Thirty percent of the human body consists of fluid, which plays a big role in maintaining good health. A centralized filtration system does not always provide the consumer with a quality product. It may contain heavy metals, bacteria and other substances harmful to people. The use of such liquid can lead to the development of diseases, among which the most common are intestinal infections, metabolic diseases and cases of oncology. You can consider spring drinking. However, due to the total pollution of the environment, it can cause irreparable harm to health. Visually, it is no different from useful, but changes in the chemical composition will only be noticeable during laboratory analysis using special equipment. We suggest you use an alternative filtering method. In our article you will learn how to make a home-made simple flow-through filter for purifying drinking water with your own hands for a country house or apartment and what is the best way to fill it.

Why is filtering necessary?

When building a private house, many land owners mistakenly think that if the extracted liquid from a well or borehole does not have foreign odors and is cloudy in color, then it is “useful.” However, experience shows that the estimate includes seven percent of the total cost of constructing a residential building for water treatment. This is no coincidence, since an apparently healthy liquid may contain such a “bouquet” of undissolved impurities that its use is sometimes unsafe for health. In addition, it negatively affects the operation of household appliances, including water heating equipment. In the latter case, the liquid should not be hard.

Let's summarize. Pros of filtering:

- Allows you to get rid of impurities of heavy metals, calcium and magnesium salts, and other toxic substances.

- Removes pathogenic microorganisms (bacteria and viruses).

- Increases the service life of plumbing equipment and household appliances. Prevents the formation of scale and sediment on the walls of devices.

- Counteracts harmful effects on the body.

- Costs for purchasing medications are minimized.

It is worth noting that only the sanitary and epidemiological station service can cope with bacteriological contamination. This means that in order to avoid poisoning by pathogenic microorganisms, the makeshift structure must be removed over time and replaced with industrial equipment.

Installation

Structurally, the sump is quite simple, so making a tank with your own hands will not be difficult. In private homes and summer cottages, the most common type of sump tank is a sealed well made of concrete rings. However, such a structure requires expensive transportation of reinforced concrete products to the site and labor-intensive work to bury them. A practical and cheap solution would be a sewage sump made from old tires.

The only condition for the construction of such a structure should be the complete tightness of the joining seams. Otherwise, sewage will begin to seep into the ground and cause biological contamination of the soil and drinking water sources. Therefore, when choosing a place for a sump, it is necessary to take into account the location of the house, well and neighboring area. You should also make sure that the sewer truck, if necessary, can drive up to it and carry out cleaning.

After selecting a location and preparing the tires, you can begin to install the sewer pipe, which should be laid to such a depth that the drains in it do not freeze in winter. The top of the pipe must be wrapped with any heat insulator that is resistant to the negative effects of external factors. When installing the pipe, the slope necessary for free flow of liquid into the storage tank should be formed. In addition, this arrangement of the pipe will prevent water from freezing in winter: it simply will not have time to freeze before it enters the sump.

After laying the pipe, the tire reservoir should be buried in the ground so that the expected liquid level is located slightly lower than the soil freezing line. It is recommended to place roofing felt or thick polyethylene under the bottom of the sump. And to ensure that the tires do not move relative to each other, it is recommended to strengthen them with vertically dug poles or posts.

To learn how to install a sewer sump, see the following video.

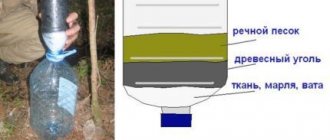

We assemble the water filter ourselves and select the filler

Initially, you need to correctly calculate the volume of liquid entering the residential building. To do this, take into account the number of people living and points of consumption (garage, barn, swimming pool, outdoor shower, watering a greenhouse, vegetable garden, flower beds, etc.). The volume of the container depends on this. All components must fit into it. As a rule, the container is filled layer by layer with natural raw materials, which are cheap to the consumer. First, the liquid is filtered through a layer of washed and dried sand of any kind. In this way, it gets rid of small debris and heavy chemical compounds. Then it passes through gravel, which cuts off large inclusions. Activated carbon or a modern cheap product such as “zeolite” do not allow suspended metals and salts to pass through, destroy organic matter and waste products from the activities of agricultural complexes. The final stage is the penetration of moisture through cotton textiles (gauze, medical bandage, etc.). Natural materials instantly become clogged with unwanted particles, so they have to be changed frequently. In addition, they are susceptible to rotting, which negatively affects the taste and smell. Therefore, an excellent alternative is the synthetic geomaterial “Lutrasil”, which is highly resistant to various types of pollution.

Quartz or river sand for a DIY water filtration system

The mineral contains virtually no clay admixture. This indicates that the incoming liquid is cleared of foreign substances harmful to the human body. This type of sand contains large amounts of silicon oxide. Therefore, it is preferable as a filler for rough mechanical cleaning. If the ingredient is of good quality, which is pre-calcined in the oven, then there is no need to replace it. It is necessary to periodically top up to a certain level.

Carbon additive

Do not pay attention to coal made from coniferous wood (pine, spruce, fir, etc.). For filtration, an absorbent made from:

- birch;

- coconut;

- shells of apricot kernels or other fruits;

- peat bog;

- deciduous raw materials;

- finished hard or anthracite coal.

The material is characterized by a high ability to maximize the absorption of harmful toxic particles, for example, such as phenol, chloroform.

"Lutrasil"

The advantages of non-woven polypropylene synthetic material include:

- Environmental friendliness of raw materials.

- Excellent water permeability.

- Resistance to breaking loads.

- Wear-resistant - used for 5-8 years.

- Excellent resistance to various stains.

"Zeolite"

The sorbent has good retention characteristics. Neutralizes liquid from organic compounds, hazardous chemicals, heavy metal ions and breakdown products of agricultural processing (nitrates, nitrites, phenols, etc.). It is used as an independent filler and can be mixed with any type of sand.

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

Radial tanks

Radial sedimentation tanks for wastewater are mostly a round, low container. The water in such a sump enters the center of the tank from the bottom up. Moves from the center of the sump to the walls.

Septic tanks need to be cleaned from time to time

A radial settling tank can be:

- Primary;

- Secondary.

Its operating principle is that the speed of water movement in the center and on the periphery is different. In the center the water moves quickly, at the edges slower. All sediment floating in the container is transferred to the receiving tray. Radial type sedimentation tanks are used mainly at large treatment plants and in industry. These are large diameter containers - from 18 to 54 cubic meters. m. The choice of the type of settling tank in certain conditions is ensured by several criteria.

It is appropriate to install vertical sedimentation tanks in places where there is sufficiently dense soil and practically no groundwater.

If the soil is weak and the groundwater level is high enough, horizontal sedimentation tanks are used.

How to make a water sediment filter with your own hands based on activated carbon

You will find this type of filler in any pharmacy chain. It is inexpensive and lightweight. Retains mineral ingredients and toxic substances with equal quality. After passing through the composition, the moisture becomes transparent without any foreign odors. To cleanse 1 liter, only one tablet of charcoal is needed. However, for the device to work effectively, it is better to use several pieces.

Small camping devices

Coal is sold at any hardware store. To do this, choose granular material, since a powdery structure can penetrate into the purified liquid, while a coarse structure will not provide a good absorbent effect. But in nature, purchased material will not always be in your backpack. You'll have to make it yourself. To do this, take any hardwood (preferably birch). Chop the wood into small pieces, place them in any metal container and place it on an open fire. The wood will turn red, remove the coal. As a last resort, ash is also suitable for filtration.

Making a carbon purifier

The base can be a drink bottle of any size or a food container. In addition, you will need:

- fabric cotton base;

- river sand;

- small pebbles;

- tools: knife, awl, electrical tape and, if available, silicone moisture-resistant glue.

Further actions:

- Cut off the bottom of the bottle. Liquid will flow here.

- On the outlet valve, drill a large hole or make several small holes using a sharp object.

- After screwing on the perforated lid, hang the entire structure on a tree branch and begin filling the absorbent layers. Place fabric folded in several layers on the bottom.

- Place fine-grained coal, sand and gravel in turn on top.

- Cover the top of the device with any material to prevent foreign objects from leaking into the structure.

How to make and assemble a water filter (purifier) from a polyvinyl chloride pipe yourself

The method for making a makeshift system is as follows:

- Cut two pieces of different sizes from the plastic pipeline. Place any cotton material inside the larger part.

- Insert the cut neck of a soda or beer bottle with the threaded hole facing up. Use electrical tape to seal. Make several holes in the screw cap using a sharp object.

- Place padding polyester in the pipe.

- Pour any charcoal filler into the smaller part.

- Connect both products using a threaded connection, so that the cleaning equipment with coal is at the bottom.

- Attach bottles to both sides of the homemade block. Liquid will flow from above, and already filtered liquid will flow out from the lower container.

The absorbent is not laid too tightly, since the compacted layer can delay the passage of moisture.

Homemade cleaning structure for a well

If you have a well in your dacha, you need to take care of filtering the liquid. Pesticides, nitrates, and other harmful impurities seep through the ground. They enter the consumed water and then into the human body. Well cleaning systems are expensive; for a small dacha, making a bottom water filter with your own hands is more reliable.

Prepare for work:

- ordinary river pebbles;

- crushed stone (it is strictly forbidden to use construction stone);

- shungite;

- zeolite (effective against viruses, bacteria);

- gravel.

A shield for the well is made from boards, wrapped in geotextile, then lowered to the very bottom. Large stones are also placed there at the first stage. After this, you can proceed to making a filter (reverse, direct).

If the bottom of a country well “sparkles” with soft clay, a direct filter is needed. First, a fraction of a larger diameter is laid, then a smaller one. It is necessary to adhere to the optimal thickness of each layer. The average is 15-20 cm. The minimum number of layers is 3. First, crushed stone is laid, then small pebbles, and lastly, thoroughly washed river sand.

A reverse system is suitable for a country well with a sandy bottom. Initially the small fraction is laid, then the larger one. It is necessary to adhere to the same layer rules as in the previous case.

Over time, the filter will become clogged with sand, clay particles, and other impurities. It must be “updated” annually. The sand is replaced, the stones are washed well, and then laid back.

What are aquarium water filters made of?

To create a homemade design, you must have the following materials:

- Two medical syringes.

- A spray bottle, for example, from dishwashing detergent.

- Hard sponge.

- Fasteners

Cut off the tips of the syringes and throw away the moving parts. Attach the blanks to each other. Using a soldering iron, make perforations over the entire area of the medical instrument. Fill the improvised filter element with some kind of granulite, for example, zeolite. The flexible spray hose must be cassette length. The last step is to wrap the sponge around the craft and secure it with wire.

Sand filler for pool

SF-mix manual up to 0.8 m3/h

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

You can create a filter system yourself if you intend to use a small displacement. Otherwise, a home-made device will not be able to properly purify water. For large containers, it is better to purchase specialized equipment from companies that have been successfully working in this field for a long time, for example, in our company.

To create a temporary cleaner, you will need a plastic container of the required volume from 25 to 50 liters with pipes inserted at the top and bottom for inlet and outlet of liquid. The filler is created from small pebbles and river or quartz sand, which are separated from each other by geotextiles. A layer of lutrasil is required on top to avoid the formation of a sand funnel. The entire system operates using a connected pump.

How to make your own cleaning structure for a well

How to make a water filter with your own hands for a well? The cleaning system is simpler than it might seem.

The following materials and tools are prepared:

- durable plastic pipe;

- wood plug;

- mesh with the smallest holes (cells), preferably brass;

- drill, drill.

Important! The length of the pipe is calculated individually based on the depth of the well. The diameter is taken less than the diameter of the well.

How to make a water filter: process description

- Initially, the total length of the sump is measured.

- At an angle of up to 60 degrees (minimum 35), it is necessary to drill small holes in a checkerboard pattern, leaving a minimum distance of 2 cm between them.

- The pipe is thoroughly cleaned of any remaining chips, the area “with holes” (25% of the total length) is wrapped and secured with rivets.

- A plug (plug) is installed.

Passing through the mesh, small particles of dirt and sand will be retained. Larger impurities settle in the settling tank. Water that has undergone such filtration must be additionally boiled before use, since the purification system does not remove harmful substances (germs, bacteria).

Downhole equipment

Drinking in individual wells also needs to be thoroughly cleaned, because it contains large quantities of small particles of clay, sand suspensions, and decay products of flora, fauna and human activity. The production of the device requires precise calculations and is within the capabilities of engineers with special knowledge. If you decide to create a device yourself, then read the information about what methods you can use.

gravel element

The main condition for effective work is the correct selection of factions. The grain size of the filling should be eight times larger than the sand particles. After selecting the filler, the granules are poured onto the bottom of the source in a layer of at least 50 cm.

Hole filter

Making a perforated part is simple. You will need an electric drill and a drill bit. The photo shows the creation process:

Slotted

In the picture you can see how carefully the device is made. To avoid making mistakes, we do not recommend that you make a design using a makeshift method. It is better to purchase the mechanism in a specialized store, for example, “Water of the Fatherland”.

Wire mesh device

It will not be possible to create this design yourself, since in order to correctly and accurately reproduce the gap between the turns of wire, welding with a special tool is required in thousands of places.

What is graphene sorbent?!

So, a graphene sorbent is, first of all, a chemical element, carbon, the structure of which has been radically changed. Graphene carbon is a kind of modification that allows the passage of water molecules, various salts and allows the retention of impurities, which include chemical elements and petroleum products.

In order for the graphene sorbent to perform its specified functions, it must be compacted to form a membrane.

How to make a water filter for a faucet with your own hands at home

You can solve the problem using available materials. Below we provide you with instructions on how to make the cleaner.

From a plastic bucket with a lid and a five-liter bottle

Cut off the bottom of a bottled liquid container. Make a hole of a suitable diameter in the bucket. Connect the two elements together with fum tape. Activated carbon is used as a filler. It is advisable to filter the liquid twice before drinking.

From two bottles

In addition to containers, you must have geotextiles or cotton fabric with you. If you are outdoors near a pond, then take sand from there and calcine it over a fire. The resulting coals are also suitable as a filler. Pour the raw materials into one bottle without a bottom, one at a time.

Main table dispenser AquaPro 919H/RO (hot and cold water)

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

From paper

This method can be used if you need a small amount of drinking liquid, since the paper towel will quickly become limp and will have to be replaced with a new one. Create an improvised funnel and insert it into a glass, place a paper bag inside the container, preferably from newspaper.

Sand traps

In this facility, wastewater is purified from large particles, the size of which is at least 250 microns. In fact, these are primary settling tanks, because if sand is not first removed from any wastewater, then further cleaning will be difficult due to the fact that sand will begin to clog treatment facilities. The operating principle of the sand trap is based on influencing the speed of movement of large particles in the general flow.

Sand traps use several cleaning methods:

- Horizontal flow movement with a rectilinear direction.

- Horizontal flow movement in a circular direction.

- Vertical flow movement.

- Translational-rotational flow.

Laying the external main

The pipe is laid with a certain slope

It is necessary to lay a pipeline from the point where the sewer pipe exits the house to the septic tank. The main must lie at a slope that ensures the drainage of contaminated water. The larger the diameter of the pipes you use, the smaller the angle of inclination required for their operation, on average it is 2 degrees. The depth of the trench for laying pipes must be greater than the amount of winter freezing of the soil. If the depth of the trench is small, provide thermal insulation of the line.

The average depth for laying a sewer system is 1 meter; in warm regions it is enough to go down to 70 cm, and in cold regions you will need to dig a pit up to 1.5 meters. The bottom of the dug hole is covered with a dense cushion of compacted sand. This procedure will protect the pipes from soil displacement.

Pit for a septic tank near the fence

The best option would be to lay a direct pipeline to the collector. If it is necessary to make a turn, this place will be equipped with an inspection well. For the main line, you can use plastic and cast iron pipes with a diameter of 110 mm; their connection must be airtight. After installation, the pipeline is covered with sand and then with soil.

Fundamental structure of a settling tank

There are 2 main types of settling tanks: contact and flow. Contact is simply a sealed container in which household waste is kept until it is removed by sewage disposal equipment. Such a sump prevents dirty water from entering the soil. It is the simplest, but regular cleaning is required - the drains must be removed as soon as the container is full. This is not very convenient, and such blind containers are not very common.

Sometimes such containers are improved by installing a discharge pipe in the upper part so that the settled water is drained into the soil. For a small family this is a perfectly acceptable option.

A flow-through settling tank is much more convenient, although it requires some effort to set up. It consists of several containers (minimum 2) through which wastewater flows sequentially. More or less purified water from the last container can be discharged into the soil through an underground pipe.

If you add anaerobic bacteria (living and working without oxygen) to the sewer sump, the wastewater treatment will go much faster.

Why is it better to buy a sewer system for a private home from the Zagorod company?

- From us you can buy sewerage for a private house in installments

. The payment period is 6 months. There is no down payment or interest! - We are official

dealers of manufacturers of sewerage systems for private homes. We provide a guarantee on all treatment facilities. - Our company provides a guarantee of up to 5 years

for installation work. No one else on the market has such a guarantee. - We complete standard installation in 7-8 hours (1 business day). To control quality , installers

are required to take photos of each stage. In addition, we have technical supervision that monitors work at the facilities.

If you are building or rebuilding a private house, then contact us right now! Leave a request on the website and our managers will call you back. We work in St. Petersburg, Moscow, Yekaterinburg and Pskov.

Choosing a location for a septic tank

The location of the septic tank is influenced by several factors:

- the terrain of the site, the movement of water is carried out by gravity, so it is important to take into account the slope;

- groundwater depth;

- frost mark in winter;

- location of drinking water supply or water source;

- Soil composition – sandy soil easily allows liquid to pass through, so it can cause groundwater pollution.

Installing a septic tank requires compliance with certain conditions: the distance from the house must be at least 5 meters, the distance from the drinking well is 30 meters, and from green spaces is 3 meters. The place is equipped with the possibility of a sewer truck entering.

Differences in purpose

Depending on the purpose in the technological scheme, settling tanks are of two types:

- Primary. Installed before the physico-chemical or biological purification process. Excessive amounts of suspended solids and mechanical impurities (sand) are removed.

- Secondary. Installed after biological treatment at the end of the process flow. They are used to retain activated sludge that comes along with purified water. As well as biological film.