Select products by parameters

Products:5

DefaultPriceRating

Manual press pliers used for working with metal-plastic pipes are designed to connect pipelines together using press fittings. Such connecting elements differ from threaded analogues by the presence of a sleeve instead of a nut.

The tightness of the connection is ensured by crimping a pipe placed on a fitting and inserted inside a metal sleeve. It is this sleeve that is compressed by the press pliers. The pressed area should not be re-exposed to mites, as this may break its tightness.

What parameters characterize press jaws?

Before you buy press pliers for metal-plastic pipes, it is advisable to familiarize yourself with their main parameters. In this case, you can make the right choice of tool:

The diameter of the pipes is maximum, which can be subjected to crimping.

This data is available in the passport that comes with the tool. A rotating unit on which replaceable attachments are attached. Its presence makes working in hard-to-reach places more convenient. Tool life. This is the minimum number of crimps produced by the pliers over the entire service period. The telescopic handles of the pliers make it possible to change the length of the lever, which is very convenient when crimping large diameter pipes. Vespress pliers.

The ease of use and mobility of the tool depends on this parameter. Types of press attachments. Some models of pliers are only suitable for working with fittings from certain companies. Before you decide to buy press pliers for metal-plastic pipes, find out what fittings you will have to work with.

How to use manual press jaws

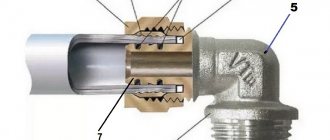

By spreading the handles of the pliers, the halves of the press insert, the diameter of which corresponds to the diameter of the pipe, are inserted into the holder. The clip snaps into place and is considered ready for use. A metal-plastic pipe with a sleeve is inserted into it, which is already connected to the fitting.

The handles of the press pliers close on the sleeve, squeezing it with a certain force. Marks from the liner remain on the surface of the sleeve, indicating that the installation was carried out correctly. Re-compression of the connection is not allowed.

How to choose pliers for metal-plastic pipes

When choosing a suitable model of pliers, pay attention to the following points:

Cost of ticks. A tool designed for manual use has always been cheaper than an electric or battery-powered option. At the same time, the quality of the connections will be no worse than when using the most sophisticated model. Nowadays, almost all press jaws are capable of working with small diameters, which characterize metal-plastic pipes.

If you have to crimp pipes of significant diameters, then inquire about the working range of the pliers. The pliers can work with smaller diameters due to the presence of replaceable attachments. It is recommended to buy pliers that come with sets of replaceable inserts. By doing so, you will expand the range of your work.

If you really like a particular model, but there are no replacement attachments included, then purchase them separately. Just make sure that they fit your press jaws. With a small difference in cost, a tool produced by well-known companies specializing in this will be much more durable and stronger. The following manufacturers of hand press tools have proven themselves to be excellent: REMS, Hydrosta, VALTEC, Rothenberger, FORA, Novopress.

You can select and buy press pliers for metal-plastic pipes by contacting the Eurotools store.

In our offices located in Krasnodar, Moscow and St. Petersburg, you can get professional advice and choose the right tool model. Our store's website, email and phone number are also at your service. A system of personal discounts, a wide selection of tools and affordable prices will leave you in no doubt about choosing a store.

Gifts for products in this section

Personal recommendations

All productsSelect storeDisplay:Sort by: PopularityRatingAscending priceDecreasing priceDisplay by: 204080productsUseful information

Press pliers are designed for crimping terminals and connecting wires. They allow you to quickly and efficiently lay wiring. Necessary for technical equipment of companies providing electrical installation services, energy departments at enterprises, public utilities, and private craftsmen.

Types of equipment and principle of operation

There are hydraulic and mechanical manual press pliers for crimping. The former require less physical effort from the operator and allow for greater developed force, and therefore are ideal for frequent use in various production conditions. For rare use, it is more advisable to purchase mechanical press pliers - they are cheaper.

Hydraulic equipment is divided into several types. Non-autonomous models require connection to a pump; autonomous models are more convenient, as they can be used without additional equipment. Hand press pliers with a remote pump are great for working in hard-to-reach places.

There are special press pliers for fittings - equipment designed for crimping the connecting parts of various pipelines.

Main characteristics

- Crimping area – selected with a margin based on the maximum diameter of the cable and tip that will be used. The price of manual press pliers depends on it. Working stroke – indicates the minimum and maximum size of cables for crimping. Developed force – determines the capabilities of the equipment: the larger it is, the better the quality of crimping.

Manufacturers

Top

Down

Metal-plastic pipes are widely used in plumbing systems, as well as in heat supply. These parts are able to withstand various aggressive environments, so their use is widespread, along with similar elements made of polypropylene materials, not only in residential premises, but also in industrial enterprises, during the distillation of petroleum products, and so on. When installing systems, it is necessary to carry out a set of operations to test the pipeline system, called crimping, in which a press tool for metal-plastic pipes is used. Metal-plastic pipes can withstand various aggressive environments, so their use is widespread. Purpose of the crimping operation Crimping of metal-plastic pipes allows you to check the level of tightness and endurance of these parts in any system. This operation is carried out during installation, as well as during emergency replacement of some heating sections (boilers, radiators or small parts of pipes).

Pressure testing allows you to identify leaks or defects in the entire system. In this case, you can use free-plan heating system projects, for example, with pipes running in the floor. As a rule, in such premises a concrete coating is used, and the screed is carried out after a pressure test. Installation of metal-plastic and polypropylene pipes is carried out using special devices - fittings.

They are fasteners or assemblies (angles, tees, couplings, plugs and other elements). Fittings are fastened when connecting polypropylene pipes using a welding machine. There are two types of these fasteners: crimp and press fittings. The first type is named after the connection method - crimping the pipes together.

This method is easier to implement, but the connection is fragile. Conditions for installing pipes and crimping Installation of metal-plastic and polypropylene pipes is carried out using special devices - fittings. During installation work, the following conditions must be observed: Installation of parts made of metal-plastic, as opposed to polypropylene pipes, the connection of which must be carried out at least +5°C, is usually carried out at a temperature not lower than +10°C; When pressing, defects (concavity or breakage) must not be allowed to occur. If they are present, it is necessary to replace the pipe section; When laying pipes, it is necessary to avoid the occurrence of tensile stress; The open ends of the parts must be closed with special plugs to avoid the ingress of debris or dirt; The concrete floor covering is poured after testing, and the pressure in the pipes should be equal to 0.3 MPa. Correctly carried out installation work on metal-plastic pipes and polypropylene elements can ensure a service life of the entire system of more than 50 years. To perform crimping, use the following equipment and tools: cutter or pipe cutter; calibrator for stripping and leveling the end edge; press fittings of the required diameter; press tool (manual or electric). Press tool or pressure tester is a unit whose main element is a hydraulic pump. This part sets the pressure value that is necessary for proper crimping of pipes. There are two types of pressing tools: Manual pressing tool.

This tool is mainly used for small-scale work and in areas where there is no access to power. A hand tool requires some effort to press, which is a disadvantage in using this type of device; Electric tool. This device is used for large volumes of work.

It has a number of advantages: easy to operate, reliable and durable. The procedure for installing metal-plastic pipes with a press tool is as follows: A manual crimping machine is used mainly for small-volume work and in areas where there is no access to power. Preparing and checking the fitting and pipes. In this case, the metal-plastic part must be cut at a right angle. The edges of the end part must be cleaned using a calibrator, the chamfer from the inside of the pipe must be removed. The fitting (pipe with a threaded connection) must be checked according to several parameters, having previously lubricated it with a soap solution or silicone grease. Check whether the fitting is seated correctly.

If the seal rings are not in the intended grooves, you must remove the sleeve using a regular screwdriver. Then install the rings correctly and put the sleeve back on, making a few gentle blows with a hammer on the socket. Connect the fitting fitting to the crimping tool, and if you use a hand tool, then you need to bend the “jaws” of the device and connect it to the sleeve so that the special recess in the nozzle, which the manual crimper has, came into contact with the restrictive edge. This can be observed through a special window in the sleeve. The crimper must be at right angles to the axis of the fitting sleeve.

The pressing process is carried out until the “jaws” of the tool are completely closed. It is important to take into account that the operation of the electrical device is 2 minutes, and the rest period is at least 8 minutes. The pressure testing procedure is necessary during installation work of heating and plumbing systems, as well as during seasonal inspections and emergency repairs of individual sections of the pipeline. In this case, a special device is used - a press tool for metal-plastic products, which allows you to identify various defects when installing systems. Share a useful article: Similar articles:

Press pliers for metal-plastic pipes are included in the line of mandatory tools, without which it is impossible to install a metal-plastic pipeline. For example, to work with copper systems you will need a tool such as a soldering iron, and to lay steel gauges you will need a welding machine. Likewise, laying a metal-plastic (MP) network is impossible without pliers.

MP systems are used very often. These designs boast durability and reliability. They comply with all hygiene and operational standards.

But, all this is possible only if the installation and installation work is carried out in accordance with the technology. One of the important factors in its compliance is the use of special tools, which also include pliers.

The crimping press for laying metal-plastic assortments is manufactured by most manufacturers not only in a standard version, but also in a unified and professional version. These are the following types of devices.

- hydraulic devices;

- electrical machines equipped with a set of various clamps.

It is clear that a home craftsman will not need such a crimping mechanism.

For one-time work, a hand tool is quite suitable for him. By the way, it should be noted that professional equipment costs much more. Also, using a professional crimping device requires certain knowledge and skills from the master.

IMPORTANT! Professional craftsmen claim that the quality of the joint, which is made with a manual crimping mechanism, is not inferior in reliability to the joint made with an electric device.

Thus, we can come to the conclusion that if the amount of work is not large and is carried out one-time, there is no point in buying expensive professional tools.

Speaking about hand pliers, professional craftsmen highlight tools from Novopress from German manufacturers. Each such mechanism is equipped with a fast reverse motion, has a compact size, and is distinguished by a consistently high level of quality.

And for heavy loads, Rems pipe tools are recommended. This equipment is manufactured by stamping from solid steel blanks, and is equipped with step-type clamps. They will not only withstand high loads, but will also serve for a long period of time.

Crimping process

Pressure testing of heating systems in a private home begins with disconnecting the heating boiler, automatic air vents and expansion tank from the system. If there are shut-off valves leading to this equipment, you can close them, but if the valves turn out to be faulty, the expansion tank will definitely fail, and the boiler will fail, depending on the pressure that you apply to it. Therefore, it is better to remove the expansion tank, especially since this is not difficult to do, but in the case of a boiler, you will have to rely on the serviceability of the taps. If there are thermostats on the radiators, it is also advisable to remove them - they are not designed for high pressure.

Sometimes not all heating is tested, but only some part. If possible, it is cut off using shut-off valves or temporary jumpers are installed - surges.

The following is the process:

- If the system has been in operation, the coolant is drained.

- A crimping machine is connected to the system. A hose extends from it, ending with a union nut. This hose is connected to the system in any suitable place, even in the place of the removed expansion tank or instead of the drain valve.

- Water is poured into the container of the pressure testing pump and pumped into the system using the pump.

- Before increasing the pressure, all air must be removed from the system. To do this, you can bleed the system a little with the drain valve open or drain it through air vents on the radiators (Mayevsky valves).

- The system is brought to operating pressure and held for at least 10 minutes. During this time, all remaining air is released.

- The pressure is raised to the test pressure and maintained for a certain period of time (regulated by the Ministry of Energy standards). During the test, all devices and connections are checked. They are inspected for leaks. Moreover, even a slightly damp connection is considered a leak (fogging also needs to be eliminated).

- During crimping, the pressure level is monitored. If during the test its fall does not exceed the norm (as specified in SNiP), the system is considered to be in good working order. If the pressure drops even slightly below normal, you need to look for a leak, fix it, then start pressure testing again.

As already mentioned, the testing pressure depends on the type of equipment and system being tested (heating or hot water supply). The recommendations of the Ministry of Energy set out in the “Rules for the technical operation of thermal power plants” (clause 9.2.13) are summarized in a table for ease of use.

| Type of equipment tested | Test pressure | Test duration | Allowed pressure drop |

| Elevator units, water heaters | 1 MPa(10 kgf/cm2) | 5 minutes | 0.02 MPa (0.2 kgf/cm2) |

| Systems with cast iron radiators | 0.6 MPa (6 kgf/cm2) | 5 minutes | 0.02 MPa (0.2 kgf/cm2) |

| Systems with panel and convector radiators | 1 MPa (10 kgf/cm2) | 15 minutes | 0.01 MPa (0.1 kgf/cm2) |

| Hot water supply systems made of metal pipes | operating pressure+ 0.5 MPa (5 kgf/cm2), but not more than 1 MPa (10 kgf/cm2) | 10 minutes | 0.05 MPa (0.5 kgf/cm2) |

| Hot water supply systems made of plastic pipes | operating pressure+ 0.5 MPa (5 kgf/cm2), but not more than 1 MPa (10 kgf/cm2) | 30 minutes | 0.06 MPa (0.6 kgf/cm2), with further testing for 2 hours and a maximum drop of 0.02 MPa (0.2 kgf/cm2) |

Please note that for testing heating and plumbing made of plastic pipes, the test pressure holding time is 30 minutes. If no deviations are detected during this time, the system is considered to have successfully passed the pressure test.

But the test continues for another 2 hours. And during this time, the pressure drop in the system should not exceed the norm - 0.02 MPa (0.2 kgf/cm2).

Correspondence table for different units of pressure measurement

On the other hand, SNIP 3.05.01-85 (clause 4.6) has other recommendations:

- Heating and water supply systems are tested at a pressure of 1.5 times the working pressure, but not lower than 0.2 MPa (2 kgf/cm2).

- The system is considered operational if after 5 minutes the pressure drop does not exceed 0.02 MPa (0.2 kgf/cm).

What standards to use is an interesting question. For now, both documents are valid and there is no certainty, so both are valid. It is necessary to approach each case individually, taking into account the maximum pressure for which its elements are designed. So the working pressure of cast iron radiators is no more than 6 Atm, respectively, the test pressure will be 9-10 Atm. It’s also worth deciding on all the other components in approximately the same way.

https://youtube.com/watch?v=ruN3puj3EyU

What fitting is used for the press

When assembling the main parts, components are used - these are adapters, collet and press fittings (which are the most reliable and practical). With the help of such devices you can get a high-quality and durable joint.

It is very important to choose the right press jaws. The easiest to use are hand-held devices.

They are distinguished by their simple design. A press coupling for a metal-plastic pipe can be easily connected with this device. Even an inexperienced master can cope with this task.

The range of this type of coupling for crimping metal-plastic pipes is very large, which makes it possible to carry out wiring of any level of complexity. And the combined coupling allows you to connect not only metal-plastic, but also steel lines.

Also speaking about shaped elements, it should be noted that the press coupling allows you to reduce the amount of assortment and fittings used.

When purchasing a pressing coupling for an MP network, you should not skimp on it. Purchasing a product from a dubious manufacturer may result in subsequent expensive system repairs.

Heating thermal test

Thermometer for thermal testing

Timely thermal testing of heating systems will determine the uniform heating of all radiators and radiators. Unlike the documents discussed above, this procedure is recommended to be performed without fail for stand-alone circuits.

For central heating, these actions are not performed every year. A thermal test report for the heating system is drawn up only in the following cases:

- Putting the system into operation;

- Replacing most of the components with new ones, changing the pipeline configuration.

Testing the heating system for warming up is often combined with a test run before the heating period. To do this, it is not enough to fill the pipelines with coolant and turn on the boiler. First, you should clean the system, ridding it of accumulated debris and limescale. If this is not done, thermal tests of the heating system will be incorrect. Foreign elements will affect the thermal conductivity of radiators and pipes, which will directly affect their energy output.

It is best to combine hydraulic and thermal testing. This way you can prevent the occurrence of air pockets.

Central heating

Thermal testing of central heating

For a centralized scheme, filling out a test report for the thermal effect of heating systems is carried out according to certain rules. The main one is the water temperature - it should be heated to +60°C.

The inspection time must be at least 7 hours. At the same time, individual components are adjusted to temperature balance the units. This is reflected in the thermal test report for the heating system. In apartment buildings, separate measurements are taken for each riser and the general indicators are compared with similar ones in the elevator unit.

Thermal test report

What benefits do heating system warm-up tests provide for home occupants?

- Verification of actual heat supply indicators with those declared by the management company;

- With an installed metering and regulation device for coolant flow (in the elevator unit), it is possible to determine the optimal operating mode of the system;

- Timely detection of air jams.

All this work must be performed by the management company. This is reflected in the heat supply contract. The result of the inspection will be a test report of the thermal effect of the central heating system.

The thermal test report for the heating system takes into account not only the degree of heating of radiators and pipes, but also the temperature in the room.

Heating system

Thermal imager as one of the thermal testing tools

Warm-up testing of the autonomous heating system is also necessary. During this procedure, points of sharp temperature changes can be determined in advance. Using control valves, the operating modes of radiators and batteries are adjusted.

In practice, for autonomous circuits it is not necessary to draw up a test report for the thermal effect of heating. But to determine the procedure, it is best to adopt the methodology for central heating. The difference may lie in the measurement methods:

- The degree of heating of the heating elements is checked using installed thermometers or according to the readings of a thermal imager;

- The room temperature is controlled using external sensors.

However, in summer the influence of low outside temperatures will not be taken into account.

Therefore, in addition to the above indicators, you need to take into account the degree of thermal insulation of the house - heat losses

Remember that each type of heating system test (hydraulic, thermal or pneumatic) must be performed according to a specific method. It also depends on the type of heating system and external factors.

The video describes the features of hydraulic testing of heating in an apartment:

Technical parameters of the instrumentation

Before purchasing a press for installing metal-plastic pipes, it is necessary to study in detail the main parameters and characteristics of the equipment. These include:

Range of crimping diameters. Types of shaped elements for installation.

Some tools can only crimp certain manufacturers' fittings. The type of circuit that performs the crimping. The purpose of the model is indicated by a specific letter when marking. By looking at the profile view, you can determine the purpose of the model for installation. Handle length.

Any novice craftsman will be interested to know that this factor affects the cost of the device. The thing is that when crimping fittings with pliers with small handles, you need to put in more physical effort. Resource capabilities of pliers. This includes the amount of fitting crimp that the press can produce.

The ease of operation depends on this indicator. Equipped with a rotating mechanism into which replaceable attachments for pliers are attached. This addition to the tool makes it possible to crimp fittings on a vertical pipeline. Manufacturer. This factor largely affects cost and quality.

Watch the video

In order for the fittings to be crimped efficiently, you need to perform the following steps.

Place a removable ring at the connection point, which is intended for crimping fittings for a specific type and volume of pipe. Calibrate the line while simultaneously chamfering.

At this stage of installation, a calibrator will be needed. Then the end part of the pipe and the fitting are combined. Often, special holes are provided on the fittings; they allow you to control the position of the pipe part. Using press pliers, the fittings are crimped, which requires some effort. The quality of crimping is checked by the grooves formed; their appearance indicates the strength of the connection. The joint is checked for strength level.

IMPORTANT! Pressure testing of fittings can be done once. When this work is repeated, the connecting parts become unusable and cannot be repaired.

Test pressure

According to SNIP 3-05-01-85, which was replaced in 2003, pressure testing must be carried out according to the rules. When carrying out work in apartment buildings, it is necessary to:

- The pressure was more than 1 mPa (that's 10 bar) - for hot water supply systems and heating circuits with heaters.

- At least 10 bar for panel and convector heating systems.

- At least 6 bar for circuits in which radiators made of stamped steel or cast iron are installed.

- The pressure for hot water supply must be greater than the working one and another 5 bar on top (but cannot exceed 10 bar).

If panel heating and heat exchangers are used, the pressure should not have a pressure greater than the maximum permissible for the devices. If you are testing air in a steam or panel heating system, you need to check the pipes that fit into the ventilation equipment. The air should have a pressure of 1 bar.

Mini pliers

A mini press designed for metal-plastic pipes is a small-sized device that provides manual crimping of the coupling. These mini pliers are used for highways with a volume of 16 to 20 mm. These mechanisms are complemented by sets of nozzles with a TN profile.

Mini pliers are not equipped with telescopic handles, so you will have to put in more effort when working. The compression force in such devices is 10.5 kN.

Without attachments, the mini device weighs no more than two and a half kilograms. The handles on these pliers are often covered with PVC material, and the axial eccentrics on mini pliers make it possible to make adjustments when excessive play occurs.

Professional craftsmen highlight the quality of small-sized devices from VALTEC. These manufacturers offer not only high-quality mini crimping pliers, but also threading tools, scissors, and other tools for installation work.

All the pros and cons of using pressing equipment

As is clear from the information presented, it is necessary to use presses for metal-plastic pipes. Without them, it is impossible to fasten the MP line with a press coupling.

They are indispensable for work when you need to install taps, install a heating network or install heated floors. Now it’s time to summarize all the positive and negative aspects of this connection method.

- The pressing connection is one-piece and does not require constant tightening and monitoring. Connecting metal-plastic pipes with fittings using presses allows you to install a line in a concrete screed, and any other hidden types of installation. The connection made with pressing pliers easily works under pressure up to ten bar. Press connections connections are characterized by mechanical strength and durability. They can stand for more than 50 years. Simple installation, performed by presses, is not labor-intensive and is completed in a short time.

But connections that involve pressing equipment also have some disadvantages. These include:

- the system becomes not dismountable, and errors when installing press joints are fraught with subsequent cutting of pipes and installation of a new fitting; the cost of presses for many home craftsmen is significant, so this toolkit is not widely popular among this category of craftsmen.

How much heat should the pipeline supply?

Let's take a closer look at the example of how much heat is usually supplied through pipes, and select the optimal pipeline diameters.

There is a house with an area of 250 sq. m., which is well insulated (as required by the SNiP standard), so it loses heat in the winter by 1 kW per 10 sq. m. To heat the entire house, 25 kW of energy is required (maximum power). For the first floor - 15 kW. For the second floor - 10 kW.

Our heating scheme is two-pipe. One pipe supplies hot coolant, and the other pipe cools it to the boiler. Radiators are connected in parallel between the pipes.

On each floor, the pipes branch into two wings with the same thermal power, for the first floor - 7.5 kW, for the second floor - 5 kW.

So, 25 kW comes from the boiler to the interfloor branch. Therefore, we will need main pipes with an internal diameter of at least 26.6 mm so that the speed does not exceed 0.6 m/s. A 40mm polypropylene pipe is suitable.

From the interfloor branching - along the first floor to the branching on the wings - 15 kW is supplied. Here, according to the table, for a speed of less than 0.6 m/s, a diameter of 21.2 mm is suitable, therefore, we use a pipe with an outer diameter of 32 mm.

7.5 kW goes to the wing of the 1st floor - an internal diameter of 16.6 mm is suitable, - polypropylene with an outer diameter of 25 mm.

Accordingly, we use a 32mm pipe on the second floor before branching, a 25mm pipe on the wing, and we also connect the radiators on the second floor with a 20mm pipe.

As you can see, it all comes down to a simple choice among the standard diameters of commercially available pipes. In small home systems, up to a dozen radiators, in dead-end distribution circuits, 25 mm polypropylene pipes are mainly used - “per wing”, 20 mm - “per device”. and 32 mm “to the main line from the boiler”.

Instrumentation with electrohydraulics

Watch the video

The battery press, used for metal-plastic pipes, is one of the electro-hydraulic tools. This also includes networked and universal machines.

As a rule, a device with a battery is a small-sized mechanism that is light in weight. But, if you compare a battery-powered device and devices that do not run on electricity, the first one is distinguished by high performance and ease of use. A battery-powered device is used to process highways with a diameter of no more than 110 mm.

Any rechargeable model operates on a battery. These mechanisms use only universal pressing heads that are suitable for specific sizes of metal-plastic pipes.

IMPORTANT! The battery pack can perform approximately fifty to one hundred compressions per charge cycle.

The essence of crimp tests

Pressure testing of a water pipeline (as well as any other systems for pumping liquid or gaseous media) is the most important in the pipeline construction process, especially in such industries as the chemical or oil and gas industry, hydraulic engineering, and housing and communal services. Along with checking the value of permissible compression in pipes, an analysis of the stress-strain state of pipes is also carried out, which makes it possible to assess their service life.

Some pipe manufacturers - for example, the Rehau brand - are developing their own original methods for crimping their products. For these purposes, Rehau sells a special electro-hydraulic tool, with which you can test the pipeline immediately after its installation. The verification method is local: a pressure testing pump is connected to the sealed area, creating the necessary internal air pressure. The stability of the indicators is established by a pressure gauge.