Installing a heated towel rail in the bathroom has many advantages; it is useful not only in winter, but also in summer.

The device allows you to quickly dry towels and linen, and the very fact of additional heating of the bathroom, with its constantly high humidity, is a guarantee of the absence of mold and mildew, unpleasant odors and dampness, the appearance of which is possible throughout the year.

Typical construction projects at the end of the last millennium included equipping each bathroom with a device for drying towels.

Of course, the location and shape of the device itself were not always convenient for apartment owners, so when carrying out repairs or the need to replace an old device, the question of moving the heated towel rail to another wall often arises.

Types of heated towel rails and their advantages

Heated towel rail

Let us clarify that there are several types of heated towel rails, each of them has advantages, but they are not without some disadvantages.

Typically used devices:

- Standard water ones - work when connected to the hot water supply of a house or its heating system. The problematic nature of such a device is associated with the possibility of operation only during the heating season or when hot water is available. Otherwise, the device will be useless. The second point is difficulties with connection - illiterate implementation can have a negative impact on the operation of the water supply or heating system of the entire house.

- Electric heated towel rails are metal tubular structures with an electric heater inside. The big advantage of such a device will be the ability to work autonomously.

- Universal heated towel rail - Probably the most convenient and unpretentious option. It runs on both hot water and electricity. The only drawback will be the price of such devices - almost 2 times higher than standard models.

There are also very convenient portable electric models, they are installed on the floor, do not require any installation, they can be used not only in the bathroom, but in the kitchen or in the room, as a heating device.

Helpful hints

- The seamless steel model is recommended for installation in apartment buildings. This model will withstand increased liquid pressure in the pipeline, pressure surges, and changes in water flow speed.

- Brass appliances are installed in a house with an autonomous water supply.

- It is worth considering whether it is possible to mount the device on the border wall with the living room, or move the heated towel rail to another wall.

- When installing pipes in a riser, either threaded connections are used or welding work is performed.

- It is not advisable to use carvings in hard-to-reach places: behind decorative trim.

- It is necessary to slope the supply pipe towards the movement of hot water. This will ensure that there are no air traffic jams.

- A distance of 3.5-5.5 cm is maintained between the wall and the middle of the supply pipe.

If you do not want to seek the help of a specialist to move a heated towel rail in a water-type bathroom, then it is recommended to install an electric device. But then electricity bills will increase. The choice is yours.

How to choose a heated towel rail

When choosing an installation, you should pay attention to imported devices.

Models made in Germany and the Czech Republic are in demand on the market; they are of higher quality than those from domestic manufacturers.

When choosing, special attention should be paid to seamless models.

When choosing, we take into account that the best option is a product made of stainless steel or a more expensive one made of brass.

But if you live in a country house or cottage, you should trust the heating and drying of towels to models made of ferrous metal or brass. If the quality is good, such a device will last more than twenty years.

Let's watch a video on how to choose the best model:

Specifications

When choosing a heated towel rail, check its technical characteristics.

We'll tell you what to look for when buying a water device:

- Thermal power of the heated towel rail

. The bigger, the better. This parameter depends directly on the surface area of the device and the temperature parameters of the coolant. - Center-to-center distance between terminals for connection to DHW

. The standard value is 50 cm, but there are other options. It can be ignored if you are planning a new pipe layout. - Pipe wall thickness

. It must be at least 2 mm - the operating period and heat transfer of the device depend on it. The unit, made of a pipe with a cross-section of one or 3/4 inches, can completely cope with heating a small bathroom. - Maximum operating pressure, coolant temperature

. The higher the values, the more difficult the conditions the heated towel rail can operate in. - Availability of a “Mayevsky tap” with a relief valve

. Thanks to it, you can easily carry out the first start of water into a newly installed device, as well as when connecting hot water after summer maintenance. The valve allows air pockets to be expelled for normal circulation of the coolant liquid.

Dryers that operate on water may have different connections to the hot water supply. The most practical is the side one, since products with this design can be adapted to any installation location. This allows the connection unit to be made almost invisible so that it does not spoil the interior.

Indicators that need to be taken into account when selecting an electrical appliance:

- Power

. A 100-150 W device can easily cope with heating one square of a bathroom. This is enough to dry towels. But to warm up the room you need a more powerful unit. - The method of connecting the device to the electrical network is open or hidden

. The first option is simpler - the wires from the device to the electrical outlet are laid along the surface of the wall. In the second case, they are disguised under the finishing, which increases safety. - Economical

. Electricity consumption can vary significantly depending on the type of appliance. Dryers are equipped with heating elements with a power of 100–2000 W. Powerful models often have sensors installed that turn them off automatically when the desired temperature is reached. This helps save electricity.

Also consider the availability of additional functions. The devices are equipped with timers, thermostats, and indications. This makes the unit a little more expensive, but more comfortable to use.

Standards for transferring heated towel rails

The transfer of the device to another wall will not be assessed as a violation by the housing inspectorate, since the design is not indicated in the BTI plans and changing its position will not affect the configuration of the room layout.

Heated towel rail connection diagram

Other problems with transfer often arise, because the device belongs to common property and will require the collection of signatures for permission to transfer from all residents of the house.

But the device is not included in the BTI plans, and it works for each apartment separately.

At the same time, the water heated towel rail is fed into the heating or hot water supply system of the house and, if connected incorrectly, can affect its operation. All three points will need to be taken into account when carrying out repair work.

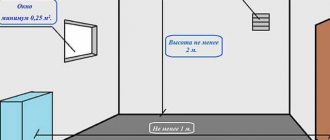

To correctly transfer the device, you will need to comply with some technical conditions.

| for water device | the wall on which the device is planned to be placed should not be adjacent to the bedroom or living room. The pipes used for connection must be either heating or heat-resistant, capable of withstanding high temperature and pressure. the device must be seamless and protected from water shock loads It is advisable to carry out the transfer at a minimum distance from the previous location |

| for electric | It is recommended to first calculate whether the permissible load on the electrical wiring of the apartment will be exceeded make sure there is a convenient outlet for connecting the device |

We should not forget the standards specified in SNiP:

- A stair-type heated towel rail is attached in such a way that an adult can reach the top bar;

- U-shaped is mounted no lower than 110 cm from the floor.

- M-shaped is placed at a height of at least 90 centimeters;

- The average mounting height is from 90 to 170 centimeters, for convenient use by a person.

Complex of preparatory work

Owners of electric models will have the least difficulties during transfer. They are completely autonomous and manipulation with them does not require additional capital investments or approvals from supervisory authorities. The actual dismantling and installation of the device is extremely simple and most often involves removing the device from one wall and attaching it to another. If necessary, the socket is additionally moved or grooves are made for wiring. This is where all the work ends.

With water equipment there will be much more hassle. To carry out the transfer of a heated towel rail, approval from the authorities responsible for the operation and condition of internal communications and buildings will be required. This is due to the fact that independent movement of heating appliances, and this includes a water heated towel rail, makes the owner responsible for changing the technical parameters of the system and its condition.

Water heated towel rail transfer diagram

Thus, if problems arise, claims will be made specifically to the owner of the property. As a result, it is strongly recommended that all changes to heating systems be formally approved.

Relocating a heated towel rail is best left to professionals.

When choosing new equipment, you must take into account that it should not put additional load on the thermal system. Therefore, it should only be a certified device, correctly selected for thermal power in strict accordance with the volume of the bathroom. The hydrodynamics of heating pipelines should also not be disrupted. Consequently, the device is installed without the formation of an air lock and without creating additional hydraulic support. All these conditions can only be met if the device is installed correctly, for which it is best to invite a specialist.

Do-it-yourself heated towel rail installation

Moving a heated towel rail to another wall - is approval necessary?

There are 2 ways to coordinate the transfer of a heated towel rail:

- If the house is undergoing renovation and redevelopment, then it is worth noting the transfer in the design documentation, which will need to be submitted for approval to the housing inspectorate, which will subsequently allow or prohibit the transfer;

- If you just want to start repairing and remodeling your house, then it would be better to move the device with the help of employees of the management company, who will enter the new location of the installation.

It is always worth coordinating the transfer with the relevant authorities. If there is a breakdown in the water supply of the entire house, only you will be to blame, since you did not coordinate the transfer with the housing inspection.

Before installing a new heated towel rail, you need to calculate whether it will put additional load on the heating system of the house. The device must be completely original and free of defects.

Installation of taps ↑

Before installing the device, you need to do the carving. If the old device has been cut off, a new thread is cut on the remaining section of the pipe, using a die of the appropriate diameter. If there is an old thread, it is worth “driving” it to improve the quality of the new connection. All work is carried out extremely carefully. It is even better to have a professional do the threading, especially if there is significant wear on the pipes or the threads must run close to the ceiling or below floor level. In any case, before starting the procedure, you need to make sure that torsional loads cannot damage pipelines located outside the premises.

Now you can install the shut-off valves. The use of taps is necessary because they allow you to regulate the operation of the heated towel rail. This can be done by opening or closing taps. In addition, if there is a need to replace or repair equipment, using shut-off valves you can easily shut off the water and begin work. At the same stage, a bypass jumper, the so-called bypass, is also installed. Of course, if this element was planned to be installed.

Installation diagram of a heated towel rail with bypass

Relocation of the structure as a design solution

The world is gradually leaning more towards minimalism, and therefore small and neat models are increasingly gaining popularity.

This device has many advantages:

- Great view;

- Takes up little space in the bathroom;

- Costs less;

- Due to its small size, if the pressure of hot water is poor, it will be just as hot

Of the minuses, it is worth noting that such a device is not suitable for all baths. For large baths, such a unit will be disproportionately small.

Heated towel rail as a decorative item

There are companies that produce heated towel rails to order. You can order a design service and make the device according to your sketch, the required dimensions and color. It will succinctly fit into the interior of the bathroom. Colored models look good in a bathroom whose interior has a bright color scheme.

For standard bathrooms, a stainless steel model is best.

The best place for installation would be above the washing machine. According to SNiP rules, the distance from a household appliance to plumbing equipment should not be less than 60 centimeters.

Budget water tank Tera M-shaped 500×500

- low price;

- compactness;

- resistance to pressure up to 15 atmospheres, water hammer.

The device, made of durable stainless steel in the shape of a curved snake, is not very spacious, but it is cheap - from 1,200 rubles. Type of connection to the DHW system - lateral on the left and on the right. It has compact dimensions - 50x50 cm, consists of four sections, center distance - 50 cm.

The model maintains pressure up to 15 atmospheres and is not afraid of water hammer. The maximum coolant temperature is 115 degrees, heat transfer is 63 W. Manufacturer's warranty – one year.

Suitable for an apartment with a small bathroom.

Reviews

According to the owners, the device is compact and inexpensive. Made with high quality, installation will not cause problems.

Pros:

- high-quality material – stainless steel;

- thick walls;

- ease of installation;

- resistance to coolant temperatures up to 115 degrees.

Minuses:

How to prepare for the job of replacing or moving a heated towel rail in the bathroom to another wall

First you need to prepare the tools:

- hammer drill

- drill bits for working on concrete

- electrical tester

It is advisable to prepare screwdrivers, a tape measure, a marker, and mounting brackets.

Convenient place to install a heated towel rail

It is worth choosing the right place for installation; as mentioned earlier, it is best to install the heated towel rail above the washing machine, about one hundred and twenty centimeters, and at a sufficient distance from the pipeline.

After determining the installation location, it is worth marking it with a marker. It is advisable that there is a power source (socket) near the installation site. But if there is none, then you will have to lay a separate wire for our device.

There are 2 ways to install a new socket:

- When completely renovating a bathroom, a reliable option would be to lay the wire under the cladding.

- You can also run the wire directly through the cladding, but this will not be as safe. The first option, although more complicated and more labor-intensive, will be much more reliable than the second.

After which you need to dismantle the device from its original installation site.

We make new holes in the marked place for the mounting system of the device. All that remains to be done is to install the mounting system and place the device itself on it. Afterwards do the finishing work.

We invite you to watch an interesting video about installing a new heated towel rail:

Choosing a company

In the case of towel dryers, it is better to take a domestic version. In terms of its operational parameters, it is much more suitable for our conditions.

The best manufacturers include:

- Terminus

. They offer classic options for dryers and appliances with unusual designs. The model range includes more than 200 dryers, both water and electric. - "Sunerzha"

. The manufacturer was one of the first to create dryers made of stainless steel. High-quality pipes and unusual design are the distinctive features of the brand. - Tera

. The main emphasis in production is on constructive excellence, elegant design, simple installation.

Among foreign manufacturers, products from Margaroli (Italy) and the Swiss brands Zehnder and Arbonia deserve attention.

Moving a water heated towel rail, what difficulties arise

Firstly, legal problems may arise with permission to move, and secondly, when moving a water apparatus, problems may arise with the load of the new structure on the water supply system of the house.

All other difficulties are not serious compared to the first two.

Before starting the transfer, be sure to turn off the supply riser. It is not recommended to do this yourself; it is better to entrust it to a professional plumber.

Typically, water devices do not have a heat control system, but you can install a ball valve on it, which will allow you to regulate the heating of the installation.

First of all, you should always find out whether moving a structure in a house is allowed. If not, then you definitely need to coordinate this with the relevant authorities.

If you transfer the installation and do not agree with the housing inspectorate, you will be held administratively liable. The case may go to court, and you will have to be punished or get off with a fine for a tidy sum.

Watch the video for an interesting and safe option for connecting a heated towel rail:

Dismantling the old device ↑

Before starting work, you need to be sure that there is no water in the system. Just in case, experts advise preparing a rubber band about 4 cm wide and a little more than a meter long. Cut from a car camera. If necessary, it is applied to the damaged pipe. We place the first turn loosely, the subsequent turns tightly. This makes it possible to stop almost any leak.

When dismantling the old device, it must be taken into account that the length of the remaining pipes must be sufficient for cutting a new thread

All devices that are not part of the pipe are dismantled by unscrewing the threaded connection. “Stuck” or welded heated towel rails are cut using a grinder. It must be remembered that the section of pipe remaining after cutting must be of sufficient length for threading. Before starting work, it is worth covering all surfaces with a damp cloth, otherwise indelible marks from the grinder’s sparks may remain on them. The cut off or unscrewed heated towel rail is carefully removed from the brackets and taken out.

Features of installing an electric heated towel rail

Electric heated towel rail

It will be much easier for residents of private houses to choose a place to install the unit. Residents of apartment buildings have a limited number of options when choosing a location.

The electrical design will not cause much trouble when transferring to another wall. There is no need to coordinate the transfer of such a device with the housing inspector.

There are two nuances that exist when moving an electric heated towel rail:

- The distance from the water source must be at least 60 centimeters;

- Correct power supply.

The electric model has a large number of advantages over its water counterpart, here are a few of them:

- The closed circuit allows el. the heated towel rail must be in working order all year round.

- With such a device, you should forget such words as: corrosion, hard water and pressure drops.

- And of course the biggest advantage will be the ability to regulate the heating strength.

Methods to improve performance and safety:

- It is necessary to carefully hide the wiring that is connected to the heated towel rail;

- It is worth grounding the device due to the fact that it is installed in a room with high humidity;

- It is advisable to install an RCD (residual current device)

Scheme 1 lateral and diagonal connections, non-restricted and unbiased bypass.

The most effective connection for the vast majority of substations (exceptions will be added a little later) is with the supply of coolant to the upper part and the release of cooled coolant from the bottom. This can be achieved by using a lateral or diagonal connection with an unnarrowed and unbiased bypass.

Figure 12. Connection of a PS ladder operating on natural circulation, without narrowing and without bypass displacement. Lateral connection.

Figure 13. Connection of a PS ladder operating on natural circulation, without narrowing and without bypass displacement. Diagonal connection.

The schemes are equivalent; the diagonal version has practically no advantages over the lateral one.

This PS connection diagram is the most universal:

- Works in any direction of supply in the riser.

- It is completely independent of the circulation speed in the riser.

- There is no need to bleed air from the substation after turning off the water.

- The distance from the riser is arbitrarily large.

Conditions for the circuit to work:

- The lower outlet of the riser must be below the connection point to the substation, and the upper outlet of the riser must be above the connection point to the substation.

- It is necessary to observe the slope of the supply pipes (the direction is shown in the figure). To be certain, you can take a difference of 3...30mm per meter. More is better. At small distances from the riser (a couple of meters) and a large diameter of the supply pipes (PPR 32mm), strictly horizontal laying is permissible.

- There should be no “humps” (completely unacceptable, otherwise air will accumulate in them and circulation will stop) or dips on horizontal routes (allowed only within small limits; deep “holes” will serve as “pockets” for airing).

- With bottom feed, there should definitely be no narrowing between the bends! It will interfere with the operation of the PS until it becomes completely inoperable! With top supply, in extreme cases, it is permissible to narrow the bypass by 1 step of the riser diameter (we will consider this option in detail below), but it is not required for the operation of the substation.

- The diameter of the pipes to ensure maximum circulation is preferably at least DN20 (3/4" for steel, 25mm for good reinforced PPR), ball valves - at least 3/4". The practical maximum distance of the substation from the riser when using a plastic pipe with a diameter of 25 mm is approximately 4.5 meters.

- It is highly desirable to place the supply pipes in thermal insulation. In addition to the fact that this is mandatory when embedding any plastic pipes (provides mechanical protection and compensation for thermal expansion), such insulation can improve the performance of the substation in certain cases (sagging pipes or “holes” in them).

It is strictly prohibited to install any taps on the bypass - this is vandalism and harm to yourself and your neighbors. Overlapping or excessive narrowing of the bypass:

- a) Slows down circulation throughout the riser (the temperature of hot water drops from water collection points in apartments).

- b) Radically worsens the water pressure in all apartments located further in the direction of supply. And with a certain location of the hot water outlet - even to the vandal himself. Indeed, when the bypass is narrowed by one pipe size, its throughput becomes approximately half as large.

- c) Does not significantly improve the efficiency of the above scheme, and with a lower feed, even on the contrary, it interferes with the operation of the substation.

Safety precautions

When installing a dryer with an electric heater, it is necessary to ensure safe operation of the equipment:

- wiring is hidden in the wall or in boxes;

- contact connection points are protected by insulating materials;

- a protective shutdown device is provided in the power circuit;

- The socket is equipped with a grounding line to which the metal body of the heated towel rail is connected.

The socket must be protected. The socket housing must meet IP4 or IP65 protection standards. The design does not allow dust and splashes of water to penetrate into the internal cavities, but if a jet of liquid enters, a short circuit occurs. It is recommended to move the outlet to an area out of reach of water (for example, under the ceiling of a bathroom).

DIY bathroom renovation video

Modern ideas for decorating a window opening between the bathroom and kitchen in Khrushchev

How to connect a bathtub to a wall

User manual

Before installation and further operation of the heated towel rail, you must carefully read this document. In it, the manufacturer must describe safe installation techniques for any type of heated towel rails, such as the absence of water in the system when connecting water appliances, the presence of grounding of the electrical wiring for electric ones and other similar factors. Recommendations are given on how to properly operate the device during its operation, pictures and installation diagrams for water structures are provided.

Compliance with the requirements of the instructions, which are mandatory for each heated towel rail, will help extend the life of the device and avoid disruptions in the hot water supply system.

Welding of polypropylene pipes

We will connect the heated towel rail using polypropylene pipes. Why polypropylene? This is the best option.

The most common materials for supply pipes are steel, copper, and polypropylene:

- Steel pipes are heavy, susceptible to corrosion, and require a welding machine for installation.

- Copper ones do not rust, but are very expensive and are mounted by soldering.

- Polypropylene is not subject to corrosion, is cheap, and lightweight. Reinforcement with special fiber significantly increases their strength and resistance to high temperatures. The presence of a variety of fittings makes it easy to connect polypropylene to metal pipes. They are very easy to install. For this, there are special welding devices that you can master in just half an hour and easily make high-quality connections. In addition, these devices can be rented at most stores that sell plastic pipes and building materials. This service costs approximately 400 rubles per day.

You can read more about soldering and installation of polypropylene pipes here.

Why are they refusing to approve the redevelopment project?

There may be four reasons: 1. The departments do not have the necessary information about the apartment. In this case, the administration must ask the applicant to provide documents. If he does not do this within 15 working days, then there will be a refusal. 2. The redevelopment does not comply with the law, violates building codes, GOST and SNiP, and threatens safety. For example, you touch a load-bearing wall or decide to expand the kitchen at the expense of the living room. 3. The design organization issued a conclusion that redevelopment of the house is impossible due to the technical condition of the building structures. 4. The Department of Culture does not allow redevelopment due to the specifics of the building - when the house is a cultural heritage monument. In the refusal, the administration will indicate the reason and type of violation. Part 1 art. 27 of the RF Housing Code clearly establishes an exhaustive list of grounds for refusal of approval. This list cannot be expanded or interpreted differently. Remember this if you have an unauthorized redevelopment and the court refuses to legalize it.