The original design solution of a table lamp often determines its price and popularity on the market. Everyone wants the chosen product to serve without fail and for a long time. However, technology is technology, sooner or later breakdowns may occur and you have to think about how to fix the lamp.

In such cases, it is not necessary to take the lamp to the workshop. If you have at least a school understanding of electrical engineering and the ability to hold a screwdriver with pliers in your hands, most faults can be identified and repaired yourself at home. We'll tell you how to do this in the article.

Before you start repairs

If a table lamp breaks, the first thing you need to do is disconnect it from the power supply and remove the plug from the socket. All repair work, including inspection, must be carried out with the lamp completely disconnected from the power supply. Indeed, in the event of an insulation breakdown, exposed wires can come into contact with the metal elements of the lamp body, and if they touch, you will receive an electric shock.

You should not touch its metal parts immediately after turning off the lamp; this is unsafe. Capacitors retain a static charge for some time, and if the insulation is broken, the product body may become energized. We need to wait for the capacitors to discharge! The lack of current in the switched off lamp is checked with a voltmeter, and only after that can the repair begin.

Typical design of a table lamp.

If the lamp uses an incandescent lamp, it is important to remember that during operation it heats up and can heat nearby elements, including the metal lampshade. Wait until the lamp cools down to avoid burns when touched.

For this reason, table lamps do not use bulbs with more than 60 watts of power.

You should handle the light bulb carefully when unscrewing it; it may crack in your hands. There is no need to screw the light bulb into the socket too tightly - unscrewing it after prolonged use at high temperatures will not be easy, and this often ends in the socket breaking.

How to check the lamp's performance

After connecting, check the operation of the circuit with a tester. The resistance of the cathode filaments should not exceed 10 Ohms.

Checking the functionality of the circuit.

Sometimes the tester shows infinite resistance. This doesn't mean it's time to throw away the lamp. The device can be turned on with a cold start. Typically the starter contacts are open and the capacitor does not allow DC current to pass through. However, after several touches with the probes, the indicator will stabilize and drop to several tens of ohms.

What to do if the lamp does not turn on

It happens that the lamp stops turning on. Or the new light bulb does not light up. The reasons are mainly as follows:

- the light bulb itself is faulty;

- there is no contact in the cartridge;

- faulty switch;

- broken contact in the wires.

First you need to check the functionality of the new light bulb. The easiest way is to screw it into another lamp, which is known for sure to work. If it doesn’t light there either, the reason is the light bulb.

If the lamp is in order, you need to check the integrity of the electrical wiring and the presence of current at the input and output contacts of all elements of the lamp from the socket to the light bulb. According to technical specifications, all 220 V table lamps must be equipped with switches for safety reasons. It is prohibited to plug them directly into a power outlet. Thus, we check the conductivity of the connections one by one on the plug, switch and socket.

Experts call this operation “diagnosis” of the system and, when searching for a breakdown, do it in the reverse order - from the light bulb to the plug. For this purpose, an electrical tester is used - a device for determining the voltage in the network.

Testing wiring using a multimeter.

Checking and repairing the cartridge

We call the cartridge contacts. If there is current on them, but the light bulb does not light, the problem is in the socket. It often happens that high-quality repair of a table lamp is limited to cleaning the socket contacts with fine-grained sandpaper.

It may be that the central or side cartridge contacts have sagged and do not contact the light bulb or touch its base. Then you need to bend them with a screwdriver. If the contacts are burnt, broken off or corroded, the cartridge will have to be replaced. It must also be replaced if the metal thread is damaged or shorted to the body.

Video: It was about - Patron!

Checking the switch

If the cartridge is working, we test the switch contacts. You can ring it without disassembling it - through the wires connected to it. If there is voltage at the input but not at the output, then there is an open circuit inside the switch housing.

Switches can be push-button or key switches, built into the wiring or into the housing, but always of a delicate and thin design. It is often difficult to disassemble them, and even more difficult to eliminate the malfunction, so advice: if it breaks, it is better to replace it with a new one.

We recommend viewing: How to correctly connect a switch.

Broken contact in the wiring

A table lamp may stop turning on if there are breaks or breaks in the wires, which are often accompanied by a short circuit. Sometimes the wire breaks off at the terminal block fastenings at the base of the plug, switch or socket. The light then either goes out completely or blinks randomly. The wire at the break may spark and a crackling sound can be heard.

The location of the damage is sought by visual inspection and feeling the wire along its entire length. Repairing an electrical wire is not difficult - you need to thoroughly clean it, solder it together and insulate the broken ends.

But it is still better to simply replace the damaged area. However, you should remember the rule - if you have to change a flexible power cord, then only with a homogeneous one and with the same or larger cross-section. Otherwise, the cord may overheat and catch fire.

It will be useful to read: Restoring table lamps

If you need to repair a lamp on a clothespin, you should especially carefully examine the integrity of the wiring and all elements of the device. Over time, the fastening of the lamp weakens, sometimes it falls and is damaged.

Serial connection of two light bulbs

The method involves operating two lamps with one ballast. For implementation, an induction choke and starters are required.

It is necessary to connect a starter to each lamp , maintaining parallel connections. The free contacts of the circuit are sent to the network through the inductor. Capacitors are connected to the contacts to reduce interference and stabilize the voltage.

High starting currents in the circuit often cause sticking of the contacts in the switches, so choose high-quality models that are not greatly affected by the network parameters.

The simplest electrical circuit

To repair lighting devices, you need to know at least the general principles of constructing electrical circuits. Modern lamps are equipped with many additional electronic mechanisms and have a variety of functionality. However, the principle of connecting a lighting device (light bulb) almost always remains the same.

The simplest electrical circuit of a lamp.

The figure shows diagrams of different types of lamps with several light sources, but they are also typical for table lamps.

An important feature, especially for desktop models, is the ability to adjust the brightness and intensity of lighting. It is these devices that are widely used for students, creative workers and in the electronics industry for the assembly of small parts and precision mechanisms. In such models, the electrical circuits are somewhat more complex and include additional elements for adjusting the lighting.

Brightness control circuit, where S2, S3, S4 are step controllers.

The device of fluorescent lamps

The connection diagram of a conventional fluorescent lamp differs significantly from the similar diagram of incandescent devices. They consist of main components:

- control board that regulates the flow of current;

- electrodes;

- glass tube or flask coated with phosphor.

Inside the flask there is a mixture of mercury vapor and inert gases, and electrodes. The input voltage causes particles to move, generating ultraviolet radiation. However, it is invisible to the human eye. It is converted into visible light by a phosphor that coats the inner surface of the bulb. Changing the composition of the phosphor changes the hue and color temperature of the lighting.

Installation of fluorescent lighting devices.

The processes are controlled by a starter and a ballast, stabilizing the voltage and ensuring a uniform glow without pulsations and flickering.

Principle of operation

Operating principle of a fluorescent lamp

Supply voltage is supplied. At the initial moment, no electric current flows, since the medium has high resistance. The current moves through the spirals, heats them and is supplied to the starter. A glow discharge appears. After heating the contacts, the bimetallic plates close. The temperature on the bimetallic part drops and the contact in the network opens. This leads to the fact that the choke creates the necessary impulse as a result of self-induction, and the lamp begins to shine. The arc discharge is maintained by thermionic emission occurring on the surface of the cathode. The electrons are heated by current, the magnitude of which is limited by the ballast.

Light appears due to the fact that a special substance is applied to the lamp - a phosphor. It absorbs ultraviolet radiation and produces a certain range of glow. The color can be changed by applying phosphors of different composition to the flask. They can be made from calcium halophosphate, calcium-zinc orthophosphate.

The main advantages of the lamp are energy savings, long service life, and bright light. Disadvantages include the inability to connect directly to the network and the presence of mercury inside the flask. Lamps are more expensive than incandescent light bulbs, but cheaper than LED light sources.

Operating principle

Read also: Installing a gas boiler in a private house: all the necessary requirements for quickly and legally starting a heating system (Photo & Video) + Reviews

Operating principle of fluorescent lamps

Let us briefly describe the interaction diagram between the starter, ballast and lamp:

Advantages and disadvantages

The main advantage of luminescent devices will be high luminous efficiency and excellent efficiency. They give the room a good brightness that does not harm the eyes, and work properly after long hours.

Different color temperatures, similar in shade to daylight, help you choose the right lamp for a variety of tasks and for rooms of any purpose.

The light from such lamps will be diffused. A soft, eye-pleasing glow is emitted not only from the tungsten filament, but also from the entire bulb container at once.

This allows the use of fluorescent lighting not only for illumination, but also for zoning the room.

The service life of luminescent devices will be in the range from 10,000 to 20,000 hours or up to 4 years.

Lighting for plants

The main big disadvantage of light bulbs is their high sensitivity to temperature changes. Even at a temperature of −15 degrees, the product will not work well. In high heat, the light bulbs stop turning on and can become very hot.

Characteristics

Main parameters of fluorescent lamps:

- light bulb power spectrum - from 10 to 90 watts (for household use);

- medium voltage - 220 and 127 V;

- tungsten melting point - 6000K;

- light beam - can exceed 100 Lm/1W;

- base parameters - 1E14 and standard E27;

- vessel size - 14, 18, 28, 38mm;

- service life - from 10,000 to 35,000 hours;

- Efficiency over 20%.

Operating principle

Main functions

It is not possible to connect fluorescent light sources directly to the electrical network. There are the following reasons for this:

- to create a persistent discharge in a fluorescent lamp, it is necessary to preheat its electrodes and apply a starting pulse to them;

- Since gas-discharge light sources have a negative differential resistance, they are characterized by an increase in current strength after entering the operating mode. It must be limited to prevent the light source from failing.

Based on the reasons described above, it is necessary to use ballasts.

Electromagnetic type ballasts

Electronic ballast

All the shortcomings of the scheme described above stimulated research. As a result, an electronic ballast circuit was developed. It does not supply a network frequency of 50 Hz, but high-frequency oscillations (20-60 kHz), thereby eliminating the flickering of light, which is very unpleasant for the eyes.

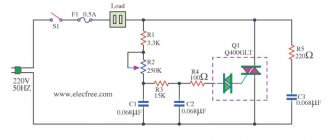

One of the electronic ballasts is electronic ballasts

The electronic ballast looks like a small block with terminals removed. Inside there is one printed circuit board on which the entire circuit is assembled. The block has small dimensions and is mounted in the body of even the smallest lamp. The parameters are selected so that the start-up occurs quickly and silently. You don't need any more devices to work. This is the so-called starterless switching circuit.

Each device has a diagram on the back side. It immediately shows how many lamps are connected to it. The information is also duplicated in the inscriptions. The power of the lamps and their number, as well as the technical characteristics of the device are indicated. For example, the unit in the photo above can only serve one lamp. Its connection diagram is on the right. As you can see, there is nothing complicated. Take the wires and connect the conductors to the indicated contacts:

- Connect the first and second contacts of the block output to one pair of lamp contacts:

- serve the third and fourth to the other pair;

- supply power to the entrance.

All. The lamp is working. The circuit for connecting two fluorescent lamps to electronic ballasts is not much more complicated (see the circuit in the photo below).

Electronic ballasts for two fluorescent lamps

The advantages of electronic ballasts are described in the video.

The same device is built into the base of fluorescent lamps with standard sockets, which are also called “economy lamps”. This is a similar lighting device, only greatly modified.

These are also fluorescent lamps, only the shape is different.