An important condition for the proper functioning of a warm water floor is the use of thermal insulation, which allows you to reduce energy costs and avoid heat loss.

The most modern and convenient type of insulation is mats for heated water floors, available in a wide range on the construction market.

It’s sometimes quite difficult to understand the variety of thermal insulation materials, isn’t it? Each manufacturer tries to demonstrate the best aspects of their product, sometimes keeping silent about possible shortcomings.

We will help you choose the optimal solution for water floor insulation. The article describes different types of polystyrene foam mats and provides practical advice on their selection and installation. We also identified manufacturers whose products have won the trust of consumers and are in active demand.

What is the function of thermal insulation?

When installing a water heating system, the most important task is to minimize heat losses and direct all the heat directly to the room where the structure is installed.

If you simply lay pipes on the main floor, then there will be very little use from this system, since most of the thermal energy will go down to the basement or to the neighbors on the lower floor.

Thermal insulation is precisely designed to solve this problem, which, on the one hand, is a barrier to the entry of cold air from the basement (if the system is installed in a private household), and on the other, serves to preserve and distribute heat evenly throughout the room.

Properly selected and installed thermal insulation allows you to eliminate the loss of thermal energy and redirect the warm flows coming from the heating pipes upward, towards the room. In addition, the insulation prevents condensation from accumulating and prevents the formation of mold on the walls

When choosing a particular material, you need to focus on its initial characteristics and the features of the room

The classic types of insulation that were widely used in the past are ecowool and polystyrene foam. Actually, even now the inexpensive cost of these materials still attracts very thrifty buyers.

However, progress does not stand still, and manufacturers offer more practical and convenient thermal insulation materials - special mats for water floors.

Connecting the system

The heated floor is connected to the network through a thermostat, with which you can turn the heating on and off, as well as change the temperature. This device automatically turns off the electricity supply when the floor warms up to a set limit.

An example of installing a heating cable for a heated floor

The connection diagram of the thermostat is indicated on its body. From it to the floor you need to run a cable for supplying electricity, connecting to the heating elements using a coupling, and wiring for a sensor that will read the temperature.

Features of the material for the production of mats

Modern mats are made from extruded polystyrene foam - a material that not only has excellent thermal insulation properties, but also has a whole list of other advantages.

Main advantages:

- Low vapor permeability rate (0.05 mg (m*h*Pa). For comparison, for mineral wool this figure is 0.30. This means that polystyrene foam does not allow water vapor to pass through well and does not accumulate moisture, is constantly in a dry state, and as a result does not contribute to the formation of condensation .

- Low thermal conductivity , which means maximum heat retention in the room.

- Soundproofing characteristics.

- Does not attract rodents and is not a breeding ground for the formation and development of microorganisms.

- Durability . According to the results of tests (alternating high and low temperatures from plus 40 to minus 40 degrees and exposure to water), the service life of products made from this material is up to 60 years.

The mats use expanded polystyrene with a density of up to 40 kg/m3, so they can withstand heavy loads perfectly.

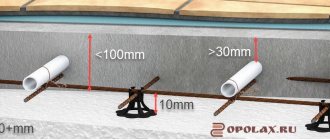

This property is especially valuable when installing a water floor, since a fairly heavy structure consisting of water pipes, a layer of concrete and a finishing floor covering is laid on top of the mats.

Weight of the water heated floor system per 1 sq.m. is about 200 kg, the thickness of the layers is approximately 150 mm. The main load falls on the bottom layer. The high density of polystyrene foam ensures the strength of the mats and allows them to support a heavy structure (+)

The main advantages of using mats

Mats for water heating structures are a modern thermal insulation material manufactured in accordance with accepted European standards for quality and safety.

The slabs are produced using the latest technologies and combine all the advantages of traditional insulation materials, and at the same time are free from their inherent disadvantages.

Advantages of mats:

- have excellent performance characteristics;

- have good thermal and sound insulating properties;

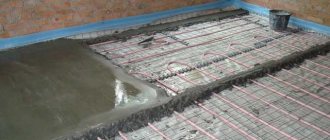

- suitable for both semi-dry installation and wet screed;

- with prolonged use they do not deform or change size;

- equipped with a locking system, thanks to which the slabs are quickly and easily laid;

- most mats have markings, which greatly simplifies the pipe installation process;

- do not rot, resistant to bacteria;

- do not swell from exposure to water;

- safe for humans, under normal temperature conditions they do not emit harmful odors;

- withstands both high (up to +180°C) and low (up to -180°C) temperatures;

- have a long service life of up to 50 years.

It must be taken into account that untreated polystyrene foam is a flammable and fire-hazardous material and emits toxic smoke when burned.

To reduce this property, fire retardants are added to the insulation during production, which makes it a self-extinguishing material. In domestically produced products, such material is marked with the letter “C” at the end.

Safety precautions when laying heated floors from thermomats

To avoid accidents and failure of the electric heating system both during its installation and during operation, it is important to comply with a number of safety requirements:

- Do not shorten the cables yourself;

- not me installation wires, breaking the coupling connections;

- do not touch the thermostat when trying to change its design;

- Do not install or repair the thermostat under voltage.

( 59 votes, average: 4.80 out of 5)

Heating without gas - the best ideas

Related Posts

Recommendations for choosing mats

When choosing insulation, you should pay attention to such various technical and operational indicators.

Main selection criteria:

- waterproofing;

- the ability of the material to withstand static and dynamic loads;

- pipe diameter;

- features of the room in which the water floor is laid.

Thus, roll material, due to its low waterproofing characteristics, is not suitable for installation on basement floors. It should also be used with caution in apartments where people live below, because if the pipes leak, it will not be able to retain moisture, and the water will flow directly into the neighbor’s apartment.

Sheet mats and foil-coated polystyrene foam blocks, on the contrary, have good waterproofing qualities, which eliminates the possibility of leakage. In addition, they belong to materials whose thermal conductivity coefficient is very low, due to which their use ensures the maximum level of heat transfer to the floor.

When organizing a water-heated floor, the characteristics of the material such as load retention are no less important. Profile mats made of polystyrene foam with a density of 40 kg/m3 cope excellently with this. Flat boards and foil mats also have a high density.

These insulation materials can be safely used to organize a heated floor system in an apartment or private house, which will be used as the main heating.

But rolled material remains an outsider in this position. Its density is not enough to withstand the loads, so it can only be used for organizing additional heating.

The diagram below shows what values make up the total thickness of the layers of the water floor, and what height of the room it can take (+)

Another parameter that needs to be taken into account is the thickness of the mat. If the floor already has some kind of thermal insulation, you can use thinner slabs. Also taken into account are the height of the room itself, the diameter of the pipes, the thickness of the future screed and the floor covering.

Installation of heated floor mats with a two-core cable

In general, for the sake of objectivity, it is worth saying that, like any other truly high-quality repair or finishing operation, the installation of heated floors from single-core or double-core thermomats requires certain (special) knowledge, as well as professional skills.

But patience and accuracy, as well as the availability of a sufficient amount of free time, can also help a non-professional install an electric heated floor with his own hands.

With two-core mats, installation is a little simpler than installation of single-core mats, but the preparatory operations are a little more complicated. After all, thermomats with a two-core cable can be laid on almost any surface, and it will be necessary (at a minimum):

- clean from dirt and dust layers;

- level (and seal all cracks, potholes, etc.);

- and prime.

There are two professional ways to lay heating mats:

- Cable up and mesh down. This method is considered the most common and is carried out as follows:

- the mat is cut out;

laid on the prepared surface with the cable facing up;

- glue is pointwise attached to this surface;

- and a thin continuous layer of tile adhesive is applied to the fixed mat;

- The tiles are laid on the dried adhesive layer.

- Heating cable downwards. The essence of the method is simple:

- the mat is cut out according to the installation plan and rolled up;

- the adhesive composition is applied to the floor in a layer of 2-3 mm;

- the matte roll unfolds with the cable facing down - laying directly over the glue;

- and then pressed (lightly) into the adhesive layer;

- Apply a second layer of glue (5-6 mm) on top with a notched trowel;

- the structure is dried;

- and then tiles are laid over it.

With this installation, it is important to avoid voids and air gaps in order to prevent total overheating and burnout of the cable during operation.

Detailed instructions for installing heated floors from thermomats are presented in the video review:

Tips for installing thermal insulation

Regardless of what type of mats will be used for a warm water floor, it is necessary to lay a layer of waterproofing underneath it. This is necessary to protect the bottom layer from the penetration of drops of moisture, as well as to create a strong barrier that can prevent flooding of the lower floors of the building in the event of a pipe leak.

The waterproofing material can be thick polyethylene film, bitumen coating or penetrating waterproofing.

If film is used, it must be glued to the walls with damper tape. The same tape is installed around the entire perimeter of the room after laying the mats.

Installation of profile mats is quite easy; special locks facilitate quick and high-quality assembly of the heat-insulating material

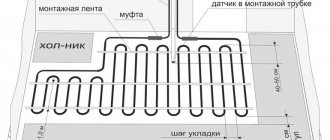

The easiest installation option is to use profile mats. They need to be laid on a layer of waterproofing and fastened together using a locking connection. Then the pipeline is laid in the spaces between the bosses using the chosen installation method, and with a light pressure the pipe legs are fixed in the desired position.

Installation of flat polystyrene plates is also not particularly difficult. The panels are either fastened with locks or simply glued to the waterproofing material, and their joints are fixed with waterproof tape.

The locking connection allows you to simply and very quickly fasten polypropylene slabs together

Roll insulation raises the most questions regarding installation. It is placed so that the foil layer is on top. The heat insulator also needs to be glued to the base, and the joints between the tiles are connected with mounting tape.

Then markings are applied to it and the pipes are laid. The pipeline is fixed using clamps or clips.

To fasten the rolled material, a special foil tape is used, which fixes the sheets and seals the joints between them

The difficulty of installation lies in the fact that the thin and light insulation is very mobile. Therefore, you need to tie it very carefully so as not to move the structure attached to it.

It should be noted that when laying mats of any type, only plastic fasteners can be used; metal parts can damage the integral structure of the mats and break their tightness. Installation of the pipeline system can only be carried out after all work on laying thermal insulation has been completed.

How to lay

Let's start with the fact that the flooring of special film waterproofing is a mandatory installation stage, regardless of the type of mat. Along the bottom of all walls of the room it is glued with damper tape.

The next layer of mats is laid using a locking system, and if the thickness and weight are small, using the adhesive method.

Attention

With this installation, you cannot use metal fasteners, as this may damage the integrity of the thermal insulation layer and waterproofing.

The assembly joints of the foil plates are taped with tape. If necessary, mark the surface for water pipes and proceed directly to the installation of heating circuits.

Review of manufacturers and models

Mats for warm water floors are produced by many foreign and domestic companies. However, the leading positions are occupied by only four brands, whose products are in greatest demand among buyers.

Insulation materials from the German brand Oventrop . The model range includes profile mats with bosses, slabs for dry installation, installation roll and folding insulation in polypropylene film.

The slabs with bosses have dimensions of 100 x 100 cm, they are available in two types: with thermal and sound insulating properties, and also without thermal insulation

Another German manufacturer of thermal insulation is the company Rehau , whose mats are also attracting increased interest from consumers. The main products are polystyrene foam mats with bosses, equipped with layers of thermal and sound insulation.

The slabs have dimensions of 145 x 85 cm and are suitable for laying pipelines with a diameter of 14 to 17 mm. The total thickness of the insulation is 50 mm. The delivery set includes clamps for securing pipes

Among Russian manufacturers, the most famous are the products of the Energoflex .

The model line includes several items:

- foil-coated polystyrene foam boards;

- thin roll insulation with foil;

- expanded polystyrene slabs with bosses.

All heat insulators are marked with a coordinate grid with a pitch of 50 mm.

Foil boards are covered with a protective film, they are available in the form of a roll or book, have dimensions of 100 x 500 cm, the insulation thickness is 2.5 cm

Water floor insulation produced by the Russian brand Ecopol .

The manufacturer offers smooth polystyrene foam boards and mats with bosses. The panels are equipped with a locking connection and covered with film waterproofing.

The mats are available in three versions: with 20 and 30 mm thermal insulation and without thermal insulation. The dimensions of the slabs are 115 x 85 mm, the total thickness of the layers is 38 mm