A gas boiler running on propane is capable of heating a room no worse than a unit configured for regular mains gas. When installing equipment, you must remember about the oxygen regulator, since according to the standards, more of it should be supplied to the unit than to a conventional boiler. In order to guarantee the uninterrupted and safe operation of such a device, boilers are equipped with special devices that stop the operation of the device in the event of an emergency. Another feature that significantly distinguishes a liquefied gas installation from a natural gas boiler is that the burner in it has a significantly smaller diameter, and, as a result, lower gas pressure that comes from the cylinders.

Heating a private house with gas cylinders. General description and principle of operation. Fuel consumption

Heating with gas cylinders is a good alternative for main gas supply with many advantages. When installing equipment, it is important to take care of the oxygen regulator, since according to safety standards, more air must flow into a liquefied fuel boiler than into a traditional unit. For uninterrupted and safe operation of the system, additional devices are used that come into action in emergency situations.

Unlike classic equipment, which operates solely through connection to a centralized mains, autonomous gas heating of a private house is completely independent. Moreover, it functions normally even when the fuel pressure decreases. Similar units are also distinguished by the presence of a nozzle with a reduced cross-section of holes, ensuring a stable supply of the propane-butane mixture.

In order for the device to properly heat the house, heat water and solve other plumbing and household needs of the owner, it is important to refuel it on time. For this purpose, a gas tank is placed on the site - a special underground container that contains propane-butane. Depending on the volume of the tank, the fuel can last for a whole year, and the refilling process will take no more than 20-50 minutes.

Some companies producing traditional boilers equip them with injectors. They are able to switch equipment to liquefied fuel if there are failures in the main line. In this case, the user will also need to purchase a nozzle, reconfigure the valves and change several operating parameters on the heat generator board. However, after performing such actions, the unit will work flawlessly, providing efficient heating, water heating, etc.

In the absence of a gas holder, fuel can be kept in gas cylinders in the amount of 2-15 units. To connect other communications, a gas reducer is used, which controls the supply of the fuel mixture and reduces its consumption.

Autonomous gas boilers have the following components as standard:

- Safety valves.

- Temperature controllers.

- Flame and pressure sensors.

If the listed elements are present, the operation of the system will be smooth and uninterrupted.

As for fuel consumption, the exact figures depend on various factors. First of all, the area of the heated room is taken into account. So, for a building of 100 m² you will need 2-3 cylinders with a volume of 50 liters per week. For a suburban building with an area of 200 m², you will need to buy 4 tanks.

Features of heating with liquefied gas

Liquefied gas in cylinders is used as a coolant for autonomous systems. It can be pure propane or a propane-butane mixture. Experts say that this type of gasification is effective in houses of 70-100 m² with good thermal insulation. At the same time, to reduce fuel consumption, they recommend combining gas boilers with electric heating systems.

When choosing this heating option, you cannot disassemble the unit in case of malfunctions or breakdowns, since it runs on high-pressure gas and is explosive.

The user also needs to constantly monitor the condition of the cylinders during the cold season, since when the temperature drops to critical levels, interruptions in the supply of the fuel mixture may be noticed. This is due to different boiling temperatures of gases.

In what case can such a system be used?

On the territory of Russia there are a large number of settlements that are isolated from the usual benefits of civilization, such as gas. However, with the help of modern autonomous systems, gasification can be implemented anywhere in the world. There are no restrictions or prohibitions on the use of such equipment, but the implementation of the project requires considerable financial investment.

To avoid unreasonable expenses, you should understand in which cases autonomous gas supply is justified. Experts are of the opinion that it will be rational if:

- Maintenance of buildings up to 100 m².

- The presence of good thermal insulation of the room.

- Low level of heat loss.

Heating with liquefied gas may also be needed for a short-term solution, since in the future it will be possible to convert the system and connect it to the central main line.

For heating country houses and country cottages, 50 liter cylinders filled with liquefied butane and propane are used.

How long will a 50 liter cylinder last? Calculation of gas consumption

Depending on the area of the room and the characteristics of the heating system of a private house with gas cylinders, the consumption can vary from 50 to 400 liters. Consumption of liquefied gas for heating a building up to 50 m². will not exceed 50 liters per week, i.e. – 1 bottle for 7 days. If the house is larger, you will need 2-3 cylinders.

Advantages and disadvantages of balloon heating

Propane heating has both pros and cons.

If we talk about the positive aspects, then these are:

- Environmental safety of the fuel: during the combustion process, propane does not leave behind ash or slag.

- Complete independence from the centralized highway.

- Stable work.

- Easy to use and configure.

- Relatively low costs for purchasing the fuel mixture.

- High efficiency indicators.

- Easy to convert the boiler to connect to the main gas supply.

- Long service life.

- Such boilers are widespread on the secondary market, so selling them after several months or years of operation will not be difficult.

The disadvantages include the need to refill the tanks and provide special conditions for uninterrupted operation. The owner of the house will also need to carefully study the connection diagram so as not to freeze in the winter due to breakdowns or malfunctions in the equipment.

How to calculate the need for thermal energy

The simplified formula for this calculation looks very simple - 1 kW of thermal energy is spent on heating 10 m2 of building area. A more accurate formula operates not with areas, but with the cubic capacity of the house, also taking into account the height of the ceilings in the room. But for standard-type dwellings with a ceiling height of 2.5-2.7 meters, the above simplified proportion is valid. An accurate calculation of the need for thermal energy operates not only on the volume of heated space, but also on the heat resistance of walls, openings and ceilings. In addition, in this case, the average annual temperature and other nuances are taken into account.

Boiler room

However, in order to calculate the volume of fuel, a simple formula will be enough for us: 1 kilowatt = 10 square meters. As a result, heating a building with an area of 150 or 200 square meters requires spending 15 or 20 kW, respectively. And this is only an hour. But the boiler does not consume gas every minute. The work/downtime period here is divided in the proportion of 50/50 percent. Therefore, per day, a house with an area of 150 square meters will spend 180 kW (15x24/2), and a home with an area of two hundred square meters will spend 240 kW.

The cold season in our latitudes lasts from October to April - 7 months or 210 days. Therefore, annual thermal energy consumption will be 37,800 and 50,400 kW. We will focus on these values in our further calculations.

Types of propane boilers

When choosing a propane boiler, you need to understand the main types of such units, their operating principles and characteristics.

LPG gas boilers available on the secondary market are of 3 types:

- Single-circuit.

- Dual-circuit.

- Condensation.

In terms of purpose, they are practically no different from each other, but the principle of operation, design and design features look different.

Features of single-circuit devices

Single-circuit units are used only for heating purposes, so they are in demand in buildings where water heating tasks are solved in other ways. Such models cost much less than their dual-circuit counterparts, which is due to their limited functionality.

The main module is equipped with a closed combustion chamber, and when a flame occurs, it is enriched with oxygen from the outside. Combustion products are discharged to the street using a specially equipped chimney.

Nuances of double-circuit products

Installations with 2 circuits are used for efficient heating of residential buildings of any size, as well as for heating water. The fuel mixture is heated through 2 burners, which are ignited by an igniter.

After a fire, a temperature sensor is activated, transmitting all the necessary information to automated units. If the temperature exceeds the permissible values, access to the chamber is closed.

If there is a closed combustion chamber, it is additionally equipped with a coaxial chimney with forced draft. This is necessary to organize a uniform flow of oxygen and stable combustion. Waste products enter the ventilation or chimney ducts and exit outside.

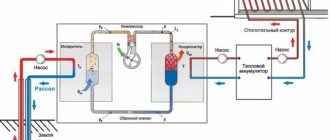

How condensing units work

Condensing units are designed to supply hot water and heat the building, but the principle of their operation differs from the 2 previous options. After entering the heat exchanger, the cold liquid warms up and enters a closed circuit.

Units of this type are high-tech equipment with economical consumption of the fuel mixture. The exhaust gas warms up to +40°C, and efficiency indicators reach 97%. Heat loss values are minimal - up to 0.5%. After this, half of the water is sent to communication channels, and the rest is sent to taps for washing, laundry and other household needs. Having completed the full cycle, the liquid from the radiator is returned to the heat exchanger.

Electric heating costs with a two-tariff meter.

Again, according to Mosenergosbyt, the price of 1 kilowatt of electricity from 7-00 to 23-00 (that is, within 16 hours) is 2 rubles. 72 kopecks, and from 23-00 to 7-00 (8 hours) – 92 kopecks. It is also known that the main energy losses of a building occur at night. Thus, the cost of heating our house will be:

150*5*(16*2.72+8*0.92) = 38160 rubles

In reality, this figure will be even lower, due to the fact that at night the heat loss in the house increases, and during the day it decreases.

Types of products by location

A gas boiler using liquefied gas can be floor-standing or hanging. Depending on the installation method, it may have specific properties that increase its practicality and attractiveness. Based on the information received, home owners can determine which option will be most optimal for their home.

Floor equipment

Floor-standing models are especially popular because they are characterized by high power and comfort. Such units are capable of serving not only small country houses, but also large-sized cottages and hotels. The main working element is a gas burner with highly efficient heat transfer.

The device is stable even during pressure surges, and its service life reaches 25 years if the operating rules are followed.

The units are equipped with heat exchangers made of steel or cast iron. The first option has reduced weight, but is quite fragile and sensitive to shock; it can last a short period of time. Cast iron elements are heavier, but durable.

Advanced modules are equipped with auxiliary elements that make them safer and more reliable. Such components include temperature sensors, draft, gas, pressure level controllers, thermostats, shut-off valves and other parts.

Depending on the design features, the unit can be equipped with electronic or piezo ignition systems. Representatives of the first group are activated automatically, and fuel consumption is minimized, since the system does not have an igniter with a flame.

Wall devices

Devices designed for wall mounting are characterized by compact dimensions and ergonomic design. They take up little space and can be installed in rooms with limited space and complex layouts.

For error-free installation of the system, you should use professional help. Devices must be installed taking into account the safety standards specified in SNiP standards.

In terms of their set of functions, wall-mounted models are practically no different from floor-mounted ones, but their power is much lower. Because of this, the use of installations in large-sized cottages is not justified. However, in terms of efficiency and operating comfort, they are superior to the floor-standing type.

Gas holder or cylinders as storage?

For many homeowners, it is more convenient to store supplies in cylinders, which pose a potentially greater danger. The absence of a safety valve increases the risk of tank rupture.

That is, it is not the gas inside that explodes, but the cylinder itself.

Gas holder for storage

The gas holder is considered a safer method of storage, which does not require the assembly of an insulating cabinet, and also comes with an electromagnetic safety valve.

The unit is placed underground, buried with sand, leaving it under pressure. This way, the integrity of the walls is maintained and the chance of fire getting in is completely eliminated.

In practice, there are cases when, during the burning of peatlands, a gas holder, which began to heat up, completely released the existing gas into the surrounding space and became completely safe. The installation circuit heats up to a red state, but no explosion occurs.

Advantages and disadvantages of units

Gas equipment for heating a private home has the following advantages:

- Autonomy and independence from the central highway, changing prices and emergency situations.

- High efficiency rates - 92-95%. Sometimes the values reach 97%.

- Quiet operation.

- Ease of maintenance and repair in case of failures. The system is easy to maintain, since all maintenance consists of replacing fuel filters, injectors and cleaning the coolant.

- Possibility of converting the system to work with centralized gas supply. If you want to connect it to the highway, you will not have to buy additional equipment.

- Long service life. For some models it reaches 25 years.

- Work safety. The fuel remains non-flammable even at high temperatures inside the chamber.

Non-volatile units are available on the market, guaranteeing complete autonomy in remote communities.

The disadvantages of the equipment include the following points:

- The need for simultaneous use of 3-4 cylinders. In this case, a gas reducer is used to connect the cylinders to the boiler.

- Fuel tanks should not be installed near the boiler - it is better to place them in adjacent rooms with a working ventilation system.

- When performing installation work, it is important to be careful and careful.

- The desire to re-equip the system will require considerable financial investments. Sometimes they reach 30-50% of the cost of the unit.

Safe Operation

It is prohibited to use heaters, electric heaters, heating cables, etc. as a means of heating heating cylinders.

Tanks with fuel reserves can only be stored inside separate cabinets, the top of which is drilled to form ventilation. It is recommended to insulate the structure from the inside on the sides and below with polystyrene foam, without covering the ventilation holes. It is not allowed to insulate the cylinders themselves by heating them from the outside, even if they are partially covered with frost.

Frozen cylinders

It is important to follow the rules for filling tanks so that equipment does not explode at home.

Immediately after assembling the heating unit, it is necessary to check for leaks.

Gas pipes must have walls 2 mm or more thick, and in places where they pass through the wall, before pulling the pipeline, a special case with soft filling or a piece of pipe of a slightly larger diameter is placed. In the latter case, the voids are filled with construction foam.

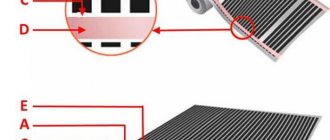

Connection diagram to the boiler

The connection of the working elements of the system is carried out according to a special scheme using a gearbox. The device converts liquid fuel into a gaseous mixture and supplies it to the boiler chamber. If the gas supply is provided by several tanks, you will need to purchase reducers for each tank.

Components for balloon heating systems

The main components of the system are:

- Boiler with burner.

- Tanks 50 l.

- Gearboxes.

- Locking mechanisms.

- Rubber fabric sleeve.

- Ramp.

The installation diagram is simple and understandable even for a beginner.

Disadvantages of heating with liquefied gas

The main disadvantages of a heating system using gas cylinders:

- The inconvenience of periodically refilling cylinders, especially in the case of self-refueling (there is no delivery of cylinders to your home);

- The imperfection of the method of determining the fullness of the cylinder - by weighing;

- High gas consumption with an incorrectly adjusted system and, accordingly, a decrease in its efficiency;

- It is not always possible to create the necessary conditions for installing cylinders - stopping the boiler at low temperatures;

Gas cylinder refilling device

Tips for the end

Modern gas heating boilers are operated for both types of fuel after the burner has been adjusted by a gas technician.

If the budget allows, then when using liquefied gas it is better to install not a pair of individual cylinders, but gas fittings for group installations with automatic control.

The formula given in the article is used to calculate gas fuel costs for a house of any size. Carefully apply the coefficients for main gas and for a liquefied mixture of propane and butane.

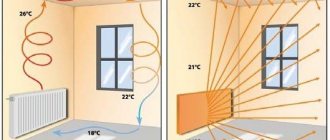

Reducing consumption

This is known: if you insulate your house well, the fuel consumption for heating will be significantly reduced. Therefore, before selecting and installing equipment and laying main routes, it is necessary to properly insulate the house: walls, roof and attic, floor, replace windows, and make an airtight sealing loop on the doors.

Particular attention should be paid to the roof and windows. It is assumed that out of 100% of lost heat, 35% goes through the roof, about 25% is lost at the windows. Therefore, use the best thermal insulation materials and good double-glazed windows, which have a low thermal conductivity coefficient. Cheap double-glazed windows are immediately obvious: their aluminum or steel “skeleton” is always very cold in winter, and a lot of heat is lost directly through it. Even the glass itself does not transmit heat as much as the metal profile on which the glass is held does.