the garage itself. In addition, there are options for garage buildings that are even more complex in design. For example, a guest house may be located above the garage. Often now they build garages combined with a bathhouse.

A separate design stage is the calculation of the garage roof. Typically garages are built with a pitched roof. In this case, it is necessary to properly consider its slope.

Garage layout

Construction of a new garage involves the need to select high-quality building materials, gates, design ventilation, install lighting, organize a storage system and create an inspection pit.

Finishing materials

After choosing a project, it is necessary to select building materials for the construction of the structure and finishing of the walls, floor and ceiling. It is important to take into account several requirements: products must be fire-resistant, safe, resistant to shock, chemicals and dirt. For construction, it is best to use cinder block or brick.

- Walls.

The cheapest finishing material is plaster. If applied properly, it will last for many years. You can also use water-based or acrylic paint. Before applying the material, the walls must be leveled and a primer applied to them. For a garage project with a bathhouse, it is better to purchase tiles: they are suitable for rooms with high temperature and humidity. Also, many motorists install lining, siding or build a section of sandwich panels. But they are not functional and are only suitable for creating aesthetic design. - Ceiling.

To decorate it, the same material is often used as on the walls. Small rooms should be decorated in light colors, but large ones can be experimented with in every possible way and selected to suit your taste. - Roof.

If the room is not planned to be heated, you can install a metal ceiling. For a warm room, the simplest and, most importantly, cheapest option is to lay concrete slabs.

Combination of building materials in finishing

Flooring

To cover the floor you can always use:

- Cement.

This is the simplest and most budget option, but it doesn’t look so bad. Most suitable for a technical garage. - Tree.

It is important to use thick boards so that they do not bend or break under the weight of the machine. Such material will not last long - no more than 5 years. - Self-leveling floor.

It looks like shiny concrete. To decorate it, you will need to spend money and purchase expensive materials. - Tile.

It is important for her to level the floor so that there are no unevenness, otherwise it will simply crack from the weight. To do this, choose high-quality tiles with high strength: the smaller the model, the lower the likelihood of it cracking.

Concrete slabs look stylish and practical

Gates

There are several types of gates. Depending on the size of the room, choose the option that suits you best:

- Swing gates

require free space in front of the garage and on its sides. They are made of strong material and reinforced with a frame. - The retractable model

is the most convenient option. It does not take up additional space and is often used in a room located at the entrance to the territory. - Overhead gates

are suitable for small spaces. When using this option, it is necessary to take into account the location of the lamps on the ceiling. - Roller shutters

are an inexpensive type of gate that folds into a special box. Please note that they are easy to hack and require additional security.

Most often used on old plots and cottages

The finishing material can be anything: for example, wood or metal

Popular design option

Mainly used in public garages

Ventilation

For quality repairs, ventilation holes should be placed. They will protect the room from external odors, dampness and large amounts of dust. The holes are usually installed on both sides of the entrance and covered with special grilles. The same ones are created on the wall opposite the gate.

Equipment example

Lighting

Natural light is important in any home, so install window treatments. If there are no free walls, then place several lighting fixtures.

When repairing, electrical installation must be carried out immediately. Make wiring throughout the garage so that all functional areas are equipped with sockets.

Place one light outside

Storage system

To create a comfortable garage design, a large area is required. When planning, allocate space for several shelves or cabinets. Place them so that there is room for free movement. The distance to the car on each side should be at least one meter.

Shelves can be placed everywhere: above tables, cabinets and racks

Inspection hole

Such a deepening in the field is only necessary if you plan to do serious car repairs in the garage.

If you need to equip an inspection hole, you should remember several nuances:

- the bottom and walls of the recess must be finished with concrete;

- create a drainage hole so that the water has somewhere to drain;

- place light sources or arrange a place for a portable lamp;

- make recesses for tools;

- When building a pit, it is important to perform high-quality insulation.

Inspection pit in an industrial building

Material calculation

The number of blocks must be calculated by the designer or qualified builder. You can do this using a special online calculator. Calculations can begin only after the designer, together with the customers, have decided on the type of foam blocks. To make the garage warm enough, it is recommended to build it from blocks with a thickness of 200 mm or more.

Foam blocks of different thicknesses Source all-atop.com

In order to pre-calculate the consumption of foam blocks, it is necessary to take into account their dimensions and the parameters of the garage. First you need to divide the height of the garage walls by the height of the blocks. The result will be the number of rows that will need to be laid out during construction. After this, the perimeter of the garage is divided by the length of the block. The result is the number of blocks in one row. Next, the number of blocks in a row is multiplied by the number of rows.

This way you can calculate how many blocks are required. But before purchasing, you also need to subtract the size of all window and door openings, as well as gates. You need to purchase material taking into account the battle and defects. Experts recommend purchasing 10% more material than was calculated.

Bottom line

Families who have two cars need to build a large garage that can accommodate the vehicles. Before starting construction, you will need to decide on the size of the room. This point is especially important because the comfortable use of the garage depends on it.

It is important to calculate not only the space for cars, taking into account open doors and comfortable movement, but also to calculate additional space for personal needs: your own workshop, motorcycle, bicycle and other small vehicles, as well as storage of various items.

After determining the required area, you can begin preparatory work, choose a place to build a garage for two cars, and then begin construction. It is important to pay special attention to the design of the space, especially when it comes to a two- or three-car garage.

It will allow you to approximately calculate costs, materials and distribute construction stages.

Marking

Marking the site begins with pegs being driven into the corners of the future building. Next, string is stretched between the pegs. To build a garage made of foam blocks that will meet the highest requirements, everything should be done accurately and without errors even at the marking stage. The length of the parallel threads stretched during marking should be the same. The angle of convergence of perpendicular threads is strictly 90 degrees.

Marking and trench for the garage foundation Source readmehouse.ru

Foundation

Since the blocks have minimal weight, there is no need to construct a complex and expensive buried foundation for the building. However, in addition to the characteristics of the wall material, when calculating the foundation, it is also necessary to take into account soil conditions.

If the site has good, non-heaving soil, and the groundwater depth is low enough, you can build a garage on a strip foundation, up to 50 cm deep. But if the soil is heaving, it makes sense to build a monolithic foundation. The fact is that the blocks are characterized by low resistance to bending loads. Without a firmly fixed base, they can break, and this leads to the destruction of the entire structure.

When arranging a strip foundation, certain stages of work are performed.

- A trench is dug to the required depth and width to match the width of the foam block.

- The bottom of the trench is compacted.

- A sand cushion of approximately 100 mm is poured onto the bottom.

- Crushed stone is poured onto the sand; it should be slightly less than sand.

- The formwork is being installed.

- A pre-prepared metal frame is installed in the trench.

- The trench is filled with concrete, which needs to be thoroughly vibrated.

Strip foundation for a garage Source nauka-i-religia.ru

Inspection hole

This is an optional, but very convenient element of the garage. Arranging a viewing hole may present certain difficulties. So, in an area where water occurs at a depth of more than 2.5 meters, everything can be done easily and quickly. But if the water flows higher, then the inspection hole must be provided with a drainage system.

- First, a hole is dug for the hole. This takes into account the desired depth of the finished pit, as well as the thickness of the drainage, waterproofing, sand cushion and finishing screed.

- A layer of gravel (100 mm) is poured into the bottom of the hole and compacted.

- A layer of sand (50 mm) is placed on top and compacted too.

- A trench is dug along the perimeter of the finished pit for drainage.

- Then geotextiles are laid with overlaps of 80 cm on each side.

- Next, a layer of gravel is poured into the trench and a drainage pipe is laid with a slight slope.

- The pipes are covered with gravel and covered with geotextiles.

- The floor of the pit is covered with clay.

- Lay waterproofing.

Waterproofing inspection pit Source stroyservis-74.ru

- Formwork and a reinforcing frame are installed at the bottom of the pit.

- The bottom is filled with concrete with the addition of waterproof components.

- Another layer of waterproofing is laid on the dried screed.

- The walls of the pit are also treated with clay.

- The walls can be lined with brick or monolithic concrete. The second option requires formwork and reinforcement.

- The finished surfaces of the walls and floors are covered with cladding. Any option of the owner's choice will do.

- A metal frame must be laid along the perimeter of the upper edge of the finished pit.

- A safety rail is placed on top of the frame to prevent the car's wheels from accidentally falling into the pit.

Gate installation

Installation of a gate or frame under a gate is often carried out even before the construction of walls begins. At the place where they are installed, roofing material is first laid on the foundation in several layers. The gates are fixed with wooden blocks. In order for them to end up being built into a foam concrete wall, pieces of reinforcement must first be secured to them. They must then lie in the masonry joints of the wall, so the height of their location must be correctly calculated. The gate is fixed at the top using a beam with a metal frame.

Frame for garage doors Source www.stroytal.ru

Walls

The walls are laid from the corner of the building. Foam blocks are placed with the long side along the wall. A rope is stretched between the laid out corners, which serves as a guide for aligning the masonry vertically. The outer blocks across the row are sawed using conventional hand tools. When working, it is necessary to use devices to check the level of the masonry.

It is better to lay the blocks not on a cement mixture, but on an adhesive composition. This speeds up the construction process and improves the quality of the wall. Laying of the top layers is carried out taking into account the roof slope. To withstand the slope, some blocks need to be reshaped by sawing. To give the building greater strength and reliability, the walls are reinforced.

Reinforcement of a foam concrete wall Source dompodrobno.ru

Practical interior decoration

Independent arrangement of a 6x4 garage or buildings of other sizes requires a systematic and comprehensive approach, taking into account various nuances.

Particular attention must be paid to preliminary design, which ensures full use of the internal space and creates all conditions for rest and work:

- maintaining the required microclimate and comfort in the room;

- efficient use of the usable area of the building as a whole;

- division of premises into functional areas for work and leisure.

To implement an integrated approach, it is necessary to use the entire space of the room, taking into account the basement and inspection pit.

Carry out competent work on the selection of effective storage systems, materials for heat and sound insulation, and organize the work area so that all the necessary tools are at hand.

Roof

The roof can be arranged in various ways. Consider the option of using an I-beam.

- First, beams 800 mm thick are laid across the future roof. with allowance for slopes. They are embedded in the plane of foam concrete walls. Slopes are needed so that a garage made of foam blocks with a pitched roof is protected from precipitation and wind.

- Then the roof structure is supplemented with 400 mm thick beams, which are laid in smaller increments.

- Ruberoid is laid on top, the edges of which should protrude by 10 cm. The edges are folded.

- The roofing material is covered with a dry heat insulator, for example, expanded clay.

- A cement-sand screed is laid on top, which after drying must be covered with liquid mastic.

- After all this, sheets of rolled soft roofing are fused, overlapping. The top sheet should cover the edge of the bottom sheet.

Roll fused roofing Source cs.aviarydecor.com

Floor

The floor in the garage should be as durable and reliable as possible. With a strip foundation, it is laid on the ground, which must be compacted well. Next, waterproofing is laid, and then layers of crushed stone, sand and gravel are poured. Each layer should have a thickness of about 100 mm.

A concrete screed is poured on top with a layer of 200 mm. In the garage, the floor can remain concrete. But it can be decorated with a durable coating. For example, the floor in a garage can be painted, covered with a special rubber-containing material or PVC tiles. But experts consider self-leveling flooring to be the most successful option.

How to arrange an attic?

There are many ways to create a second room in your garage. The attic may contain:

- room for games or relaxation;

- wardrobe;

- workshop;

- billiard room;

- sauna;

- bedroom or other.

The choice directly depends on the preferences and needs of the owner of the site. If desired, you can organize a kitchen on the second floor or divide the room so as to make a full-fledged one-room apartment of a small area.

It is recommended that zoning of the second floor be carried out by erecting additional walls from thin sheets of plywood. Thanks to this, the total area of the second floor will decrease slightly. In addition, working with plywood is easy.

Ventilation

In a garage made of foam blocks, as in any garage, it is necessary to equip a ventilation system. It can be natural, forced or combined. A natural ventilation system is the easiest and most economical way to get air circulation in your car. When choosing this option, it is necessary to provide 2 ventilation holes in the walls of the garage at the design stage. One should be located at the bottom of the room, and the second near the ceiling. They should be located in opposite walls.

The lower hole in natural ventilation is needed for air flow, and the upper one serves as an exhaust hood. This type of ventilation works due to the difference in temperature indoors and outdoors. Therefore, natural ventilation is effective only in the cold season. In addition, it cannot cope with the fumes of toxic substances and exhaust gases. This means that natural ventilation can only be used in a detached garage. In the design of a country garage made of foam blocks, which will be attached to the house, a forced or combined system must be provided.

Typical projects

There are several convenient layouts that will allow you to place your car, equipment and things in the best possible way. Each project has its pros and cons, and is also suitable for organizing a specific area: a car repair shop, a hobby or work area.

Garage with attic

Creating a room with an attic is a great idea for small areas. On the ground floor you can place a car, and in the attic room you can organize a living or utility area. It is important to consider that to access the second floor you will need to install a staircase, and for good sound insulation, take care of high quality materials.

This project is most suitable for cottages: at the dacha it is better to use a different type of layout

Garage with sauna

This layout is not used often due to difficulties during construction. Due to the different temperatures in the two rooms, it is necessary to create good thermal insulation and moisture insulation between the rooms.

The advantage of such a project is the savings when purchasing building materials. In addition, you do not have to provide heating: the sauna will heat the garage.

Typical layout drawing

Garage with basement

A garage layout with a basement would be a great idea to save space. On the additional area it will be possible to organize a recreation area, a workshop, a pantry with supplies and food, and a place to store things.

Such a project has a number of features: it is necessary to take care of high-quality ventilation and waterproofing. It will also be cold in the basement and heating devices will need to be installed.

Basement room design

Simple garage

A standard type of room that offers space to place a car and a small area for things or work. This project is not difficult to implement, but there are a few things to consider:

- ✓ In such a room it is important to zone the space. First of all, you need to designate an area for the car. Then you can place cabinets, shelves, tables and large tools.

- ✓ Take care of ventilation. If it is absent, moisture will appear inside the room, and this will lead to rust on the car.

- ✓ The presence of electricity will make the garage more comfortable: it will allow you to stay there at night, and can also be useful when carrying out repairs.

- ✓ You can arrange a terrace on the side of the garage. It will be comfortable to place tables, barbecues or, for example, hang a garland on it.

Large garage space with workshop

Insulation and finishing

Walls made of foam blocks retain heat well. The main thing is to protect them from moisture with finishing materials. If there is a need for insulation, this can be done using ecowool, mineral wool or polystyrene foam.

It is best to use mineral plaster as an exterior finish. It should be applied along a grid fixed to the wall. Without such protection, foam concrete will gradually collapse under the influence of precipitation and wind.

The inner surface of the foam block wall should also be protected. For this purpose I use plaster for interior work. It can be coated with paint.

Construction of walls for a frame garage for 2 cars

Walls of a frame garage for 2 cars

For the finished foundation to harden, you need to wait a day, after which you can begin choosing the material for the frame and its installation. The supporting structure can be assembled using two materials:

- Beam. The lumber has excellent strength qualities, and the easy processing of the material allows you to make adjustments at the attachment points of the slats without any extra effort.

- Profile tube. This metal product is extremely durable and can cope with any support and wind loads. However, with these products, the work of assembling the frame will require significantly more time and costs (welding, complexity of fastening). A garage using Canadian technology using screw piles can be assembled in a short time, but requires a large set of professional power tools (a hammer drill, a welding machine).