A staircase is an integral attribute of any cellar. To ensure comfortable movement, the structure must be strong, reliable and stable. A do-it-yourself cellar staircase, made according to ready-made drawings and recommendations, will last for many years.

An attached or marching structure is built in the cellar

Material selection

Tree

A staircase to a basement made of wood is the most budget-friendly solution. Wood is more susceptible to external factors than other materials. To increase the service life of such a design, it is necessary to take care of the correct and high-quality processing of the finished product.

Metal

A structure made from this material will be much stronger and more reliable. Metal structures are less susceptible to destruction from external factors.

It is recommended to cover the finished structure with primer and paint it with enamel, especially in the welding areas. Such actions will protect against corrosion and increase the service life of the ladder.

Concrete

Stairs made from this material are the most reliable and durable, but also the most expensive. This option is most suitable for large basements and basements that are intended for regular use.

Reinforcement

Why do you need to reinforce the steps to the basement? Reinforced concrete structure is much stronger and more durable. With reinforcing bars, the steps will last ten years longer. Reinforcement is performed with metal rods 10–12 mm thick. They are tied into a mesh, the cell size of which is 100x120 or 150x200 mm. The bundle is made with soft wire. The reinforcement can be connected manually or using a special hook. To prevent the edges of the steps from crumbling during operation, these places are also reinforced with transverse reinforcement.

Types of stairs

There are many types of stairs, but not all of them are suitable for a basement. Most often, metal attached or marching passages are valued for their ease of installation, durability and moisture resistance, and less often, screw ones.

The latter design justifies itself when you need to descend to a considerable depth, but there is not enough space for a full march. The big disadvantage of a spiral staircase is the need for precision calculations, cutting and assembly of parts.

In this video you will learn more about the stairs to the basement:

Pristavnaya

The simplest staircase to the basement is often made of wood for 2 reasons: ease of manufacture and low weight. In terms of weight, only aluminum can compete with wood, but creating a durable structure at home by welding or riveting is quite problematic. A staircase for descending to the ground floor of this type can be universal, i.e. be used for other needs.

Due to the relative lightness of the material from which it is made, the stepladder can be moved to other parts of the house, used for climbing into the attic, and the like. The main task when making such a basement staircase using ready-made drawings with your own hands is to ensure the required rigidity and stability during ascent/descent.

It must be taken into account that the lower edge of the structure should in no case be able to move from its place or change its position - for this purpose, special stops or recesses in the floor can be provided.

Marching

Also a fairly common type. Depending on the material, it can be a concrete staircase to the basement or a steel one; sometimes, in special cases, it is replaced with a lift (elevator). The main thing is to maintain the required width of the steps, their pitch and tread height.

If you need to get into the underground, which is relatively shallow below ground level, then a few steps will be enough, but for the basement you will need a more serious structure. The specific dimensions of the flight of stairs are tied to the dimensions of the basement, and also take into account the requirements of GOST.

Structurally, a flight of stairs consists of load-bearing elements - stringers or bowstrings (beams) and the steps themselves. In turn, the step is formed by a tread (horizontal part) and a riser (vertical). It is imperative to take into account the ratio of the sizes of these parts: if they are disturbed, the staircase will be uncomfortable, the steps will turn out to be excessively high. Conversely, a low riser also causes discomfort when moving.

To understand how to make a staircase to the basement, you will need to study the requirements of regulatory documents or use the tips on our website.

Do not forget to accurately calculate the dimensions of the stairs

Screw

In design, the spiral staircase to the basement resembles a flight staircase, with the only difference being that the load-bearing beams are not straight, but arranged in a spiral. The support of the entire system is a central post or column, around which the internal stringer bends. This is perhaps the most difficult staircase to make to a basement in a private house; making it yourself is quite problematic.

It is unlikely that it will be possible to calculate its parameters using online calculators; you will need the help of professionals who specialize in the design of metal structures. The calculation of the stairs to the basement must take into account the load-bearing capacity of the staircase frame and guarantee human safety. Based on it, the required material is selected - a corner with a side of 5 cm or a channel 14 cm wide, 4-5 mm thick.

Pros and cons of using screw products

A spiral staircase to the attic or basement is a fairly common occurrence.

What are its advantages:

- The most important thing here is the compact size of the product. Installation of such structures does not require much space.

- A small spiral staircase does not need a large opening. Consequently, the area of the first floor is significantly saved.

- The cost of a simple product will be lower than a marching system.

- Most of the models can be easily manufactured and installed independently.

But there are also disadvantages to using such systems:

- It is quite inconvenient to move around the small circular structure.

- The compactness of the products does not allow large objects to be moved around them.

- Some models are quite difficult to install.

If we consider that a spiral staircase to an attic or attic is not used very often, then these negative aspects become not so important. Such products have many more advantages.

Advantages of a staircase to a cellar made of a profile pipe

Practice shows that using a metal corner is no longer practical and modern; it is much safer and easier to use a metal profile. Most often, a metal pipe with a medium-sized square section is used for stairs.

Advantages of this design:

- On such a staircase you can make any turns; there is an option to make it a spiral one;

- It can be placed not only in a cellar or garage, but also used to move it to the second floor of the house; it goes well with glass, plastic, and wood coverings;

- You can experiment with color;

- It is possible to use only a metal profile as a material, then paint it;

- This ladder, when assembled correctly, is reliable and strong;

- Affordable price.

Despite all the advantages, this material has some features that need to be taken into account before construction: this material is heavy, and you need to think in advance about how to make the stairs lighter. Iron surfaces must be protected from corrosion and painted. To install the structure, you need quite a lot of experience and ability to work with similar materials, calculate vibration and other effects on the stairs.

What are the types of stairs to the cellar?

The simplest and cheapest option is a ladder. No installation is required, as it can be removed and installed at any time. The safest marching structures made of wood and metal. Concrete monolithic structures are expensive, but at the same time the most reliable.

An extension staircase to the cellar in a private house is simple to implement. Two vertical posts are fastened with crossbars. Usually they are used to equip shallow small basements. A properly made cellar ladder can last a long time. Reliability will be ensured by a combination of materials: wood for the steps and a metal profile or corner for the frame.

The attached combined ladder is fixed at some distance from the wall and reinforced with vertical metal rods

Experts consider a flight of stairs to be the most convenient and reliable design for a cellar. It can only be installed in a large storage facility. Usually they set up one march without a platform. If the room is small, make two narrow flights.

The staircase is made of wood, metal or concrete. Sometimes materials are combined to strengthen the structure and give it an attractive appearance.

To prevent wood from bending due to humidity in the basement, it is treated with water-repellent agents.

Monolithic concrete structures for cellars require the manufacture of complex formwork and reinforcement. In practice, such structures are reinforced with a metal corner.

To make the structure last longer, it is coated with sealant and faced with floor tiles

If there is very little space in the cellar, install a spiral staircase. Such structures look attractive. Typically the frame is made of metal and the steps are made of wood.

What material to build from?

Wood is an affordable and easy-to-process material, but it needs additional protection.

Special compounds protect the structure from insects, moisture, and moss growth

A staircase made of a metal profile or corner is more reliable, but more expensive to manufacture. The frame is treated with anti-corrosion agents and painted in the required color.

Concrete cellar stairs are durable. Like any material, they require treatment with moisture-resistant agents. They are built in basement-type basements, in spacious rooms.

Concrete stairs are faced with floor tiles, wood or painted. If necessary, the product is coated with an anti-slip rubber agent. The structure is additionally reinforced with concrete pouring or a metal corner.

Attention! A brick cellar staircase is built extremely rarely, only in spacious rooms. The descent is filled with soil or other bulk material.

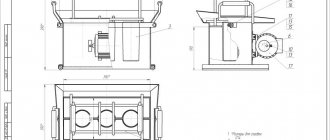

Options, drawings and dimensions of stairs to the cellar

When arranging the staircase to the cellar, determine its purpose. This allows you to most accurately select the design and material for manufacturing.

Having made the necessary calculations, the drawing is applied to paper

Before creating a project, they study the criteria that the staircase to the cellar must meet. This takes into account:

- cellar size;

- width and length of the release hole;

- frequency of use of the ladder;

- load on steps;

Stairs to the cellar on bowstrings are reinforced with a steel rod so that the structure does not move apart

- where the construction begins, outdoors or indoors;

- estimated dimensions of the stairs;

- compliance with the interior;

- price.

They also take into account the convenience of the design from the point of view of use: ease of moving the legs, space in the width and height of the flight

Based on the specified parameters, a drawing is made. The width of the stairs to the cellar is usually at least 70 cm. The height of the steps is 16-22 cm. The width of the tread is 25-30 cm.

Bowstrings are made from a solid board 5-6 cm wide

Almost any staircase is equipped with railings. This simplifies the descent and ascent into the cellar. The stringer is made from a single board. The teeth are cut to the size of the treads.

To secure the tread on the stringer, fillets are used, which are secured with dowels or dowels

The next cellar design takes into account filling the space under the stairs. This arrangement of shelves allows you to take a jar without falling down onto the storage floor.

The angle of inclination allows you to build a convenient handrail

Extension stairs to the cellar are made of wood or metal profiles. Treads for frame structures are made from boards 3-5 cm thick.

The attached structure has a steep slope of 40-600

Spiral staircases to the cellar consist of a support post and steps. Metal structures are welded to the base. The stand is made of a steel pipe with a cross-section of 10-12 cm. Decorative steps made of wood or metal mesh are attached on top of the frame.

The treads are cut into a triangular shape, its size allows you to set a screw descent

Recommendations

To make the descent and ascent comfortable, experts do not recommend building too steep structures. The choice of material should be approached carefully. When choosing, take into account the humidity of the cellar. If a reliable design is required for long-term use, water-repellent agents are used.

When building a staircase to the cellar with your own hands without the help of specialists, you should take care of safety precautions. Some owners of private houses order the production of a ready-made metal frame, and do the decoration and protection from moisture themselves.

Twice a year it is recommended to inspect the stairs in the cellar after winter and in the fall, before loading products for winter storage. If necessary, the structure is tinted, metal parts are welded, or rotten boards are replaced with new ones.

Construction of the stairs to the basement (video)

A convenient staircase leading to the basement may vary. Metal, wooden, allowing you to enter from the street or garage to go up to another floor of the room - there are many variations. A comfortable staircase can be made with your own hands; you just need to make a calculation to find out the section of the steps, select materials and get to work. If you do everything according to the instructions, you will definitely end up with a reliable and durable ladder. It should be remembered that concrete stairs are the most reliable, but metal and wood can be used to make a wide variety of variations.

Let's sum it up

Having assessed the whole situation, your strengths and skills, you can choose the staircase option that will be ideal in your case. Each type has its own advantages and disadvantages. For example, basement ladders can be moved and rearranged to any location if necessary. In addition, their creation will take several hours, and their cost is low. The downside is the safety and comfort of walking. In this regard, flight stairs are much better. But to implement the idea will require more money, time, effort and skills. Having made your choice, you can start working. And visual videos will help you navigate the process of creating a cellar staircase.

Recommended Posts

DIY formwork for concrete stairs

Stairs for the terrace

How to make a metal staircase with your own hands

DIY staircase

Staircase on metal stringers

How to make a porch on the veranda with your own hands

Selection of alternative materials for the construction of stairs to the basement

You can choose absolutely everything that your soul allows. When choosing a sample of stairs to a house or basement, they are guided by the following postulates:

- reasonable possibilities of the available budget;

- comfort of further use of the structure;

- future expected loads on the structure;

- applying your own hand to the construction project;

- compliance with the generally accepted design model (structure that connects the room, dimensions, etc.);

- the ability to carry out operations related to construction work.

Before you begin successful construction, it is necessary to prepare drawings and diagrams of the stairs in the basement, according to which the building will be erected. We still have to consider the feasibility of further construction, what harmful factors it will be exposed to and how this will generally affect it.

One of the main guiding factors is convenience and stability, which guarantee its functioning. Your new staircase in the basement of a private house or garage should not complicate your life. There are several types of design:

- straight single-march;

- single-flight with the letter “Z” and an intermediate platform;

- double-flight with perpendicular and parallel flight with an intermediate platform;

- screw mounted on a central pipe or wall;

- double-flight (with semicircular and wedge-shaped steps).

Of course, the first type of design will be simple and easy to install. But its disadvantage is that it may not be suitable for all types of premises, and installation will become quite problematic. When constructing a staircase, do not forget about the individual characteristics of the room. One of the first problems that you will have to face is adjusting the angle of inclination of the structure.

An angle that is too obtuse is inconvenient, as it will take up more space than usual, but an angle that is too steep is no better either. Steep corners are especially dangerous if you have metal stairs in your basement. If condensation occurs, the skating rink is guaranteed. That is why the correct choice of the type of staircase should also not be ignored.

Ladder

The attached type of escapement is a popular option. This allows you to reduce the space of the stairs in the lower tier of the room. Concrete, despite its popularity, is not used in this case.

There are two main options for ladders based on material. The first is a wooden ramp. According to standards, it must meet two requirements: surface strength and lightness. In this case, an important factor is also the possibility of securing the ladder without the option of sliding it. All boards should be at least 18mm thick to maintain rigidity and reliability. Thinner boards simply will not be able to withstand the load, especially with frequent use.

When using the wooden version, only the parameters and the required slope change. For a metal type of an attached nature, the design may differ in the type of material used, which can be either tubular or sheet.

In both cases, a welding machine will be required to connect the tubular or sheet elements to the base. The base here is the most important element, as it must be significantly larger than the step spans. This is necessary to hold the load without deformation and bending, which lead to damage to the material and corrosion in the future. This part needs to be strengthened.

For different use cases, a metal structure may have different characteristics in terms of size and diagonal cross-section of elements. This is due to the fact that different metals have different rigidity and reliability. For example, aluminum, brass and similar metals are not used for long-term use. Iron can only be used if it is of a grooved nature for steps. The main part is always made of steel. It is worth considering that for durability, stainless steel elements are used, or coated with a special compound.

Only with this option will the structure last a very long time and will not require replacement or repair.

The main rules when installing attached structures:

- the height of the step depends on the width of the span and the parameters of the step itself;

- The similarity with a flight of stairs is the clearance of the stairs, which can have different parameters, but must not be less than the minimum that is necessary for convenient and safe movement;

- Only high-strength materials must be used.

When the staircase frame is ready, only then, after fitting, do they begin to equip it. This is necessary for a complete structure that will exactly fit the parameters of the room.

It is also worth considering that the base of the frame is strengthened with channels and corners. The length of the entire staircase should not exceed ¼ of the width of the spans. This allows for safe and secure ascent and descent.

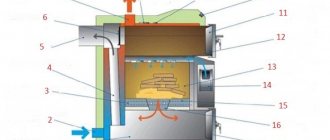

Creating formwork

The first step is to create a deck. This is the bottom of the stairs. It is made from a single sheet of waterproof plywood (WFP), 18 mm or more thick. The lower part is reinforced with supports, since it will bear the load from the entire structure. And these are all the elements and the weight of the concrete solution. Bars measuring 100x100 mm or boards measuring 50x150 mm are used as supports.

Then the flanging is done. It serves to prevent the flow of concrete mass, and also acts as a place for attaching supports for steps. The final appearance of the structure is formed by these cross members. The sides need to be reinforced with boards to make them rigid and reliable.

Boards for creating steps must be attached to the stringers through the ends. As an option, use reinforced metal corners. The bottom step needs to be strengthened best. All the load from other elements will be on it.

Here are some requirements for creating formwork:

- The fastening elements are exclusively self-tapping screws. With them, subsequent dismantling of the formwork will be much easier. Concrete steps will not be damaged.

- Since concrete will be poured into the formwork of the stairs, it is made very strong and stable. No shifts or damage should occur after filling with concrete mixture.

On the stringers

If you planned to make a basement staircase on stringers, then you probably chose this option due to its simplicity and accessibility. As a rule, designs are used that provide for the presence of 2-3 stringers. This option is highly durable, which is achieved largely thanks to the central stringer. Structures on stringers are perfect for installation in a cellar or basement.

Options for attaching steps to stringers.

A staircase to a basement of this type can differ in the type of steps:

- The first method of arrangement involves the construction of special triangular cutouts in which the steps are subsequently fixed.

- The second method involves installing additional parts (fillies) on the stringer. It is on these parts that the basement steps will be attached. The fillies are placed on the longitudinal part of the stringer.

As a rule, the fillies are secured using dowels that are placed in grooves. The grooves are pre-made in suitable adjacent parts. The dowels are installed in the grooves and fixed there using a suitable adhesive.

A staircase to the basement or to the ground floor on stringers can be made with your own hands without the use of fillies. To do this, you need to find a stringer made of a wide and durable board. The main thing is that the board, after all the necessary cuts are made in it, does not lose its strength characteristics. It is recommended to choose beech or oak wood, because it is the most durable and holds the load well

It is necessary to take into account the fact that the boards will be under constant load, so when choosing boards you need to pay attention to the absence of knots. All structural elements should be connected using screws (nails should not be used)

Using one metal stringer.

The thickness of the step board will depend on how wide you want the tread to be. If the width of the step is 90-110 cm, then a thickness of 5 cm will be enough. Experts note that the thickness of the tread should be 20 times less than the width of the flight. Some deviation from these indicators is allowed, but only in the direction of increasing the thickness of the tread. Basement steps, by and large, can be of any thickness. But, at the same time, it will be necessary to increase the size of other structural elements.

The flight of stairs is mounted on racks. They must be placed vertically and secured to the floor with anchor bolts. If the presence of railings is expected, then their height should be at least 80-90 cm. Very often, when a basement in a private or country house is made with your own hands, a storage room is arranged under the stairs for the basement.

Graphical calculation method

You can calculate the number of steps of a flight of stairs graphically. This method of calculation is distinguished by its ergonomics, since only natural parameters for a person are used in the calculations. Thus, the average step width on a horizontal surface is 62 centimeters, and the height is 31 centimeters.

We draw a coordinate system, set a unit segment on it, put 62 units on the abscissa (x) axis, and 31 units on the ordinate (y) axis. Connect the resulting dots. Then you need to draw a line that determines the angle of steepness of your structure. Find the intersection points of the resulting lines, and through them draw straight lines parallel to the axes of the coordinate system. Then draw a step diagram.

Using this method, you can determine the dimensions of any staircase structure from a drawing, regardless of the slope of the staircase, as well as measure the height and width of the staircase steps, and make adjustments to the scale.

To create a drawing, it is best to use graph paper or paper in a small square. When calculating the parameters of the steps, keep in mind that this is only a project, so you can adjust the data. For example, you can make a wider tread or make a beveled riser; this will make the design more convenient to use, but changing such parameters does not increase the safety of the device, since the design parameters of the device remain unchanged.

The safety of the stairs depends on the angle of steepness of the structure. Regardless of the fact that the permissible angle of inclination is in the range of 20-75°, the ideal option would be the rise of a flight of stairs with a steepness of 23-45°. If the slope angle is smaller, then it is recommended to construct a ramp instead of a staircase; if it is larger, the staircase must be made folding or attached.

When calculating the stairs, you need to take into account a number of factors

How to make a cellar staircase correctly: dimensions and calculations

In addition to selecting the material, it is necessary to carry out special calculations in order to immediately produce a model that will be convenient to use and will correspond to the size of the room (Figure 1).

To correctly calculate the size of the stairs, consider the following parameters:

The width of the finished structure must fully correspond to the area of the room. For a standard basement, a width of 70-90 cm will be sufficient, but, depending on the characteristics of the room and personal preferences, this figure can be increased or decreased. The slope is usually about 25 degrees, since a steep slope (45 degrees) is only possible in attached models

It is important to consider that the greater the degree of slope, the more convenient it will be to use the structure, but at the same time it will take up more space. Clearance is an indicator that displays the distance between the steps and the ceiling of the cellar. If you do not include this data in the calculations, it is possible that while using the basement you will hit your head on the ceiling

That is why the distance from the top step should be 10-20 cm above human height.

Figure 1. Example of calculating the main dimensions of a staircase

These are the main indicators that are taken into account during construction, even if the product is designed for a ready-made underground storage facility. But there is another important indicator - the size of the steps, to which we decided to devote a separate section.

Calculating the size of steps

Calculating the size of the steps is a really important indicator, because the ease of use of the stairs will depend on this. First of all, you need to correctly calculate the width. It should not exceed 30 cm, but also not be less than this indicator (Figure 2).

Figure 2. Example of calculating the width of steps

The height of the steps also plays an equally important role. The most universal height is considered to be 15-20 cm, and all steps should be the same in height. In extreme cases, a slight deviation is possible for the top and bottom.

It is also necessary to calculate the number of steps. To do this, the estimated length is divided by the height of one step. As a rule, division does not result in a round number, so you can slightly increase the height of the top and bottom steps, or evenly increase the height of all steps.

Handrail size calculation

Not all cellar owners provide special handrails, since they require additional time and materials, take up additional internal space and are not always useful.

But, if you still plan to install handrails, make them so that it is convenient to go down to the basement, but at the same time the structure does not occupy the interior space of the room. In other words, the handrail can be located at the top and in the middle, and completely absent at the bottom. It is advisable to make it low so that it does not take up much space, but, if necessary, you can easily lean on it.

Stages of work

- Preliminary preparation for installing stair stringers. They can be installed in two ways:

- We determine the location of the structure, and in the place where its lower part will stand, we dig a hole 50 cm deep, its length and width depend on the size of the stairs (standard - 100x40 cm). Next, you need to fill the hole with crushed stone and cement so that the top 15 cm are left unfilled. The bottom edge of the stairs will be placed in this space and filled with concrete;

- we make the same hole. We install two reinforcement bars with a 12 mm cross-section and fill it with crushed stone. The upper edge of the reinforcing rod should be 25 cm higher than the hole. Fill the hole to the brim with cement.

- Installation. We screw two channels to the ceiling at a distance of 90 cm from each other. Depending on the chosen method, the lower edge of the channel is either poured with concrete or welded to the reinforcement bars. The base for the steps is made from the corners and welded from the inside to the channels.

- The last stage is processing. All protrusions must be removed and the metal is leveled in the right place. We cover the steps with either wood or metal sheets. We weld the railing from the outside to the channel. We treat the finished structure with an anti-rust agent and paint it.

Metal staircase from corners

The metal staircase to the cellar is quite simple to make. To do this, you need to prepare a metal channel, 5-centimeter corners for steps, 1 mm thick metal sheets, an angle grinder, a welding machine, crushed stone and cement mortar, anti-corrosion impregnations and paint.

Sequence of work for metal stairs

Before starting work, it is necessary to perform all calculations on paper. Such drawings are important so that when cutting metal you do not have to change its dimensions. A grinder is used to cut the channel and angles into pieces of the required size. The frame for all stages is connected by welding. Experts recommend immediately removing the beads that form during welding; this is done with a grinder.

Mark a place to pour concrete on the floor. The pit is filled with crushed stone, filled with cement, and after the solution hardens, the structure must stand very firmly.

Sheets of metal are welded to the frame of the steps. Again, all sagging is protected, burrs and other defects are removed. Anti-corrosion impregnation and final painting are done. With such a coating, the storage descent can last for many years.

Pipe ladder

A small staircase can be made from metal pipes; this option is made very quickly, since all elements are connected by welding or an inverter. It is necessary to prepare pipes with a cross-section of 60 mm and crossbars with a round diameter of 3 cm. Measure 25 cm in the upper part of the pipe and fix the first step there.

The rest of the crossbars are assembled in the same way. All elements are connected by welding; if necessary, at this stage you can involve specialists who know the features of working with a welding machine.

A metal staircase to a cellar, a photo of which can be found in many manufacturer catalogs and freely available on websites, will become a reliable and safe option for descending if all stages of its assembly are correctly completed.

Staircase with concrete steps

The design of the descent with steps made of concrete is the most optimal option for cellars, since it is resistant to corrosion, does not sag over time, and will not creak under the weight of the products being carried. Installation is quite complicated, but it is done at the initial stage of building a house in conjunction with other work.

If you need to make such a staircase in an existing cellar, then you should prepare for a lot of work and serious expenses. It is necessary to make the correct calculations by calculating the amount of concrete mortar, boards and reinforcement.

It is important to calculate the height, width of the steps, slope, etc. The design is one-piece in its composition, so it will not be possible to make adjustments to maintain the work.

Manufacturing of formwork

To start work, you need to make a wooden formwork, a shell into which the concrete will be poured. The optimal material for this is plywood sheets with a thickness of 18 mm or more. The bottom of the structure must be reinforced with supports, since they will bear the weight of the entire structure. As a rule, boards or beams are used for this purpose.

They install sides that will prevent the solution from leaking out, and supports for the steps are attached to them. These crossbars create the final look of the entire staircase. The edges of the sides are reinforced with boards, which will give it additional rigidity. All wooden elements must be secured at their ends using reinforced metal corners

It is important to fix the lower steps especially tightly

Concreting

Before pouring the mixture, it is important to seal all joints with a solution of cement and sand. This procedure avoids changes and simplifies finishing work.

When mixing the solution, you need to carefully monitor the proportions of sand and cement.

To begin with, the first two steps are formed, which is very important for the correctness of the frame. To lay concrete in the formwork, you need to use rods that pierce the mixture to be poured to avoid voids

The concrete is also subjected to vibration by slightly shaking the structure or using a vibrating lath.

The surfaces of the steps are leveled with a spatula or trowel, giving them a finished look. This is done with all steps until the very end of the stairs.

Filling the floors

Before concreting the floor in the basement, you need to stock up on the following tools and materials:

- Buckets, shovels. A huge trough for making the solution would also be useful.

- Rebar and a grinder for cutting these rods. The rods themselves are necessary for making the frame - with them the base will be more durable and, accordingly, will last longer.

- A roll of thick film. We will lay the working mixture on it.

- Two-meter rule with level and guide beacons.

Well, of course, you need cement, sand, water and a mixture filler (in other words, crushed stone or expanded clay).

Now let's move on to work.

Surface preparation

Preparatory work consists of the following situations:

- We remove all debris such as paper, bags, etc. from the rough base.

- Pour some sand on top of the soil. Sand is needed here to even out the relief of the subfloor. It turns out that it is easier to pour on a relatively flat plane, and less concrete is used.

- We compact the sand.

- We lay the film on the taken plane with a small “turn” on the walls.

Let's move on to the next stage.

Assembling a frame from reinforcement and installing beacons

We measure the width of the room from wall to wall, add 10 centimeters to each side and, in accordance with the taken figure, begin to cut the reinforcing bars. As a result, we should end up with a “mesh” of reinforcement with a cell size of approximately 60 by 60 cm.

At the time when the required number of rods is ready, it is necessary to drill cement blocks for the basement walls with a hammer drill in accordance with State Standards. To do this, take a drill with a diameter larger than the diameter of the rods, drill the required number of holes and hammer the reinforcement into them. At the intersection of the rods, the metal is tied together with ordinary steel wire.

After the frame is assembled, it is necessary to objectively assess whether there will be any communications on the horizon line. If so, then you may have to make holes in the wall in advance and insert pipes or something else into them.

If you have wide cement blocks and it is difficult to make the necessary opening with a simple hammer drill, then pay attention to such a service as diamond drilling of holes in concrete. For fairly reasonable money, they will quickly make a hole of any diameter, even in very durable concrete.

Now we need to install guide beacons, which will be a guideline for how much mixture we should pour and at what level we need to stop. To put it simply, with their help it is possible to make a very flat final plane.

Beacons are installed like this:

- We determine the point of the desired horizon. In this place we apply a pile of mortar.

- Using a level, focusing on the length of the beacons, we make another slide, as if from the other edge of the rail.

- We lay the plank on the made “slides”, adjust the correctness of its position and leave the solution to dry.

- At a time when the mixture has dried and the rail is firmly fixed, we make intermediate mounds, and after they have dried, we lay the required number of beacons using the same method (parallel to each other). The distance between them should be approximately a meter.

At a time when everything freezes, it is possible to work with beacons.

We mix the solution, pour it between the beacons and, using the rule, stretch the mixture between the slats over the entire area of the basement.

After the cement floor has dried, if necessary, it is possible to make a finishing cement-sand screed without the use of crushed stone and expanded clay.

Now let's briefly look at how to make a standard cement staircase to the basement with your own hands.