In buildings that are not equipped or connected to a central heating system, a gas gun is often used to heat the premises. This mobile and easy-to-use device with a thermostat is able to quickly heat the air in the room and maintain a comfortable microclimate at a given level. Therefore, many owners of country and private houses, as well as industrial premises, prefer gas guns to their diesel counterparts.

Features of using composite gas cylinders

Composite gas cylinders have recently become increasingly popular. This is due to their advantages over their steel counterparts.

- Weight. Almost twice as light as steel.

- Ease of handling. There are comfortable handles.

- Transparency. The fill level can be easily seen.

- Convenient storage. Can be placed one on top of the other and stacked.

- Life time. The service life is practically unlimited.

- Operational safety. It is caused by the absence of sparking and a safety valve and fusible link built into the gas cylinder.

Composite cylinders supplied to the Russian market are produced in the Czech Republic, Norway and India. When purchasing such a cylinder, it is necessary to clarify the connection standard. If the gas cylinder is equipped according to the Russian standard, you can use a regular reducer for the gas cylinder. If the gas cylinder comes with a European connector, then you will need to either order an adapter or purchase an imported reducer. Please note that each additional connection increases the risk of gas leakage.

The further into the forest...

As the LPG system is used, it is not only the filters that are subject to natural wear and tear in the gearbox. Of course, their timely replacement every 10 thousand kilometers will help the unit last longer and save on complex repair work. But after 80-90 thousand kilometers, it will not be possible to get by with just installing new filter elements, since very soon one of the main protective components - the membrane - will die for a long time. And in this situation, having a high-quality repair kit, selected in accordance with the gearbox model, will be very useful. Most companies that assemble emergency kits divide them according to the level of completeness:

This picture, for example, is observed in Tomassetto, the gearboxes of which are most often found in our latitudes. The price difference between the initial and full versions is not that significant, but the effectiveness of these products is at different levels. At the turn of the second hundred thousand mileage, it is better to use kits with full equipment for repairs. They will contain both gas and antifreeze membranes, as well as a set of filters, O-rings and other consumables.

Kinds

The types of gearboxes differ in the following ways:

- View. Post model - for cylinders. Central - for pipelines.

- Working method.

- Connection type.

- Appearance.

- Throughput potential.

- Reduction level. 1 or 2 cameras.

There are household and industrial types. The latter are equipped with pressure gauges.

Since the importance of a reducer for a gas tank is great (safety, stable operation, etc.), then the question of whether a reducer is needed for a gas cylinder disappears instantly.

And when choosing a device, you should take into account the compliance of its dimensions with the needs of the equipment connected through it.

Cylinders with these devices are placed inside or outside the house. In the first situation, the room should have the option of rapid ventilation in case of a dangerous situation.

The outdoor version is safer.

Types of devices according to such criteria as gas flow:

- Acetylene. The gearbox is white.

- Hydrogen. Dark green color of the device.

- Oxygen. The gearbox is blue.

- Propane-butane. Red gearbox.

- Methane. Also red.

What kind of reducer is needed for a gas cylinder? The answer is point 4.

Versions designed for other gases are prohibited for use with liquefied hydrocarbon mixtures.

The characteristics of the device must be equal to those of the cylinder and the device on which it is mounted.

Proper adjustment of the power of the outgoing gas flows is also of great importance. When the parameters exceed the permissible values, the automation in modern gas technology turns it off. If the equipment does not have such protection, an accident may occur.

Gearboxes are also required to be certified.

There are the following standards for connecting to a gas tank (by thread):

- W 21.8 x 1/14 – cylinder type DIN 477/T1. Abbreviated as SP 21.8

- G – pipe-cylinder type. The number after the letter is the template diameter (measurement in inches).

- M – metric. After the letter there are two numbers. The first is diameter. The second is the thread distance (in mm).

For connection, you can use a regular flexible hose. The fitting of the device is wetted with water. A screw clamp is used to secure the connection.

To connect bellows hoses, an adapter with thread is used. It is screwed in to replace the fitting. After which a check takes place - gas is passed through without the devices being turned on. The gas consumption valve is unscrewed and the control screw is turned out. The spring is extremely weakened. When the pressure gauge reflects a smooth development of pressure, the device is not suitable.

Having assembled the system, you need to arrange the flow of gas from the tank to the reducer. You need to rotate the adjusting screw to set the optimal pressure at the outlet section. The contact points are moistened with a soapy mixture. This is a gas leak test.

Required materials and tools

It is important to understand that homemade production of gas heat guns should only be carried out with proper qualifications and extensive experience in working with gas and tools. If you take on work unprepared, it can lead to irreversible consequences.

To make a gas gun you will need the following tool:

- Metal pipe. Fuel will be supplied through it to the main system.

- Bulgarian. It is better to use 125, as it is more convenient to work with.

- Sheet steel.

- Electric drill and metal drills.

- Steel tube with a diameter of 8 mm. It will be used to make a heat exchanger.

- Thick reinforcement for the stand on which the gun will be located.

- Fan power – from 12 W.

You can use a welding machine to speed up the process. You can also buy paint that is resistant to high temperatures in advance.

When creating this gun, do not forget about safety precautions

Self-connection: is it possible or not?

Almost all representatives of gas services say that only specialists who receive money for their work have the right to work with gas. However, to avoid unnecessary expenses, it is quite possible to carry out such an operation yourself.

The master will not encounter any special difficulties on the way to his goal. To connect a gas stove, you first need to choose the most suitable location for the tank, and then start organizing the outlet (flexible hose, pipe) to the household appliance.

The only skill required is working with gas keys. But you will have to follow the safety rules for handling gas equipment. Household cylinders can be installed both indoors and outdoors. However, according to fire codes, the ideal place for such equipment is still outside the home.

The kitchen or utility room in this case are not the best alternatives. Of course, when placing the tank outside, you will have to install a longer pipe (hose) and make a hole in the wall. But from a safety point of view, this option will maximally protect residents in the event of force majeure: for example, there will be less likelihood of a fire or explosion.

Areas of application of gas guns

The popularity of gas heat guns is determined by their safety, practicality and wide range of applications. These devices are used not only for heating living rooms, but also for domestic needs: drying objects with large dimensions, as well as for ventilation of rooms.

Operating a gas gun in a garage will create conditions for normal starting of the car, as well as performing repair work. In addition, the gas gun is in demand not only in domestic conditions, but also in production. This equipment is used for high-quality and economical heating of greenhouses, greenhouses where vegetables, seedlings and flowers are grown.

A gas gun is an autonomous heating device, but it can also become a structural element of an entire installation, which is designed to maintain the necessary microclimate in the room. Structures that run on natural gas can be used to heat automotive, agricultural and specialized equipment.

The capabilities of this device are often used during repairs, when it is necessary to quickly dry walls after puttying. In addition, this type of equipment is used when installing suspended ceilings, since the fan built into the structure speeds up these processes.

In addition, the functionality of a gas heat gun will be useful in large areas, the size of which exceeds 25 m².

Operating principle

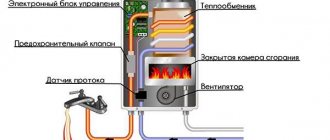

The operating principle of the gearbox depends on its type.

The direct reducer kit includes 2 chambers with high and low pressure zones, which are separated by rubber membranes . Such devices are equipped with fittings. Modern models are designed in such a way that the bellows line is integrated directly into the gearbox.

On sale you can find devices with a third fitting; it is intended for installing a pressure gauge.

The gas entering through the hose ends up inside the chamber. The generated pressure tries to open the valve. On the other hand, a spring locking mechanism exerts pressure on it, returning it to its original place. The valve prevents uncontrolled penetration of high pressure fuel coming from the cylinder.

The principle of operation of the reverse gearbox is the opposite of that described above. Gas enters the chamber and forms increased pressure. As it accumulates, it prevents the valve from opening. In order for fuel to enter the household device, it is necessary to change the position of the adjusting mechanism towards the right-hand thread.

How to choose a gas heater?

To select a device with suitable parameters, the following characteristics must be taken into account:

- the material from which the building is constructed (brick, stone or metal);

- quality of thermal insulation (types and features of internal and external insulation);

- the absence or presence of electrical wiring in the room (the gun will not be able to work without electricity);

- features of the ventilation system;

- total area of the room;

- operations that take place indoors.

- manufacturer and level of product quality;

- gas gun body shape;

- heating method (direct or indirect);

- unit power level;

- dimensions of the device.

In addition, it would be a good idea to read reviews from other consumers who have already purchased and used the device.

Precautionary measures

Household gas is very dangerous. The main threats posed by propane are:

Reminder about domestic gas

- Fire hazard.

- Unsuitable for breathing.

- Explosion hazard when the maximum concentration of propane in the air is reached, as well as when the temperature in a closed volume rises sharply.

- During a gas leak, the temperature drops sharply and frostbite is possible.

To preserve the life and health of people and their property, precautions should be taken:

Rules for using gas

- Avoid proximity to open flames and heat sources.

- Avoid the presence of other flammable materials in the work area.

- Eliminate the presence of nitrates and perchlorates near gas equipment due to their chemical activity.

- Do not use the reducer for a propane cylinder if it is damaged or leaking.

Design features and maintenance

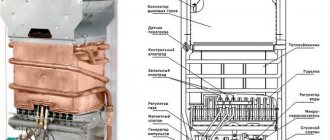

According to their design, gearboxes differ into direct and reverse acting devices. The differences between them are in the design details, the performance characteristics are identical.

Design of gearboxes for a gas cylinder

In addition, gas reducers are used in single-stage and two-stage types. In single-stage, the pressure is reduced in one stage. In a two-stage reduction, the reduction is carried out in two steps. Balloon single-stage reducers are most widely used due to their reliable design and ease of use.

A gun

Today, many owners use a heat gun to heat rooms or small houses.

It can also be attached to a cylinder. And here the question may arise - why do you need a gas reducer for a heat gun?

The fact is that pressure drops, especially increased pressure surges, are extremely dangerous for such a device. This is fraught with a rapid explosion. And here it is simply necessary to stabilize gas flows and their pressure. This must be much higher than in cases with burners.

Attaching the gun to the cylinder is easy. Connection method: gas hose. Its minimum length is 3 m. The optimal pressure is assigned to the reducer, usually 1.5 MPa.

The container and the gun are connected with this hose and union nuts. Paronite gaskets are placed under them. The position of the cylinder is only vertical. The tap opens only after it is installed.

How to make a gas gun with your own hands?

If your knowledge and experience allow you to make such a complex heating device yourself, then you can make an indirect heating gas gun with your own hands.

To make the device you will need:

- two pipes 1 m long and with a diameter of 18 cm (body) and 8 cm (combustion chamber);

- pipe with a diameter of 8 cm and a length of 30 cm (outlet pipe);

- axial type fan with round flange;

- gas burner equipped with a piezoelectric element.

Before you start creating a device, you should carefully study the diagram, which will become a guide during the work process.

Do-it-yourself gas heat gun manufacturing technology:

- First you need to take a pipe with a large diameter and make a couple of holes. The size of one of them is 8 cm. An outlet pipe for heated air will be attached to this hole. The size of the second is 1 cm. This hole will be used to fix the gas hose. You need to make a combustion chamber from a pipe with a diameter of 8 cm.

- Then you need to assemble the plug. It can be cut from a sheet of metal. This part must cover the gap between the housing part and the combustion chamber. In this case, it is very important not to block access so that it is possible to connect the structure to the chimney.

- After this, all the elements come together. To do this, you will need a welding machine and skills in handling it. The combustion chamber along with stiffeners is welded inside a large pipe. A pipe and a plug are fixed from the outside. Through this element, heated air will enter the room. All that remains is to install the gas burner and fan. All elements must be firmly fixed.

Helpful advice! To keep the combustion chamber firmly in the central part of the housing, it is better to use plates that are welded to the pipe.

The process of assembling a direct fired gun is much simpler. Such a device consists of a pipe, at one end of which a fan and burner are attached. Combustion products and hot air flows will come out from the opposite side.

Periodic inspection and service work

Inspections and service work are divided into daily and periodic.

Leak check

Daily inspections must be carried out before starting work. Periodic checks are usually carried out in specialized workshops. For gearboxes equipped with a filter, the work includes cleaning or replacing it

Second phase. Replacing jets

Then I started changing the jets. I didn’t want to unscrew anything in the old stove, everything had already worked there, so I looked at the components from the new stove.

Manufacturers of modern gas stoves supply a set of jets designed for propane-butane or natural gas. Usually the threads are all standard. A jet is similar to a bolt, but it has a hole in the center through which gas flows. The diameter of this hole varies for different burners and even stove models. For bottled gas, nozzles are installed with a smaller diameter. If the diameter is larger, then more gas will pass through it, and this will lead to soot appearing on the dishes, since the gas will not burn completely. In addition, each burner on the stove also has a certain nozzle; the smaller the burner, the lower its power, and this means that the diameter in the nozzle will also be small.

They are made of bronze or brass. At the end of the nozzle there are numbers stamped, indicating the diameter of the nozzle in hundredths of a millimeter. For example, the number 115 means the diameter is 1.15 mm.

Source levnesporaky.cz

There are several signs that the jets were selected incorrectly, this is when the flame on the burner hisses and comes off from it. The gas does not burn blue, but yellow-white with red flashes, or it burns unevenly and soot appears.

One of my burners was burning with a bright red flame. I had to turn off the stove, unscrew the jet and go to the store with it. There, based on the brand of slab, they selected the right one for me.

Source apparat.ch-sever.ru

It is not difficult to distinguish jets designed for liquefied gas from natural gas. For a plate connected to a cylinder, the jets are longer, there are more threads and the hole size is reduced.

To change the jets you will need a Phillips screwdriver and a set of 7 mm wrenches or socket wrenches.

First you need to remove the top cover to gain access to the burners. Then you need to find the latch, squeeze its ends and remove it, then remove the tips with nozzles from the traverse with the burners. The jets are unscrewed counterclockwise with a socket wrench. We put new ones in their place.

Source sovet-ingenera.com

If everything is done correctly, the gas will ignite without popping, and the flame will burn evenly, without red flashes or hissing.

HBO

Why do you need an LPG reducer and what are its types? This is a special device that converts a liquefied mixture, which is under powerful pressure, into a vapor mixture. And this mixture can be safely added to the engine.

There are usually 1-4 generations of this gearbox on the market. Each process has its own characteristics. The stable, coordinated operation of the car depends on the level of setup and operation of the device. This is also the answer to why do you need a gas reducer on a car?

Popular models of factory gas heat guns

If it is not possible to make a gas heater yourself, you can study the modern market of heating appliances and choose the best option.

Some of the most popular companies producing gas heaters include companies such as:

- Ballu;

- Fubag;

- Neoclima;

- Master;

- Resanta;

- Interskol.

According to a survey conducted among users of specialized forums, the top included the following models: MASTER BLP 17M, Neoclima IPG 15, Interskol TPG-15.

All gas heating appliances from the famous American company MASTER are distinguished by high-quality assembly, reliability, efficient operation, and excellent design.

MASTER BLP 17M . The unit has an adjustable power of 10-16 kW, making it possible to maintain a comfortable temperature in a room with a volume of up to 655 m3.

Power is supplied by connecting to a gas cylinder through a reducer and connecting to a household electrical outlet. Mechanical ignition causes some inconvenience.

Neoclima IPG 15 . A device with a power of 18 kW is capable of heating a room measuring 400 m3, while the fuel consumption is 1.4 kg/h. The model also includes a hose and a gas reducer.

The Fubag Brise 15 model has a power of 18 kW. It features minimal fuel consumption. Heating a room with a volume of 500 cubic meters will require only 1-1.2 kilograms of fuel per hour. The heat gun has a flame control device, as well as a high-quality protection system

Interskol TPG-15 . The unit has a capacity of 300 m3 per hour, the power of which can be changed within 3-15 kW, while fuel consumption will vary from 0.73 to 1.3 kg/h. Such a device can operate on both propane and butane.

How to combine two cylinders into HBO? Implementation options

- The first method is to install two separate cylinders with their own air pumps. This option is less convenient, but easier to implement. Two cylinders are installed, which are connected through a tee to the central line leading to the reducer. Before inserting into the central highway, you can install one solenoid valve, although many argue that one is enough.

- The second option is to install two gas tanks with one VSU. This option is more convenient, since gas cylinders will be refilled through one device. The connection to the VSU is made through a tee, while some installers remove one multi-valve so that the second tank is filled more fully and acts as an additional tank, while the two tanks are perceived by the system as one. But I would not recommend taking risks by removing the second multivalve; this smart and multifunctional unit is very important.

There are other options, but, in my opinion, these two are the most optimal. The only thing you should remember is that the installation of gas equipment, as well as cylinders in particular, should be done by a professional. Any, at first glance, little things can lead to dire consequences or at least to incorrect operation of the gas equipment. Remember this!

If you know of other options for installing two cylinders in the HBO system, tell us about them in the comments, I will be very grateful.

Bye everyone, thank you for your attention, and see you again at HBOshnik.

Frequent breakdowns and their elimination

Common problems with gas guns and possible causes:

- If the flame goes out when the forced fuel supply button is released, this may indicate a breakdown of the safety sensor.

- There is no ignition when gas is supplied - there may be no spark in the design, so adjustment of the piezoelectric element may be required.

- The fan operates without fuel supply - this sign indicates a malfunction of the solenoid valve.

- It is not possible to adjust the fuel supply while the device is operating - most likely, the gas line is clogged.

- During operation, a strong smell of carbon monoxide appears - the device requires cleaning and adjustment of the gas pipeline on the heat generator. You must immediately turn off the equipment and under no circumstances continue to use it.

Important! It is better not to risk trying to repair the device yourself. All repair work should be performed by a professional.