Penoplex and mineral wool

“The wise power of a builder is hidden in every person, and one must give free rein to its development.” (Maksim Gorky).

A huge hello to all blog readers! I hope you have already “come to your senses” from the holidays and are ready for the next portion of construction information. If yes, then read on, if your health still leaves much to be desired, close the site, turn off the computer and go to visit friends for “treatment.” Well, we will continue...

Today I decided to choose the topic of choosing two main “ideological competitors”, well, like a car with front or rear wheel drive. Or something similar, which has approximately an equal percentage of supporters on both sides. I’ll try to make a neutral comparison, and the choice is clearly yours. So, penoplex or mineral wool, which is better?

The right question is - what are we going to insulate? Well, let's take a little look at the main structures: walls, foundation, floor.

Variety of mineral wool

Subtle point. If penoplex* is, in fact, the name of the final product, then mineral wool is a broad concept, including glass wool, slag and stone wool. Therefore, as the Germans say, “apples must be compared with apples,” which means we’ll focus on one thing. I choose stone mineral wool, which is more often called basalt. It has better thermal insulation properties in comparison with its “slightly backward brothers”.

*There is another subtype of penoplex - technoplex. This is a bird of a feather. True, there is not a big difference in the name and minor parameters, but we will not go into these details. That's it, let's begin. In the red corner of the ring there is penoplex, in the blue corner there is mineral wool. Gong!

Insulation of walls with penoplex from the outside

Building a personal home is only part of the story.

You also need to make it comfortable. A healthy atmosphere should reign in residential premises in any season; the appearance of mold in the home is completely unacceptable. It is important to provide high-quality and thoroughly thought-out thermal insulation of the building; this will allow significant savings on coolant consumption without compromising the comfort of the house. Today, the building materials market is replete with the supply of insulation materials. Polystyrene-based heat insulators are very popular. These include the now familiar foam plastic and more high-tech and effective options. For example, such as extruded polystyrene foam. If we discuss brands that produce the material, the name “Penoplex” immediately comes to mind. This brand is distinguished by benchmark quality indicators among this type of insulation.

Foamed polystyrene slabs provide thermal insulation for most structural elements of a residential building, from the base to the space under the roof. This article offers a comprehensive review of the process of insulating walls with penoplex from the outside. The technology is not particularly complicated and is intuitive, which means that, following the proposed recommendations, everyone is quite capable of coping with the task on their own. But first you should learn more about the insulation itself, called “Penoplex”.

Basic elements of style

Improvements in construction technologies and the emergence of new materials contributed to the further development of this style, which is successfully used today for the construction of not only individual luxury houses and cottages, but also for architectural complexes and entire villages.

The basis of a modern house in the half-timbered style can be a power frame made of laminated veneer lumber, steel or reinforced concrete. To fill the free space between the purlins, foam blocks, aerated concrete, and insulation are used. Recently, mineral wool or polypropylene boards with membrane layers are used - windproof and moisture-proof. Instead of ordinary window blocks, double-glazed windows are installed.

Updated half-timbered building

In the second half of the last century, an updated half-timbered building appeared. Houses finished with a solid glass facade and frames made of modern materials began to look original and unusual. Sometimes they install glass with tinting or light spraying.

For panoramic glazing, single-chamber double-glazed windows with multifunctional or energy-saving glass with argon filling are used. Windows can have additional features such as:

- protection of the room from overheating and powerful ultraviolet rays;

- self-darkening - achieved by installing an electromonochrome package with a blue or white tint;

- installation of packages with armored glass;

- double-glazed windows with electric heating.

If previously the load-bearing frame was not hidden inside the room, then in modern planning gypsum fiber slabs are used for this.

Step-by-step technology for wall insulation with penoplex

Penoplex panels can be mounted on the wall surface only after preliminary cleaning of various contaminants, dust and small debris. For better adhesion, the surface is slightly wetted, and the insulation is thoroughly coated with special glue. Then the fragment of material must be applied to the surface of the wall with the adhesive side inward and pressed tightly against it.

Gaps between tiles can be eliminated using polyurethane foam; otherwise, “cold bridges” may form on the insulated surface. After the adhesive layer has completely dried, they proceed to fastening the dowel-nails. The following sequence of actions will help you carry out high-quality installation of insulating material on your own:

- The adhesive composition is mixed in a separate container. An electric drill with a special attachment will help to stir it better.

- The glue is applied to the penoplex fragment using a notched trowel with a suitable tooth height. The optimal layer thickness is about 10 millimeters.

- Place the sheets in the direction from left to right and from bottom to top. An indent of 30 to 40 centimeters should be made from the bottom edge of the base.

- Penoplex fragments need to be glued along the entire perimeter of the walls above the base. This row will become the initial level of thermal insulation of the facade.

- The laying of the insulating layer must be carried out in compliance with the technology of overlapping vertical joints, therefore it will resemble the principle of alternating brickwork.

The next stage of wall processing includes the mandatory installation of scaffolding, since each sheet of material will be secured, in addition to glue, also with an “umbrella” for installation. Its length should be 2 times the thickness of the insulation sheet. When the surface is completely pasted over, all that remains is to wait until it is completely dry.

REFERENCE! Plastering of the heat-insulating layer is carried out using a basic composition. It includes, among others, a reinforced mesh, the density of which must be at least 145 g/m2. It is mounted with an overlap of 10 centimeters. Then a corrective layer of plaster coating, about 5 millimeters thick, is applied, after which the insulated surface can be decorated decoratively.

Penoplex fragments are secured to dowel-nails. To do this, a number of special holes are formed in the wall, which can be created using a hammer drill. Their diameter should be equal to that of the dowels. Then the mounting umbrellas, the length of which is equal to the thickness of the insulation sheet + 5 centimeters, are installed in the holes. The number of fasteners is 5 pieces/m2. For door and window openings, 6 to 8 fasteners will be sufficient.

The slabs are mounted only end-to-end; if there are gaps, they are eliminated by pouring polyurethane foam. When it dries, the excess is removed with a sharp knife, a construction knife or a stationery knife. After this, a layer of plaster about 5 millimeters thick is applied, which will help level the surface. When the plaster is completely dry, you can begin applying finishing material with a decorative effect.

List of required tools

It is not difficult to insulate a brick house with polystyrene foam; anyone can do it without the help of professional builders. You just need to properly prepare the materials and tools that you will need for the job.

Here is a sample list of them:

- perforator;

- drill with an attachment for mixing adhesive and plaster solutions;

- several hammers;

- construction level (ideally laser);

- ordinary smooth spatulas of medium and large sizes (from 80 to 100 and from 350 to 450 millimeters);

- notched spatulas (20 centimeters with a tooth height of 10 millimeters);

- sandpaper for sanding;

- plastic buckets;

- construction or stationery knife;

- roller for painting;

- required amount of penoplex;

- polyurethane foam;

- fiberglass reinforcement mesh with cells 5×5 mm;

- aluminum perforated corner;

- special glue designed for penoplex;

- plaster;

- primer;

- putty;

- dowel-nails (“umbrellas”).

Features of insulating a brick house with penoplex from the outside under siding or plaster

Penoplex is a synthetic insulation material produced in the form of slabs. It has a porous structure, due to which it has excellent thermal insulation characteristics.

It can be used to insulate almost any surface and does not require special skills to install the slabs on the walls of the house.

The standard sheet width is 60 cm, and the length is 120 or 240 cm. The sheet thickness can be from 2 to 10 cm.

To insulate external walls, it is recommended to use the “Facade” modification, the density of which is 25-32 kg/m³, and the operating temperature ranges from -100 to 75 degrees Celsius.

What to glue

To attach penoplex, you can use cement, waterproofing mixtures, polyurethane glue, composite polymers, gypsum-based mixtures . If the surface is dry, then you can use compositions based on gypsum or cement.

Waterproofing compounds are made based on bitumen. Foam adhesive can be used. The adhesive composition should not contain gasoline, solvent or other components that could damage the penoplex.

Pros and cons of penoplex as insulation for a brick house

Advantages of penoplex for insulating brick walls outside:

- Good thermal insulation properties . The thermal conductivity coefficient of the material is 0.030 W/(m*C) according to GOST 7076-99. This is one of the lowest indicator values among all insulation materials.

- Low vapor permeability . The vapor permeability coefficient of the material is 0.007-0.008 mg/(m*hour*Pa). A 2 cm thick slab can retain fumes in the same way as a layer of roofing felt.

- Almost zero water absorption according to GOST 15588-86. Moisture is not absorbed into the internal structure of the material, so it can even be used to insulate baths and saunas.

- High strength . Penoplex can withstand significant loads, strong compression and significant breaking force.

- Good sound insulation.

- Fire resistance . During production, the material is impregnated with special substances that prevent fire.

- Easy to process and easy to install . Penoplex can be cut well with a painting knife, and you can work with it in any weather.

- Penoplex is lightweight (due to its cellular structure with air bubbles).

- Service life – up to 50 years . During this time, penoplex slabs retain their original shape and all their properties.

Disadvantages of penoplex:

- Destruction by direct sunlight and some solvents.

- Unnatural origin.

- Strong smokiness (even after fading).

- Quite a high price.

Self-installation

The insulation is mounted on foundations made of reinforced concrete, soil and wood. When working, the following rules should be observed:

- strictly follow the installation instructions;

- Carefully adjust the slabs to each other so that there is no free space between them.

- Distortions and rolls are unacceptable.

If the material is laid in two layers, then you need to ensure that the joints of the upper plates do not coincide with the joints of the lower ones. Otherwise, pockets filled with air will appear in the insulating layer. Condensation will accumulate in them. Such defects impair thermal insulation and subsequently lead to delamination of the insulation.

A special compound is used to glue the boards together. It improves the thermal insulation properties of insulation. A “finish floor” is laid on top of the penoplex, for which the following materials are used:

- laminate;

- linoleum;

- parquet;

- polymer coating;

- ceramic tiles;

- boards.

Decorative coating is mounted on foam boards

Technology for insulating a brick house with penoplex from the outside

Insulation of brick walls with penoplex can be carried out using various methods :

- Using the “wet facade” method with further finishing with plaster.

- Using the “ventilated facade” method with siding cladding.

“Wet façade” insulation method

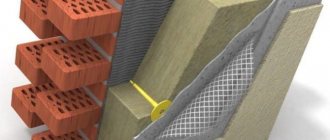

The wet facade method is based on the use of mixtures and compounds that are diluted in water for insulation: this is glue for fixing foam boards and a layer of plaster with a reinforcing mesh.

The output is a multilayer structure without air layers .

Multi-layering is a feature of this method , in which each layer plays a specific role:

- adhesive – special glue or dry mixture diluted with water, fixes the structure;

- thermal insulation – foam layer;

- reinforcing – painting mesh, gives strength and facilitates further wall finishing work;

- plaster – a layer of plaster that protects the insulation layer from snow and wind and mechanical damage;

- decorative – finishing layer.

Insulation technology using this method:

- Cleaning walls of old coating and dirt.

- Applying a layer of primer.

- Fastening the insulation boards with glue (for example, Teploklue or Cerezit CT-43 ).

- Laying the slabs begins from the bottom corner of the wall. For external brick walls, it is recommended to take penoplex slabs 5-6 cm thick. An adhesive layer is applied to the sheet, the sheet is applied to the wall and held for 30 seconds.

- The glued sheets are additionally fixed with plastic dowels with an umbrella cap.

- Fastening with special glue of the painting mesh.

- After the glue has dried, within 1-4 days , apply a layer of plaster.

- Applying finishing – façade primer and wall painting.

The complete technology for applying plaster on penoplex is described in the article “Plastering on penoplex is the best way to protect the facade from bad weather.”

Insulation method “ventilated facade”

This method is used when insulating a house with penoplex under siding .

Varieties

There are several types of penoplex, differing in composition and technical characteristics.

The final cost of penoplex depends on its quality, and when making the final choice, many are guided by brand names:

- roofing Used for thermal insulation of roofing structures of all types;

- wall Used for wall decoration;

- fundamental. They are used to insulate foundation structures or basements. The main advantage of this type is considered to be moisture resistance;

- penoplex-comfort. Popular for insulating balconies and apartment rooms. It has good performance, but is quite expensive;

- penoplex-45. A material with maximum strength, used for the construction of roads, runways, and withstands critical temperature conditions.

Materials and tools

To insulate a brick house with penoplex, you will need the following tools :

Materials required for insulation:

- penoplex;

- wooden blocks;

- reinforcing mesh;

- glue;

- self-tapping screws;

- plastic dowels;

- primer;

- plaster;

- siding panels.

In conclusion, we can say that insulating the external walls of a brick house with penoplex is one of the most popular methods of thermal insulation of buildings. The material gained its popularity due to its high quality and excellent thermal insulation characteristics.

, you can do the insulation of external walls or contact experienced specialists.

For a master class on insulating a brick house with penoplex outside under siding, watch the video:

Warm floor - what is it?

The warm floor consists of mats and a heating system.

The first heated floor surfaces were used by the ancient Romans to heat baths. Hot air passed through special channels installed under the floor. The principle of modern heating designs has remained the same, but during this time the heating system has been significantly improved. The design is used for installation in premises of any purpose; it is considered an excellent alternative to conventional central heating. Efficiency is achieved due to increased heat transfer. Installation of the structure does not take much time; the procedure can be carried out in any room.

Penoplex and brick in a house insulation system

Insulating the outside of a house with penoplex has recently become more and more in demand. It is used both for insulation of panel multi-storey buildings and in private housing construction. It is never too late to insulate your house with penoplex, but it is better to do this at the construction stage, immediately calculating the necessary parameters. One of the most popular designs is penoplex and brick - this tandem provides good heat conservation and is easy to install. But before you start work, ask yourself what thickness of penoplex is better for external walls? Let's consider what options there may be.

Choosing glue

The choice of adhesive for insulation is influenced by the fact that penoplex has low resistance to substances such as:

- benzene, toluene, xylene;

- formaldehyde, formaldehyde;

- acetone, methyl ethyl ket;

- diethyl alcohol, solvent based

- gasoline, kerosene, diesel fuel;

- coal tar, epoxy resin hardeners;

- oil paints.

Mineral (cement) based adhesives are recommended:

- Stopter K-20 company “ATLAS”;

- UNIS®Teploclue Group of Companies “Unis”;

- PlitonitSTF from the company “MCBauchemieRussia”

- CERESIT CT 85 from Ceresit;

- STYROFIX company TERRACO.

or polyurethane base:

- TYTINSTYRO company “SelenaCo.SA”;

- ISOLEMFI Z 104/11 company “EMFI”;

- KleiberitPurLeim 501 from Klebchemie;

- INSTASTIK company “DowChemikal”;

- ZENIT -36/1K “EMFI”.

We prepare glue according to the manufacturer's recommendations.

Layered brick and foam masonry

When building houses, sometimes brickwork with penoplex, called layered, is immediately used. It consists of three layers: an inner brick or concrete layer, a middle layer of extruded polystyrene foam, and an outer layer of facing brick. Its peculiarity is that the outer parts must be connected to each other with special embedded parts (knitting wire, fiberglass); therefore, their presence must be foreseen in advance.

Insulation of brickwork with penoplex occurs according to conventional technology: heat insulation slabs are placed on a special glue, then a straightening gap is left, which will be covered with sand, followed by cladding. In the finished building, it is also possible to carry out external insulation with penoplex foam and brick cladding. In this case, the parts that will fasten the facing brick to the load-bearing wall must be installed additionally.

Production of expanded polystyrene

The French were the first to start producing it. The industrial production of expanded polystyrene was mastered in the late 30s of the twentieth century, only 10 years after the first production. In the early 60s of the last century it began to be used in construction

Possessing a whole range of qualities useful for construction, extruded polystyrene foam has attracted the attention of manufacturers of the Penoplex material

Penoplex acquires its properties during the production process. When receiving EPS, polystyrene foam is converted into a liquid state under the influence of heat and extruded using screw machines into a mold. Under the influence of temperature, the gas in the granules expands many times and the granules sinter together, filling the entire provided volume. Then the mold and material are cooled, the mold is halved and the resulting product is ready for packaging.

Insulation of brick walls with penoplex from the outside and inside

You can insulate a house made of clay or sand-lime brick with penoplex not under the cladding, but under the plaster. This method is much less labor-intensive; even an inexperienced craftsman can do such work. Insulating brick walls from the outside with penoplex begins with preparing the walls: they are leveled and primed as far as possible. The use of special glue for insulation, again, is mandatory. Plates made of extruded polystyrene foam are additionally secured with plastic mushrooms. A sickle mesh is glued on top of the slabs. All that remains is to plaster, and the external insulation of brick walls with penoplex can be considered complete.

If necessary - if it is not possible to insulate the outside or it is necessary to ensure rapid heating of the room - insulate the brick walls from the inside with penoplex. The technology in this case is practically no different from the previous one. The difference, of course, is in the finishing: from the inside, the walls, insulated with penoplex, are covered with plasterboard, clapboard, and plastic.

Calculation of the thickness of penoplex for a brick house

In order not to waste money on materials, you need to clearly calculate the thickness of the penoplex for a brick house. The calculation of the thickness of penoplex for a brick house is carried out according to SNIPs, which take into account the location of the house, climate zone, masonry thickness, internal insulation and other factors. A specialist will be able to tell you exactly what thickness of penoplex foam will be needed for brickwork in your home. We will give an example: in a temperate zone, to effectively insulate a wall of two bricks (24 cm), penoplex with a thickness of about 6 cm is suitable. Considering that 50 mm of penoplex is equivalent to brickwork a meter thick, it is easy to imagine what kind of walls would need to be built to ensure such heat transfer.

Building codes

Certification documents are issued for facade insulation systems in Russia - Technical Certificate of Rosstroy of the Russian Federation. But so far, not a single technical certificate for a facade insulation system with a thin plaster layer specifies penoplex, technoplex or its analogues as the main wall insulation.

That is why you will not find the facade of an administrative building insulated with extrusion, because not a single state inspection organization will approve the insulation project for such a facade (and the insulation of the facades of administrative buildings must be approved), unless it is a “squatter construction”.

Easy to use, easy to buy

Penoplex is produced at factories under the same name in Perm, Leningrad region (Kirishi), Novosibirsk, Taganrog and Irkutsk. This manufacturer has 10 official representative offices in all federal districts of Russia.

Technoplex is produced at the enterprises of the TechnoNIKOL group of companies in Mineralnye Vody, Novoulyanovsk, Uchaly (Bashkortostan), Ryazan, Yurga (Khanty-Mansi Autonomous Okrug). And also has 10 representatives throughout Russia.

Both manufacturers have their dealers in each regional (territorial) center, as well as in large regional cities.

Economy

For facade insulation systems with a thin plaster layer, two insulation materials are certified - polystyrene foam PSB-S25F (white, density 16-19) or basalt slab (mineral wool).

Indeed, penoplex and its analogues have excellent characteristics in terms of thermal resistance coefficient. It is better than PSB-S25F by about 30%. Those. In order to get the same coefficient of thermal resistance of the walls, we must insulate the walls with penoplex 70 mm thick or polystyrene foam PSBS25F 100 mm. Extruded polystyrene foam is 3 times more expensive than ordinary facade polystyrene foam (PSBS25F). That is, by insulating walls with penoplex, you lose 40% on the cost of insulation.

Ground mounting

Penoplex is widely used to insulate earthen floors. Floors on the ground are installed as follows:

- Carefully level the installation site.

- Cover it with expanded clay and sand to a height of 40 cm. The layers should be positioned strictly horizontally.

- Insulation boards with a thickness of 5 cm or more are laid. The sheets are carefully joined together, leaving no gaps. The joints are sealed with tape.

Penoplex can be used to effectively insulate an earthen floor

- The entire base along the edges is covered with roofing felt or polyethylene. They are also mounted on penoplex.

- Cement is poured on top, on which a metal mesh is laid to strengthen it. Its layer must have a thickness of at least 5 cm.

- The screed must be strictly leveled horizontally, otherwise difficulties will arise when laying the floors.

Installing a floor in a bathhouse has its own characteristics. Here the screed is installed at an angle to ensure water drainage. To cover the floor, it is better to use sanded boards mounted on joists.

Vapor permeability

Extruded polystyrene foam has a very, very low vapor permeability coefficient - 0.007 mg/(m×h×Pa) according to Penoplex and 0.018 according to other manufacturers, i.e. it's almost a "vapor barrier". Insulating a house with penoplex prevents moisture from escaping from the wall structure and prevents them from drying out and ventilating. When insulating the facade with penoplex, the microclimate in your home first of all deteriorates - the humidity in the room increases and air exchange decreases. To correct the situation, it is necessary to install forced supply and exhaust ventilation.

It’s amazing to look especially at brick houses, which, like a thermos, are packed with absolutely “non-breathable” extrusion.

Answers from experts

Engineer:

Both brick and foam are different.

Formally, the thermal conductivity of red brick is 10 times greater than that of highly porous foam. (0.56 and 0.05 W/m*deg - respectively)

That is, feel free to multiply the thickness of the foam by 11 and get the thickness of the brick wall.

Kirill Gribkov:

none

Bolt-gnawer:

Extruded polystyrene foam "Extraplex" with a thickness of 20 mm is equivalent in its heat and sound insulating properties to a brick wall with a thickness of 370 mm

Samson Altunyan:

Hello, the best!

You forgot to mention the conditions (parameters) of the assessment...

1) If you mean thermal conductivity? . The engineer answered you.

2) If we are talking about mechanical strength? . Polystyrene foam is NOT a replacement for brick. Especially in earthquake-prone regions.

3) Durability? The brick will last longer.

4) Resistance to environmental influences (temperature changes, humidity, etc.)? Foam plastic, in this case, is not even a building material...

5) Safety (physiological, chemical, environmental)?..Again, the comparison will be in favor of fired clay (brick)...

And generally speaking.. . That's not what they teach you... ;-( Foam plastic is NOT a good choice of material for construction or interior decoration. And in this ODIN is absolutely right...

Good luck to you!

Nurgaliev Marat:

5 cm of penoplex is half a meter of brick!!! And don't listen to the reindeer herders!

kukuzya:

I read the answers and I'm confused. What kind of tusk do you need to be in order to answer the question about the equivalence of brick and foam plastic and compare their load-bearing abilities... Of course, they compare thermal conductivity...

ST:

10cm of foam replaces 50cm of brick

Lulechka:

thickness is the same. in terms of strength, thermal insulation and other qualities - this is for builders!!!

Igor Chekalin:

Considering the beginning of winter, I suspect that we are talking about thermal conductivity?

Is the brick hollow or solid, silicate, ceramic, silica or even slag? The difference between different types is almost two times, and with silica it is 5 times.

For the worst case - solid sand-lime brick - the thickness ratio is approximately 20 times. That is, in terms of thermal conductivity, a 250mm wall (ordinary one-brick masonry) corresponds to only 13mm of polystyrene foam. For hollow bricks the ratio is ~10 times. That is, in our case - ~25mm foam. However, brickwork is almost airtight, and when insulated with foam plastic, there are gaps at the joints, loose edges, etc., so it’s not entirely correct to take such a formal and mathematical approach.

Well, more accurate numbers - google for “thermal conductivity table of building materials”

Alexander Kulikov:

The thickness of your knowledge of the Russian language...

Albert Belkov:

In fact: 1 cm of foam plastic in terms of thermal conductivity can be estimated as half a brick inside the masonry or backfill.

ST:

10cm of foam replaces 50cm of brick