When connecting sewerage from a private house to a septic tank or local treatment facilities, the main issue is the correct layout of sewer pipes. The process is not considered difficult, but during work it is required to adhere to SNiP (building codes and regulations) standards to ensure proper operation of the sewerage system. Ignorance of installation principles can lead to improper drainage and breakdown of the entire system.

All work on bringing the sewer system into the house can be divided into several stages: selecting sewer pipes, digging a trench of the required width and depth, connecting the pipes to each other and laying them. The final stage is the insulation of sewer pipes followed by backfilling of the trench. We will analyze each stage of work in detail.

Choosing pipes for laying in the ground

External sewerage pipes experience more severe loads than those located inside the building. In internal networks, pipes are laid along the walls; in extreme cases, sewerage pipes are laid under the floor.

External sewerage pipes are laid in deep trenches, and they have to experience soil pressure. Advice! If it is necessary to lay a sewerage pipeline under a road, it is necessary to use pipes of the highest strength class.

Sewer pipes for laying in trenches

A special type of pipes is produced for external networks. To prevent consumers from being confused with the choice, manufacturers paint such pipes brown-orange or red. While pipes intended for installation of internal sewage systems are usually dark gray.

The following types of pipes are used to assemble external sewerage:

- Smooth polymer - made of PVC or polypropylene.

- Corrugated polymer - made of polyethylene or polypropylene.

- Cast iron.

- Asbestos-cement.

It must be said that polymer pipes are most often used. Moreover, corrugated products are recommended to be used where the load is especially high - when deep installation is necessary or when placing a pipeline under a highway.

Advice! The most common pipe size used for the construction of external sewerage in a private house is 110 mm. In addition to pipes for assembling the pipeline, it is necessary to purchase shaped parts - bends, crosses, revisions, etc.

Procedure for replacement

Let's look at how to replace a cast iron sewer with a plastic one. The main difficulty of the procedure is replacing the riser. Most often it is necessary to replace the vertical part of the system in one apartment. This is a rather complex and responsible procedure. It is necessary to carefully remove a section of the old riser, and then insert a vinyl fragment in its place. At the same time, it is important not to collapse the upper part of the old assembly, otherwise you will have to restore everything at your own expense.

If it is necessary to completely replace cast iron sewer pipes with plastic ones, remove all old parts of the system. Work begins from the top floor, gradually going down. This option is considered the simplest. Sequential dismantling is carried out, after which the assembly of system elements begins from below. The main labor costs come from disassembly, since the old elements were connected very reliably. Connecting PVC nodes is not difficult and is done very quickly. First, the riser is installed, and a tee is attached at the required height to drain the horizontal line. Assembly begins from the riser and continues until the very last plumbing fixture.

Sometimes the riser is not touched. All you need to do is replace the cast iron sewer tee with a plastic one. This is done in cases where the vertical part is still relatively new and can stand for a long time. Then only the tee (or crosspiece, if the system configuration is complex) is changed. To connect dissimilar elements, special rubber adapters are used.

All sizes are available for sale. Finding an adapter is not difficult, you just need to know the diameter of the metal pipeline.

Stages of laying external sewerage

Many people, thinking about installing sewerage into their home, wonder how to lay sewer pipes? The whole process can be divided into several stages:

- Drawing up a plan for the future sewer system and calculating all the necessary materials that will be needed to install the system. Here, not only the required length of pipes is taken into account, but also all the necessary corners, transitions and branches that may be needed are calculated.

- Carrying out all earthworks.

- Installation of the entire pipeline.

- Carrying out backfilling.

This instruction will help you lay a sewer system in a country house or cottage without any unpleasant surprises, since all possible cases have already been calculated at the planning stage, and thus you have nothing to fear.

Laying depth

The process of installing a sewer system in a country house is simple, but it is best left to specialists. If the work is carried out independently by the owners, then it is necessary to carefully consider the arrangement of the system and select a high-quality basis for collecting wastewater: most often a septic tank is used for this. In addition, the depth of the well and trench should be correctly calculated; it should be minimal. When installing a drainage pit near the house, it is recommended to maintain a distance of 5 meters, and the septic tank should be deepened into the ground by 1.5 m. Thanks to these parameters, it is possible to protect the septic tank from the negative influence of groundwater and avoid its damage.

To know at what depth to lay communications, it is necessary to determine the level of the building. When laying a pipeline from a building to a septic tank, it is advisable to make the system absolutely straight, avoiding bends and turns. It is best to lay pipes at a depth slightly above the freezing point of the soil. At the same time, we must not forget that under the sites or roads where the pipeline is located, they may freeze in winter, as the snow will be cleared. In such situations, the depth is increased.

Standards according to SNiP

Installation of external sewerage is carried out in accordance with SNiP standards, which stipulate the maximum and minimum permissible installation depths, but they may vary depending on the characteristics of the system and methods of laying pipes. For structural elements that are used to drain dirty wastewater, a recess of 30 cm from the ground surface is allowed; their cross-section is chosen to be no more than 50 cm. Pipes with a diameter of more than 500 mm must be laid to a depth of at least 50 cm.

In addition, it is worth remembering that sewage waste at the outlet, even in winter, has a high temperature, which on average can reach +18C. Therefore, they never freeze when passing to the collector. Using this property, it is possible to reduce the depth of the pipeline, but this is most often done when the distance between the system exit from the building and the collector is insignificant. It is also worth noting that the minimum installation of sewerage according to SNiP standards also depends on the type of loads affecting the soil surface in the areas where the system is being constructed. If they are high, then the pipes must be closed.

Factors for selection

The choice of trench depth is important for many reasons. For example, if pipes are laid at the level of freezing of the ground, then liquid waste can cool down, as a result of which a congestion will appear, and the sewer system cannot be used until the weather warms up. You can also avoid blockages by installing a minimum number of connections. In cases where it is impossible to avoid turning the pipeline when installing it, a well is installed at the joining points. Access to it must be free.

To calculate the optimal depth for laying external communications, be sure to take into account the diameter of the pipes, the material from which they are made, and the angle of inclination of 0.03 m for each linear meter of the system. The point where the sewage system exits the house and the location of the cesspool also play a huge role.

Reduction options

In some cases, it is possible to reduce the installation depth of external pipes. Most often, this is available if pumping stations are connected to the system; they provide quick cleaning of the channels and thereby clear the pipes, whether cast iron or steel, from freezing. Such systems are considered not gravity, but semi-pressure. The penetration is also reduced when the pipes used are made of durable material and have thick walls. The depth level can also be reduced by insulating the route; for this, a plot of land is covered with a special bedding, and decorative mounds or flower beds are placed on top.

The main types of autonomous sewerage for a country house

Despite the fact that many consider cesspools to be a thing of the past, this type of autonomous sewage system is the easiest to build with your own hands.

An equally important argument in defense of cesspools is the fact that their internal arrangement has now changed.

Before you make a sewer system in your house like a cesspool, you need to find out the engineering and geological features of your site.

The easiest way to build the walls of a cesspool is from brickwork, with red ceramic brick being the most acceptable option.

If it is possible to use additional equipment, then you can build a cesspool from reinforced concrete rings. Experts recommend concreting the bottom of the cesspool, covering the pit with a slab with ventilation and a special inspection hatch.

Septic tank made of polypropylene

Are you still undecided on how to make a sewer system in a private house yourself?

We recommend installing a local autonomous sewage system, for example, a septic tank.

This type of sewage system is especially relevant in those houses where people constantly live, and has gained particular popularity among Russians.

The septic tank is quite simple and reliable to use; it can be easily installed on your own by following the step-by-step installation guide (it is included when purchasing a septic tank, for example, their polypropylene).

In addition, septic tanks do not require frequent cleaning, so you will spend less money on calling a sewer truck.

Modern septic tanks are even three-chamber; they have a very high degree of purification of wastewater and domestic water thanks to elements of the aeration system and biofilters.

Sewerage in a private house video will help you decide which type of autonomous sewer system is most suitable for your home and site.

Sequence of actions during the construction of an individual sewer system

Before making a sewer system in the house, you need to decide on the initial steps:

Determine the area where the sewer well (cesspool or septic tank) will be located.

Important: the drainage well must be located below the level of the house. Determine where the sewer exits the house. Carefully inspect the exit point of the collector pipe. Please note that at this point all drains and used water from all plumbing fixtures in your home will accumulate (kitchen sink, toilet, bathtub, boiler). Inspection of the place where water enters from the entire house is necessary in order to to ensure that the collector is installed correctly (there should be no distortions or deviations). Only after a preliminary inspection has been carried out can a preliminary design for the sewer system of a private house be drawn up. Please note: the external sewer system is usually straight, the internal sewer system usually has many bends and angles. Therefore, when drawing up its project, it is very important to calculate all the dimensions of the pipes, their bends, and so on. Only after everything has been thought out and calculated can you begin to purchase the necessary materials. We begin the installation of external and internal sewerage systems.

Bends for corrugated pipes Korsis

Korsis corrugated pipes are products made using the latest technologies; the design features a two-layer structure with smooth internal walls and a black outer corrugation that protects the surface from ultraviolet radiation. Thanks to this structure, the pipes have high ring rigidity, allowing them to be used at great depths. The material of the pipe inner walls is polypropylene - this allows the products to be used at temperatures of flowing liquids of about 65 C.

Rice. 8 Korsis pipes, socket with O-ring - design and appearance

Carrying out internal sewerage

Recently, polypropylene pipes have become especially popular. They do not corrode, so their service life is much longer than pipes made of steel and cast iron.

And installing polypropylene pipes is not that difficult. However, you need to take into account this fact: how many sources of drainage are there in the house.

For those houses where many plumbing fixtures are installed, a pipe with a diameter of at least 100 mm will be required. Consider this fact: when leaving the washbasin, the pipe has a diameter of 50 mm, so you will have to join pipes of different diameters.

But today this is not a problem - there are special adapters. Therefore, you don’t have to worry about sealing the joints - it will be reliable.

It’s a good idea to check the quality of the gaskets: they should not be damaged. Then there will be no leaks at the joints.

Connecting plumbing fixtures

As a rule, the riser is equipped with an inspection (it is installed from the floor at a height of at least 1 m) and a special exhaust pipe (it is installed 0.7 m above the roof of the house).

Why is such a complex riser design needed?

Connecting a private home to a sewer system involves the formation of gases and an unpleasant odor.

If the riser is equipped with reliable ventilation, then this is a guarantee of ventilation of the entire sewer system in a private house.

Essentially, polluted air is forced out through the riser. And the people living in the house do not suffer at all from the unpleasant odor.

Important: insulate the riser if it is located in an unheated room. In order to connect the riser to the external sewer, you need to use a special outlet, its diameter should be smaller than the diameter of the pipe on the riser

Experts recommend installing the outlet to the riser along the movement of dirty water at an angle of 90 degrees or more. To connect the risers, two bends with an angle of 135 degrees are used.

In the case when another additional riser is required, then you need to use an oblique tee with an angle of 45 degrees and another additional outlet.

Therefore, it is much easier to connect to the sewer system of a private house yourself if there is one riser or one collector pipe.

For laying external sewerage, a polypropylene pipe with a diameter of 150 mm is best suited.

Sewer fittings

For those who still doubt their own abilities, we recommend watching: how to make a sewer system in a private house video. We hope that all your doubts will disappear and you will get to work with enthusiasm.

Basic Rules:

(return to main content)

These rules are formulated based on the operating principle of gravity (free-flow) sewerage , and if any of the provisions set out below are not clear enough, then you can refer to the specified article for clarification.

The fewer joints and turns you make when laying pipes, the more reliable the system will work.

Each joint or turn is a potential site for sewer leakage due to poor-quality joining and, in addition, additional resistance for liquid and especially solid waste.

The sockets of vertical pipes (risers) and horizontal pipes must be directed towards the movement of wastewater.

This is done in order to minimize the risk of sewer leakage. And it’s unlikely that you will be able to lay horizontal pipes differently. Sometimes, in the case of repairing a sewer pipe, it is allowed to install connecting (slide-on) couplings, in which one branch pipe (bell) is directed along the movement of wastewater, but in general it is advisable to avoid using couplings; if you cut the pipe , it is better to buy a new one.

Cutting and shortening of shaped parts (sockets) is prohibited. The following are not allowed for installation:

- all pipes, pipes and fittings that have chips, cracks or cuts;

- shaped parts having an internal lining with sharp edges;

- rubber rings and cuffs that have ruptures, cavities and unremoved pressing, as well as rings that do not have plastic spacers provided by the design;

- metal fasteners, the elements of which have sharp edges and burrs at the points of connection with pipes and fittings.

Logical and without comment.

The diameter of the pipes depends on the number of connected sanitary fixtures and the slope.

Of course, there are formulas that allow you to calculate the diameter of the pipe depending on the slope, the number of joints and turns, taking into account the number of sanitary fixtures or, more simply, washbasins, bathtubs, sinks and toilets. But in practice, these formulas for indoor wiring are rarely used, and there is no great need for this. And besides, the exact calculation of the required pipe diameter is the topic of more than one scientific dissertation.

Pipes with a diameter of 100 or 150 mm are placed on the riser and on the area connecting the riser to the well, and if you had a cast iron pipe with a diameter of 200 mm (although this is very rare - pipes of this diameter are installed on risers only if the number of connected sanitary fixtures is more than 1200, I don’t think If this is your case, although anything is possible), then a new plastic pipe must be installed with the same diameter. The exception is their own homes. There, the sewerage system was laid not from the pipes required by technical specifications, but from those that were available.

For internal horizontal wiring, pipes with a diameter of 100 mm are usually installed when connecting the toilet to the riser, all other pipes with a diameter of 50 mm (sometimes 40 mm).

If you have some incredibly complex wiring, and you doubt that a diameter of 50 mm will be enough for normal sewer operation, then you need a hydraulic calculation of the pipelines. And to understand the intricacies of the movement of wastewater and waste through a sewer pipe, sometimes a higher technical education is not enough. If you still want to try it yourself, then take a look at SNiP 2.04.01.85, or familiarize yourself with the basic provisions of the hydraulic calculation of sewer networks. There you can also find out the water flow and the amount of waste from any sanitary fixture and, accordingly, the minimum diameter of the connected sewer, and determine whether the main conditions are met: flow speed of at least 0.7 m/s and pipe filling (ratio of water height to diameter) of at least 0.3; what to do if these conditions are not met, and many other interesting things that I am trying to briefly outline in this article.

Horizontal sewer pipes must be laid with a slope towards the riser.

Since the sewage system is non-pressure, and pressure losses occur due to air resistance and friction of the pipe walls, a certain slope of the pipes is necessary to maintain the flow rate. And to prevent the pipes from silting (self-cleaning of the sewage system), the flow speed must be at least 0.7 m/s - to ensure turbulent flow of liquid, and the filling of the pipes must be h ≥ 0.3d. Like the diameter, the slope of sewer pipes is determined by calculation. When the volume of wastewater is not sufficient to satisfy both conditions, flow turbulence comes first. When performing standard intra-apartment wiring or installing a sewer system for a small private house, the following requirements must be observed:

Minimum sewer pipe slope i=0.025 for pipes with a diameter of 50 mm, recommended slope i = 0.035

Minimum sewer pipe slope i=0.015 for pipes with a diameter of 100 mm, recommended slope i=0.02

i is the ratio of the height difference between the center of the pipe diameter and the length of the pipe. Translated into normal human language, this means that if you have a sewer pipe 1 meter long, then if the bottom of one of its sections touches the floor, then the bottom of the second should be 2 cm above the floor level, of course, provided that your floor is horizontal and the increase in diameter at the socket for joining pipes is taken into account. In this case, the slope of the pipe is assumed to be equal to the hydraulic slope of the fluid flow, thus ensuring a constant flow speed.

Maximum slope for horizontal sewer pipes i=0.15

With large slopes, the speed increases significantly, which in turn increases the force of the hydraulic shock and can lead to clogging of the pipe in areas with high local resistance (changes in the trajectory of the fluid - turns of sewer pipes, the point of connection to the riser). Although this limitation is conditional - it is unlikely that you will be able to lay a 10-meter long pipe with such a slope (external work does not count). If the pipe length is less than 1.5 m, this limitation does not apply, since in such a relatively short section of the pipe the wastewater will not have time to develop a high speed.

Recommended sewer pipe slope i=0.04-0.07

The floors may not be horizontal and determining the slope of the sewer pipe based on the floor level may lead to an error; the foundations of houses may sag, which is why the slope of the pipes may not change for the better. To avoid problems with the operation of the sewer system, it is advisable to make a slope of 4-7 cm per meter (for pipes with a diameter of 50 mm). The more turns and joints there are on the sewer route (see point 1), the greater the slope must be to compensate for local resistance.

If pipes are laid without a slope or even with a counter-slope, then such pipes will clog quite often. The correct solution to the problem would be to eliminate counter-slopes or other causes that lead to clogging of the sewer, but this is not always possible; in such cases, a check valve .

Questions about sewer slope are collected in a separate article.

For normal sewerage operation, pipes must be secured to the floor or wall.

Plastic pipes, unlike cast iron ones, are easily deformed and long loose sections can sag, which will lead to a change in slope. To prevent this from happening, the pipes must be secured to the wall or floor with special fasteners (sold in the same place where the pipes are) every 50-100 cm, depending on the diameter of the pipe. Fastening the riser pipes to the walls is also necessary to reduce the load of its own weight. In addition, it is recommended to fasten pipes in places of turns and connections to partially absorb the load from water hammer.

Availability of fan ventilation.

The ventilation pipe, which is installed on the roof of the building or in the attic, is designed to equalize the air pressure in the drain pipes, which can drop sharply if a large volume of water is discharged through the riser, for example from a toilet. A sharp decrease in air pressure in the riser sucks water out of the siphons of plumbing fixtures, thereby destroying the water seal. And this leads to free access to the apartment of sewer gases with extremely unpleasant odors. In addition, these gases can cause dangerous diseases. As a rule, all houses with more than two floors, and often even two-story Stalin buildings, have fan ventilation. Moreover, if you, living on the top floor, want to remove the pipe leading to the roof during redevelopment (and changing the riser route is redevelopment), then no one will officially allow you to do this, but unofficially, options .

For small volumes of wastewater, the use of an unventilated sewer riser is allowed. Those. The riser does not lead to the attic or roof. In this case, at the point where the horizontal wiring is connected to the riser (according to building codes), it is necessary to “clean out” and close it with a plug (so that wastewater does not leak out). And if, in addition to cleaning, you also make a vertical outlet for a non-return air valve that costs $4-10:

(of course, if you wish, you can buy a branded valve for $100), then in the future you will save time, money and nerves necessary for cleaning the sewer.

If for some reason you do not have the opportunity to place a check valve directly on the riser (this sometimes happens when repairing sewerage in your houses), then a check valve with a diameter of 50 mm can be placed on any section of a horizontal pipe, but it is desirable that the valve be located on height 30-50 cm from the axis of the sewer pipe. Installation options for a non-return air valve can be as follows:

Option A is the most correct. Option B is acceptable in your homes, for example, at the dacha I installed a check valve according to option B four years ago. Option C is also acceptable in your homes when it is not possible to install a check valve on the riser, for example, I installed a check valve with a diameter of 50 mm according to option C for my sister, who lives in her house 5 years ago, according to option C; I placed the outlet for the check valve under the bathtub (the fact is that other people did the drainage for my sister and did not provide for ventilation, and then it was easiest to insert an outlet for the air valve under the bathroom). The diagrams do not show outlets for cleaning.

The essence of the operation of a non-return air valve is that it allows air to pass in only one direction - into the sewer; when water is flushed in the toilet, the air pressure in the sewer pipe in the area up to the toilet and in the riser (if any) decreases and the valve opens. When the air pressure in the sewer pipe is the same as in the room and greater than in the room, the air valve is closed - this prevents gases from escaping from the sewer, so if installed correctly, there should be no odors in the room where the air valve is installed. It makes no sense to install an air valve on the sewer pipes after the toilet; in this case, the valve will not work correctly. When the water in the toilet flushes, and the toilet is a plumbing fixture that creates the maximum flow of wastewater, then the air pressure in the sewer pipe after the toilet will be increased. The higher the non-return air valve is from the axis of the sewer pipe, the lower the risk of clogging the valve with wastewater when the sewer is clogged, so option A is the most correct.

Questions about the check air valve are collected in a separate article.

It is necessary to install “cleaning” in places of turns, changes in angle of inclination and connection of a sanitary fixture to a sewer pipe.

A good rule, but it was observed a long time ago, when installing cast iron sewers. In old houses you can still see somewhere under the sink the appendix of a sewer pipe with a wooden chop sticking out of it for a good 20 cm. Nowadays, plumbers who install plastic sewers do not install “cleaning” (at least I have not seen them) for several reasons. Firstly, sewer pipes are often sewn up for aesthetic reasons. Secondly, modern plastic sewerage, unlike cast iron, is quite easy to disassemble and, if necessary, you can always disconnect some sanitary appliance, for example, a washing machine or sink, and insert a cable through the resulting hole for cleaning.

The inspection (inspection hatch) should be installed no more than 15 m apart.

In five-story buildings, audits were installed on the first and last floors. If on your sewer riser at a height of about 1 m from the floor there is some kind of iron plate, screwed with powerful bolts and causing unpleasant associations with kingstons, then this is an inspection. The revision for plastic sewerage looks much more aesthetically pleasing:

If you are going to sew up the riser, then make an inspection hatch to access the revision.

Plastic sewer pipes can be joined to cast iron ones.

If you have a cast iron riser, it is not at all necessary to replace cast iron pipes with plastic ones if the riser is in good condition. In addition to significant physical effort, you will also need a lot of moral effort to convince your neighbors not to use the sewer for several hours and, as usual, someone will definitely forget. But even if you completely change the cast-iron riser to a plastic one only in your apartment, you will still have to join plastic and cast-iron pipes .

When transitioning the riser into a horizontal pipeline, it is prohibited to use a 90° bend.

(SP 40-107-2003, clause 4.16)

It is recommended to make the transition with 2 bends at 45o, 3 at 30o or 4 at 22.5o.

A good rule, the observance of which allows you to reduce the force of water hammer, the turbulence of the flow of liquid waste and thereby avoid frequent sewer blockages. If the sewer system in your multi-storey building is often clogged, go down to the basement and check whether the builders violated this rule when installing the sewer system.

And if you have your own home and 5-6 sanitary fixtures are connected to the sewer, then you can ignore this rule.

It is allowed to lay plastic pipes in the ground in the absence of additional external loads.

Inspection wells are installed at a distance of no more than 50 m, as well as in places of turns, changes in the angle of inclination and height differences of the pipeline.

The first inspection well is installed at a distance of no more than 8 m from the axis of the riser - with an outlet diameter of 50 mm, 12 m - with an outlet diameter of 100 mm, 15 m - with an outlet diameter of 150 mm or more. In general, the last two rules are relevant for owners of private houses involved in sewer installation. Usually these people are smart and don’t need additional comments. But just in case, I will give a link to an article that briefly describes the design of sewer wells .

UPD: I was wrong, a lot of questions about laying external sewerage have accumulated, so I put them in a separate article.

Factors that determine installation depth

When choosing the depth of pipe laying, it is necessary to take into account a number of factors that have a significant impact on this value and, accordingly, determine the cost of installation work.

- Purpose of the sewer network.

- Method of laying sewerage.

- Climatic conditions in the region.

- Possibility of additional load on the sewer pipe.

Let's look at these criteria in more detail.

Types of sewer networks

For most ordinary people, sewerage is associated only with the removal of sewage from residential premises, but in fact, the concept of sewerage is more extensive and includes various networks.

Storm drainage system

- A storm drainage device is designed to collect and drain atmospheric precipitation. The depth of the storm drainage system should not be less than the depth of soil freezing. When insulating the system, it is possible to reduce the depth to 0.7 meters.

- Cable ducting is designed to ensure the safety and possibility of replacing electrical lines. Laying electrical cables in special pipes greatly simplifies the installation process. The depth of the cable duct is determined mainly by the material of the pipes from which it is made. When using plastic pipes, it should be at least 0.4 m, and when using steel sewers - 0.2 meters.

The depth of laying a domestic sewer depends on a whole range of factors, which we will consider below.

Installing a new

- A rubber cuff is placed on the upper cut of the cast iron pipe. The connection is carefully coated with sealant.

- A plastic adapter is installed on top of the cuff.

- At the bottom, a second rubber adapter is inserted into the socket.

- The compensator is installed in the tee, each connection is carefully coated with sealant.

- The pipe is firmly fixed to the wall with clamps to avoid displacement.

Installation of a plastic riser

It is important to accurately calculate your strengths and capabilities when carrying out such work of increased complexity. Replacing a sewer riser is a job for an experienced team of plumbers.

In the event of a mistake and a sewer break, the cost of the error can be very high.

Construction of an external sewer system

If the internal sewerage system of a private house is practically no different from the sewerage system in an apartment, then the scope of work in the first and second cases differs significantly.

There is much less work to do if the house already has an old sewer system. In this case, you just need to dismantle the old pipes and use the same sewer paths as before.

But it may happen that you have to completely redo everything. In this case, there is a lot of work ahead: you need to raise the floor (spread it) and if the depth of the sewerage outlet from the house is not sufficient, we deepen it.

To do this, we dig a hole under the foundation, then measure the distance from the bottom edge of the foundation to its top edge.

This distance should be 1 meter or more, then the drains in the collector pipe at the exit from the house will not freeze, even in the Russian winter.

From the outside of the house we also dig a trench to the drain well. Moreover, experts recommend digging a trench deeper on the street than inside the house, and ensuring its constant slope.

This measure is necessary to ensure the unimpeded flow of water and wastewater.

Waste collector

If there is no way to the central city sewer, you will have to take care of the waste disposal problem yourself. To do this, you will have to build a septic tank or drainage pit on your personal plot.

Laying sewer pipes in the ground is not the only work that is carried out outside the home. In addition, you should make a place for drainage. The simplest option is to build a pit. This is a more economical process and does not require special technologies. But you should know that the waste storage tank cannot be placed closer than five meters to the house and thirty meters from the well. Such a pit is made mainly in the far corner of the territory. The distance between sewer pipes and water supply should not be less than three meters.

The size of the drainage pit is calculated based on the residents of the house. So for each resident it is necessary to take into account about half a meter (cube). But if several people constantly live in a building, you will have to call a sewer truck several times a year.

How to properly lay sewer pipes in a trench

A do-it-yourself sewerage system in a private house involves laying pipes both inside and outside the house. Let's take a closer look at laying external pipes.

Connection of sewer pipes

Experts recommend pouring a layer of regular sand (about 15-20 cm thick) onto the bottom of the trench. This measure will save sewer pipes, including those made of polypropylene, from excessive pressure.

On sand, the pipes will sag slightly and take a comfortable position. This will save them from excessive pressure from the buried soil.

An important issue when laying sewer pipes is their connection and sealing of joints.

An inspection is needed so that if the pipe becomes clogged, it can be cleaned. We advise you not to save on installing revisions; the money spent will pay off during the operation of the entire system.

It is advisable to install an inspection after every 4 m; it is advisable to close the pipe exit from the outside with a special plug.

Why is the bias made?

In order for the water flow in the sewer to wash away solid particles, the pipes must be laid at an angle. In this case, the angle of inclination of the sewerage system must comply with the standards established by SNiP. But in pursuit of installation speed or using the labor of unskilled workers, you can end up with a sewer system made with serious errors:

- Ignoring the established standards, they do not make a slope at all or the sewer angle is very small. Thus, the movement of wastewater will be excessively slow and plugs of solid particles will begin to form in the pipes. Very quickly this will lead to the need to clean out the entire sewer system, because if a toilet is installed, but the pipe slope is not adjusted, then there will be practically no flushing and feces will begin to decompose right in the pipes, spreading the smell throughout the house.

- The angle of the sewer pipe is made too large. In this case, the drains through the pipes will move too quickly, washing the solid particles, but not taking them with them. This fact will again lead to clogged pipes, which will have to be cleaned regularly.

If the angle of inclination is incorrect, the water flow does not work Source termo-house.com

Do not neglect the standards established in SNiP, since they were determined based on calculations and observations over many years.

Features of pipe laying

- For an autonomous sewer system, pipes with a diameter of at least 110 mm are used.

- Plumbing equipment can be connected to the system with pipes having a diameter of 50 mm.

- The horizontal angle of adapters and bends should be 45 degrees.

- Slope the sewer pipe from the drain point to the septic tank. The slope per linear meter of pipe must be at least 2 cm.

- For sewerage passing through the site, inspection and inspection wells are installed.

- The sewer system pipeline is insulated if it is laid above the freezing level of the soil.

- Silicone or a special sealant is used to seal the connections.

- The sewerage system begins with a discharge point and ends with a treatment facility or wastewater receiver.

- To remove gas accumulations, the entire system is equipped with ventilation holes.

- To lay a cast iron pipe you need special equipment.

- Installation of the sewer pipe begins after marking the entire system on the site.

You can make a sewerage system yourself without the use of heavy equipment if you choose polymer or plastic pipes.

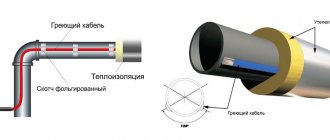

Installation of plastic pipes for heating

Visual installation diagram with description

The main problem that a home master solves when installing a new heating system: connecting plastic pipes to metal pipes. Industry responds:

- threaded connection fittings are available with cross-section up to 40 mm;

- from 40 to 300 mm – flanged.

The operating instructions are similar to connecting polypropylene pipes.

Pipe laying

Removing the sewer pipe from the house

The pipe laying process can be divided into three stages:

- Excavation.

- Pipeline assembly.

- Backfilling.

Excavation work

Before laying sewer pipes, it is necessary to properly prepare the trenches. Rules for performing earthworks:

- Trenches can be dug by hand or using earth-moving equipment.

- The width of the trench should allow the installer to work with the pipe while at the bottom.

Advice! If the pipes have a diameter of 110 mm, then the width of the trench should be 60 cm.

External pipes laid in trenches

- It is more difficult to determine what is the optimal depth for laying sewer pipes. According to standards, it must exceed the depth of soil freezing in a given area by half a meter. But in practice this condition cannot always be met. If pipes are laid at a shallower depth, then care should be taken to insulate them.

- Trenches must be dug with a certain slope. As a rule, the project requires a slope of 2 cm per meter of pipeline.

- When digging trenches, they are made 10 cm deeper than the designed pipe laying depth. This depth will be used to create a shock-absorbing cushion.

- The bottom of the dug trench must be well compacted; if there are large boulders or frozen lumps of earth on it, then they will need to be removed, the resulting holes will need to be filled with earth and compacted there.

- Sand or fine gravel is poured into the bottom of the trenches. Compaction of the cushion along the entire length of the trench is not required. But in places where inspection wells are planned to be installed, the poured sand will need to be compacted at a distance of two meters in each direction from the well installation site.

- In those places where the pipe sockets will be located, pits are arranged.

Pipe laying and assembly

Laying external sewer pipes in trenches

Let's consider the basic rules for laying sewer pipes:

- The installation of the pipeline begins from the point where the pipe exits the foundation of the house.

- The pipes should be laid along the trench, and the pipe sockets should be directed in the direction opposite to the movement of the drains.

- We make pipe connections. To do this, you need to clean the bell well and make sure that the rubber O-ring is installed in it. The smooth end of the pipe, which will be inserted into the socket, is cleaned no less thoroughly. Make a preliminary measurement of how the pipe fits into the socket until it stops, placing a mark on the smooth pipe. To facilitate insertion of the pipe into the socket, silicone grease is applied to the smooth end. If there is no lubricant, you can use liquid soap or dishwashing liquid. The pipe is inserted into the socket, and in order to compensate for linear deformations of the pipeline, the pipe is not inserted all the way, but a centimeter gap is left (when inserting the pipes, they are oriented according to the previously set mark).

- If it is necessary to rotate the pipeline, you must use bends with an angle of 15 or 30. The use of bends with an angle of 90 degrees is prohibited.

- In addition, the technology for laying sewer pipes involves the installation of inspection wells. These devices are necessary to monitor the operation of the pipeline and carry out cleaning in case of blockage.

- If this is provided for by the project, then the pipes are insulated. For this purpose, it is recommended to use insulation based on foamed polyethylene.

Performing backfill

Preparing to fill pipes in trenches

- Once the pipeline has been assembled and the slope of the pipes has been checked again, backfilling can begin.

- It is recommended to fill the first 10-15 cm of the backfill height with sand. In this case, it is necessary to carefully compact the sand along the edges of the pipe, but compacting the backfill on the pipe itself is strictly prohibited.

- Next, the pipeline can be backfilled with ordinary soil, which was removed when digging trenches. You just need to make sure that there are no large stones in the ground.

The process of laying pipes in trenches is not a difficult job, but requires care and patience.

It is very important to follow the rules for preparing trenches and installing a pipeline; only in this case will the work done be effective

https://kanalizaciyam.ru

Additional recommendations:

(return to main content)

Sometimes rubber seals (gaskets) are sold separately from pipes and may not ensure a tight connection of pipes during installation.

When purchasing pipes and gaskets, insert one gasket into the socket and try joining two plastic pipes. If one pipe fits quite easily into the socket of another, then it is advisable to immediately change the gaskets or look for another seller.

To facilitate the installation of plastic pipes, it is recommended to use lubricant.

Since a high-quality pipe must fit very tightly into the socket of another pipe, the use of shampoo or liquid soap (they are usually always on hand) greatly facilitates the joining process.

When joining pipes, one pipe enters the socket of the other by 47 and 36 mm with a diameter of pipes and fittings of 100 and 50 mm, respectively.

When installing plastic sewerage, pipes of standard length are used.

But the design of the apartment should not be changed because of the modular dimensions of the pipes, and the modular pitch is not very pleasing: 150 mm, 250 mm, 500 mm, 1000 mm, 2000 mm, 3000 mm. If you need a pipe of a different size, then you can always cut it evenly and accurately , as a result you will get a pipe cut that is sometimes better than the factory one.

Scheme of sewerage supply to the house

As you know, there are three types of sewer network arrangement schemes, namely:

Scheme of sewerage supply to the house

- Centralized type, which involves connecting the outlet from the house to the general highway.

- An autonomous type without pumping, which involves connecting the house to a septic tank for collecting solid waste and subsequent installation of a drainage system for settled water. In this case, the soil of the site is responsible for filtering the discharged water.

- Autonomous type with pumping, involving the collection of wastewater in a large storage facility, released by periodic pumping out of settled water. Moreover, the pumping of such water should be carried out by a special company that provides sewage disposal services.

And all sewerage schemes require an original plan for laying and connecting sewerage to the house.

Sewage arrangement diagram

Thus, in the case of a centralized wastewater collection scheme, the laying of sewer pipes in the ground is carried out from the central outlet of the sewer pipe of the internal network to the entrance to the collector of the central network. Such a pipeline is laid in one line and is supplemented with inspection wells, where dampers and revisions are installed to facilitate system maintenance.

In the case of installing an autonomous system without pumping, the laying of external sewerage networks is carried out in one line from the outlet of the waste pipe to the entrance to the storage facility. The pipeline is equipped with revisions and dampers.

In the case of installing an autonomous system without pumping, the sewer pipe is pulled from the sewer outlet to the septic tank, from which the drainage pipes are diverted. This is the most labor-intensive option for eyeliner, but also the cheapest to maintain.

System design

Sewage in a private house is a complex system consisting of internal, external circuits and a septic tank. In order for all devices to operate smoothly and smoothly during operation, their installation requires proper design. A sewer pipeline is installed inside the building, the parts of which are connected into one common channel using fittings. It is taken outside and equipped with a check valve that protects the system from rising water levels when external containers are overfilled with liquid. In this case, pipes can be installed not only inside the house, but also in other outbuildings located on the territory of the land plot.

As for the external part of the communications, it looks like a cesspool or a biological treatment station. The outer part is characterized by a different operating principle and may consist of additional devices, as it will depend on the size and complexity of laying the overall system. If its productivity allows, then a storm sewer with a separate drain is also laid.

Internal circuit

The design and installation of internal sewerage in a country house requires precise calculations, since the slightest errors can lead to operational problems, and installation work will have to be done in a new way. The internal communications circuit consists of a set of pipes, plastic risers and fastening parts; their main task is to drain used water from plumbing fixtures and other devices. The main element of this system is a vertical riser, which accumulates water from the entire horizontal distribution. Often in large buildings two risers are installed, this allows for convenient layout of rooms and simplifies installation work in general.

Compared to a centralized city system, the system in a private house is much more complex. This is due to the fact that she needs to provide high-quality service not only to the residential building, but also to the summer kitchen, barbecue, bathhouse and shower, since all additional outbuildings need improvement. In this case, pipes can be placed both inside and on top of walls, as well as in the floor. Many home owners try to hide communications in the walls, but this is a very labor-intensive process; in addition, all connections must be open.

The upper part of the riser, as a rule, is placed 50 cm higher than the roof of the house and is equipped with a special valve or cover, this is necessary in order to avoid the failure of the water seal. Many schemes also often provide for ventilation ringing, when a horizontal pipeline is connected to the riser slightly above the drain point. The riser is led out of the building into the well through the space under the floor or basement. Siphons must be placed between plumbing equipment and fittings to protect the premises from the penetration of unpleasant odors.

In the case when the layout of internal circuits is carried out independently by the owner of the house, and not by a specialized company, then it is necessary to correctly plan the placement of piping, bathrooms and kitchens.

External part

The outer part of the sewer system is a diagram consisting of pipelines transporting wastewater to the disposal site, waste collection containers and a settling tank (cesspool). Its design is carried out taking into account current regulations and standards, since a properly equipped sewage system is considered the key to comfortable and reliable living conditions in the house. Any inaccuracy in the layout of the external part of the sewer can lead to various problems, including the formation of blockages, which may result in the entry of dirty drains and waste into places located near sources of drinking water. To prevent this from happening, the external pipes are supplemented with a drainage system and precise calculations are made for the cesspool: it should be located below the laying of the pipelines. In the case when wastewater is delivered using pumps, the circuit is provided with the appropriate pressure.

The main part of the external sewerage system is the septic tank; all sewage enters it through pipes, accumulates and over time seeps into the soil or is easily disposed of. After filling the pit with heavy fractions, it is necessary to clean it using special sewer equipment.

Unloading and storage of PVC sewer pipes

Installation of PVC sewer pipes begins with unloading the resulting pipes and fittings and organizing their careful storage. Any pipe after transportation must be checked for defects

Unloading of pipes, either manually or using machinery, must be carried out with great care to avoid damaging them.

When unloading, it is unacceptable to throw frozen PVC pipes onto the cold ground or floor. The pipe should never be thrown at all, although PVC pipe is quite flexible, if not handled correctly it can crack even in warm weather. Moreover, a crack may be invisible, but during operation of the pipeline, it can cause leaks.

Preparing for work

Before you begin installing the sewer system, you will need to prepare the following tools and materials:

- plastic pipes that have a cross-section of 5 and 10 centimeters;

- elements that will be used to connect pipes;

Pipes and connecting elements for sewerage installation Source 911stroy.ru

- cuffs for sealing joints;

- glue intended for gluing plastic;

- marker, tape measure, level and saw;

- cement.

If the sewer system is not being made new, but the existing one is being reconstructed, then before proceeding with installation, you need to study the old structure or photograph it. After this, you need to draw up a plan for installing the new system:

- a drawing is drawn onto graph paper, where all wiring points and bathrooms are displayed, distances are determined and the riser is marked;

- it is checked that the new plan coincides with the existing sewer system;

- then calculations are made and the amount of material required is determined.

What pipes can be used

The material and profile are selected in accordance with the existing design of the wastewater system.

Cast iron products remain relevant due to their low price and durability.

They are resistant to loads and temperature changes, but are susceptible to corrosion. Modern technologies create anti-corrosion coatings that increase the service life of the product. Cast iron pipes are heavy, so trenchless installation of a sewer system will require special equipment and support personnel to create an engineering structure. When performing external sewerage, cast iron products must be provided with thermal insulation.

In recent decades, plumbing products made from PVP and PVC have appeared, which are not inferior in their properties to metal ones. They are much lighter, so installation with such products is easier. When installing an internal system in a bathroom or toilet, it is better to use polyvinyl chloride pipes. Polyethylene and polypropylene pipes are more suitable for outdoor systems. The advantage of plastic ones is that they practically do not accumulate deposits.

Asbestos pipes are resistant to aggressive environments. In an aquatic environment, asbestos only becomes stronger over time. In addition, under the influence of water flow, overgrowth does not occur on the inner surface of the pipes. Installing an asbestos system is not difficult, but it is sensitive to mechanical stress. You need to be careful when transporting and installing them. Protection must be provided to prevent subsidence and fractures. Asbestos products are not recommended for use in sandy soil as they have low resistance to sand.

Rules for installing plastic pipes for water supply

Water supply from plastic pipes

After connecting the sewerage system, water supply is supplied.

A diagram of the connection of all elements is drawn. For hot water supply, a technological gap of 10 mm is left, since the plastic expands when heated. Afterwards, the total length of the line and the necessary fittings are calculated. Number of locking and fastening elements. For subsequent addition of new devices, it is recommended to leave several taps with plugs.

When planning plumbing, it is important to know that plastic pipes are made in gray color. Their markings:

- PN10 – cold water;

- PN16 – hot and cold;

- PN20 – hot water with heating;

- PN25 – heating.

Where the water temperature is below 60°, the first two points are suitable. If the temperature is higher, then use the third and fourth options, since they are reinforced.

To save time and ensure control over the condition of the water supply system, it is better to use an open connection scheme. Pipes are installed at floor level, in the corners of the rooms. The standard option, it is the simplest, is a sequential supply of water to all consumers. To carry out repairs without turning off everyone, a shut-off valve is installed in front of each one.

Step-by-step instructions for soldering plastic pipes

The parts were purchased, the tools were prepared, the question of how to install the water supply system began to be resolved. According to the diagram, sections of pipe are cut with special scissors. They are connected using fittings or welding. The technology is simple:

- the ends are cleaned and degreased;

- nozzles of the required diameter for the soldering iron are selected, it is heated;

- insert the elements to be connected, wait a certain time (determined by the cross-section of the products);

- After welding, fix the parts until they cool completely.

The structural elements are secured to the wall with clips. Risers - using a clamp and a rubber gasket.

Additional elements, such as valves and meters, have a threaded metal connection; it is sealed with tow. Professional plumbers prefer to use fluoroplastic sealant.

With a little experimentation, any home craftsman can connect a water supply system with his own hands, which will function like a clock.

Installation features

The structure of plastic water pipes

This is a relatively new device. Combines the properties of metal and polymer pipes. Reminiscent of a layer cake: polyethylene, glue, aluminum, glue, polyethylene. The performance characteristics are excellent: at a pressure of 9.8 atmospheres they can withstand temperatures of 95°. With short-term overheating up to 130o. They are frost-resistant, easily retain their given shape, and can be bent even by hand.

They are used in systems for transporting liquids and gases, heating and air conditioning systems, and for heated floors. The connection diagram is similar to polypropylene pipes. But since they are more susceptible to mechanical damage and exposure to UV rays, installation is carried out inside special boxes, walls, and floors.

Special fittings are produced for connection:

- detachable;

- compression (clip);

- press fittings (for press pliers).

Installation does not require expensive equipment or special education. When assembling a water supply system with your own hands, know: the last connection is permanent, it can be “packed” inside the floor or wall. The first two are in special boxes for access in case of an emergency.

Pipe selection

Trench diagram for sewer pipe.

External sewer pipes, like water pipes, experience much more serious impacts and loads than those laid inside the building. In addition to its own, dynamic loads, water hammer, a pipeline laid outside also experiences a static external load - the pressure of soil masses. The values of these influences are especially critical in sections of the pipeline located under the roadway - roads, especially dirt roads.

Therefore, it is important to make the right choice of the type of pipes used for arranging the external pipeline

Today the following products are used as sewer pipes:

- smooth polymer pipes - polyvinyl chloride or polypropylene;

- polyethylene or polypropylene corrugated pipes;

- cast iron;

- asbestos-cement.

The first 2 varieties are the most technologically advanced, reliable, and easy to install. Although a cast iron pipeline is considered very reliable and durable, it has significant drawbacks, the main one being high cost.

Layout diagram of sewer polymer pipes.

In addition, cast iron pipe products have a significant mass, so the production of a pipeline with a diameter of more than 200 mm is very difficult and practically impossible without the use of special equipment - an installation crane (or a pipe-laying crane).

Asbestos-cement pipelines are used even less frequently today. The reason for this is the low manufacturability of installation work, the need for coupling joints and, most importantly, the low mechanical strength, high fragility of asbestos-cement products, and the low maintainability of a pipeline made from such pipes.

PVC sewer bends

Sewer lines made of unplasticized polyvinyl chloride are widely used outside and inside buildings; a 110 mm sewer outlet has standard deviation angles from the central center line of 15, 30, 45, 67, 87 degrees. The PVC sewer line has the following features:

- The elements are designed to operate with liquids whose temperature does not exceed 45 C and does not fall below 60 C.

- The pipes are lightweight and have a smooth internal surface, providing high throughput.

- The products are not subject to corrosion, resistant to acid and alkali, and neutral to most chemicals.

- The material has low thermal conductivity, comparable to thermal insulators - this reduces the risk of line freezing in winter.

- Due to the chemical resistance of the material to various substances, the service life of PVC sewers reaches 50 years.

Laying external sewerage overview of process stages

The procedure for laying a sewer network of any type involves the sequential implementation of the following work plan:

Choosing sewer pipes for laying in the ground

Plastic sewer pipes

At this stage you need to select the diameter and length of the pipe. Everything is simple with the length - it is equal to the distance from the waste outlet to the inlet into the collector or septic tank. The diameter of the pipe is selected based on the expected volume of waste. However, in reality you will have to choose between 110 millimeters and 150 (160) millimeters. These are typical sizes of household sewer pipes. If you are planning to build an industrial highway, the diameter will start from 400 millimeters.

In addition, you need to choose the type of “pipe” material. This is usually polyvinyl chloride (smooth pipes) or polypropylene (corrugated pipes). PVC products are less durable, but will cost less than PP pipes.

Determining the slope of the sewer pipe

This slope guarantees the flow of liquid through the pipeline under the influence of gravitational forces. That is, the system will discharge wastewater in a non-pressure mode.

We carry out excavation work

The depth of the trench for the sewerage must correspond to the level of soil freezing. Otherwise, the system will freeze in the winter.

Laying sewer pipes in the ground

Therefore, the entrance to the sewer main (outlet from the waste pipe) is immersed in the ground to a depth of 1.2-1.5 meters. The outlet depth is determined based on a 2-centimeter slope (per linear meter of pipeline).

As a result, at this stage a trench is being dug, the bottom of which goes towards the catchment point at a slope. Moreover, the width of the trench is 50-100 millimeters. And its walls, after being deepened to a level of one meter, are strengthened with shields and struts. The selected soil is stored in a special area; it will be useful for filling the trench after installation of the pipeline.

Sewage well

Extended sections of the sewer main are equipped with wells, the walls of which are reinforced with concrete rings. The bottom of the well coincides with the depth of the trench or falls below this mark (the missing part of the soil can be added).

At the same stage, a pit is dug for a septic tank or waste storage bunker. The selected soil is removed from the site and disposed of. It won't be useful for filling. After all, the selected volume will be filled by the structure of the septic tank or bunker.

In addition, at the same stage you can start laying trenches for the drainage system of an autonomous sewer system.

Laying sewer pipes in a trench

Laying sewer pipes

The pipeline is installed in measured sections (4, 6 or 12 meters each), which are connected into a socket. Moreover, it is better to lay a layer of sand 10-15 centimeters thick at the bottom of the trench; it will save the line from possible ground vibrations caused by heaving deformation.

Laying is carried out with the sockets up, that is, the socket should be the first in the flow path, and the smooth end should be located at a slope. Therefore, the assembly is carried out from the drain pipe outlet towards the septic tank.

Having completed the assembly, the pipe is covered with coarse sand, after which the trench is filled with selected soil, leaving a bump on the surface that will “sag” next spring, after the soil has “settled”. The remaining soil is disposed of.

Commissioning

Before filling the trench, it would be a good idea to check the tightness of the joints and the throughput of the pipeline. To do this, you can wrap the bell sections with newspaper and pour several buckets of water into the toilet.

If there are no wet spots on the newspapers, the system functions without compromising the tightness of the pipeline. Well, the throughput can be assessed by comparing the volumes of “introduced” and “output” liquid. If the same bucket of water reaches the outlet, then there is no stagnation in the sewer system, and you will not have problems maintaining the system.

How to control the slope

For an example of installing an external main, let’s take the installation of a single straight pipe leading from the building to the septic tank.

The purpose of the pipe is to transport sewage coming from plumbing fixtures to a common reservoir. This includes greasy waste from the kitchen sink, fecal matter from the toilet, and dirty water from the shower.

It is reasonable that the pipe must have a cross-section of at least 110 mm. It is important for us that the required slope is maintained throughout the entire length of the pipe, in this case 0.02 m/linear meter.

Using a laser level, you can measure the slope angle at different stages of work. The photo gallery will help to visually represent the controlled work areas.

Image gallery

Photo from

Stage 1 - digging a trench

Stage 2 - installation of a sand cushion

Stage 3 - pipe insulation

4th stage - entry into the tank

If the angle of inclination is maintained in all places, there will be no problems with the movement of sewer water. However, it should be remembered that the result of undetected errors in the future may be the complete dismantling of the external line, so each measurement must be taken very seriously and not done “by eye”.

Selecting material for laying external sewerage

Before you begin installing a sewer system, you should select pipes that can withstand environmental influences, since the impact on them in the house is much less than on the street. Since the pipes are laid in deep trenches, they must accordingly withstand significant soil pressure, which makes it necessary to use stronger materials than for internal sewerage. Today, the store offers the following pipes for laying external sewerage:

- smooth pipes made of polypropylene or PVC;

- corrugated pipes made of PVC or polypropylene;

- asbestos pipes;

- cast iron pipes.

Smooth PVC pipes for external sewerage

To prevent buyers from getting confused about which pipes are intended for indoor and which for outdoor use, manufacturers paint them in different colors. Pipes intended for indoor use are dark gray in color, while outdoor pipes are painted red or brown-orange.

Today, as a rule, smooth and corrugated PVC pipes are used for sewerage. This is due to the fact that, firstly, they are much cheaper than others, and secondly, they are very easy to install without additional equipment.

Septic tank installation

It is much more convenient if a septic tank is used for the sewer system. Of course, it is more expensive, but the requirements for arranging such a drive are much simpler. Step-by-step instructions for installing such a waste storage tank will make the job easy.

Previously, septic tanks were made primarily of concrete. But this material lost in competition with plastic products. They do not react to the presence of an aggressive environment, can be placed anywhere on the site, and are not subject to corrosion and fungi. Its installation is much simpler, and the prices for devices made from this raw material are the lowest. The only unpleasant point is their low strength and tendency to deform.

Septic tanks consist of three sections. In them, waste settles, decomposes and is cleaned. After this, the water enters the ground, and the settled waste must be pumped out from time to time. They serve as fertilizer for the garden plot. To install a septic tank, first dig a hole, fill it with gravel and fill it with concrete mixture. After this, the tank is lowered there. A trench is also dug through which pipes are laid to the septic tank. Sufficient depth for a septic tank is within one and a half meters.

Before installing the tank, fill it with water. This will prevent the walls from being deformed during installation. The distance between the pit and the device is filled with foam or sand. It is very important to install the septic tank in such a way that the lid is slightly above ground level. Then rainwater will not get inside. It is also important to install a cleaning facility in a place in the garden where the sewer hose can reach.

If you decide to make a sewer system for your home yourself, you should buy high-quality materials. Otherwise, as the saying goes: “the miser pays twice.” Do not forget that the sewage system on the street must be protected from environmental influences. That is, additionally insulate the entire pipeline. If you follow the rules for laying pipes, the system will last for many years.