PVC pipes are also popular because they are very durable, reliable and easy to install.

Initially, such products were not soldered. Polypropylene pipelines were connected by gluing with special adhesives.

In some countries of the world, polypropylene pipes with small diameters, which are used indoors, are still connected by gluing today.

However, a more reliable and simpler method of fastening is soldering. From this article you will learn how to solder polypropylene pipes with your own hands.

And so that you better understand the technology of work, we recommend reading articles and watching videos on how to solder polypropylene pipes.

How to cut into a plastic pipe: features of the work and analysis of all the important nuances

Do you have plastic communication systems in your private home and do they require modernization or repair?

It’s not difficult to install plastic yourself, thanks to the features of this material, right? But how can you cut into a plastic pipe if it is under pressure? And is it possible to do this yourself? We will give you answers to your questions. Here we consider several ways to organize a diversion from an existing highway. The insertion options are provided with a detailed description of the process and supplemented with photos, which will allow you to understand the intricacies of the technology for installing cheap and durable plastic pipes.

By following the recommendations given in the videos, you can do most of the work on your own without involving experienced plumbers.

The purpose of the procedure is to connect the branch to the main pipe or main.

New wiring needs to be done inside the house.

Connection to a common pipeline occurs during the construction of an individual house or other capital construction project, or when organizing a diversion to another direction. At the same time, water intake is calculated, the diameter and material of secondary pipes are selected. Outlet pipes are selected based on the pressure values in the main line.

Pros and cons of this type of installation

A definite advantage is the large selection of fittings to achieve this goal. PPR pipelines also have such advantages as a long service life and non-susceptibility to corrosion processes.

Disadvantages and various difficulties may arise if the various elements of the pipeline are incorrectly connected.

Most often, the tightness is broken in systems with hot water due to temperature fluctuations at the joints.

It is worth noting that polypropylene products should be connected in the same color and from the same manufacturer.

Insertion options

The most reliable technology for inserting into a plastic water pipe is the method of inserting a tee into it. In fact, this is a normal installation of a branch using standard fittings.

First, a section is cut out of the pipeline, and then a part with an outlet is installed in its place. However, this option is not always possible.

The use of overlays (clamps, saddles) simplifies the process of inserting into the water supply system. And if he is under pressure, then this is the only possible option.

To install the tee, the water will have to be completely drained from the plastic pipeline, but for insertion using special saddles this is not particularly necessary.

Method #1 - tee or manifold

The main problem with any method of tapping into a water supply system is the water pressure. It's best when it's covered.

Then there will definitely be no splashes during the work, which is simply dangerous, since you have to work with power tools. Yes, and according to the rules, welding of plastic pipes must be done dry.

You can use the following as an inserted element to organize a branch:

- ordinary tee ;

- a manifold for connecting several outlet pipes.

- pre-prepared piece of pipe with a soldered outlet.

The end with the outlet pipe can be threaded or soldered. The choice of fitting type depends on the type of plastic and the type of installation of the entire pipeline system.

If the water supply system is initially made in a collapsible version, then the insertion into it should be made with a threaded connection. And if the entire pipeline was welded with an electric soldering iron, then it is better to insert into it in a similar way.

The technology for inserting a tee is as follows:

- The water is shut off and completely drained from the system.

- A pipe cutter is used to cut a section of pipe to size so that an additional fitting can be connected in its place.

- Installation of the tee using a soldering iron (for HDPE and polypropylene) or glue (for PVC).

- Installation of a shut-off valve on the outlet.

After installing the tap on the created branch, further work can be performed with the water turned on. When inserting a branch, plastic pipes can be welded end-to-end or into a socket. Both options are acceptable.

If getting to the water supply with a soldering iron is problematic because it is close to the wall, then you can use collet clamps or press couplings.

To do this, first prepare a section of pipe with a welded outlet, and only then it is inserted into the place of the cutout in the water supply.

Method #2 - electric welded saddle

An overhead saddle on a pipe is understood as a part of a water supply system, which is intended for organizing branches from the main line.

This element greatly simplifies the installation of branching units and does not imply a violation of the end-to-end integrity of the pipe product. To make a branch in a plastic pipe at the insertion point, only drill a hole of the required size.

A regular saddle is fixed to the pipe with clamps and bolts. Its electric-welded counterpart has built-in heating coils in its design.

When voltage is applied to them from the electrical network, these elements melt the plastic, which, after cooling, forms a reliable connection between the fitting and the water supply.

Which bath mixer to choose?

Manufacturers produce several types of bathroom faucets.

Choosing a bathroom faucet

Consumers are given the opportunity to install the following products:

- Valve products that allow you to regulate the flow of liquid medium using two valves. Various types of models are available. This allows you to select a mixing device for a specific room design.

- Lever products with cartridge. It uses one lever to adjust the temperature and pressure of the liquid.

- Thermostatic products with a stylish design that automatically maintain the required temperature and water flow. Such devices save water.

High-quality mixer taps are made of brass. This alloy is heavier than silumin. Therefore, to purchase a durable crane, you need to pay attention to weight.

Silumin is widely used even by well-known manufacturers to create mixing devices. It is an alloy of silicon and aluminum. The material makes it possible to create cheap plumbing fixtures that are not resistant to crystalline corrosion.

During operation, white spots similar to salt deposits appear on silumin devices. Devices made from cheap materials often develop cracks after a short period of use. Such taps cannot withstand heavy loads and burst when pressed.

The spout neck of silumin products is gray in color. For brass products, this place will be yellow. High-quality devices are made with thick walls, which also affects the weight of the devices.

For trouble-free installation of a bathroom faucet on polypropylene pipes, it is necessary to take into account the dimensions and design of the product. The device must be suitable for the installation location. After all, it is impossible to install on the wall a model designed to be mounted on the side of a bathtub.

A plumbing fixture should be easy to use. It is recommended to take into account the length of the spout, the correspondence of the model to the design of the room, the length of the shower hose, and the presence of a wall mount for a watering can in the kit.

Scheme of connection to a centralized water supply system

If there is a collector well in the area where your house or plot is located, then tapping is carried out (if permitted) in this well. If it is located far away, then access to the pipe is carried out through an additional well.

- in the place indicated by the project, they dig a square hole measuring 1.51.5 meters;

- from the pit, towards the house, they dig a trench for future drainage;

- Upon completion of all work, an additional well with a lid is built above the insertion point for access to the connection point.

Connection to a centralized pipe, which is under pressure, is carried out in two stages:

- Installation of an outlet flange with a shut-off valve.

- Reaming the pipe body.

You can cut into a plastic water pipe either with or without welding. Connection to steel communications is usually made using a welded flange.

Note! The general rule for tapping a branch pipe is that the diameter of the pipe tapping is always smaller than the diameter of the central pipe.

Features of a mortise valve

Cutting without cutting - a few simple steps.

This is a compact part that performs a dual function: diverting the working flow from the main and the possibility of blocking it, as well as adjusting it. The valve is made of polyethylene and metal. The main part of the device - the spindle - is made of alloy steel. Standard mortise valves are designed for connection to a pipeline with a current operating pressure of up to 16 atmospheres (water supply) or 10 if the pipe is gas. Manufacturers offer valves in sizes from 63 mm to 225 mm.

The design of the valve provides for an integrated drill-cutter with lower and upper stops. Both of them move along a metal sleeve. In order to completely block or, conversely, open the flow, it is enough to make 10 revolutions. The pressure tapping valve also has a heating element at the bottom. This makes the process of welding to a HDPE pipe better, because uniform heating of the entire surface occurs. To remotely control such a valve, there is usually a telescopic mounting kit. The valve for tapping under pressure, widely used in the gas, oil and housing industries, is not the only device that facilitates connection to a pipeline if the pressure of the working medium in it is absent or not too high.

Connecting pipes using the crimp method

Often, repairs will require disassembling the pipeline. If the connection of the main components is made by soldering, which is reliable and durable, then disassembling it is almost impossible. Let's look at how to connect polypropylene pipes without a soldering iron, which cannot always be bought or rented from friends. In this case, you will need threaded fittings with a pressure ring, which are called collet fittings (crimp). And for good reason, because this kind of connection can withstand loads of up to 16 atmospheres.

Summarizing

Installation of heating and plumbing systems using modern polypropylene pipelines is impossible without the welding (soldering) process. This process has nothing in common with welding metals; soldering polypropylene is much simpler. Thanks to this, even a novice plumber can cope with the task of joining a polypropylene pipeline.

The video in this article shows an example of proper soldering of polypropylene pipes.

Did you like the article? Subscribe to our Yandex.Zen channel

When is it needed?

Here are the most common cases of connecting operations.

Replacement of water supply

Major renovation of housing in an apartment building involves the replacement and repair of sections of the water supply system, limited to the territory of the owner. Polypropylene looks more aesthetically pleasing and modern, and in old houses, where iron in plumbing networks “the old fashioned way” pleases the eye, apartment owners everywhere decide to replace pipes. Even if it is expensive to completely replace the metal part of the riser belonging to the apartment, the outlets to the consumer devices are in any case made using polypropylene.

Emergency repairs

If an emergency situation arises when repairing a burst pipe in the basement, the damaged area is replaced in most cases with plastic, since steel pipes are more expensive and heavier, and the procedures for eliminating the accident are more labor-intensive.

Radiator replacement

When replacing an old cast-iron battery with a modern steel or bimetallic radiator, you will have to switch from metal to polypropylene if plastic pipes are used in the heating system.

Replacing a heated towel rail

Installing a heated towel rail in the bathroom also involves connecting an iron pipe to a polypropylene pipe if the hot water supply is made of plastic.

General information

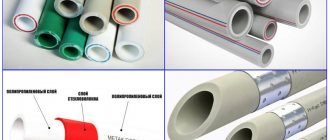

During the construction of private houses, polypropylene water pipes began to be installed more and more often. The popularity of such products is justified by their low cost, long service life, ease of installation and lack of rust. They are used to create water supply and heating systems. Three types of products are produced from polypropylene:

- copolymer;

- block copolymer;

- homopolymer.

The above products can be connected in various ways. Many people use the connection of polypropylene pipes without soldering.

Insertion into a water supply using a pipe

In fact, the answer to the question of how to cut into a water pipe can be very simple. One method of this process does not require cutting the piping element at all. To begin with, purchase a piece of pipe from any specialized store with a pipe, of course, the same diameter as the water supply pipe.

Cutting without cutting - a few simple steps

You need to cut a pipe from the purchased piece of pipe, but in such a way that at its end you get an element of the “half-pipe” type. It is he who must ensure reliable overlap of the future insertion site. Simply put, a kind of second wall of the pipe should be formed. A hole is drilled in a predetermined location, the diameter of which must correspond to the diameter of the pipe.

Any non-drying sealant, for example, Body 940, is applied evenly to the entire internal surface of the flange. You should look for it in car dealerships and car cosmetics departments. The area around the hole is lubricated with the same composition, but you do not need to reach about 1 cm to the hole itself.

Next, when installing such a curved flange on a pipe, you will have to use a fastening element such as a clamp for cutting into the pipe. Or rather, you will need two of them to pull the edges on both sides. The clamps must be tightened very carefully, but so that the sealant begins to squeeze out from under the flange. Any remaining grease is removed.

Attention! If a connection is made into a polyethylene water supply (sewer) pipe, where a slight pressure is detected, then the use of clamps is an optional condition. You can simply “bandage” the flange using wide electrical tape.

There are cases when a more rational solution would be to use a ready-made tee with a larger cross-sectional size. In this case, you need to cut off the section of pipe where there is no pipe. In this case, the general procedure will involve cutting the pipe longitudinally, drilling a hole in the remaining section, and then installing a pipe to it.

What tools and materials will be needed for replacement?

In order to change the tee, you will need the following tools:

- grinder with cutting disc for cutting cast iron or plastic;

- a long screwdriver or chisel for removing the cement seal of cast iron sockets;

- lubricant for the repair coupling (ordinary shampoo will do);

- new tee;

- a piece of straight sewer pipe of the same diameter as the main pipeline;

- through coupling;

- adapter from cast iron to plastic (if necessary);

- device for hanging a vertical pipe (selected according to the situation);

- hammer, possibly with a rubber striker.

If the sewer crosspiece is being replaced, the procedure and set of tools will be needed the same. Only the most necessary items are listed. Disassembling the riser is not easy. You need a strong and reliable suspension. To avoid collapsing the top assembly. Usually they use a clamp that is attached to the wall. It must be taken into account that the toilet of a typical apartment will not accommodate large structures. Therefore, it is necessary to make the suspension as compact as possible. Even combined toilets (as in Khrushchev) are very limited in working space. Therefore, before replacing a cast iron tee in a sewer riser, you need to think through the procedure. It is important to ensure free access to the work area and reliable support for the top of the riser.

In addition, it is necessary to notify neighbors about the start time of work. If someone uses the drain during the replacement, the entire contents of the pipe will end up on your floor. It is important to organize the process correctly so that it goes quickly and with the desired result.

You may also like:

How to make a tap into a main water supply

Before starting the main water supply, you must go through all the permitting approvals necessary to obtain permission from the responsible institution (Vodokanal). Undoubtedly, it is better to go through this process legally than to receive a fine for an illegal connection, since sooner or later it will still be revealed during a routine inspection by the volume of water consumption

Before submitting documents, it is necessary to calculate the volume of water required in a house or apartment and, as a result, the size of the diameter of the supply line. Once all approvals have been received and permits are available, work can begin. Mostly, if possible, it is planned to tap into an existing well, but if this is not possible, then it is possible to install a new one, opposite the place of water supply.

The well is planned to be built to the depth of the main pipe route. The outlet should face towards the house. Next, after completing all the work, it is necessary to hand it over to the employees of the controlled organization in a certain way, with the sealing of the metering point and the tap that shuts off the incoming water.

Price

If you need an approximate estimate for inserting into a sewer pipe, then calculate the costs of connectors, sealant, and fasteners. For example:

- Flange mount or saddle VBT 10388 W4 – 450 rubles / 4 pcs;

- Silicone colorless sealant – 90 rubles;

- Additional elements (bolts, gaskets) – 200 rubles.

The total is 740 rubles. You can buy all the rest at any plumbing supply store or on an online platform. When purchasing in bulk, the price may be slightly lower. The diameter of the fasteners also plays an important role - the larger the size, the more expensive it will cost.

At the same time, the cost of work carried out by professional companies often exceeds 2,000 rubles, and in Moscow it can amount to 3,000 rubles.

www.kanalizaciya-stroy.ru

Threaded

This type of plumbing connection is called “American”. Plastic is soldered on the coupling side. By the way, polypropylene, metal-plastic, polyethylene and polyvinyl chloride pipelines are considered plastic. The metal part is attached with a thread accordingly. Here's what it looks like in practice:

- Installation begins with unscrewing the coupling at the intended joint. If there is no coupling, then the pipe is simply cut off. After which it is necessary to cut a thread at the joint. To do this, it is recommended to lubricate the entry point of the thread cutter with oil or grease.

- The threaded connection must be made airtight to prevent possible leaks. This is done using fum tape or flax, which is wound between the threads. For greater reliability, silicone is applied on top. The amount of wound material should not exceed 1-2 turns. Otherwise, it will be difficult to screw on the fitting. It is necessary to wind flax or fum tape in a clockwise direction.

- Then screw on the fitting. This is best done by hand, without using a gas wrench. The fittings are made of a fairly fragile material, and excessive compression can damage the adapter. The best solution would be to slightly tighten the fitting if a leak is detected after water is supplied. But remember that you need to use the tool extremely carefully.

- The polypropylene pipe is welded on the smooth coupling side.

- Water is supplied to the pipes.

Advice. If the threaded connection is used for a heating system, it is recommended to replace the rubber gasket on the coupling side with a silicone one. Temperature changes will quickly destroy the rubber, and water will leak at the junction of the pipes. Silicone seems more reliable in this regard.

Faucet installation

The tap can also be welded into the system, but then it cannot be replaced if necessary. You will have to cut out part of the pipeline. It makes more sense to install a metal tap on threaded connections. Two such (see Fig. 6) “American” parts are welded into the pipe. A ball valve can be easily installed between them at any time using a wrench.

PHOTO: avatars.mds.yandex.net Pipeline elements for fastening a ball valve

PHOTO: avatars.mds.yandex.netOption for installing a ball valve

Types of fitting connections

When inserting a tee fitting into a cut metal-plastic pipe, in most cases, such recognizable methods of making connections as crimping, crimping or thread fitting are used.

In accordance with the technique used, two types of fitting tees can be used, in particular:

- Compression.

- Crimping.

In addition to the indicated main modifications, combined tees can also be used for inserting into metal-plastic pipes, the working parts of which are designed for different types of connections.

Such a variety of connections used allows you to work with both detachable (crimp nut and thread),

and with one-piece (press sleeve) mounting diagrams, which increases the functionality of the equipped unit.

Thus, when using a tee with one internal thread and two crimp nuts, it will be possible to connect not only a washing machine or dishwasher to the system, but also any measuring device with a threaded fitting.

Best answers

Oleg:

the diameter does not match there will be no reliable seam

BASIL:

buy adapters, why solder if you can connect, unless you have to solder an adapter to polypropylene and that’s it

Online magazine Tips for owners:

Theoretically it is possible. But it’s like crossing a hedgehog and a snake and hoping that you get barbed wire. ) Such a “joint” will have no real application.

A metal-plastic pipe is a metal “screen” lined with polyethylene on both sides. The outer layer is thin, it will spread when heated, and the “alloy” of polypropylene and polyethylene will not provide a strong seam, despite the similarity and similarity of the formulas; the materials are still somewhat different.

In addition, it is not realistic to select the appropriate diameters.

The connection of these pipes both with each other and with metal pipes is ensured by appropriate adapters.

Bely Oleg:

No, it won’t work - different polymers cannot be soldered together. It is better through combined threaded couplings. By the way, compression fittings from HDPE pipes work great on polypropylene - I needed a detachable connection between polypropylene and HDPE. For 20 metal-plastic and Pp-r pipes, you can try this method...

Igor Shkurny:

Why such difficulties in life? No you can not!! ! These two pipes connect perfectly without soldering!

Gluing individual elements

In addition to the above option, there are other ways to connect plastic pipes. One of these is the gluing process, when the ends of the component parts are joined using a special chemical composition. During the work, it is possible to ensure sufficient tightness.

The principle of operation of the composition

Adhesive intended for plastic products usually contains polyvinyl chloride, which dissolves in methyl ethyl ketone, tetrahydrofuran and cyclohesanone. Special additives are also added to two-component formulations to improve adhesion.

Advantages of the glue method

- High-quality adhesion

of the chemical to the surfaces of the elements allows for high tightness. - The availability of

the basic material makes it possible to use it for a wide range of consumers. - The invisibility of the joint

has a positive effect on the aesthetic perception of the components of the communication system.

Attention! The glue used must be stored at a sufficient distance from open flames, as it easily ignites. In addition, during work it is necessary to protect the skin from contact with the substance.

Application of the composition

You can do the gluing yourself. Work must be carried out at temperatures from +5 to +35 degrees. You need to prepare a brush with natural bristles in advance. In most cases, it comes directly with the adhesive.