As in any other room, the ceiling in the bathroom can be finished in completely different ways. There are methods that are expensive and spectacular, practical, traditional, original - it all depends on the financial capabilities and taste of the homeowners. But when choosing an option, you need to take into account the specifics of the room, otherwise the decoration will very soon lose its decorative effect. Let’s take a closer look at what kind of ceiling is better to make in the bathroom so that it is attractive, reliable and does not cause any hassle with cleaning.

What is the best ceiling for a bathroom?

How to make a backlit polycarbonate ceiling

The traditional area of application of polycarbonate is greenhouses and greenhouses. For these buildings, the combination of transparency and good thermal insulation is important, and the material, while slightly inferior to silicate glass in the first characteristic, is significantly superior to it in the second.

Polycarbonate ceiling

No less often, polycarbonate is used for the construction of canopies, roofs of gazebos, terraces, and so on. But they began to sheathe the ceiling with it relatively recently.

Suspended ceiling: design features

Polycarbonate sheets look like transparent, colored or unpainted slabs of different thicknesses, solid - monolithic, or with partitions inside - honeycomb. Using them as a finishing material in an apartment seems a dubious idea.

However, polycarbonate is successfully used for glazing complex roofs, not only in greenhouses, but also in office, industrial, and residential buildings. In these cases, the material replaces glass.

Polycarbonate plays the same role in suspended ceilings.

- Suspension system is a structure made of a metal flat frame, which is fixed to the base ceiling using hangers. The frame is hemmed from below with finishing materials, or decorative sheets are placed on top in a cell of the frame. The latter option has become widespread under the name “Armstrong” system and is a more advantageous modification: there is always access to communications.

The materials used for the boards are glass, mirror, plastic, mineral fiber, cellulose, fiberglass and so on. As a rule, glass panels are installed in cases where the light sources are mounted on the base floor, and the panel acts as a lamp.

Judging by the reviews, nothing prevents you from using a polycarbonate slab instead of glass. The photo shows the hanging system in the apartment.

Colored

This is a budget-friendly and therefore quite common finishing option. But, given the absence of a masking coating, the base for such a ceiling should be as even and smooth as possible. If the walls are plastered, you will have to putty twice - with a rough compound and a finishing compound. When the base is moisture-resistant board materials with a flat surface, a thin finishing layer is sufficient. When using a dry mixture, when mixing it is worth adding a concentrated acrylic primer to the water or replacing the water with a diluted one.

You can hardly find whitewash anymore, even in rural houses, not to mention apartments or country cottages; water-based paint for wet rooms is in use. She is not afraid of water, but if not only splashes, but also foam accidentally gets on the ceiling, marks may remain. The paint can be tinted in almost any color, the imagination of designers today has gone far from pastel colors, but the classic is white. In most cases, such a ceiling is done temporarily until there is an opportunity for something more presentable, but often opportunities do not appear immediately, and a flat, white surface does not look so dull. As an option, use stickers or stencils, as well as moldings.

Materials for ceilings with lighting

Both monolithic and cellular polycarbonate are used in this embodiment. The first, painted in the appropriate color - milky, golden, provides better light dispersion. Cellular is lighter, and thanks to the longitudinal section of the honeycomb, it can create additional lighting effects. For example, slabs can be laid with your own hands, alternating the direction vertically, horizontally or diagonally.

If the ceiling is hemmed with material, for example, in a garage, then cellular is chosen due to ease of installation and lower cost. Both plates have the same moisture resistance and are easy to clean. When installing in a garage, you should pay attention to the markings: judging by expert reviews, slabs made of self-extinguishing polymer are preferable.

For illumination, fluorescent, metal halide and LED lamps are used. Polycarbonate is resistant to high temperatures and does not suffer from heating the lamp. But its light transmittance, especially that of painted glass, is 10–20% lower than that of glass, and therefore the power of the devices must be “reserved.”

The material is produced not only in color, but also with ornaments. It looks very decorative, but transmits light even worse. When choosing lamps for illumination, this point is also taken into account. The photo shows a patterned ceiling.

Installation technology

If the hanging system is being built in a bathroom or toilet, then it can be sheathed entirely with polycarbonate: the area of the room is small, the lighting fixtures are used with low power. If some of the slabs are made opaque, the lighting will be insufficient. The photo shows an option for the bathroom.

If you install the hanging system yourself throughout the apartment, it makes sense to combine polycarbonate slabs with opaque ones - made of mineral fiber, metal, mirrors, and so on. In the garage or on the terrace, lighting is not provided, and the color is chosen arbitrarily.

- For better light reflection, the base surface is painted with white or silver paint.

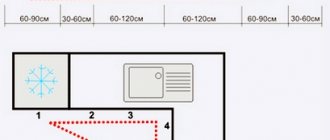

- The wall and base ceiling are marked according to the dimensions of the slab. Standardly it is 60*60, 120*60 cm and so on. However, there may be other sizes, and even a shape - a hexagon, for example.

- An L-shaped profile is attached to the wall along the marked line.

- Suspensions are fixed along the lines on the ceiling - no less than every 1.2 m.

- The frame is assembled from the main guides, longitudinal and transverse. The profiles are connected to each other with locks.

- Electrical wiring is installed on the base ceiling, and lighting devices are installed. In an apartment, fluorescent tubes or LEDs are usually used.

- The material is cut to the size and shape of the cell. The ends of the panels are covered with tape to prevent moisture and dirt from getting inside.

- The slab is placed in the cell on top. No fixation required.

In the video you can see how to build a ceiling in an apartment with your own hands.

Source: https://propolikarbonat.ru/potolok-iz-polikarbonata

Dyeing technology

Almost all modern paint and varnish products can be applied to the surface to be painted mechanically and by air. That is, after covering the adjacent sections of the walls with masking tape and a brush, painting is done in the corners.

Then the water-based emulsion is applied to the entire surface with a roller, spray gun, brush or spray, taking into account the following nuances:

- the minimum number of layers is 2; with low hiding power or a light color of paint on a dark primer, 3 or more layers will be required;

Applying paint with a roller to the bathroom ceiling. - layers are applied at right angles to each other, the first is usually across the room, finishing from the front door to the far wall of the bathroom.

Scheme of the sequence and direction of layers.

You should not force dry each layer; it is enough to ensure the room is ventilated naturally.

Advice! If you need bathroom renovation specialists, there is a very convenient service for selecting specialists from PROFI.RU. Just fill out the order details, the experts will respond and you can choose who to collaborate with. Each specialist in the system has a rating, reviews and examples of work, which will help with the choice. Looks like a mini tender. Placing an application is FREE and does not oblige you to anything. Works in almost all cities of Russia.

If you are a master, follow this link, register in the system and be able to accept orders.

The nuances of installing polycarbonate ceilings with lighting

Polycarbonate and its areas of application are currently not known to many. Some knowledge about the material can be shared by people who are owners of country houses such as gazebos and terraces. Comparing its transparency with silicate glass, with the naked eye one can notice the advantage of the second option. But in terms of thermal insulation properties, polycarbonate proves its superiority. They also resort to using these slabs for arranging the roofs of terraces and gazebos, as well as for constructing canopies.

Of particular interest is the creation of ceilings. This idea began to be implemented relatively recently. The most original layout can now be confidently called - a polycarbonate ceiling with original lighting.

Lexan or cellular polycarbonate wholesale and retail

Polycarbonate ceiling with lighting Polycarbonate ceiling - how convenient, practical and fashionable is it?

The most popular design direction associated with polycarbonate today is considered to be polycarbonate ceilings. Such ceilings are stylish and elegant elements of any room, giving them a bright and sunny look.

‼️ Polycarbonate ceiling can be used not only as a roof covering for a winter garden or flower gallery, but also as a ceiling on the top floor of any private mansion, house or cottage, giving the room and the building as a whole an original and exclusive look and creating a special positive atmosphere in the room.

✅ The material is not susceptible to mold and mildew, fat and gasoline. Can be purchased in any color range

☝ With respect, the team of PROGRESS POLIMER STANDARTPLAST LLC To each client ♀️ ♀ ♂️ ♀️ ♀ ♀️ individual approach, assistance in selecting material.

LLC "PROGRESS POLIMER STANDARTPLAST" - Cellular Polycarbonate wholesale and retail, at affordable prices! Phones: ☎️ + 998(98) 115-68-00 ☎️ + 998(93) 383-30-70 https://www.polygard.uz/

Lexan or cellular polycarbonate wholesale and retail

- offers cellular polycarbonate sheets that have properties such as good transparency, low weight, high strength, fire and weather resistance. ️ Sheets of cellular polycarbonate measuring 4️⃣ mm are available for sale - 35,000 thousand soums per square meter. ‼️ Polycarbonate 4 mm is the main raw material for greenhouses and greenhouses. ❇️ The main advantages include elasticity, strength, transparency, lightness, resistance to various temperatures, heat and sound insulation. ❇️ Which is ideal for use in the greenhouse business. ❇️ Buy Polycarbonate wholesale and retail, at an affordable price!

Components of a suspended ceiling

Polycarbonate is an interesting material with its own unique properties and characteristics. Most often found in the form of transparent, unpainted and colored slabs. It is worth noting their structure. Its first option is a solid formation, called monolithic polycarbonate. The second structure is characterized by internal partitions (honeycombs). Such plates are called cellular polycarbonate.

The layout of the ceiling made of polycarbonate sheets was initially poorly understood and raised a lot of doubts. However, overcoming the contradictions that arose, they proved their reliability and quality during the installation of the roof. And not only in greenhouse structures, but also in buildings used for industrial and commercial purposes. There are plenty of examples of installing canvases on residential buildings. And the explanation for the latter is a high-quality replacement of another material - glass. In a suspended ceiling, the role of polycarbonate is similar to the above details.

Installing a ceiling covering with your own hands is a multi-stage job. To begin with, the foundation is built - a frame structure. Its main task is to “support” polycarbonate slabs. The material is either securely attached to the frame, or the elements are placed into the formed cells. Laying the slabs on top gives the advantage of hassle-free access to utility lines.

A suspended ceiling is a collection of slabs, which in some cases may consist of different types of building materials. A sheet of glass, in turn, acts not only as a ceiling surface, but also acts as a light source, transmitting rays from the lamp through itself. The device itself is installed on the base ceiling plane. As mentioned above, polycarbonate becomes an excellent replacement for glass. Based on this, this property of the material makes it possible to create a suspended ceiling with lighting.

From plasterboard

And now there are, but are gradually losing their relevance, suspended structures covered with moisture-resistant plasterboard sheets. This is due both to the relative complexity of the installation and finishing process, which includes several stages, and to the emergence of various alternative cladding options. Although, if desired, it is possible to create an original multi-level design with lighting that will decorate the bathroom interior.

How to make a polycarbonate ceiling with your own hands

Polycarbonate appeared on the construction market a long time ago and has already established itself as an excellent roofing material for arranging hanging structures, gazebos, terraces and canopies. However, designers began to use it as an interior element when designing apartment ceilings only recently. Thanks to a number of decorative and design features, polycarbonate panels have become widespread as interior decoration. The rest of the article will describe in detail the qualities of the material and instructions for assembling ceilings using it.

Price

The price of such structures for each specific room can vary significantly. The most important influence on the cost is the area of the ceiling surface: the larger it is, the greater the number of fasteners, wall corners, and load-bearing elements will be needed. The quantity of the main material - polycarbonate sheets - also has a great influence on the pricing of ceilings. For example, monolithic material costs about 650-700 rubles per square meter, cellular material is much less: from 120 to 500 rubles for the same meter.

Features of ceiling cladding with cellular polycarbonate

Constructing a suspended ceiling from cellular polycarbonate with your own hands is a job consisting of several stages. The first step is choosing panels. The material is produced in two varieties:

Cellular polycarbonate consists of two outer sheets of polymer raw materials, fastened with stiffeners made of the same plastic, which form voids (honeycombs). This type of panel is available in various thicknesses, both unpainted and colored.

Monolithic polycarbonate sheets are made in glossy and matte, transparent and colored. Outwardly, they are very similar to glass, but lighter and stronger.

Advantages and disadvantages

Polycarbonate ceiling construction has a number of positive and negative qualities.

The advantages of the panels include:

- The raw materials for the manufacture of parts are absolutely moisture resistant. This circumstance allows the material to be used in “wet” areas such as sanitary facilities, showers, baths and swimming pools.

- Polycarbonate panels are translucent, which means they can be used to create interesting decorative ceiling solutions using lighting fixtures.

- The color palette of the sheets also does not limit the design.

- Thanks to its cellular structure, polycarbonate is lightweight, which practically does not load the floor.

- The material has thermal insulation characteristics due to the hollow elements inside, which reduces heat loss in the room.

- Polycarbonate sheets are easy to bend, so they are used to create wavy surfaces.

- No special skills or tools are required to work with the panels.

- Relative cheapness of the material.

- The plastic used to make sheets is easily susceptible to mechanical damage. It is for this reason that the panels are sold in plastic film, which is not recommended to be removed until installation is complete.

- Polycarbonate melts quite easily, so installing a heat source in close proximity is prohibited.

- The material is temperature dependent. As the microclimate in the room changes, the sheets contract and expand. Taking into account this nuance during installation, it is recommended that the panels are not attached too rigidly to the base.

Installation of the structure

The polycarbonate ceiling is a suspended structure fixed to the floor slab. For installation you will need the following materials and tools:

- screwdriver;

- self-tapping screws;

- construction knife;

- metal hangers;

- aluminum profiles;

- locks for aluminum profiles;

- polycarbonate panels.

Source: https://potolok.expert/otdelka/potolok-iz-polikarbonata.html

The use of polycarbonate in interior design

Undoubtedly, polycarbonate was the first to be appreciated by summer residents and greenhouse owners: after all, its characteristics are not inferior to glass, while in price and ease of assembly it even surpasses it. However, over time, the scope of application of this material has grown greatly and now, when we encounter polycarbonate products on the street or at a party, we often do not even understand that this is what it is.

Polycarbonate for the interior turned out to be no less relevant than for dacha farming. For example, a polycarbonate ceiling with lighting is very interesting. Previously, such ceilings were made of glass, a more expensive and heavier material. In general, this ceiling looks very original, providing high-quality lighting in the room and, as it were, scattering light. Considering that polycarbonate

It can be cellular or monolithic, glossy or matte, colored or transparent - there is a large field for experimentation. Experts say that to achieve better lighting, it is necessary to cover the base surface with silver or light gray paint.

Polycarbonate is also actively used in the arrangement of apartments

and division of space. Screens made from this material can have absolutely any shape and color and, just as importantly, are very affordable. In the presence of a translucent wall made of such material, the integrity of the interior is preserved, but it is also divided into zones, for example, for relaxation and for cooking. Such walls are no less relevant if there are few windows in the apartment. If there is only one window in a living space and the division into zones is made using opaque drywall or blocks, then residents may experience discomfort from the lack of natural light. However, a polycarbonate wall will solve this problem.

Considering that one of the qualities of polycarbonate is the ability to retain heat, it has found its application in construction. Some owners who value large windows but don't want to feel cold in the colder months due to glass's low heat-retaining ability make an entire wall or roof out of polycarbonate. In this case, it is more ideal to consider not even ordinary cellular polycarbonate, but so-called modular polycarbonate systems, which can be both roofing and facade.

You can buy polycarbonate in Sochi in a large number of stores. The price-quality ratio will vary both depending on the honesty and pricing policy of the seller, and depending on what materials and equipment are used for its production. In order for ready-made solutions made from this material to last for many years and delight owners with the characteristics inherent in polycarbonate, it is worth contacting trusted sellers, without focusing on the lowest prices.

Tiled suspended ceilings with lighting - plexiglass, polycarbonate, .

I'm trying to figure out the possible material options for the transparent panels of a suspended tile ceiling. I'm going to put lights behind some of them. In appearance (tiles, not guides), I would like to get something like

- " > , only illumination preferably from the inside

- » >

- » >, excluding mirror tiles.

The problem is standard - I can’t decide on all the shortcomings of the solutions and choose the final option. Maybe someone has encountered a similar question and chose one of the options (or maybe some other thread)? Maybe someone has just worked with such materials and is aware of their applicability? One more question: how suitable are these materials for sliding doors with a top hanger with a thickness of about 6-8 mm (one piece or broken into sections)?

I took all the plastic from " > , since they have the most information on them and I can only find their representative at home.

Price aspect Prices are taken from the website in terms of one 600x600 mm tile. 1. Cellular polycarbonate (4mm, milky). Price

$2/piece 2. Monolithic polycarbonate (3mm, milky). Price

$11/piece 3. Molded plexiglass (Plexiglas GS, imported, 3mm, milky, matte). Price

$9/piece 4. Frosted molded plexiglass (Plexiglas Satinice SC, 3mm, milky). Price

Standard ministove AMF costs: economy

$1.5/piece – Mineral (Ecomin) average price range

$3-4/piece – Mineral (Thermatex)

The price range is more than respectable.

Please safety 1, 2. Cellular polycarbonate 4mm (milk) and Monolithic polycarbonate. It is claimed that plexiglass is better from the point of view of fire. security. 145-155C “Another important characteristic is fire resistance. Polycarbonate is classified as a self-extinguishing material. The combustion of polycarbonate is not accompanied by the release of toxic substances, unlike other plastics. Due to the low coefficient of linear expansion, the sheets can be profiled taking into account temperature differences. For the installation of cellular polycarbonate, special polycarbonate profiles are used, which have the same color range and the same mechanical properties. They are very easy to assemble and create the appearance of a solid structure."

Advantages

The industry produces polycarbonate in the form of slabs of different designs, thicknesses and colors. There are two types of material:

- monolithic (solid) – single-layer panel;

- cellular (cellular) - consists of several layers fastened with jumpers.

The ceiling can be made from different types of polycarbonate, cellular or monolithic.

Although you can buy panels that are transparent and colored, matte and unpainted, until recently it never occurred to anyone to use them for interior decoration of residential premises. But since such sheets are successfully used for glazing roofs of complex configurations for agricultural buildings, offices, industrial and residential buildings, they can be used when installing roofs indoors, constructing original suspended ceilings.

It is permissible to use both types of material for such purposes. Panels on the ceiling can be laid in a pattern in different directions, alternating vertically or diagonally.

It should be taken into account that:

- the monolith is usually painted in a certain color - white, golden, which allows it to diffuse light more evenly;

- Cellular is lighter, and using internal voids, it is possible to obtain original lighting effects.

Cellular is more suitable for covering the ceiling in a garage, it is easier to work with, and the cost of the material is low. It is also recommended to select slabs with improved sound-absorbing characteristics.

Paint and glue - the advantages of simple finishing

Everything is clear here - paint and wallpaper are considered the most affordable options. Their main advantage is speed of application, gluing and simplicity. The main thing to remember is that the paint should be high-quality acrylic (which is intended specifically for the bathroom), and the wallpaper should be vinyl.

vinyl wallpaper for ceiling photo

- Using regular paint, you can create patterns on the ceiling or combine several shades of the same color to give the ceiling an original design solution.

- Vinyl wallpaper is good because over time it can be completely repainted to a different color.

- The wallpaper is moisture resistant - the outside is covered with a synthetic film

wallpaper on the ceiling photo

Components of the structure

Suspended is a system assembled from several slabs, and the elements can be different materials.

We list the main components of the design:

- The metal flat frame is attached to the ceiling using special hangers.

- The bottom of the frame is sheathed with decorative materials: they are secured with fasteners or the panels are placed in special cells (the famous “Armstrong” system). In the latter case, it is possible to run all communications above the ceiling and quickly reach them if necessary.

The most common finishing materials are:

- glass or plexiglass;

- mirror;

- plastic;

- mineral/cellulose fibers;

- fiberglass.

When laying a polycarbonate ceiling, you should carefully follow the diagram

Glass or fiberglass is used in cases where light sources are mounted on the ceiling above the frame, then the finishing sheets also perform the functions of lamps. Nothing prevents you from using stronger and more reliable polycarbonate instead of glass.

The lighting is provided by fluorescent, metal halide and LED lamps. If you use polycarbonate that is colored or decorated with patterns, you should take into account that the transparency of such material is low - 20% less than that of glass. In this case, the power of the light sources is selected higher.

Basic requirements for the ceiling

(By the way, it is also important to think about lighting in the bathroom; high-quality lamps and sconces for the bathroom can be found on the website).

https://comfort-home.ua/bra-dlya-vannoy/)

The bathroom is characterized primarily by high humidity, which affects the durability, strength and aesthetic appearance of the finish. Dampness and heat contribute to the development of mold on the ceiling and walls, corrosion of metal elements, and the formation of smudges and stains on the coating.

The ceiling must be moisture resistant

That is why the ceiling in the bathroom must meet several important requirements:

- be resistant to moisture, easy to clean and wash;

- do not emit harmful fumes;

- have a neat appearance and match the design style of the bathroom interior;

- hidden structural elements must be easily accessible.

The ceiling should be made of safe materials and easy to clean

It is important that the ceiling is durable

Finishing materials, in addition to being water-resistant, must be resistant to fungi and corrosion, and be durable enough so that the ceiling does not have to be repaired every year.

Ceiling “Starry Sky” with blue lighting and gold inserts

Stage-by-stage execution of work

To get a beautiful ceiling, you need to follow certain rules during installation. We list the main stages of work:

- First, it is recommended to paint the “basic” ceiling in the room with white (preferably silver) paint. This approach will significantly increase the reflective ability of the surface, allowing more light to be directed towards the suspended ceiling.

- Markings are applied to the side walls and the base surface, taking into account the dimensions of the polycarbonate sheets. The standard sizes are 60x60, 120x60 cm, etc. However, other sizes are also found. In addition, the panels can have a complex hexagon shape, etc.

- An L-shaped profile is attached under the ceiling along the perimeter of the room at the required height (along the intended line).

By attaching L-shaped profiles to the ceiling, the base of the polycarbonate ceiling frame is formed - The hangers are installed according to the markings; they should be located 1.2 m apart from each other.

- A frame is assembled on the ceiling from the main guides, longitudinal and transverse slats. All parts are secured with locks.

- Electrical wiring lines are run along the ceiling above the frame and light sources are installed. For residential premises, LEDs or fluorescent tubes act in this capacity.

- Polycarbonate is cut into fragments with a construction knife according to the size and shape of the frame cells. If cellular polymer is used, the ends of each panel are sealed with tape to prevent moisture and dust from getting inside.

- Fragments of material are mounted in cells.

The nuances of installing the backlight

Here are some recommendations given by experienced craftsmen.

The hanging system in a bathroom or restroom should be completely decorated with polycarbonate. Typically, the area of such a room is small, and minimal lighting is used. It is better to take completely transparent slabs, otherwise the lighting will have to be increased.

Small rooms should be completely decorated with lighting on a polycarbonate ceiling

For suspended ceilings in an apartment, it is worth combining polycarbonate sheets and opaque panels - metal, mirror or mineral fiber.

In the garage or on the veranda, decorative lighting is unnecessary, so the color of the panels can be chosen to suit your taste.

A beautiful ceiling made of polycarbonate slabs with lighting will give any room a unique, sophisticated style. The effect of multi-colored scattering rays of light will evoke joy and positive emotions, calming and relaxing after a hard day.

Source: https://polikarbonat.guru/montazh/potolok-iz-polikarbonata.html

Recommendations and advice for beginners

Beginners in the installation of suspended structures need to pay attention to the stage of marking the fastening of frame elements.

Walls, ceilings and corners may be uneven, so you need to carefully check the parallelism and perpendicularity of the guide lines.

When attaching polycarbonate plates to the frame from below, it is important that the self-tapping screw enters the hole strictly at an angle of 90 degrees relative to the plane of the aluminum profile.

If you are working with polycarbonate products for the first time, then when choosing a manufacturer, experienced installers recommend Novattro and Bayer Material Science, as well as the highest quality Chinese products - PlastiLux.

Polycarbonate ceiling with lighting

Polycarbonate is known as a material for making greenhouses or decorating the roofs of gazebos, but very few people use it when decorating ordinary apartments. However, you can make an excellent suspended ceiling with lighting from polycarbonate. In appearance, the design will resemble a similar glass solution, but will have many more advantages and, moreover, will be cheaper.

Rack and pinion

Also refers to stacked frame-type coverings, but the slats are often aluminum and narrower than PVC panels, and are mounted with a gap, which adds volume. The slats are flexible, so during installation the ceiling can be given almost any shape and slope, which expands design possibilities. The color range is also varied, but mainly it is white, gold or chrome, as well as their combinations. The slats go well with spotlights and do not require a perfectly flat base, since any distortions can be corrected with pendants.

What kind of material is this

Polycarbonate comes in two main types:

- Cellular, used for the installation of greenhouses and found very often.

- Monolithic, reminiscent of ordinary plexiglass.

Both varieties can be used to design floors. The difference between the types of sheets will be the presence or absence of voids called honeycombs, which give the name to one of the varieties of material.

The honeycomb type has longitudinally spaced voids between two thin sheets of outer surfaces. This type of coating can be produced either transparent or painted in various colors. The thickness of the sheets varies over a wide range.

Monolithic options are most similar to ordinary glass. However, polymer parts are much stronger, although they are much easier to process. In addition, you can choose both the thickness of the sheets and their type - there are matte, transparent and painted options.

Pros of the solution

Unlike glass, which is also used to create luminous surfaces, this type of coating will cost significantly less. In addition, any of the varieties of this polymer is superior to glass in terms of performance characteristics: the plastic is stronger, is not susceptible to splitting into small pieces, and is also easier to process using the simplest tools.

At the same time, the polymer coating is not subject to rotting, can withstand quite significant temperature changes and does not react in any way to moisture. This makes it possible to use such coatings when decorating both the interior of a house and for decorating structures outside it. This property is especially useful when decorating rooms in which the temperature is not constantly maintained in the positive zone.

Another advantage of plastic is its light weight. The assembled composition will not increase the load on the floors too much and will be easier to install than a similar solution using glass parts. But, despite its light weight and minimal cost, plastic is not inferior to glass in transparency.

Varieties of compositions

There are several types of solutions that can be assembled from such materials. Honeycomb, with voids between the outer and inner planes, provide a very beautiful dispersion of light rays.

Monolithic sheets can be made with either a transparent or matte surface, which also provides good dispersion. Both types of materials can be selected by color - there are many color options for the material.

Which ceiling to choose

Each of the described options is attractive in its own way, but if you take into account the optimal ratio of cost, decorativeness and ease of installation, then the best option is a plastic or slatted ceiling. Thanks to the wide selection of panels, you can find an interesting and unusual combination of color and texture, or, conversely, choose a discreet classic option. If the bathroom is decorated in a high-tech or loft style, panels with a mirror finish, as well as chrome and metallic colors, are ideal. This is a great opportunity to show your imagination and feel a little like a designer.

Wavy slatted ceiling

Installation nuances

Installing a backlit polycarbonate ceiling is quite simple, thanks to the possibility of using frames designed for Armstrong-type ceilings. Moreover, the installation of a structure made of cellular or monolithic polymers is practically no different from the assembly of Armstrong-type solutions.

Unlike the installation of opaque compositions, polycarbonate structures will require specific preparation of the base. It consists in the need to paint the floor plane, which will be inside the structure, in a light color. This is necessary so that the inner plane acts as a kind of reflector.

If lamps that generate a lot of heat are used for illumination, it is necessary to ensure that they are mounted at a sufficient distance from the surface of the coating. Although this type of polymer is classified as self-extinguishing, the melted surface will not be a good decoration for your ceiling.

When using cellular plastics, you need to understand that their internal structure will be visible when the backlight is turned on. Usually, the longitudinal structure of the honeycomb even allows you to decorate the ceiling, giving it an interesting look and helping to diffuse the light ceiling, however, such solutions are not always appropriate. Sometimes, it is better to opt for monolithic plastics with a matte surface.

Source: https://wikipotolok.com/potolok-iz-polikarbonata-s-podsvetkoj/

Choice by quality

When renovating a bathroom with your own hands, you usually choose easy-to-use technologies suitable for a home craftsman with low qualifications. This includes painting the ceiling. However, it is necessary to take into account that the base comes in several types:

- evenly laid concrete slabs - they can be painted with absolutely any moisture-resistant compounds with antiseptic additives against fungus and dampness, respectively (branded paints already contain them);

- cement plaster in which serious flatness defects were leveled - a water-dispersion or enamel type coating is used;

- gypsum putty applied in a thin layer for rough leveling - it is better to use water-based paints of low density with high hiding power.

Enamels will always smell like chemicals when used and for 2 - 3 days after drying. In the presence of a chemical, natural solvent, yellowness will inevitably appear on the white surface over time. Therefore, it is better to use dispersions and emulsions on water.

In addition to the solvent, yellowing can be caused by chemical reactions of pigments, fillers, paint modifiers with solar ultraviolet radiation and compounds of oxygen, chlorine, iodine, acids, and alkalis contained in the air.

The rating of paintwork materials for interior work by manufacturer and series within the brand is as follows:

| Type of waterborne paint | Name | Cost, rub./1 l | pros | Minuses |

| Latex | Tikkurila Euro Power 7 | 518 | coverage, economical consumption | price |

| Dufa Retail Eurolatex 3 | 176 | durability, water-repellent properties, hiding power | tinted mixtures darken after drying | |

| Dulux Bindo 7 BW (matte) | 580 | economical consumption, hiding power | high renovation budget | |

| Acrylic | Dulux Master Lux Aqua 40 | 700 | highest price in category | |

| Alpina Renova | 155 | easy tinting, UV resistance | high consumption | |

| Farbitex Profi interior | 93 | low consumption, price, high water repellency | easily soiled surface | |

| Silicate | Tikkurila Finngard Silikaattimaali | 500 | resistance to aggressive environments, low consumption | high price |

| Baumit Silikat Color Repro | 238 | dirt-repellent effect, fire resistance | high consumption | |

| Ceresit CT 54 | 25 | low price, consumption | high requirements for base preparation | |

| Silicone | Tikkurila Euro Extra 20 | 520 | pure color, UV resistance, wear resistance | high price |

| Caparol Capasilan | 739 | hiding power | ||

| Litokol Litotherm Paint Sil | 250 | chemical resistance, variety of colors | preparation of the base only with materials of the same brand |

Experts recommend painting the bathroom ceiling with white matte paint, or at least with a satin texture. In traditional interiors, this allows you to emphasize the decorative properties of wall tiles and other cladding. The white mat perfectly diffuses light from lighting sources, does not produce glare, and does not strain the user’s eyes.

Pearlescent paint for the ceiling.

However, in original interiors the paint is often tinted or special mixtures with various effects are used. For example, the Farbitex Pro collection has shimmering paint. Tikkurilla and Kaparol produce paintwork materials with an emerald tint and glossy effect.