A heated towel rail performs not only its main function - drying towels and small wardrobe items. Thanks to this device, the bathroom is always warm and comfortable, which is especially important during the non-heating period. Connecting a heated towel rail to a hot water riser is not the easiest task. It can be performed in several ways, which we will consider below.

Advantages of connecting to a hot water riser

Connecting a dryer to a domestic hot water system has a number of undeniable advantages:

- eliminating dampness in the bathroom;

- uninterrupted operation of the device;

- Constantly comfortable temperature in the room.

In addition, there is an opportunity to save on utility bills. Connecting the dryer to the hot water supply line allows you to not consider it a heating device. The thermal energy consumed will be taken into account as for heating water, and will not be transferred to the heating bill as gigacalories.

How to calculate power?

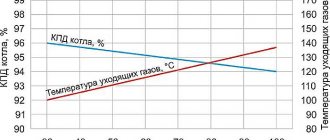

A heated towel rail is very expensive in terms of energy consumption, but at the same time it boasts a high heat transfer coefficient. The size and materials determine how much area an electric heated towel rail can heat. How to choose the right model?

To calculate how much energy it consumes per month, you need to carry out simple calculations: 100 W of energy is needed for 1 m2. This means that the power of a heated towel rail in a 4 m2 bathroom should be about 400-560 W.

You can find out how much electricity the device consumes using the formula:

- ErI = Pnom x Ks *t, where: Pnom - device power;

- Kc – demand coefficient, for an electric heated towel rail is 0.4;

- T – device operating time.

The power of a bath heated towel rail can be found in its data sheet. Working hours per day are determined individually.

After you have found out the daily figures, you can calculate how much electricity an electric heated towel rail consumes per month or per year by simply multiplying the resulting number by the number of days.

As the name implies, the main consumer property that distinguishes a rotary electric heated towel rail is the ability to rotate the coil. The dryer can be rotated 180 degrees relative to the wall. Moreover, in different models this function is implemented differently: in some places the entire heated towel rail rotates, and in others only its individual parts.

Rotary modifications are easy to use and indispensable in tight spaces, for example, if there is a niche behind the dryer that this device covers. In addition, if the rotating structure allows for independent rotation of individual sections, it is more convenient to dry several things at once.

Modern models are usually divided into three groups:

- water;

- electrical;

- combined.

The operating principle of electric heated towel rails is based on heating the heating element, which transfers energy to the thermal carrier, which heats the surface of the device. Electric models are filled with mineral oil or specially prepared oxygen-free water (metal rusting does not develop without oxygen). The last option is less common.

Combined devices combine two circuits: for hot water supply and for electricity. Such devices are not very popular due to their high cost.

Traditionally, it is believed that higher power of a heating device provides greater comfort. This is wrong. Bathrooms are usually small in size, and if you choose a heated towel rail that is too powerful, you may encounter the problem of unreasonably high temperature in the room, which, in turn, will affect the amount you pay for electricity.

The required power should be calculated based on the indicators recommended by SNiP 2.04.01.-85

In this case, always pay attention to the specific operating conditions and purpose of the heated towel rail

When purchasing a device, be sure to take into account the area of the room. A model that is too powerful will cause a lot of trouble during warm periods. If there is not enough power, fungus may develop in the bathroom. There are simple formulas for calculating the power of household appliances. So, to maintain the temperature at 18 degrees for 1 sq.m. living space requires 100 W of thermal energy. However, a bathroom is a room with high humidity, and after bathing a person freezes much faster, so it is advisable to maintain a higher temperature - 25 degrees. In this case, you need 140 W/1 sq.m.

We invite you to familiarize yourself with the design of a flush cistern with a lower water supply

If it is assumed that the device will not only dry towels, but also heat the bathroom, then the power calculation will look like this: the area of the room should be multiplied by 140. The resulting value will be decisive when choosing a specific model.

For example, for a small bathroom with an area of 3.4 sq.m. A device with a power of about 500 W (3.4x140=476) is sufficient.

Usually, the more horizontal tubes, the more powerful the device, but this is not always the case. Before making your final choice, you need to familiarize yourself with the technical documentation of each model you like and choose the most suitable one in terms of parameters.

Installation rules

Powering the “towel man” from the hot water supply should not violate the rights or cause inconvenience to neighbors in a multi-storey building. Therefore, the installation of the device should be carried out in compliance with the rules and regulations.

Primary requirements:

- mandatory installation of a bypass;

- the absence of shut-off valves on the circuit, by means of which the flow of hot water is blocked to neighbors living above;

- the dryer must be placed at a distance of no more than 2 m from the pipe, otherwise the water entering the device will quickly cool down;

- The bypass capacity must meet the requirements for the existing line and not block the water supply of neighbors.

Important! Circulation features should also be taken into account. The intensity of water movement in the dryer circuit is low. If it is installed far from the riser, then the pipes should be placed at a slight slope. The upper pipe slopes towards the riser, and the lower pipe - away from the riser. This creates conditions for the free release of air bubbles and improves water circulation.

Popular manufacturing companies

Which manufacturers' products are in greatest demand and respect among buyers?

- "Sunerja". The brand's production is located in St. Petersburg, heated towel rails are manufactured using foreign parts. The company's products are distinguished by their quality and great variety.

- "ARGO". This brand produces all types of heated towel rails, carefully controls quality at all stages and provides a long guarantee.

- "Dvin". The actively developing Russian company has been operating for more than 15 years and produces high-quality heating devices with a wide variety of designs and colors.

- "Nika". A Russian brand specializing mainly in ladder heated towel rails. Stainless steel is used in the manufacture of devices; great attention is paid to the durability and quality of polishing of products.

- Margaroli. The most famous Italian brand, supplying both water and electric models of radiators. Among the advantages of the manufacturer are high quality, elegant design and ease of use of heated towel rails.

- "Grota". The domestic manufacturer offers bathroom radiators of European quality - and pleases customers with a wide variety of design models.

- "Terminus". The brand uses the most innovative technologies in the production of devices and provides a 10-year guarantee - a very long period.

- Energy. The British company is known throughout the world for its wide range of reliable and beautiful bathroom heaters.

Device form

The shape of the heated towel rail affects the speed of water movement, the presence of airy places, and stagnant areas. The most effective are M-shaped (snake) and U-shaped “towels”, the insertion of which does not require bends and transitions. In such devices, water directed into the inlet of the end of the pipe passes freely through the entire volume of the dryer, without slowing down or stopping.

The most popular heated towel rails are made in the form of ladders or complex spatial structures made of stainless steel. They differ from standard dryers in having an increased area for placing linen and towels.

Multi-level floor

To zone the space, craftsmen install floors at different levels. They advise installing a podium to separate the kitchen and dining room. This option is considered one of the most practical because, among other things, the owners have additional free space where they can hide something. It is convenient to use boxes or crates for this. Wicker baskets will look good. But such space can remain free.

However, such a design should not be made if there are small children in the family, since the podium can become an obstacle for him. In addition, various floor coverings can be used. They will zone the space between the living room and the kitchen and protect the podium from damage. For example, tiles are laid in the kitchen area, and laminate flooring in the dining room. The main thing is to choose colors and textures and combine the finishes correctly.

Connection diagrams for a heated towel rail for an apartment

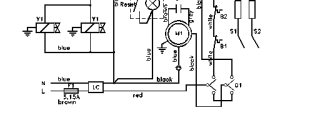

For the heated towel rail to work effectively in an apartment, a continuous circulation of water is required. If the shape of the device is close to ordinary U/M-shaped, the only connection method is used.

To install a “towel bar” of modern designs with several possible connection points, you will have to choose from various options.

Existing options

- Bottom. Both forward and return taps are connected to the lower terminals of the device.

- Upper. The supply and return branches are connected to the upper connecting points.

- Lateral. To connect the heated towel rail, use one point at the top and bottom, located on the same side.

- Diagonal. The lower and upper connection points located at different ends of the ladder are involved.

- In the center. This option is rare.

Each method has its own advantages and disadvantages. It is difficult to call any option optimal, since many factors affecting the operation of the dryer need to be taken into account.

Choosing a method

The choice of connection method is determined by the need to obtain maximum heat transfer from the device with minimal heat loss. To do this, you need to eliminate the appearance of airy places and ensure stable water circulation.

It is necessary to take into account the dimensions of the heated towel rail, the number, width and diameter of the bars. In addition, the direction of supply of hot water (from below or from above), the circulation speed, and the pressure in the hot water system also matter.

The optimal method is side mounting. Despite some disadvantages, when implemented, thermal energy losses are minimal and intensive circulation is ensured.

The bottom connection is used regardless of the direction of fluid supply. The upper one, on the contrary, creates a threat of water stagnation at the bottom of the device, into which cooled layers of water move.

In addition to the connection points, a properly functioning bypass must be included in the system. It is a straight part of the riser, located between the liners for the “towel box”. No taps should be installed on this section of the pipe, the internal diameter of the bypass section should be narrowed, or it should be made significantly smaller compared to other parts of the pipeline.

In private houses, the bypass is sometimes arranged offset from the axis of the riser. This allows you to prevent changes in water flow parameters.

Note! Only heated towel rails in the form of a ladder can be connected according to the described diagrams. Ordinary M- and U-shaped devices have only two points for connection to the DHW line, therefore there is only one option for connecting them.

Incorrect schemes

First of all, you should avoid installing complex curved bends and vertical loops. Air bubbles most often form in them, preventing the movement of water. The outlets must be located at a slight slope.

Pipelines hidden under the suspended ceiling or under the floor covering are not suitable for installing a heated towel rail. When pipes are laid hidden, hard-to-reach loops are created in which air accumulates and water is retained.

In systems with low pressure (as a rule, these are independent lines in private residential buildings), it is also necessary to take into account the inlet water pressure. There are often cases when forced circulation from a pump “competes” with natural (gravitational) circulation.

The hot water flow is directed into the heated towel rail, where it cools and falls down. In this case, the water either passes in one direction without heating the remaining tubes of the device, or stops moving altogether.

Summing up

Analyze the old diagram: diameters, presence of a jumper, feed direction. Try to keep the pipe sections unchanged. When connecting the heated towel rail, follow the recommendations given and the manufacturer's instructions.

Check the functioning of the assembled circuit before finishing finishing work. The dryer is left connected for half a day. A test run will allow you to identify leaks, heating problems, and eliminate shortcomings while access to the wiring is free.

Advice! If you need bathroom renovation specialists, there is a very convenient service for selecting specialists from PROFI.RU. Just fill out the order details, the experts will respond and you can choose who to collaborate with. Each specialist in the system has a rating, reviews and examples of work, which will help with the choice. Looks like a mini tender. Placing an application is FREE and does not oblige you to anything. Works in almost all cities of Russia.

If you are a master, follow this link, register in the system and be able to accept orders.

Instructions for connecting a heated towel rail to a hot water riser

There are several ways to connect a “towel bar” to a riser; we will consider each of them separately.

Horizontal side mounting

This heated towel rail connection scheme is popular primarily because of its simplicity.

Horizontal installation is carried out in the following order:

- The device is installed on the wall. To do this, use the fasteners supplied with it.

- The insertion points are marked on the riser. The device must be embedded in such a way as to ensure a slope of the liner of 5-10 mm per meter of length.

- The water in the riser is turned off, and the remaining water is drained. After this, the tap is opened to relieve pressure in the pipeline.

Important! In order for everything to be legal, turning off hot water must be coordinated with the housing office or management company. You should also warn neighbors living below and above who use water from the same riser.

- Holes are burned out in the pipe using welding to create a bypass, or a section of the required length is cut out.

- To make bends, pieces of pipe suitable in diameter are used.

- Shut-off valves are installed - usually ball valves.

- The bends are welded to the riser directly or using fittings (tees).

- The heated towel rail must be connected to the pipeline using American connectors (split union nuts with internal thread).

Important! To prevent electrolytic corrosion, it is necessary to use couplings and fasteners made of the same material. An exception is metal-plastic, polyethylene and polypropylene pipes.

Installation with non-narrowed bypass

There is no bypass section here; the bypass function is performed by the vertical pipe itself. The horizontal terminals of the “towel holder” are connected to it, and the area between them is, in fact, a bypass.

When installing a non-narrowed bypass, the cross-section of the riser does not change. But the efficiency of the heated towel rail may decrease due to the hydrodynamic resistance of the installed device. A large number of crossbars leads to stagnation of cooled water, preventing the flow of hot water.

Note! Insufficient throughput of ball valves also leads to a decrease in the efficiency of the “towel box” - the flow circulation will decrease. Therefore, taps should be installed with a diameter such that the nominal diameter of the pipe does not decrease.

Installation with narrowed bypass

In the area from the entrance to the device to the exit from it, a pipe is installed, the cross-section of which is reduced by one step. For example, if the riser is made of an inch pipe, then a piece with a cross-section of ¾ inch is inserted. This will lead to a redistribution of flow in the riser.

On the one hand, the volume of water entering the heated towel rail increases, which leads to an increase in its operating efficiency. On the other hand, when the device is turned off, the operating mode of the entire DHW line is disrupted.

Using a narrowed bypass is risky and in some cases undesirable. The pressure in the line is unstable, which often leads to pipe ruptures and even water hammer.

With offset bypass

The offset bypass equipment allows you to increase the flow energy directed to the heated towel rail. The design provides for a smooth bending of the riser connections adjacent to the bypass and outlets. The efficiency of the heated towel rail is increased due to the horizontal direction of the flow.

But when considering this option, one cannot do without a “fly in the ointment”. If the riser has not yet been “damaged” by other residents of the house and a good circulation pump is installed in the basement, then everything goes as it should: there is a circular circulation in the heated towel rail. Hot water flows upward through the left collector, cooled water flows downward through the right, and mixes with the hot water through jumpers.

But if one of the neighbors installed a tap on the bypass or fed a warm floor from the hot water supply line, the circulation intensity will decrease and the “towel rack” will work unstably.

Bottom connection

When connecting from below, it is allowed to supply pipes without installing channels in the walls. For ease of connection, it is necessary that a minimum distance of 0.5 m be maintained between the points of insertion into the riser.

To connect, the same steps are performed sequentially as for side mounting. You need to attach the heated towel rail to the wall using the fasteners included in the kit.

Diagonal connection

This method is considered a side connection option. The lower outlet is connected to the far lower point of the device.

Installation is carried out in the following order:

- The dryer is mounted on the wall.

- The water supply is turned off, and points for outlets with a predetermined slope are marked on the riser.

- The lower (short) and upper (long) branches are connected to the riser.

The connection can be made vice versa: from above - a short supply, from below - a long one.

Universal method

Another option for side connection of U/M-shaped heated towel rails without bypass offset. The sequence of actions is similar to connecting diagonally.

Advantages of this method:

- independence from circulation intensity;

- any direction of flow;

- the possibility of placing the device at a distance of up to 5 m from the riser.

The scheme is operational if the following conditions are met:

- the bottom of the “towel box” should be located above or at the same level as the lower outlet of the riser;

- when supplying water from below, narrowing the bypass is not allowed;

- when supplying from above, it is allowed to install a narrowed bypass one step smaller than the cross-section of the riser.

Types of fittings

Sectional extension cord. A representative of this category will help you, if necessary, adjust the distance from the heating device to the wall to which it will be attached. These fittings act as a kind of bracket, the connection of which requires at least several fasteners. Extended collapsible fittings are connected only in front of the pipe bends. This modification of connectors has one minor flaw - they have too long threads

However, this problem can be quickly fixed (threaded fittings for copper pipes are described in this article). How? Excess grooves can be quickly and easily removed (cut off or sharpened).

Winding made of polymer materials. This type of fitting eliminates the possibility of play at the adjusting connections. If the winding is done correctly, it will take the look you want. It is also worth taking into account the following fact: the above-mentioned part will not compact over time.

Angle tap. It is used to connect a tubular radiator directly to a central heating pipe. Depending on the size of the hollow products used, you can use either standard modifications of the corners or choose the option that you find more convenient. With the help of corner fittings, you can change the direction of the pipes at your discretion.

Tee. This simple connecting element will be very useful to you if you need to make a number of branches from the central highway in different directions. Using this fitting, you can directly connect the heating device and the riser. At the same time, do not forget to install a bypass. The bypass line will allow you to turn off the heated towel rail for a while, without creating any obstacles to the operation of other heating devices.

Cross fittings. With their help, the system is branched along only two different courses.

American fitting. If you need to dismantle the structure, this can be done using a kind of crane called an “American”. It is very difficult to overestimate the ease of use of this fastener - you will not need to completely disable the system. It is enough just to close this device, unscrew the nut and remove the heating device.

In this case, there are several types of connections: nut - fitting, nut - nut, fitting - fitting.

Clamping device. Implements similar functions as the “American” one. Thanks to this coupling, you can quickly disassemble and reassemble any connection. This part has one feature - it has different diameters on different sides. This property is used when there is a need to join pipes of different sizes

The thread of the clamping ring can be either external or internal.

Reflectors. These fittings do not allow moisture to seep into the fixture (read how to fix a leak in a water pipe here).

Limiters. They are used to seal pipes

When purchasing chrome-plated fasteners for tubular radiators, you need to pay special attention to the quality of the threads. The high quality of the product can be judged by the uniformity of the grooves.

The high quality of the product can be judged by the uniformity of the grooves.

Another feature of non-chrome-plated connections is that they quickly undergo the rusting process.

Your best decision will be to purchase a heating device along with fittings.

This way, you will save yourself from searching for the parts you need or exchanging existing but incorrectly sized parts.

Connection to the boiler

Connecting a heated towel rail to a boiler is considered an exceptional option. The scheme is used only in cases where the implementation of other methods is impossible. For example, in the absence of hot water supply in a private house heated by a single-circuit boiler. The supply of cold water to the boiler and the supply of hot water to the “towel box” is carried out through flexible hoses. They are connected to the device using a stainless steel or bronze coupling. The temperature of the water, and therefore the heated towel rail, is set using the water heater thermostat.

The disadvantage of this scheme is the inconsistent heating of the dryer. The hot water circuit is connected through the device and the flow directed to the mixer first passes through the “towel box”. This means that the jumpers and racks will only be warm during selection - when the hot water tap is turned on. To avoid airing the system, a Mayevsky valve must be installed - accumulated air is periodically released through it.

Required Tools

Before installation, you must ensure that you have all the tools. The presence of certain devices depends on the type of pipes. Taking into account standard steel options, the following equipment is needed:

- gas (number 2), attachment and wrench;

- hacksaw for metal;

- thread-cutting dies;

- electric drill with hammer drill, concrete drills;

- angle grinder (grinder);

- hammer, pliers and screwdriver;

- level, tape measure and pencil.

In addition, you will need a number of consumables:

- bends, bends, couplings, etc.;

- shut-off valves;

- flax tow;

- screws, dowels, bolts and brackets.

Why are parts chromed?

A layer of chromium applied to the surface of the metal forms an oxide protective film that prevents the iron from reacting with oxygen and rusting.

In addition to this main function, chrome, due to its silvery-white color with a bluish tint, perfectly fulfills a decorative role.

And finally, this metal is one of the hardest, it gives the workpiece additional strength.

Mounting methods

The following types of fitting connections are distinguished:

- Threaded. The most common and widely used by home craftsmen.

- Compression connection. It is based on the use of crimp rings onto which a union nut is screwed, resulting in a reliable connection. This fastening must be monitored and the nut must be tightened periodically.

- Capillary soldering. Suitable for metal pipes. Solder (wire) is placed between the fitting and the outlet, which melts when heated and fills the solder space. It is rarely used when installing drying devices.

- Pressing method. It is necessary to use special pressing equipment. This results in a permanent, reliable connection.

- Self-locking fittings. Fastening is carried out using a toothed ring located inside the fitting, which, when pressed with a special key, securely fixes the element.

Which heating element should you prefer?

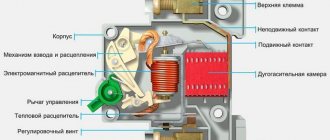

The design of electric heated towel rails includes a special heating element. This can be a special cable or heating element.

“Dryers” with a heating cable, as a rule, do not have thermostats or fuses. Purchasing these items separately significantly increases their cost. Therefore, most buyers choose the second option - a heated towel rail with a heating element and a thermostat.

We have already talked about a flow-through electric heater, the main heat source of which is a heating element. Tubular Electric Heater (TEH) has a wide range of applications: washing machines, radiators, boilers. And heated towel rails are far from the last place in this list.