Roof reconstruction: determining the scope of work

Today, the reconstruction of dilapidated, old buildings and roofs is more relevant than ever. Using attic spaces as living lofts is an economically viable option that many people are considering.

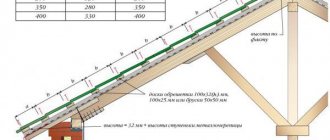

Roofing diagram.

With your own efforts, you can easily increase the living space of your country house by adding much-needed square meters.

Reconstruction of the roof in this case is often the best solution, as it allows you to relatively quickly not only strengthen the old structure and significantly increase its reliability, but also get additional living space in the form of a cozy attic.

A private house always requires certain repairs. But roof reconstruction does not always mean that the work will be very simple; in some cases it is necessary to replace the roofing material, and in others it is necessary to work with the rafter system if it is in a dilapidated condition. In our article we will look at options for roof reconstruction and note the types of defects that will need to be eliminated.

Hydro- and thermal insulation of the attic

Attic insulation device.

When making an attic, it is worth taking into account the fact that the ceiling in it will also be the roof, so the warm air that rises can cause significant damage to the ceiling, destroying the beams over time. In order to avoid these unfavorable processes, it is necessary to insulate the attic space during the construction process. To do this, you need to clog all the through cracks with glass wool or fill them with foam. This simple process will help avoid problems with heat retention and waterproofing.

Separately, you need to pay attention to waterproofing, because if problems with steam that rises upward in an old house are easily solved, then during waterproofing it is necessary to install a special film. Due to water contact with insulating materials, their properties deteriorate, so the installation of such a film will be necessary. And so that water does not linger on the film, special outlets are made.

Options for reconstruction work

Reconstructing the roof of a private house is a rather complex process that can include various types of work. Most often they do the following work with their own hands:

Scheme of strengthening rafter systems with additional struts.

- replacement of roofing sheets;

- roof reconstruction and partial replacement of rafters;

- reconstruction with changes in roof dimensions;

- complete reconstruction of not only the roof, but also the attic.

The roof has some damage, so work is being carried out to simply replace roofing sheets, organize insulation and waterproofing. This is the simplest option and often involves replacing one roofing covering with another; the roof structure is not disassembled, only some materials are replaced.

If the roof is made of metal or slate, then for work, in addition to new roofing sheets and self-tapping screws with nails, you will need the following tools:

- pneumatic or gas nailers; if you work with self-tapping screws, then a screwdriver;

- Next, we prepare a drill for making holes for fastenings, spiral drills;

- thicknesser with a marking jaw, hammer;

- metal square;

- electric jigsaw for cutting roofing sheets plus a hacksaw for metal and cutting discs.

Reconstruction of the roof of a private house within the attic space includes the conversion of attic spaces into attics. If desired, you can replace the dimensions of the roof and completely convert it into an attic. In this case, a wooden cottage can be completely transformed.

The easiest way to identify roof leaks is in rainy weather.

Here it is worth adding in addition to the list of tools listed above:

- rack and marking compasses;

- saws designed for longitudinal sawing of existing lumber;

- an axe, a chisel for picking out folds, a punch;

- construction stapler;

- punch for making marks;

- a paddle with a rubber insert and a brush for applying mastic;

- roofing pliers, if the roof will be covered with metal, and a riveter for merging sheet parts.

Features of attic reconstruction

Many home owners are wondering how to convert the roof of a house into an attic. There are no difficulties in this, but you need to understand that attic reconstruction differs depending on the shape of the roof, therefore, the complexity of further work and its cost will depend on this.

The best option for renovation is a classic gable roof, which can also be raised without much effort by building up the walls of the house. But the hip roof has a significant drawback in the form of four slopes, which significantly reduce the total attic area, including the height of the room.

Based on the design of the rafter system, you can determine what the attic walls will be like: inclined or vertical. The inclined option, unlike the vertical one, allows you to use the entire space of the attic, but at the same time limits the possibility of placing standard-sized furniture near the walls.

To better illustrate the interior of attic floors, we offer you a small selection of real houses with attics.

However, the following factors may force you to refuse to convert the roof of a wooden house into an attic:

- Small area or height of the attic, which makes roof reconstruction impractical. In this case, the optimal solution would be to demolish the old roof and install a new, enlarged one, or add a full second floor, if the bearing capacity of the foundation allows.

- The need to modify the roof or replace some of its parts, which entails additional significant costs. Often roofs are not initially designed for further reconstruction, which causes further difficulties in insulation or, over time, some of the structures become unusable. In this case, additional financial investments are required to repair or rebuild the roof;

- The total cost of all required materials and work, including, in some cases, the need to install roof windows into the roof.

Types of defects requiring reconstruction

The main reasons why a roof may require reconstruction are:

- premature wear of structures caused by improper operation or installation;

- low quality of construction work performed;

- lack of planned and major repairs during operation;

- roof design features;

- lack of ventilated space.

Among the most common defects, one of the main ones is damage to the rafter system, that is, the appearance of cracks and delaminations of various elements (rafter legs, bone elements), various chips in places of nodal connections, deflections of rafters and roof purlins, rot on wooden parts, severe weakening of nails and bolted connections. It is the number of such defects that determines the volume of reconstruction work, which must correspond to the current technical condition of the entire roof.

Reconstruction of the roof is carried out in accordance with the requirements and condition of all structures at the moment. Let us give an example of data that will help to correctly calculate the percentage of roof wear and the future volume of all work:

- Physical wear and tear up to 20%. Signs of wear: chips and deflections are observed, but within normal limits, the rafter notches are quite loose, the sheathing elements are rotten, especially in the places where the valleys are installed. In addition, there are violations in the fastening of the roofing sheets to the sheathing and leaks.

- Physical wear and tear up to 40%. Signs of wear: there are deflections that are 10% greater than is acceptable according to the standards, the working surfaces of the joints are wrinkled, there are traces of chips, the presence of cracks with a length of up to 0.1 of the length of the chip. There are rotting lesions on the mauerlat and the ends of the rafters, but the presence of insects has not been detected. From the attic side of the house, there are leaks in the roof flange connections, violations of connections, and gaps.

- Physical wear and tear up to 60%. Signs of wear: in this case, the roof of a private house exhibits deflections, the value of which is 20% greater than the permissible standards, working joints are wrinkled, and there are cracks with a length of 0.1 or more. The roof plate of a country house is affected by rot, the roof slopes are deformed, and the rotten sheathing requires replacement of more than 30% of its area.

- Physical wear more than 60%. Signs of wear: in this case, near the roof of a country house there are large areas of rot in the mauerlat, rafters and sheathing; materials are replaced by 50%. There are large depressions on the roof slopes, multiple leaks, seams are destroyed, and there are many patches on the roofing itself.

Ideal place

The house and plot ideally suited the architect's needs: on a hill, overlooking a pine forest, no boundaries, no neighbors, practically a farm. Pleasant bonuses - a fully stocked pond with running water, a mature garden. Tatyana says that even if the house was dilapidated, she would buy it just for the location. But it was in excellent condition - the foundation was without cracks, the frame was strong. That’s why they asked for a high price for it – 11 thousand dollars.

“The interesting thing is that I marked it on my map before and even came here,” says Tatyana. “However, everything looked very well maintained, I thought it was not for sale.”

Before the reconstruction began, it was a simple village house with a gas stove in a cold outbuilding, a stove and two grubs. Inside, the space was divided into two rooms - a kitchen and a bedroom. A solid, but not modern house, with amenities in the yard.

“The purpose of the planned reconstruction is to get a place for me first of all,” says Tatyana. - So that I can spend my free time there - regularly 2-3 days a week. I had been under a lot of work pressure for many years, so I wanted to stop. The village gave this opportunity: you sit in the garden and feel the minutes, yourself, enjoy life, the moment.

While making the reconstruction project, Tatyana imagined what her house should turn out to be.

— I wanted maximum connection with nature, so the project included a large glazing area. For example, the gables are glass - I woke up, and outside the window there was a garden, a pond and a forest, and you can admire it without getting out of bed. And also a panoramic window with access to the terrace in the dining room - in the morning you sit at the table, drink coffee, and outside your window it is raining, or there is snow, or the garden is blooming. The bathroom also has a window - you can take a bath and listen to the birds. And also that there must be a fireplace, and the wood in it would crackle. When I showed the initial sketch of the reconstruction project to my son, he said “this is a dream house!”

Let's summarize the reconstruction

As you have already seen, the reconstruction of the roof and its volume largely depend on the degree of damage; in some cases it is enough to simply replace the roof covering, but if the condition of the rafter system is unsatisfactory, work such as complete dismantling of the entire roof, replacement of wooden elements with more suitable ones may be required. durable, rebuildable design. Most often, restoration work is carried out for the roof of a private house, such as partial replacement of elements of the rafter system and sheathing, replacement of the roofing or its repair, insulation and waterproofing, wiring of the ventilation system and reconstruction for the purpose of installing a residential attic space.

Creating an attic project

It is well known that no building can be built without a design. Extensions such as attics also require similar projects, but, oddly enough, they have their own characteristics, which are described in GOST. The main requirements for such projects are:

- Ensuring fire safety. Escape routes should be either through the premises in the old house or in its external part.

- Height of rooms. The minimum permissible height is considered to be 2.5 m, but exceptions are possible for different roof slopes.

- The volume of the premises should be calculated from the line dividing the premises into working and living areas. In their absence, it is necessary to calculate the volume of the entire room, taking into account all the slopes.

How to reroof an old house

Installation prices are always affordable for our customers. They are completely confident that they will not be deceived here and will advise the right decision. Trust is the key to the success of our company! And high-quality materials from well-known manufacturers and the skillful hands of our professionals leave no doubt that the installation will be completed on time!

Another plus - when concluding a contract, you receive an estimate that takes into account the prices for roofing work and materials, as well as the cost of delivery in Moscow and the Moscow region, accurate to the ruble!

Dormer windows

It should be noted that dormer windows installed on the gables of the attic do not provide daylight to the constructed room. Moreover, they are not present in all projects. The best option for the attic is the so-called dormer windows.

They are presented on the market in a large assortment from a huge number of manufacturers. And each brand of windows has its own installation technology. In general, all technologies are somewhat similar, but they also have their own distinctive features. In this article we will not dwell on the technology of installing roof windows, because this is the topic of a whole article.

I just wanted to note that today’s proposals are not just standard window designs. This is a large number of additional options that increase the performance of windows. One of the new options is a roof window, which, when opened, forms a small balcony.

Roof reconstruction

| Types of jobs | Unit | Cost, rubles |

| Replacement of roofing material (dismantling of old roofing material, installation of waterproofing with sheathing, laying of new roofing material) | m2 | from 16.00 bel/rub |

| Replacement of roofing material (dismantling old roofing material, leveling the rafter system, installing waterproofing with sheathing, laying a new roofing covering) | m2 | from 20.00 bel/rub |

| Complete roof renovation (dismantling of the old roof, installation of a new rafter system, waterproofing and sheathing, installation of a new roof covering) | m2 | from 30.00 bel/rub |

For many years we have been engaged in roof reconstruction in Minsk and the region. The experience that our specialists have gained over many years of work helps us complete the robot of any complexity. If the roof needs reconstruction, then you cannot do it yourself, but you need to call a team of workers.

Today, many houses need reconstruction of the roof, which is in disrepair. Roof reconstruction will help update and strengthen an old building. If you make an attic on the roof, you can still get additional living space. We are engaged in the reconstruction of both private houses and industrial buildings. You need to entrust such complex work as roof repair to specialists, since it determines how long the entire building will last. Experts will tell you how best to re-roof and what material is best suited for the roof of your building.

Types of reconstruction

There are the following types of roof reconstruction:

Replacement of roof covering

— Replacement of roofing material. Over the years, no matter what roofing material is used, the roof needs repair or complete replacement. The coating may deteriorate due to improper use, mechanical damage, or long service life. Such roof reconstruction can take place partially on one section of the roof or with a complete replacement of the entire roof covering. Sometimes roof reconstruction is carried out in order to replace the old roofing material with a new one that is more durable and of higher quality. For example, slate is often replaced with metal tiles. Reconstruction of the roof of a country house often requires a complete replacement of the roofing material.

Complete roof reconstruction

— Complete remodeling of the roof. Reconstruction of the roof of a private house often involves not only replacing the roofing material, but also remodeling the entire roof. During such reconstruction, you can change the shape of the roof and the slope of the slopes. A complete remodeling of the roof is needed in cases where the rafter system has rotted and worn out, after a long period of use or poor quality work by the builders. If the rafters are damaged, then it is necessary to reconstruct the roof truss system. Specialists will easily find the reasons why the roof is leaking or has lost its reliability, and will eliminate the defect with a complete reconstruction of the roof. During a complete renovation, they first draw up a project for a new roof on paper, and then only bring it to life. Reconstruction of the roof of a private house - photo examples can be seen below and you can choose a suitable roof for each house. A popular option among customers is replacing a flat roof with a pitched one.

Video description

The video shows how to dismantle an old gable roof:

Formation of a new attic roof

So, the basis for the construction is a project that specifies the type of roof, its dimensions and the materials used for construction. Look at the photo below and you will immediately understand what the frame of a traditional attic is. In essence, these are slopes consisting of two parts, which are supported by racks and purlins. The latter form the room.

Frame of the attic room Source olivavip.ru

Converting a regular roof into a mansard roof, instructions.

If the house has a large attic, then it is very easy to convert it into an attic room. Reconstructing a roof into an attic is a relatively inexpensive job compared to building another floor or adding a room. Reconstruction of the attic is profitable and convenient.

To build the structure, you will need insulation, roofing material, a rafter system and the installation of a roof window. Depending on the type of roof, the attic can have vertical or sloping walls. The roof is the most important thing in the construction of an attic and therefore it needs to be well insulated. It is best to use non-flammable, vapor-tight materials as roof insulation. Typically, glass wool or mineral wool slabs are used as attic insulation.

The walls of the attic can be finished with plasterboard, which is resistant to changes in temperature and humidity. Using drywall, you can model walls and ceilings to suit every taste. If you approach the issue of reconstructing the attic roof correctly, you will get not only additional space, but also a favorite place for the whole family to hang out.

Instructions for converting a regular roof into an attic

Roof reconstruction video

Floor installation

For a high-quality floor, it is recommended to make a concrete screed. If you don't have one, get to work. First of all, dismantle the joists on the floor (you don’t need to cut them under the walls) and clear the area of debris and dust. The screed is laid in the following order: backfill (sand, small crushed stone), insulating film, concrete layer. Be sure to level the screed. The concrete should dry for about one month at a temperature of about 20 degrees.

Next, you can begin laying the floor. This could be, for example, laminate. For installation, a special substrate is first used, after which laminate sheets are laid on it, connected to each other with “locks”. An expansion gap of about 1 cm should be left near the walls, which is hidden by the baseboard.

Roof replacement: common options

Every homeowner dreams of seeing their home warm, dry and comfortable. In many ways, it depends on the condition of the roof. If there is something wrong with the roof, then problems will begin to make themselves felt one after another. So, one way or another, issues related to its current, or even major, repairs cannot be avoided.

Many people wonder what is better, permanent roof repairs or roof replacement. From a budget point of view, it is undoubtedly preferable to patch it thoroughly. However, as practice shows, frequent minor repairs do not particularly contribute to improving the condition of the structure: it continues to wear out, and the cracks only multiply. A more rational option would be complete dismantling.

When do you need a new roof ↑

A fairly convincing argument for replacing the roof of a garage or residential building will be a wet spot that spreads across the ceiling during heavy rain, not to mention water dripping from its surface.

An annual preventive inspection of the roof and truss structure will reveal the extent of the repair work and, if necessary, develop a strategy for replacing the roof yourself:

- remove the coating completely or use it as a substrate under a steel sheet. test the condition of the supporting structure, including the sheathing; check the correspondence of the diagonal measurements, otherwise due to violations in the rafter system you will get different overhangs.

Repair work involves three possible options:

1 If we are talking only about cracks in the roofing covering, and the damage did not affect the rafter system, then it will be enough to change the covering to a new one, for example, replace a soft roof with corrugated sheeting.

2 If rot or fungus is found on the sheathing under the roof covering, then the frame will also need to be repaired.

3 And finally, in case of serious damage to the rafter system, thermal insulation, or holes in the flooring, we are dealing with the most difficult option. A complete reconstruction is necessary here, since, unlike the previous case, the damage to the thermal insulation layer is sufficient to justify replacing the roof insulation. A significant scale of work leads to an increase in cost. The price for 1m2 will be formed from the total amount of all expenses for dismantling, purchasing and installing new material.

Expanding the attic with an extension

By the way, a few more words about the extension to the attic. The question is often asked, but not as simple as it seems at first glance. It usually occurs after purchasing a country house with an existing attic. The desire to increase residential squares is, of course, a good thing. But in this case, you should be prepared for costs comparable to the construction of a new attic, since the extension will require the demolition of part of the finished attic. Therefore, calculate in advance how much these coveted square meters will cost you.

Let's face it - adding an extension to an existing attic with an expansion of the square footage is technically quite possible, but it is a very complex and not cheap task. We will definitely give practical advice on bringing this “crazy” plan to life, but in another article.

Dismantling ↑

The old covering from the old slate is removed using a crowbar and a hammer. If the sheets are intended to be used a second time, then the work should be done as carefully as possible and always by two people. If not, then simply punch holes where the slate is attached to the sheathing and throw it to the ground.

Coverings made of corrugated sheets, metal tiles or other modern materials can be reused in small areas, so they are dismantled as carefully as possible.

Varieties

Depending on what material is used, the roof covering can be:

- Profiled sheeting.

- Ceramic tiles.

- Bituminous shingles.

- Ondulin.

- Metal tiles.

Roof alteration can be:

- Complete (the structure is completely replaced).

- Partial (worn areas are replaced).

Depending on who the performer is, the work can be completed:

- An employee of a construction and repair organization.

- Private team.

- With my own hands.

According to the execution time, the order is classified into two types:

Technology for replacing roofing with metal tiles and price ↑

When replacing a slate roof with metal tiles, it is usually necessary to rebuild the frame. Of course, theoretically, after dismantling the slate, the rafters underneath may be undamaged, but even in this case, some reconstruction will be required. It should be taken into account that slate is placed on one row of sheathing, and metal tiles on two. The second sheathing is necessary to provide ventilation. Only in this case, water will not collect at the bottom of the metal tile sheets.

- The work begins with a visual inspection of the rafter system. Having discovered rot on the wood or areas eaten by bark beetles, the rafters are either cleaned and treated with antiseptics or completely replaced. Lay out the hydrobarrier and attach it to the rafters using a construction stapler. They fill the sheathing by installing bars (most often with a section of 25 by 120) perpendicular to the ridge. It will finally secure the waterproofing layer. Install the counter-lattice, starting from the edge, from bars of the same section. A cord is pulled diagonally, with the help of which the accuracy of the level is checked during the work. Sheets of metal tiles are laid from right to left in accordance with the locking system. The lower edge of the sheets is placed below the rafters by approximately 70–100 mm. All protruding places are cut off with a grinder.

An example of calculating the cost of replacing a roof with metal tiles

| Types of jobs | Price | |

| 1. | Dismantling the old coating | 50 |

| 2. | Installation of a hydraulic barrier | 50 |

| 3. | Installation of counter-lattice | 50 |

| 4. | Leveling the slope plane (if necessary) | 50 |

| 5. | Installation of sheathing | 80 |

| 6. | Laying metal tiles | 200 |

| Total: 480 rub./m2 |

How to make a double ventilated gap and features of a hinged ventilated facade

After the installation of the rafter structure, a dispute arose between the user and the builders. The builders, like many “professionals,” suggested installing metal tiles directly on the sheathing laid on the rafters, which had previously been covered with waterproofing. That is, without making the required ventilation gap,

thanks to which moisture is removed from the under-roof space.

As a result, all the condensate will drip onto the sheathing.

Note that the user insisted on his own, and the builders did everything as it should, filling the counter-lattice with a block and making a ventilation gap.

A gap is also necessary if a hinged ventilated façade is installed, for example, like the user’s, made of metal siding. The operating principle of such a facade is as follows. Water vapor, trying to escape from inside the house to the outside, enters the insulation, which is protected from the outside by a vapor-permeable, moisture- and windproof membrane

.

So that moisture can escape freely, a gap of about 4-5 cm is left between the siding and the insulation. The ventilation duct will be combined with a ventilation gap located under the roofing. Due to the difference in height between the air entry point (a gap is also left at the bottom of the walls) and the exit point at the ridge (the ridge is not sewn up tightly, but a gap is left, which is closed by the ridge strip), a powerful draft arises, and all moisture is removed from the structure.

Despite Soboleff's

to reconstruct the house, it was not without forced alterations.

Soboleff

Although there is a ventilation gap about 5 cm wide between the waterproofing and the roofing, when insulating the roof from below, the insulation was pressed against the waterproofing.

The builders said that it would do anyway, they always build this way, but I decided to redo this unit and make a double ventilation gap so that moisture could escape and erode from the thermal insulation. The fact is that ordinary waterproofing (anti-condensation) film, which is often used when installing roofs, does not allow steam to pass through. To ensure the escape of steam trapped in the insulation, either a double ventilation gap is installed (between the insulation and the waterproofing, and between the waterproofing and the roofing), or, which is simpler and more technologically advanced, a super-diffusion membrane is installed.

This material allows steam to pass out, but does not allow condensation and moisture from the atmosphere to enter the insulation.

To ensure good ventilation of the insulation on an already installed roof, the user proceeded as follows. He removed the laid insulation, bought a 20x30 mm block, measured 50 mm from the top edge along all rafters and screwed the block. Every 500-700 mm, I made cross members and longitudinal strips from OSB scraps. Now, after installing the insulation into such a “sheathing”, a gap of 50 mm is formed between the thermal insulation and waterproofing, through which moisture evaporates, which can get into the stone wool even with a vapor barrier circuit mounted below.

Having installed metal tiles, installed windows and completed the main, most labor-intensive stage of reconstruction, Soboleff

I independently took care of the internal insulation of the attic and the installation of plumbing and heating on the second floor.

Replacement with corrugated sheet ↑

Many people prefer to replace slate with corrugated board. Such a choice has its advantages. Profiled sheets:

- They are light in weight, so they do not require reinforcement of the rafter system; resistant to mechanical and natural influences; incomparably more durable than slate; they can be laid independently and reliably protect the roof from leaks; can be considered a budget coating, with the exception of models covered with pural.

Installation diagram

- If possible, carefully dismantle the slate, taking care not to damage the rafters. The roof is inspected for replacement or repair of some sections of the supporting structure: rotten ones are replaced, the wood is impregnated with antiseptics. Vapor-waterproofing is arranged: the film is laid overlapping without much tension. Expanded polystyrene boards or rolled mineral wool are most often used as thermal insulation. The corrugated sheeting is mounted with an overlap in one or two waves, starting from the end part. On a flat roof, sealant is applied to the overlaps. To fasten corrugated sheets, use only self-tapping screws equipped with rubber gaskets (with the exception of the valley). This is necessary to completely protect the structure from moisture. Self-tapping screws with heads that are painted to match the color of the corrugated sheets do not stand out on the roof surface. Corrugated sheeting is a noisier material than slate. Sound insulation can be partially improved if the sheets are tightly fixed.

Why corrugated sheets

Of all the roofing materials offered on the construction market, and, as you know, there are quite a few of them (article on roofs), we chose profiled decking. It has a number of advantages:

- High resistance to mechanical stress.

- Anti-corrosion treatment.

- Durability and practicality.

- Reliability in use.

- Wide range of colors.

- Quite simple and quick installation, easy to transport.

- Its use significantly reduces the cost of the construction process.

Information for the curious - not much theory.

Corrugated sheeting is made by rolling galvanized steel of various thicknesses, which is given a trapezoidal shape. Common types and markings of corrugated wall sheeting: PS-8 (S-8), PS-10 (S-10), S-12, PS-15, PS-20, etc.

The number in the product labeling indicates the height of this very trapezoid from 8 mm to 128 mm.

The sheets are coated with a polymer coating or other composition. The service life of the profiled sheet depends on the thickness of the coating.

Profiled flooring is distinguished according to the following criteria:

— shape and height of the corrugation;

According to its purpose, it is divided into three types:

- for walls, fences;

- for flooring and fencing.

To increase the rigidity of corrugated sheets, they are profiled (corrugated). Corrugations can be of various shapes and heights.

Typically, those with a low wave height are used for fencing and cladding, while corrugated sheeting with a wave height of 20-45 mm is suitable for roofing.

Now they produce double-sided profiled flooring, which is intended for double-sided fences, gates, as well as double-sided internal partitions.

According to the developer, when using double-sided corrugated sheeting on a fence, the savings are about 1/3 per 1 m². This material will help save money, since it was often necessary to sheathe the fence on both sides, but now this issue has been resolved.

But, to be honest, I have not yet seen anyone stage it.

It is usually attached to metal screws or rivets.

The service life of double-sided corrugated sheeting, i.e. painted on both sides with a metal thickness of 0.45 mm for at least 15 years.

Load-bearing corrugated sheeting is essentially the same roofing sheeting, but has a slightly different scope of application. It is used as the bottom sheet in a stacked roofing pie, where it serves as a load-bearing structure; under formwork, for between floors. For such purposes, a profile with a height of at least 57 mm (for example, PK-57 or N-75 corrugated board) and a thickness of 0.65 mm or higher is used, which gives resistance to corrosion and the ability to withstand heavy loads.

How to choose corrugated sheets

- Thickness,

- Quantities of galvanizing,

- Thickness of the polymer coating.

To choose corrugated sheeting, you need to take into account its length and choose the type of material - the price usually depends on these factors.

↑ How to replace the roof of a wooden house with your own hands

This question arises when old structures become unusable, or the roof needs to be updated for aesthetic reasons. When renovating fairly old houses, it is likely that the roof covering will have to be removed.

- When inspecting the frame, special attention should be paid to the condition of the rafters. The roof is completely repairable - every part is replaceable. In this case, additional strength fixings are used. For this purpose, boards are suitable, which can be used to temporarily connect existing beams that cannot be dismantled. After this, you can safely remove low-quality rafters, since the frame will definitely not collapse. The Mauerlat requires no less attention. If signs of rot are found, the damaged parts must be cut out and new ones inserted and securely fixed with plate linings or using tightening bolts. In principle, the Mauerlat can be completely replaced with a new one, carefully dismantling it in parts and replacing it with new ones around the perimeter. Having repaired the roof frame, the covering is laid again.

What kind of service is this?

Remodeling the roof of a wooden house means dismantling the old roofing and installing a new one. This work is quite complex and requires certain tools, devices, and equipment. In order to remodel the roof efficiently, you need knowledge and experience in carrying out construction, waterproofing and soundproofing work. It is important to understand the types of cladding and roof construction. Therefore, it is better to order rework from professional craftsmen.

The service may be needed in the following cases:

- Wooden elements are rotten.

- The roof is made of outdated materials and needs to be modernized.

- The roof began to leak.

- There are areas that cannot be repaired.

- The structure has collapsed or dilapidated.

The process of replacing the roof of a wooden house is as follows:

- The technician inspects the condition of the coating.

- Old and unusable elements are being dismantled.

- New elements are being laid. Hydro- and sound insulation is carried out.

- Additional parts are installed.

How much does it cost to re-roof a private house with metal tiles?

The price of a metal tile roof is influenced by many factors, including the price of the material itself (from 6 to 13 $ per m²), the cost of installation work (from half to the full cost of the material), additional work and materials, as well as the structural design of the roof .

In general, the cost of a metal tile roof will be as follows:

- for a small building (about 100 m²) – approximately 1 thousand $;

- for buildings of medium size (approximately 200 m²) - approximately 1.2-2 thousand $;

- for large buildings (approximately 300 m²) - approximately 2-3 thousand $.

Pricing factors

Roof reconstruction can cost varying amounts of money. The following factors influence the final price:

- Type and quality of materials.

- Conditions of work.

- Season.

- Working area area.

- Building height.

- Difficulty of work.

- Urgency.

- Master's qualification.

- type of equipment and mechanisms used.

- the need for additional work.

- the prestige of the company, its pricing policy.

How much will it cost if covered with soft tiles?

Soft tiles are often used to cover complex roofs.

Taking into account the fact that soft tiles cost from 7 to 17 $ per m², and the work of installing them is estimated by specialists in the amount of 6 to 40 $ per m², the cost of a roof that uses soft tiles will be as follows:

- for a small building (approximately 100 m²) – from 1 to 4 thousand $;

- for buildings of medium size (approximately 200 m²) - approximately 1.2-8 thousand $;

- for large buildings (approximately 300 m²) - from 1.8 to 12 thousand $.

Approximate price

Approximate prices for remodeling the roof by craftsmen from Russian construction companies are shown in the table below.

| Expenditure | Cost depending on the type of roof, rubles | ||

| ondulin, metal tiles, corrugated sheets or flexible tiles | ceramic tiles | rebated covering | |

| Material purchase | 250-400 | 900-1000 | 500-600 |

| Removing the old roof | 100-700 | 100-700 | 100-700 |

| Installation of a new frame | 100-300 | 100-300 | 100-300 |

| Laying insulating materials | 50-200 | 50-200 | 50-200 |

| Additional work (installation of soffit, drainage, snow guards) | 200-400 | 200-400 | 200-400 |

| the total cost | 700-2000 | 1350-2600 | 950-2200 |

Construction of a new roof costs from 800 to 1200 rubles per square meter. Construction of an attic will cost from 1200 rubles/sq.m . Installation of a new window in the attic will cost 2,500 rubles . Equipment for the rafter system costs about 400-600 rubles per square meter. Installing the sheathing will cost about 100 rubles per square meter.

The cost of covering a roof with a corrugated sheet of bitumen (ondulin)

This material is most often used for the construction of outbuildings or simple summer houses. This material costs approximately $9 to $12 per sheet, and its installation costs $4-5.

In general, the cost of a roof using corrugated bitumen sheets will be as follows:

- for a small building (approximately 100 m²) – approximately 0.8 thousand $;

- for buildings of medium size (approximately 200 m²) – approximately $1 thousand;

- for large buildings (approximately 300 m²) - approximately 1.2 thousand $.

How much does it cost to re-roof a private house with composite metal tiles?

It is a little used material; it is a sheet of metal coated with stone granulate. The price for a roof made of composite metal tiles will be as follows:

- for a small building (about 100 m²) - approximately from 8 to 20 thousand $;

- for buildings of medium size (approximately 200 m²) - approximately from 20 to 50 thousand $;

- for large buildings (approximately 300 m²) - approximately from 40 to 60 thousand $.

The figures given above make it possible to see that the cheapest way to cover a roof is with a corrugated bitumen sheet, while the most expensive roof would be a roof made of composite metal tiles. But do not rush into making a choice, since the cost of materials is proportional to their service life.

Which film to choose

Vapor barrier

Vapor barrier membranes are supplied by several foreign and domestic companies. Among Russian manufacturers, Izospan stands out. It offers conventional and superdiffusion films for buildings with high humidity. The company offers the best prices per 1m2.

The price list of the Juta company will cost a little more. It is comparable to Izospan in terms of performance characteristics. The company offers models for both single-pitch and gable roofs with a high slope angle.

Foreign manufacturers Fakro, Delta and Folder attract consumers with the increased service life of their membranes and extended warranty.

Tyvek membranes (a branch of the world-famous DuPont corporation) always use the most advanced technical solutions and scientific developments. Technological leadership also determines high prices: on average, twice as expensive as similar products from Izospan.

Waterproofing

Waterproofing films are offered by the same manufacturers as vapor barriers. Delta's three-layer high-diffusivity membranes, designed for installation on a continuous substrate, stand out here.