Here you will learn:

- Advantages and disadvantages of an autonomous boiler room

- Classification and features of roof boiler houses

- Rooftop boilers

- Standards for gas boiler house projects

- Commissioning - basic requirements

- Roof boiler price

Reasons for installing an autonomous gas boiler room:

- Lack of engineering infrastructure for the development site;

- The distance of the object from city heating plants, but the presence of a gas pipeline nearby;

- Capacity shortages and inefficiency of the central heating system;

- Difficulty and/or high cost of coordinating technological connection to existing networks;

- The density of buildings in the central regions interferes with the work on laying heating networks;

- The development area, free of heating mains, allows for the creation of attractive recreation areas, parking spaces, and children's playgrounds.

In addition, the presence of an individual boiler room is presented by developers as an additional advantage for potential clients and allows them to position the property as comfort-class housing.

Advantages and disadvantages of an autonomous boiler room

So, you are thinking about the possibility of installing your own boiler room, which would heat the entire apartment building and supply hot water to each of the apartments. What advantages and disadvantages should you know about in order to make the right decision that will not make you regret it in the future?

Diagram of a heating system in an apartment building

First, it’s worth talking about the shortcomings, since there are significantly fewer of them.

- The high initial cost of the project is the purchase of the equipment itself, its installation and the provision of communications to each of the apartments. Yes, initially each of the apartment owners in the building will have to invest a considerable amount so that the group of residents can make such an expensive purchase. Many owners may simply refuse to spend such a significant expense, even if it is a one-time one.

- The need to maintain the entire system in working position. If, when connecting to a heating plant, all responsibilities for servicing the equipment fall on the shoulders of the specialists of the company providing the services, now in case of any breakdown you will have to solve the problem on your own. This means that you will need to hire specialists who will regularly inspect the equipment and, if any breakdowns are identified, repair them. This can cause unnecessary trouble and financial costs.

This concludes the main disadvantages of an autonomous boiler room. Of course, they are very significant, which is why today not every home has a mini-boiler room installed. But still, the number of such mini boiler houses is growing rapidly. Why? Due to the following advantages of independent heating.

- Complete independence from city monopolists in housing and communal services. Everyone knows very well that in every city there is only one company that provides heating and hot water services to residential apartment buildings. And they can increase the cost of their services almost uncontrollably. If you install your own boiler room, then the monopolists will no longer have leverage over you.

- Reducing heat loss to a minimum. As practice shows, when passing through many kilometers of heating mains, the coolant (hot water) loses up to 30% of the heat received (depending on the distance from the city boiler house).

An example of heat loss in an apartment building.

And end consumers also have to pay for this heat. In autonomous heating systems, heat loss is measured in fractions of a percent. So due to this, the payment is reduced by a third.

- A boiler room that heats one house, not thousands, is easy to set up. If the apartments become too hot, you can easily reduce fuel consumption, and on frosty days - increase it. Thanks to this, the temperature in the rooms will always be optimal, suiting each of the inhabitants. There is no need to ventilate the premises, lowering the temperature and at the same time releasing heat to the street, for which a lot of money was paid. But at the same time, you won’t have to use additional heat sources (electric heaters) to maintain a sufficiently high temperature in the apartment.

- In order for the boiler room of an apartment building to be kept in perfect order, it is enough to hire one dispatcher who monitors the readings of all devices, as well as one or two visiting technicians who are involved only when breakdowns are detected. If your house is connected to the city heating main, you will have to pay for the services of not only dozens (or even hundreds) of ordinary installers, but also hundreds of accountants, directors, their deputies, secretaries, drivers and many others. This also saves a lot of money.

- In most cases, heating of houses connected to the city heating plant begins on October 15 and ends by April 15. And even if autumn and spring turn out to be unusually cold or warm for a given area, no one will change the start and end dates of the heating season.

Therefore, in the off-season, apartments are often too hot or too cold. The presence of an autonomous boiler room allows you to turn the heating on and off exactly when necessary. Most often, such decisions are made by the council of residents of the building. Of course, this allows you not only to reduce heating costs, but also to maintain optimal temperature in the rooms, regardless of the temperature outside the walls of the house.

What conclusion can be drawn from all of the above?

An autonomous boiler room needs more attention and constant care from residents or specially hired specialists.

But it allows you to save a lot of money every month. Therefore, all initial costs will be compensated quite quickly, and very soon you will notice that you have free money that previously went to pay utility bills.

What a boiler room should look like

In principle, no matter the size of such premises, they are subject to certain technological rules:

- Each room of individual houses must have finishing that matches the project. For this purpose, special materials are used that are highly moisture resistant. They should not be afraid of large temperature changes.

- Every boiler room project must include a powerful ventilation system.

Detailed diagram of the boiler room arrangement - A sewer drain must be installed in the boiler room.

- Fire safety requirements must be strictly followed.

- For electrical equipment, a special package is included in the house design.

A separate room is specially designed for an apartment building.

For private houses, the best location for the boiler room is the basement; the ground floor is also suitable.

Classification and features of roof boiler houses

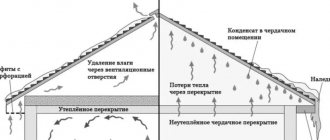

If we talk about heating one particular house, then one of the best options for locating a boiler room with a decentralized system is a flat roof. The text of SNiP describes in detail all permitted types of boiler houses. In technical documents, special attention is paid to the requirements for heating equipment intended for installation on the ceiling.

The operation and installation of heating systems are negotiated separately for two types of structures: built-in and block-modular. Separate requirements, technical conditions and restrictions apply to each option. Also, these two types of boiler houses have their own characteristics: advantages and disadvantages.

According to the rules, it is unacceptable to install heating equipment directly above residential premises. This means that an apartment building must have a technical floor

Speaking about the advantages of installing an autonomous boiler room on the roof, the following should be highlighted:

- There is no need to purchase a plot for a boiler room next to the house;

- The hydraulic load to which boilers are exposed is reduced;

- There are no difficulties associated with design calculations and installation of chimneys;

- The task of ventilating the boiler room is greatly simplified;

- Rooftop boiler houses have no restrictions on the type of fuel, and the use of gas is one of the most profitable options.

The combination of advantages of installing the structure in question on roofs determines the high frequency of use of this solution when planning autonomous heating.

Installing a boiler room on the roof is only advisable if all the requirements and restrictions described in SNiP and PPB are taken into account. Let us next consider each of the available types of roof-mounted autonomous boiler rooms.

Block-modular boiler rooms

Block or modular boiler rooms are compact in size and occupy a small area. Special blocks are brought to the site on the roof of the house, which are then connected into a ready-made and workable structure. Each element of the structure is completed at the factory and equipped with all the necessary equipment, which is connected into a common system.

After assembly, the thermal station is ready for operation. All necessary equipment is provided by the manufacturer and mounted in the module. There will also be separate rooms for service personnel.

Modern rooftop boiler houses operate all year round in automatic mode and do not require constant monitoring and the presence of personnel. Therefore, the heat supply is carried out without interruption

All equipment is selected to the required technical parameters and complies with the standards. The blocks are usually equipped with high-quality insulation and a reliable ventilation system.

They can also have an attractive appearance and unusual design. During installation, the main task of specialists is to correctly connect all components and check the functionality of all elements.

Designers and engineers provide in advance for the future installation of a boiler room for gas equipment on the roofs of multi-storey buildings. They minimize the weight and dimensions of the building frame. Typically, professionals assemble a boiler room within a few working days.

Installation of a block-modular roof boiler room consists of several stages. First of all, it is necessary to conduct an examination that will determine the load-bearing capacity of the building and the necessary procedures to increase it. If it turns out that it is necessary to strengthen the structure, then these procedures are carried out first.

Then a platform is installed that will rest on the load-bearing walls of the building. This is necessary for the stability of the block. The next step is to create a fire-resistant coating under the gas boiler room.

Typically, a layer of concrete is poured to solve this problem. You should also ensure safety by installing railings around the perimeter of the roof. Sometimes procedures to improve sound insulation are necessary.

Block gas boiler houses are fully equipped from the factory. Manufacturers provide a quality guarantee. The blocks are sent to the roof almost ready for launch and assembled in a short time

Block boiler rooms are suitable for installation in buildings that originally had centralized heating. However, to set them up, it is necessary to purchase equipment with acceptable technical conditions and have a project.

Built-in boiler room on the roof of the house

The layout of such boiler houses is included in the design documents in advance. Even at the design stage, each element of the built-in roof boiler room is thoroughly described. Engineers calculate many different indicators and, based on the calculations, design a safe and efficient heating system.

Such indicators include the value of the load on the walls, the level of fire safety, the required boiler power and others. Carrying out these calculations at the design stage is much easier and cheaper than converting a centralized system into an autonomous one.

Simultaneously with the construction of the building, a number of activities are carried out. These include:

- ensuring sound insulation and suppression of noise emitted by heating equipment;

- protection of the boiler room from vibrations;

- providing protection against fire, explosions and gas leaks.

Carrying out these procedures during the construction phase increases their effectiveness. Most houses were built with a centralized heating system, and only in the last 5-10 years have projects included built-in boiler rooms.

Stationary gas boiler houses are built from materials similar to those from which the building is built. For these purposes, prefabricated sandwich-type structures or various reinforced concrete blanks are used.

Experienced engineers design built-in boiler rooms. This is due to the need to comply with safety standards and legal regulations.

The advantages of such boiler houses include the absence of the need to spend money and time on capital construction. The customer also purchases a ready-made, tested and adjusted structure that will heat the residents of the house for many years.

Thanks to modern developments, it is possible to almost completely automate control. This allows you to have a minimum number of maintenance personnel. The environmental friendliness of built-in gas boiler rooms is ensured by modern filtration systems.

Integrated or built-in boiler rooms are usually installed within a few days, which is very profitable for the developer.

Tips for choosing

The main function of an autonomous boiler house is to provide heat and hot water to all residential or technological facilities. The advantage of such a complex is that it is ready for use immediately after installation

In order for the complex to fully perform the functions assigned to it, close attention must be paid to the process of its selection

Gas ones are considered the most popular and in demand. The principle of heat generation here is based on the fact that gas burns and produces heat, heating all the necessary rooms. The main advantage of such a system is the relative cheapness of fuel and the efficiency of the equipment itself. With proper installation and use, such boiler rooms can last for many years.

As for the disadvantages of gas options, we can note the danger of explosion. However, all modern boilers can boast of having various protective mechanisms that prevent fuel leakage

These are the ones you need to pay close attention to when choosing an autonomous gas boiler house

The second most popular is the diesel autonomous boiler house, in which diesel fuel is used to heat the coolant. It is worth noting that the efficiency here is also quite high. Among the main advantages of this option, it is worth noting its low fire hazard, which usually makes people give it preference. However, it is worth considering that the fuel smells extremely unpleasant, so there is always a terrible smell in the boiler room itself.

In addition, the equipment used in such complexes is distinguished by its demands on fuel quality. If you do not follow the basic rules, the boiler will quickly fail and you will have to purchase a new one.

In recent years, boilers that run on waste oil have become very popular. The unique burner is designed in such a way that it burns fuel without any problems. The main advantage of using such a complex is its affordable cost, because mining costs several times less than diesel fuel. At the same time, the efficiency is as high as that of diesel units, so the user will not feel the difference in the amount of heat received, but will be able to save money.

The main advantage of such models over gas ones is that there will be no need to develop any projects and obtain permission to install or equip the complex. The benefit of using such a boiler room also consists in a quick payback.

The power of the boiler room is also important in the selection process. It is worth calculating how much space it will need to warm up, and then begin arranging an individual heating system

The region where such a complex will be installed should also be taken into account. For example, if the area is far from the gas main, then there is no point in installing gas boiler houses, but it is better to give preference to other options.

For an overview of the Prometheus boiler company, see the following video.

Rooftop boilers

Boiler equipment allowed for installation on the roof, in accordance with SP 89.13330, has high automation of operation, sufficient to ensure heating of the building without the constant presence of personnel and technical workers.

Domestic thermal units, for all their advantages, are not autonomous. Therefore, the choice mainly falls on products from Italian, German and other European manufacturers:

- Futera.

- Rendamax.

- Wessex.

- Viessmann.

- Buderus.

- Protherm.

- Ferroli.

- Vaillant.

- Lochinvar.

When choosing a suitable boiler, they are guided by thermal power, availability of registration and license issued by Rostechnadzor, adaptation to domestic operating conditions and cost.

Power generators

New devices were developed that were used to heat liquid in a boiler. They are divided into several groups:

- gas;

- liquid fuel;

- electrical;

- solid fuel;

- combined.

When a gas boiler house is designed, very strict conditions are laid down especially for private houses. This is due to the high explosiveness of gas fuel.

Boilers heated with liquid fuel must have a separate room. The design provides for the installation of powerful ventilation with a separate channel through which exhaust gases will escape. Electric boilers are the easiest to install. They do not require a separate combustion room.

Boiler room with installed gas boiler

The relevant standards for the installation of safe electrical equipment come into force. In other words, the required cross-section of wires is selected and good grounding is done.

Standards for gas boiler house projects

Design standards are regulated by the conditions specified in SNiP. They are constantly supplemented and changed, as new technologies appear and modern modified equipment is produced. The requirements cover the four most important areas - gas supply, location, compliance with safety regulations and standard electrical supply. Here are the basic rules for drawing up a boiler room project:

- Installation of technical structures on the floors of residential premises is prohibited.

- Close contact of equipment to apartment walls is strictly prohibited.

- You can only operate a station that is completely autonomous from the building.

- It is imperative to install an alarm system and a special system that gives signals in the event of a complex emergency situation.

The height of installed chimneys above the roof of the building must be at least 0.5 meters relative to the highest part of the building. It may vary depending on the buildings nearby and their inherent technical characteristics.

Requirements for roofs for boiler rooms

The installation of roof boiler houses for apartment buildings takes into account the following requirements for roofs:

- the coating structure, according to expert conclusions, must withstand the load of the boiler room;

- presence of railings;

- surface area is greater than equipment parameters;

- protection of the roof from leakage;

- limited access to the roof for outsiders;

- The boiler room has sufficient space for arranging office space.

Gas supply to the boiler room located on the roof

When using gas equipment (boilers), the following rules and restrictions must be observed:

- the distribution of gas pipes must go along the outer walls of the structure (internal installation is not allowed);

- the boundary pressure in gas pipes cannot exceed five kPa;

- availability of free access to gas mains (prohibition on the installation of shields, nets, fences);

- After the company has installed a boiler room, each pipe has a personal shut-off valve, which must have round-the-clock lighting.

During installation, along with the construction of a modular system, three autonomous units are installed - gas, heating, intended for supplying hot water. These nodes must go independently of each other. When one function is disabled, the others should work properly. This is done to quickly eliminate accidents and breakdowns.

Electrical supply to the boiler room on the roof

Basic requirements and standards for reliability of heat supply:

- lightning protection (the procedure for preventing natural disasters is displayed in the project);

- arrangement of grounding separately for each unit (heating, gas pipeline);

- the presence of external and internal lamps with sealed properties (protection from moisture), an additional metal casing (protection from mechanical damage);

- the presence of an additional, alternative generator (when the main power supply mode is turned off, the automatic start-up system for spare equipment, an alarm system and a personal notification to the specialist on duty should be triggered);

- an emergency power shutdown system is provided (the panel is located in the service room);

- Different sources of electricity supply are used for the apartments in the building and for the roof structure.

Fire extinguishing of a roof boiler room

When installing separate boiler houses located near the apartment building (in a personal, specially equipped building), the risk of causing damage to residents is minimal, but citizens can still suffer from an accident. To prevent disasters, the following fire safety rules are used:

- in the absence of an individual fire extinguishing system, two hoses with a diameter of 7 cm are installed on the roof;

- if there is an individual fire extinguishing system, the diameter of the hoses is 5 cm;

- maximum thermal energy pressure – 5 kPa;

- placement above supporting structures capable of supporting the weight of the equipment;

- the highest height of the house is 9 floors;

- the smallest ceiling height in the boiler room is 265 cm;

- the width of all doorways is equal to or greater than 80 cm;

- formation of personal emergency exit;

- arrangement of alarm systems;

- installation of automatic fire extinguishing systems.

If, during the acceptance of installation work, violations in the fire safety system are identified, then use is refused, and the installer will have to eliminate all identified deficiencies.

Installation

Installation of boiler equipment under the residential area of the house is not allowed. Therefore, it cannot be done freely in every part of the basement. Optimal heat supply is provided only by low-pressure complexes. They can be placed on the ground floor or underground. But it is worth noting that experts clearly prefer installation in a separate building.

Equipping with a mixing unit allows you to use all the possibilities provided by the buffer tank. But first you have to calculate everything. Modular industrial boiler rooms almost never require a strong foundation.

The most reliable solution is a banal reinforced concrete slab

Important: chimneys will need a separate base. The installation location is selected in accordance with SNiP

It is best to install the equipment where there is already gas, water and drainage. In the absence of such communications, we need to look at where it will be easier to make them.

In preparation for the installation itself, they double-check the designs and estimates. The installation site must be leveled and cleared of anything that could interfere. They take into account where to place access roads and temporary technological structures. A sand and gravel layer is poured under the foundation, and contours for drainage are prepared. Backfilling and compaction of soil is carried out up to 0.2 m; then crushed stone is poured, concrete is poured and a layer of asphalt concrete is formed.

Pumping systems can play a big role; It is worth choosing those that are designed for quick installation. They are also more aesthetically pleasing than those assembled chaotically from different parts

Important: if during installation air exchange is provided not 3, but 4-6 times per hour, the owner will only benefit. Ventilation ducts must be sealed

Finally, commissioning work is carried out.

Commissioning - basic requirements

According to the rules of standard technical operation, commissioning of a boiler room is divided into two main activities:

- Preparation of design documents and their approval.

- Carrying out required technical and installation operations.

When installing a boiler room, work is carried out to ensure sound insulation and full compliance with safety regulations. After this, personnel are selected. Employees undergo relevant courses, after which they receive a license.

A bilateral agreement must be concluded with the residents of the house for the maintenance of the installed boiler room. The preparation of project documentation and official approvals is carried out by the contractor who built the building or an authorized representative of the management company.

The principle of operation of the boiler room

The boiler itself can be called a heat exchanger. This is a unit that heats water using steam or boiling water. The mechanism of operation of such a device looks quite simple. A coil is installed in the steel cylinder to allow cold water to pass through. The remaining free volume of the tank is filled with steam, which is directed to the top of the tank: the water is heated.

When the boiler is running, condensation accumulates. To drain it, a special drain is designed. Sometimes in a private house, condensate simply flows into the boiler without outside help. Steam heating boilers have several types:

- capacitive;

- flow-through.

Diagram of a steam boiler room

To control the heating operation, the following are used:

- shut-off valves;

- thermomanometers;

- electric pumps.

In order for the boiler to work efficiently and without breakdowns, it must be supplied with water of increased softness and well purified. To do this, an additional filter and softener are installed. The water is heated to the required temperature and supplied to the heating pipes.

Roof boiler price

Compensation for the cost of heating (installation of autonomous equipment) falls on the shoulders of apartment owners in apartment buildings. You can pay for services by making additional contributions or by transferring from the balance sheet of the management company, where the owners make fixed payments. The following expenses are included in the calculation of the final amount:

- purchase of a boiler (price depends on the manufacturer and power);

- compensation for the cost of a thermal station;

- payment for additional services (sound insulation, fire extinguishing systems) - approximately a third of the price of the boiler room;

- payment for insurance services (commissioning is not allowed without concluding an insurance contract).

The price of all work from the start of paperwork is 5-7 million rubles.

Some characteristics

So, before you start installing water heating devices with your own hands, you need to figure out which one is right for you in terms of all its characteristics.

Today there are several types of water heaters on the market:

- accumulative;

- electric flow;

- flow gas type.

Of these, each buyer chooses solely according to his preferences. As a rule, a big role is played by how often and how many people will use a particular water heater during the period when hot water is turned off.

If it’s just one person and not very often, then you can install a flow element for yourself. But if at this time there will be 3 or more family members living in the apartment, then the storage accessory will be the best choice.

Types of storage boilers

Storage heaters are divided into two types:

- Open (non-pressure).

- Closed (pressure).

A boiler device for heating open (non-pressure) water consists of a small container of approximately 5-10 liters, equipped with a special mixer that can shut off the water when the device is finished using. The heater does not create pressure and is suitable for use in garden areas for summer showers.

Closed (pressure) heaters can provide hot water to a country house. They have a large capacity - 50-200 liters, are built into the water supply system, and work on the principle of uniform mixing. That is, when hot water is taken, there is no sudden replacement of cold water, but new portions are gradually added, which contributes to a more even supply of hot water to the house.