August 18, 2021 Stroyexpert Home page » Foundation » Installation

Reinforcement of a monolithic slab

An important stage in building a house is building the foundation. This main part takes on loads from ground movements, from the mass of the structure and other external factors. Therefore, the foundation must be sufficiently strong and reliable. Reinforcement, that is, reinforcement with metal reinforcing rods, helps to strengthen the foundation of the house.

What is it, why is it needed?

Reinforcement of a monolithic slab is the procedure for placing a steel load-bearing structure into a concrete body in order to increase the strength characteristics of the foundation and increase the service life of the house that will be operated on it.

During service, the foundation is subjected to uneven pressure from both the structure and the soil around it. As a result, bending moments arise, which lead to the appearance of cracks not only in the body of the foundation, but also in the walls of the house itself.

The concrete mass itself is characterized by resistance to compressive loads, and the reinforcement compensates for the action of tensile and bending forces.

Thus, reinforcement allows:

- increase the strength of the base;

- prevent possible shrinkage of the structure associated with insufficient foundation strength;

- reduce the risk of destruction of a monolithic slab under soil pressure.

What happens if you don't reinforce it?

In order to save money, some builders refuse reinforcement.

This approach is practiced in the construction of lightweight buildings , which, according to the design, will stand on ground that is not prone to movement. In other cases, the need for reinforcement is regulated by regulatory requirements.

Violation of technology entails premature destruction of the foundation under the influence of heavy loads from the structure itself, pressure as a result of frost heaving of the soil, etc.

Correction of the reinforced concrete slab design.

If it is impossible to replace an expensive slab foundation with a strip foundation for a number of objective reasons, you can try to reduce the construction budget. For example, with a thickness of 30 cm, large structures are difficult to fill even with regular use of the mixture from mixers. The solution is often a concrete footing:

- with a thickness of 5 – 7 cm it does not require reinforcement

- poured in one go

- levels the base

- protects waterproofing from crushed stone abrasions

- reduces the thickness of the protective layer (bottom) by 20 – 35 mm

- uses lean concrete

How to calculate reinforcement for a monolithic slab.

However, in this case, the cross-section of the rods of the upper layer will have to be recalculated. For asymmetrical slabs (the internal wall is offset relative to the center of the structure), calculations are made using a larger span length, as for symmetrical ones. The safety factor will increase with a slight increase in the estimate.

In a similar way, you can calculate reinforcement for slab foundations of any complexity. In addition, there is software for designers who can do this with high precision.

Primary requirements

The designer involved in the design of the slab base must adhere to the reinforcement conditions set out in SP 52-101-2003.

The regulatory document contains:

- rules for the location and knitting of reinforcing mesh,

- description of mathematical calculations,

- recommendations for using supports for the bottom layer, etc.

According to technological requirements, the use of fittings with traces of rust, old paint, etc. is not allowed. To ensure high adhesion of metal to concrete, steel rods of periodic cross-section are used. To fix the elements of the load-bearing structure, tie wire is used or a welding method is used: plastic clamps in this case are unreliable.

Before starting reinforcement, the designer must choose a rational arrangement of rods, determine the need for reinforcement, and think over a way to fix the structure in space using supports.

Video description

How to manually knit a reinforcement cage, watch in the video:

Ready-made welded meshes are faster and easier to install than using the tying method. The only negative is the difficulty that arises when selecting the required size.

Reinforcement bars for the foundation slab Source bigbang.in.ua

When using a welding machine, it is recommended that in important areas - the corner of a building and other areas where massive walls will create a load on the structure - the reinforcement must be connected with wire.

The welding method is used in rare cases, since the main disadvantage of this option is a rigid and immovable connection. This has a bad effect on the quality of the monolithic foundation. When welding, metal elements melt, after which the strength of the reinforcing elements decreases.

Schemes and drawings for laying reinforcement

The reinforcement diagram gives a complete picture of the arrangement of frame elements in space. When the thickness of the monolithic slab is less than 15 cm, then the foundation has enough rigidity, which is provided by one grid of longitudinal and transverse rods located perpendicular to each other with a design step.

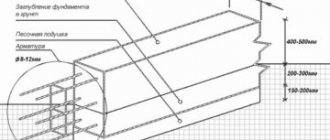

For light block buildings, the optimal slab height is considered to be 15–25 cm, for residential buildings and cottages – 25–35 cm . In this case, the reinforcement frame consists of two chords connected to each other by vertical rods - the upper and the lower.

Basic parameters of the plate

In a simple version, the reinforcing belt is a mesh where the reinforcement is placed in relation to each other with the same step, equal to 20 to 40 cm. The distance between the rods is selected based on the design loads acting on the foundation.

For example, for brick and other heavy houses, a step of 20 cm is chosen , while for one-story frame cottages the distance between the load-bearing elements can be increased to 30–40 cm.

The reinforcement pitch must be at least 1.5 times less than the thickness of the foundation slab.

In practice, most often there is a need for reinforcement in two layers. Then, according to SP 63.13330.2018, the upper and lower chords are connected to each other with U-shaped clamps. The length of such a clamp must exceed the design thickness of the monolithic slab at least twice.

The ends of the reinforcement must be recessed into the concrete body at least 2–3 cm on all sides . Otherwise, the metal quickly oxidizes and premature destruction of the load-bearing structure is possible.

Punching zones

In places where load-bearing walls rest on the foundation, there is a need to strengthen the reinforced frame. For this purpose, the reinforcement pitch is reduced.

For example, if the rods were laid out every 20 cm over the main area, then under the walls this distance can be reduced to 10 cm. Otherwise, there is a risk of deformation of the foundation and the appearance of cracks.

When the project includes an underground room in the house, the depth of the slab foundation will directly depend on the height of the basement. In this case, the designer needs to rigidly combine the structures of the foundation and walls.

For this purpose, vertical outlets are left in the reinforced frame of the base , which will serve as a connecting link between several structural elements.

Additional reinforcement of the reinforcement frame

In practice, situations often arise when it is necessary to strengthen the reinforcement frame in places where maximum loads act on the foundation, for example, under columns and operating fireplaces indoors.

In this case, you can increase the cross-sectional size of the rods or introduce additional longitudinal rods into the lower chord, since the maximum pressure is applied to the lower part of the load-bearing structure.

Information on the purpose of the calculator.

The online calculator for a monolithic slab foundation (slab)

is designed to calculate the dimensions, formwork, quantity and diameter of reinforcement and the volume of concrete required for arranging this type of foundation for houses and other buildings. Before choosing the type of foundation, be sure to consult with specialists whether this type is suitable for your conditions.

All calculations are performed in accordance with SNiP 52-01-2003 “Concrete and reinforced concrete structures”, SNiP 3.03.01-87 and GOST R 52086-2003

Slab foundation (ushp) is a monolithic reinforced concrete foundation laid under the entire area of the building. Has the lowest ground pressure among other types. It is mainly used for light buildings, since with increasing load the cost of this type of foundation increases significantly. With shallow depth, on fairly heaving soils, it is possible to uniformly raise and lower the slab depending on the time of year.

It is imperative to have good waterproofing on all sides. Insulation can be either sub-foundation or located in the floor screed, and most often extruded polystyrene foam is used for these purposes.

The main advantage of slab foundations is their relatively low cost and ease of construction, since, unlike a strip foundation, there is no need to carry out a large amount of excavation work. Usually it is enough to dig a pit 30-50 cm deep, at the bottom of which a sand cushion is placed, as well as, if necessary, geotextiles, waterproofing and a layer of insulation.

It is imperative to find out what characteristics the soil under the future foundation has, as this is the main deciding factor when choosing its type, size and other important characteristics.

When filling out the data, pay attention to the additional information with the Additional information sign.

The following is a complete list of calculations performed with a brief description of each item. You can also ask your question using the form in the right block.

Calculations

Knowing the area of the foundation and focusing on the step between the reinforcement, you can calculate the required amount of rolled metal for reinforcement. According to current standards, the maximum step between the rods will be 40 cm. The value of the parameter is also affected by the class and cross-sectional size of the reinforcement.

When engaged in private house construction, it is better to take a step equal to at least 20 cm, while in places of maximum loads the distance between the elements of the load-bearing structure must be reduced.

The algorithm for calculating the number of reinforcing bars is best considered using an example . For example, the dimensions of the foundation are 6 by 6 meters, the design step is 20 cm.

First, calculate the need for reinforcement for one layer of mesh: 900 / 20 x 2 = 90 pieces of longitudinal and transverse rods, each 6 m long. For two meshes, the need for reinforcement will double – 180 pieces. For vertical rods 10 cm high, you will need 203 m of reinforcement. The value was obtained by multiplying the intersection points (45x45=2025 pcs.) by the length of one rod.

Thus, to meet the design conditions, the need for reinforcement will be: 180 x 6 + 203 = 1283 m. If we take into account that one linear meter of reinforcement with a diameter of 14 mm weighs 1.21 kg, then it is necessary to purchase 1.56 tons of rolled metal. Practicing builders recommend ordering reinforcement with a margin (5–10%) .

Advantages and disadvantages of continuous reinforced floors

The reinforced concrete floor is made in the same way as ready-made slabs from 2 materials:

- iron rods;

- cement mortar.

Concrete has high hardness, but it is brittle and cannot withstand deformation and is destroyed by impacts. The metal is softer and tolerates bending and torsion well. When these two materials are combined, durable structures are obtained that can withstand any load.

Advantages:

- absence of seams and joints;

- smooth, continuous surface;

- the ability to make floors for any shape and size of premises;

- installation and assembly of fittings is carried out directly on site;

- a reinforced concrete monolith strengthens the structure and binds the walls together;

- there is no need to seal joints and align transitions after installation;

- the local large load on the floor is evenly distributed over the foundation;

- It is easy to make various openings between floors for stairs and communication wells.

The disadvantages of reinforcement include high labor costs for assembling the reinforcing mesh and the long process of drying and hardening of concrete.

Correct work order

First, assemble the lower mesh.

To do this, longitudinal and transverse reinforcement are laid out on the working field perpendicular to each other, observing the design spacing between the elements. After fixing the parts, vertical rods are attached at the intersection points . Then the upper chord of the reinforced frame is mounted.

Upon completion of assembly, check that the dimensions correspond to the design values.

Fixation of the rods can be done in two ways:

- Using a knitting wire and a special hook or reversible device.

- Electric welding method.

The latter option can significantly reduce operating time, but there remains a risk of metal overheating, which will reduce the strength of the entire power structure. Therefore, experts recommend knitting the reinforcement manually or semi-automatically.

The finished frame is laid on the working field on supports, maintaining the technological distance between the bottom of the structure and the walls of the formwork.

Do-it-yourself pouring and grounding of the slab

After completing the installation of the reinforced frame of the monolithic slab, it is necessary to carry out grounding. This procedure involves installing an outer ring made of galvanized strip. This ring will protrude from the outside of the slab, being its integral part. The grounding is equipped with connecting busbars, to which the rain drain elements and lightning rod will be attached. The busbars can also be taken out at the point where the electrical network is connected to the house to provide grounding for the internal electrical wiring.

The foundation is poured after completion of all work related to the installation of the reinforcing frame. During the process of mixing the solution, fiber can be added to the concrete if the requirements of SNiP require additional reinforcement of the concrete base. The filling process is carried out continuously until the entire volume is filled. Upon completion, the mixture must be freed from air bubbles by vibration compaction. The slab will gain the necessary strength after 4 weeks.

Basic installation errors

When planning to engage in construction with your own hands, the owner should first analyze the mistakes that beginners most often make:

- Lack of a protective layer of concrete between the reinforced frame and the side walls of the foundation (minimum 30 mm). As a result, the ends of the rods will be more susceptible to corrosion, which generally affects the service life of the base.

- Using wooden clamps to organize a protective layer of concrete. Additional elements remain in the body of the slab and violate its integrity. Wood is a loose material that can swell and destroy the structure. Therefore, special plastic clamps are used to secure the reinforcement.

- Assembly of the frame by welding at high current. As a result, the steel structure is destroyed at the joints of parts, and the strength potential of the reinforced frame is weakened. The selection of current strength should be done by a professional.

It is better to entrust high-quality assembly of reinforced frames to professionals, since this work requires skills and understanding of technology.

A lot of important and useful information about the construction of a slab foundation is presented in this section.

Monolithic slab foundation.

A monolithic foundation slab is nothing more than a concrete slab that has a flat or ribbed shape, containing reinforcement inside, which is called reinforcement. This type of foundation is most often used on weak, erodible soils for the construction of not very heavy buildings or for the construction of heavy stoves and fireplaces, as well as for heavy stationary equipment.

This calculator allows you to calculate for a monolithic solid foundation:

- Volume of concrete to pour the slab.

- The required amount of materials for preparing concrete.

- The number of boards required for formwork.

- Estimated cost of all building materials.

- The reinforcement of the foundation slab depends on the geological conditions and the design.

Material calculator for a monolithic foundation slab

Online calculator to calculate the approximate cost and required amount of materials for a monolithic foundation slab.

The main advantages of a monolithic slab foundation:

- high load-bearing capacity;

- ability to withstand displacement and swelling of soil;

- simplicity of design;

- good ability to withstand ground and melt (surface) water;

- the possibility of constructing a basement floor protected from melt water;

The main advantages of a monolithic slab foundation:

- high load-bearing capacity;

- ability to withstand displacement and swelling of soil;

- simplicity of design;

- good ability to withstand ground and melt (surface) water;

- the possibility of constructing a basement floor protected from melt water;

A slab foundation is good when construction is carried out on sandy cushions or highly compressible, heaving soils. Due to the fact that the monolithic slab covers the entire area of the building, there is no risk of soil displacement for such a foundation.

A slab foundation - a type of shallow strip foundation - is either a monolithic slab or a reinforced concrete lattice covering the entire area of the building. Such a foundation is used for the construction of a cottage (especially from cellular concrete blocks). On heavy heaving, bulk and weak-bearing soils, it is possible to construct so-called floating foundations from solid or lattice monolithic reinforced concrete slabs.

Disadvantage of a solid slab foundation:

- There are no disadvantages to a monolithic slab, except for its high cost.

A monolithic solid foundation, especially a buried one, can amount to from 30 to 50% of the cost of the house frame. If the slab foundation is shallow, then the costs of concrete and reinforcement are compensated by the simplicity of construction; if the slab foundation is buried, then in addition to a large mass of concrete, you will have to bring in a significant amount of sand and crushed stone for the construction of a cushion and backfill, rental of equipment for constructing a pit and other costs often exceed a reasonable proportion (20% of the total cost of the box).

Recommendation: This is just an overview article on how to calculate reinforcement for a slab foundation. For general development, you need to read it. But if you don’t want to get a lot of problems and lose money, then it’s better to involve a specialist and supervise him.

How to calculate

Concrete does not become reinforced concrete simply because there are some metal rods inside. If builders immerse a roughly assembled frame into formwork, fill it with mortar, and then call the product reinforced concrete, this is not always true.

For reinforced concrete products there is a concept of a minimum percentage of reinforcement. If in your foundation the percentage of included reinforcing parts is less than necessary, then the foundation, according to its parameters, will be classified not as reinforced concrete, but as concrete products.

In general, to calculate the minimum percentage (or coefficient), the total cross-section of the reinforcing bars is divided by the cross-section of the concrete mass that is supposed to be reinforced. In practice, it is much more convenient to determine the percentage of reinforcement of a foundation, beam, wall frame or column in the following way:

- The mass of the frame is divided by the mass of concrete in the product.

- The resulting number is converted into a percentage: it is multiplied by 100.

Installation of formwork

Professional formwork for pouring such slabs can cost a fairly large amount of money, approximately the same as the cost of the slab itself along with the work. However, do not be upset, if the house is being built on your own, you can get by with ordinary 50x150 mm boards or plywood. Plywood and boards may later be needed to line the roof and ceiling, which means you would still need to spend this money.

Today there are quite a large number of companies that rent out telescopic stands and formwork. Renting racks can cost approximately 70-100 rubles per 1 m² of area.

The formwork installation process should be carried out in stages:

- Racks with tripods should be placed in rows, and the distance between them should be 1-1.2 m.

- The longitudinal beam is laid on top of the racks, after which the racks must be extended to the required height.

- A transverse beam is laid on the longitudinal beam (laying can be done lying down). The beam will need to be knocked down into a single mesh, after which plywood will be laid on it.

- After the plywood flooring is completed, using a level you will need to completely level the entire slab. Next, reinforcement begins.

Reinforcement stages

- The very first thing is to cut the wire to the required size, approximately 20 cm.

- Then the rods are laid out along the entire perimeter of the slab foundation so that the reinforcement can be immediately placed in its place.

- The rods are also installed near the foundation formwork.

- A horizontal rod is secured with threads at the bottom of the posts at a distance of 5 - 8 cm from the ground.

- At the next stage, the rods are tied using a hook, the knot is made in the shape of a figure eight, the fastening must be strong and reliable.

- The next horizontal rod is suspended using the same method.

- of the reinforced frame is also being constructed .

- Two vertical rows are fixed using horizontal jumpers; the distance between them is allowed 1-1.5 meters.

- If the reinforcement is done correctly, concrete is laid . Concrete is used with a minimum amount of water for greater strength.

We must not forget that the reinforcement frame is installed in two rows, the reinforcement frame is attached to the formwork, this allows the mesh not to deform and increases the strength of the formwork. The farther the two rows are from each other, the greater the strength of the slab. Also sometimes they use this method of reinforcement, when the rods can extend outwards by 30 cm or more; this is done taking into account the filling of the base. To create a frame from reinforcement, it is recommended to use a rectangle or square shape; it is better to avoid complex shapes. In addition, the most important thing in reinforcement is considered to be a bunch of rods, so you need to pay special attention to this point, not skimp on material and comply with all standards.