Heating » Materials

Published August 10, 2015 at 5:06 pm

Cross-linked polyethylene is not as well known as metal-plastic or polypropylene. The inside of the pipes has a smooth surface. As a result, no deposits will accumulate on them. The material used is environmentally friendly, thanks to which cross-linked polyethylene pipes can be laid in residential buildings. But when working with such pipes, it is important to strictly follow a number of technological processes that will allow them to be used for a long time.

Why do you need to pressurize a heated floor?

Pressure testing of the heating system - checking it for the quality of tightness of pipes and fittings under high pressure. Testing can identify leaks and other defects. Each heating circuit must be checked separately.

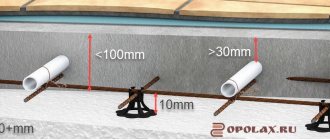

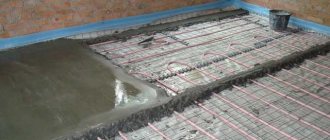

Pressure testing of heated floors is carried out before pouring the concrete screed and laying the finishing coating, so that if defects are detected, they can be easily eliminated.

If a hydrofloor is installed in a wooden house using the “dry” method, then it must also be tested before the pipes are covered with gypsum fiber sheets.

Tips for choosing

To have an idea of what components to buy, before going to the store you need to make a drawing of the network, indicating the necessary fittings with dimensions. The main thing is to know the diameter of the pipes and receiving devices and their material.

Choosing elements from the lower price category is not always justified. The longevity of the entire network depends on the quality of the connecting parts, which are more expensive than dubious counterfeits.

It is necessary to select components:

- Taking into account hydraulic and temperature conditions.

- In specialized stores, which will protect you from purchasing counterfeits and defective parts.

The best manufacturers

Preference should be given to products from well-known manufacturers who provide guarantees for their products:

- The German companies Oventrop, Wefatherm, and Aquatherm are confident leaders in the domestic market of polypropylene products. Czech and Ekoplastik are slightly inferior to them. They all provide a 15-year warranty on their products.

- Italian products are in wide demand.

- Further, experts and professional installers give preference to Turkish ones, “TEBO”, “Pilsa”, “FIRAT” mainly for their affordable prices. Manufacturers from Turkey provide a 10-year warranty.

Recently, products from Russian manufacturers have also successfully proven themselves. produces products with an EAN 13 certificate. The Egoplast enterprise near Moscow produces ProAqua polypropylene elbows.

The products of the group, a Russian manufacturer of plastic pipe products, receive a lot of positive feedback.

approximate price

Prices for fittings depend on their sizes and manufacturer.

Thus, an equilateral coupling press 20×20 Comtek produced by Compipe costs 225 rubles. The same coupling from VALTEC will cost the buyer 193 rubles.

Types of compressors, which one to choose

Compressors used to test warm water floors are manual and electric.

Their main task is to pump up the pipeline with water or air. In this case, the operation of the unit is controlled using a pressure gauge.

Do-it-yourself pressure testing pump. How to pressurize a heating system.

Hand pumps

Manual crimping devices are mechanical. The advantage of this application is its low price, unpretentiousness and ease of use. They are mobile and do not require a power source to operate. Mechanical compressors include all the necessary components, such as hoses, a pressure gauge and a tank.

The disadvantages include low productivity. If you decide to carry out pressure testing yourself with such a pump, then for high-quality testing you will need to make a lot of effort.

Electrical

Electric compressors are more bulky and more expensive, but they are fully automated. When using them you will not need to make any effort at all. Using a hydraulic pump it is easy to achieve any pressure in the system. More often, these devices are used by professionals when they need to carry out crimping frequently and in large volumes.

Despite the high cost of such pumps, a significant advantage is the increased productivity factor, since the device is equipped with a motor, which saves time and effort.

Which to choose?

When choosing the type of pump for pressure testing, you need to consider the following points:

- heating system volume;

- frequency of crimping work.

If you need to pressurize a small system, then a manual compressor is quite suitable as an option, and there is no point in buying an expensive electric device.

To check the heating system in a room with a large area, the power of this equipment may not be enough, so it is better to buy an electric-type compressor pump.

Hydraulic crimper

We recommend purchasing devices that have a steel rather than plastic body and are equipped with special valves that do not allow the pressure to rise above normal.

Installation instructions

Pipeline installation in each connection method includes the following steps:

Compression method

- First, a crimp nut is placed on the open section of the pipe, the thread of which should be facing towards the connector.

- Next, the split ring is stretched and fixed so that the pipe cut is at a distance of 1 mm from it.

- Then the end of the pipe, together with the crimp nut and ring, is pulled onto the fitting fitting very tightly, until it stops.

- Using two wrenches, tighten the crimp nut tightly (but do not overtighten to avoid damaging the pipe and fitting threads).

WARNING! Before pulling the pipe onto the fitting, it is under no circumstances disassembled, and no additional actions are carried out (chamfering, etc.)

Press-on method

- First, a clamping press sleeve is placed on the pipe.

- Then the end of the pipe is stretched with a special tool (expander) until it is given a slightly larger diameter and can be freely put on the fitting fitting: the expander is inserted into the pipe, its handles are pulled all the way and held there for several seconds.

- Now you can easily pull the pipe section onto the fitting fitting tightly until it stops.

- The resulting structure should be briefly fixed in the resulting position. Thanks to the property of shape memory, after a few minutes a piece of pipe stretched over the fitting will “sit” on it as tightly as possible.

Electric welding method

- An electric welded coupling is placed on the pipe cut.

- A special welding device is connected to the welding fitting terminals.

- The device applies voltage to the internal spiral of the fitting, which heats all its components and the pipe section until melting (to a temperature of at least 170 0C).

- After turning off the welding device and cooling the polyethylene, a strong connection is obtained that can withstand pressure of 10-12 atm or more.

ATTENTION! If you do not have experience in working with polyethylene, then even if you have a strong desire to do everything yourself, it will be safer to leave this task to specialists.

Methods for crimping water heated floors

Pressure testing of heated floors can be done in several ways:

- hot coolant;

- cold water;

- air.

Before carrying out pressure testing, it is recommended to rinse the line with ordinary water from the water supply to remove possible contaminants from it.

To do this, you need to fill and then drain water from the pipeline several times. When completely clean water comes out, you can stop the procedure.

Hot water crimping

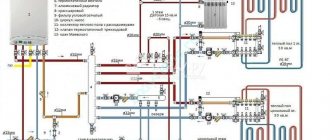

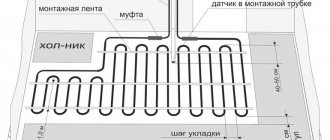

Before performing pressure testing of a warm water floor, it is necessary to roll out the pipeline and install a manifold to which the circuits are connected.

Let's look at the process step by step:

- The return valves at the collector unit are closed.

- The pressure is set to around 2.5 atmospheres.

- The main line is filled with water through the supply pipes. At the same time, there is a hissing sound, which indicates the release of air from the Mayevsky tap or through the air vent.

- One return valve opens to bleed air. When water starts flowing, it means that all the air pockets have come out, the valve can be closed. Such actions must be carried out with all circuits.

The presence of air in the pipeline causes the formation of voids, which reduces the efficiency of the system, as this leads to a decrease in pressure.

- The tap closes before the supply comb and opens before the return.

It is important that during the hydrotesting process, raise the temperature level of the coolant gradually, first set to +20 degrees, and every few hours add 5 degrees. At this time, you should check the heated floor for leaks. If leaks are detected, the water from the main should be drained and the leak repaired.

Then, the pipeline is filled with water again and left for 2 - 3 days for further testing and observation to identify possible problems.

If no more defects are found, then the temperature of the coolant gradually decreases. Filling the screed begins only after the system has cooled.

Cold water crimping

A warm hydrofloor should be pressurized with a cold coolant if there is high pressure. The pipeline must be inflated with chilled water, at a pressure 2 times higher than the working one. System testing is carried out for 2 days, this is enough to identify defects.