A simple siphon (also known as a water seal) can be found in every kitchen without exception; its design provides reliable protection against sewer odors in the room. An overflow is a simple addition to the classic design that will allow excess water to be discharged into the drain without the risk of flooding the kitchen.

Conventional flush-overflow system

A small hole in the top of the sink.

Water drains through it if you forget to turn off the tap or the pressure is too high. This system was invented in Western Europe and is especially common in England, where they use water very sparingly and wash from a bowl with a closed drain, which increases the risk of flooding. When the water level rises above the maximum level, the water flows through the overflow hole into the drain rather than onto the floor. In our country, it is customary to wash under a stream; the need for a “drain-overflow” arises less often, but most sinks are still equipped with a “drain-overflow” system. This is not an additional option, but an integral part of the design of the sink: either it is there or it is not.

Does such a system prevent flooding?

Under certain conditions. If the drain-overflow system is even slightly clogged or a foreign object has entered the drain channel, flooding is inevitable, as is the case if the bottom valve is closed. But the overflow will happen later.

Siphon installation: step-by-step instructions

It is better to entrust the installation of plumbing fixtures in general and drain fittings in particular to professionals. But no one will judge you if you decide to do it yourself. Plastic systems do not require additional tools; only a screwdriver is needed to install the outlet. All components are screwed in by hand. Arm yourself with photo instructions, a good mood and you can get started.

First of all, the upper part of the outlet is screwed on. Often it is made of stainless steel. The drain system kit includes an O-ring for the decorative mesh. Place it on the drain hole of the sink, press the rubber seal and the rest of the outlet from below. Screw the two pieces together tightly. Check whether the seals have moved.

Diagram: siphon installation

Connect the overflow hose to the outlet and the mesh to the sink by tightening the stainless bolt in the same way as the outlet system. Screw the assembled siphon to the outlet using a plastic nut located on the neck. Be sure to check for a flat gasket. Tighten the nut all the way by hand. Don't put too much pressure on it. The plastic may not withstand the pressure and burst.

In the same way, screw the outlet pipe to the siphon body. Be sure to check the presence of the seal. Then connect the outlet pipe to the sewer system using a cone seal. It is installed, as on the siphon neck, with the narrowed part towards the hole into which the pipe is inserted.

Siphon equipment

If there is a difference in the diameters of the pipe and the outlet of the sewer system, you can use reducing plastic or rubber adapters.

Advice. For better sealing, lubricate all cuffs and gaskets with silicone lubricant. The entrance of the outlet pipe to the sewer can be additionally sealed with sanitary silicone.

After installing the system, you must perform a test run. To do this, fill the sink with water up to the overflow hole. First check its operation. Then open the drain, the water will quickly flow into the sewer. Carefully inspect each siphon connection. If not a single drop forms on it, it means the installation was successful.

Connecting a siphon to a double sink

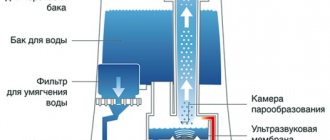

Hidden drain-overflow system

A modern alternative to the conventional system.

Its presence is outwardly invisible and practically eliminates flooding. Due to the absence of an extra hole in the sink, it looks more aesthetically pleasing and the surface is less dirty. The hidden “drain-overflow” system is quite complicated to implement and the combination with it increases the cost of the sink, but it is a very convenient and aesthetic option.

Device.

Some manufacturers use CLOU technology: a hidden siphon is used for overflow, located behind the back wall of the bowl and connected by two channels to the drain pipe. If the drain is blocked by a built-in bottom valve (of a special design), the water in the overflow device will rise along with the general water level and when it reaches the maximum specified height, the excess volume will overflow through the siphon partition and go into the drain pipe below the bottom valve. There is another technology: as soon as the water reaches a certain level, the system will automatically recognize this and open the drain plug itself.

On the picture:

Bowls without drain-overflow system

If you are purchasing a standard sink without accessories, a siphon will not be so difficult to purchase. If you choose a designer model, it is advisable to purchase a siphon included.

In the photo: siphon A750114CR from Daniel Rubinetterie.

Bowls on the tabletop.

The design of the bowl may be hampered by an extra hole, or due to its unique shape there is nowhere to mount a drain channel, and not all sinks can be equipped with a built-in system. Most often, there is no “drain-overflow” in bowls that are placed on the countertop, visible from all sides, or, for example, in sinks made of colored glass or natural stone.

Alternative.

Such bowls will necessarily (this is the norm for manufacturers) be equipped with a regular drain, which cannot be blocked - although it has a “cap”, its function is only decorative. When choosing fittings for such a drain, take into account the minimum and maximum thickness of the entire structure (sink, countertops in the place where the drain is installed).

On the picture:

Invisible drain

No holes.

The water spreads over the flat bottom of the sink and disappears at the edges. Where does she go? Into small grooves around the perimeter of the bowl, which can be detected by looking closely, and then into the drain. Most often, rectangular sinks with a straight or sloping bottom, made of ceramics, artificial and natural stone, wood, and glass, are equipped in this way. Regardless of the shape of the bowl, such an unusual drain in the bathroom is mounted to the sewer system in the usual way. There are no problems with water overflow, since the throughput of such a drain is no less, and often greater, than that of conventional bowls, since it has a large drainage area.

Source

Siphon for a sink with overflow: features and nuances of choice

Such a plumbing detail as a siphon is known to almost everyone. It firmly takes its place in every home and apartment, and there is simply nothing to replace it. A siphon is a hydraulic valve. In plumbing terms, this product is a water valve that prevents sewer gases from escaping into the room through a hole in the sink or through the toilet. In the modern world, all products that perform drainage are considered to be a siphon, but this is not entirely true. The sink siphon with overflow is especially famous.

Assembly and installation on the sink

The most common type of drain plumbing fittings are products with bottle designs. Despite the fact that they are somewhat more difficult to assemble than other types of products, they provide an optimal set of consumer characteristics. Therefore, let's look at how to assemble a sink siphon, complemented by an overflow function, based on a regular plastic bottle model. Installation will be easier if you initially completely screw together all the elements, thoroughly compress the threads and carefully position the gaskets, and then connect the finished product to the outlet and overflow holes of the sink.

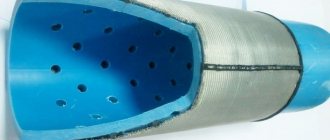

Assembling a siphon for a sink, complemented by an overflow function

- We twist the two lower parts of the flask through a large flat gasket. The threaded cap (cup) is tightened until it stops, while you need to control the position of the gasket, preventing it from distorting.

- An intermediate pipe is inserted into the upper hole of the flask, which can be without an outlet or, if you have a siphon for a washing machine with or without a check valve, have an additional outlet to which a herringbone fitting is attached with a union nut through a flat gasket-valve. Union nuts must first be put on the upper and lower parts of the intermediate pipe, and then conical gaskets with the sharp parts facing outwards.

- We tighten the flask with the lower nut, and the overflow unit with the upper one.

- We insert and tighten the outlet pipe with a union nut and a cone gasket into the larger side hole of the flask, similar to the intermediate pipe. The outlet can be a straight or angled tube, or a corrugated hose.

- The same connection diagram is for the overflow tube, which must be connected at the lower end to the side outlet of the overflow tee, and at the top to the overflow pipe.

- Now you can attach the assembled structure to the outlet and overflow holes of the sink. The siphon for the kitchen sink is attached with screws to the corresponding holes through decorative grilles. For some models of plumbing fixtures, a decorative grille is provided only at the outlet hole, and the overflow is mounted by screwing a screw into the body of the overflow pipe through the wall of the sink. Regardless of the fastening features, flat elastic gaskets must be inserted from the side of the drain fittings.

All that remains is to connect the sink siphon with overflow to the sewer outlet. If the diameter of its outlet corresponds to the mounting diameter of the outlet, then it is simply tightly inserted through the o-ring into the sewer socket. To facilitate the operation and increase the reliability of the connection, silicone lubricants or sealants are used. If the outlet is thinner, then adapters or rubber cuffs with holes of suitable diameter are used.

Important! It is better to purchase the entire set of plumbing fixtures, including a siphon for a sink with overflow, at one retail outlet, so that unforeseen difficulties do not arise during installation of the equipment. This recommendation especially applies to products of non-standard designs and shapes.

What is “overflow” and why is it needed?

Sink siphon with overflow

An overflow is a pipe through which water comes out of a sink when it has reached a certain level. Simply put, an overflow prevents water from overflowing over the edges of the sink. If for some reason the water does not come out through the sink mesh, then, having reached a certain level, it simply flows out through an additional hole - the overflow.

This truly useful invention appeared relatively recently. In Europe, cases of flooding due to water overflowing from the kitchen or bathroom sink have become more frequent. For this reason, nosy Europeans invented an additional hole in the top of the sink, which eliminated the risk of overflow. The kitchen sink siphon with overflow instantly gained popularity. Initially, it was made from the most accessible and relatively inexpensive material - cast iron.

Connection materials and standards

In the production of the vast majority of models of overflow devices, polymeric materials are used: polyethylene or propylene. Brass, copper and stainless steel are less common, as they occupy the segment of high-quality expensive products. The chrome-plated sink siphon is distinguished by its special aesthetic sophistication, which will look impressive on plumbing fixtures installed in an open manner, without installing it in furniture or decorative structures.

Despite the huge variety of forms of outlet fittings, all of them are typical water seals, with the exception of the siphon of a dry design.

Thanks to the inert materials of modern water seals, they are not subject to corrosion, unlike their previous cast-iron counterparts, and the low roughness of their internal surfaces makes it difficult for fatty deposits to form. For the same reason, models in which the outlet and overflow channels are assembled from rigid pipes are preferable. Sometimes they are more difficult to assemble and connect to the sewer, however, they will have to be cleaned less often than flexible corrugated connectors. In addition, the strength and service life of corrugations, especially polymer ones, leaves much to be desired.

Overflow siphon-spark with outlet for washing machine

When choosing a siphon for a kitchen sink, it is important to determine the diameter of its outlet and overflow pipes. If Ø 25 mm is sufficient for an overflow, then the main outlet should be much thicker. Today, the most common standards are Ø32 mm and Ø 40 mm. For households where you have to cook a lot, and even more so when there is an abundance of fatty food, preference should be given to products with outlets Ø 40 mm, they are less susceptible to blockages. Convenient for connection is the drain fitting, which has an outlet of Ø32 mm or Ø 40 mm, adapted by a transition to Ø 50 mm for direct connection to a sewer of the same standard diameter.

On a note. All types of drain fittings with an overflow pipe can have additional outlets with Ø 19 mm herringbone fittings for connecting washing and dishwashing equipment, and can also be equipped with a bifurcated inlet designed for installation on a double sink.

Siphon straight, corrugated or with an elbow?

In addition to the well-known elbow, not long ago a similar product appeared without a sump. It is a corrugated or straight pipe. The corrugated one can be tilted at any angle and even reduced in size. Their functionality knows no bounds, but there is still one drawback.

A straight corrugated siphon, due to a non-smooth inner surface, can accumulate impurities in its relief. This threatens extensive blockage and an unpleasant odor.

A siphon for a sink with a bottle-type overflow is an optimal and, not least important, inexpensive solution. In plumbing stores you can see a lot of hydraulic valves, which differ mainly in the presence of an overflow. All modern siphons are made exclusively of plastic.

Quite recently, it would seem, all apartments had cast iron water valves, and no one even knew about corrugated polypropylene pipes. Of course, cast iron products had plenty of advantages, but there were more disadvantages. Cast iron is heavy and bulky. Such a siphon does not have an aesthetic appearance and is prone to corrosion and destruction.

A siphon for a kitchen sink, according to experts, must have an overflow.

Types of siphons with overflow

What are siphons made of?

Siphons can be made from the following materials:

1. Plastic . There are few varieties here - PVC and polypropylene. This is the most popular material for such products. It is inexpensive and easy to operate.

A plastic sink drain is also characterized by the following advantages:

- there are no corrosion processes inside or outside the device;

- plastic is not subject to destruction and rotting from prolonged exposure to moisture;

- the permeability of smooth internal walls is quite high;

- fat is not deposited inside the products.

Plastic fixtures are used for installation on any plumbing fixtures.

2. Brass, copper and bronze . These are expensive products that, although they do not corrode, do oxidize. They require treatment with special materials or electroplating. Used in bathrooms under washbasins.

3. Stainless steel . These are the most expensive products, used quite rarely. They have an excellent appearance.

4. Metal products with external coating . Sometimes devices made of ordinary steel or alloys, coated with a decorative layer on top, can be used. For example, a chrome siphon for a sink looks very good, although its cost is impressive.

Example of a chrome bottle siphon under a washbasin

Sinks and siphons

The use of overflow in siphons began several centuries ago, and it is obvious that this development has taken root. Now all manufacturers create sinks with an overflow hole, as demand creates supply. By the way, there are a great variety of materials for making sinks.

In the modern plumbing market, you may encounter difficulties in choosing a sink; there is a huge variety of them. As for the siphon, its choice cannot be called difficult. You need to choose only one type out of three and not “miss” the choice of manufacturer.

In Russia, several manufacturers are engaged in the production of hydraulic valves and other plumbing elements. It is worth saying that domestic plumbing is not inferior to European, but is more affordable in terms of price.

Siphons are mostly created from plastic, but it is also possible to create a unique product from copper and tin. They are produced in single quantities, since the demand for them is not high. They do not differ in functionality from their plastic counterparts, but, of course, they look much more solid.

A copper siphon is a striking product, but you should be wary of streaks and darkening caused by time and moisture. This product must be properly cared for.

Materials for the manufacture of siphons of various types

Siphon casting materials must meet specifications for a longer service life. They must certainly be invulnerable to high temperatures and chemical reagents. As a rule, drainage devices for sinks are made of plastic, cast iron, nickel, brass, brass-bronze, and metal.

- The most practical and economical option is to use plastic siphons in the drain structure. These models are not capable of rusting, rotting, or corroding. They are easy to clean, wash, and treat with chlorine-containing solutions. Installation of plastic drain mechanisms does not require the use of plastic siphons; no additional sealing material is required. This task is performed by the coupling.

- Chrome-plated siphons made of brass and bronze are also reliable. They have little susceptibility to corrosion and rusting, but can still oxidize. Because of this, solid particles and waste deposits stick to the resulting irregularities, which leads to gradual clogging. Plastic drainage devices are inferior to them in this regard and are considered much more practical.

- The metal siphon has gained its popularity in the last decade and has become popular due to its durability, aesthetics and hygiene. Metal products are produced with an external coating that serves a decorative function in the device. Material of manufacture – steel or metal alloys. The cost of metal siphons is an order of magnitude different from other options, which once again proves the high quality of workmanship and durability of the device.

Manufacturers

There are about a hundred manufacturers of plumbing fixtures in the world. Only a small part of them is located on Russian territory. Plumbing manufacturers try to keep up with the times, therefore they tirelessly introduce innovations. This applies to both large plumbing fixtures and related consumables.

A siphon for a sink with an overflow is, for the most part, made from high-quality plastic, but this is not always the case. There is plumbing that has been extremely popular for several decades. First of all, this applies to Italian manufacturers. It was in this country that the production of advanced, sophisticated and extremely functional sanitary ware initially started. She was distinguished by both beauty and unsurpassed quality. At the moment, Italy is the supplier of the highest quality and most sophisticated plumbing products.

Components of a siphon with overflow

When choosing a hydraulic valve, you should pay attention to a number of points. First of all, you need to focus on where exactly you plan to install the product. If in the kitchen, then the bottle type is the best option. If we are talking about a bathroom sink, then it is better to opt for a straight plastic pipe. Overflow in both cases is necessary, since it significantly increases the level of safety in the matter of possible floods.

Russian manufacturers, every single one, produce siphons with overflow. Cast iron products, which were used in all Soviet apartments in the recent 80s, are now practically not produced. They have high functionality, but are not reliable and durable. In addition, installing a cast iron product is not an easy task. While even a woman can install a modern siphon, not every representative of the stronger sex can install a cast iron siphon. The main “scourge” of such valves is the low level of tightness. It was necessary to make great efforts to join all the seams with maximum tightness. Often a kind of plasticine was used to prevent leakage.

Thus, the choice of siphon with overflow is limited to three varieties. Each has its own advantages and disadvantages that you need to pay attention to. Each product comes with installation instructions, which you should also read. The service life may be specified in the warranty card, but not every manufacturer provides it. On average, a plastic valve can last a couple of years if the sink is used daily. In the case of a toilet siphon, this period can be 6-8 years, since a different type of plastic is used for the manufacture of such structures, and the pipe walls are much thicker.

A hydraulic valve for a sink with an overflow is an excellent and modern solution that will eliminate annoying flooding and, as a result, material waste. The cost of such a product starts at 190 rubles. Depending on the type of device and manufacturer, the price of the part also changes.

How to choose?

Expert opinion

Romanova Ksenia Petrovna

Interior design expert and fabric store manager

The types of siphons with overflow designs are varied. The most convenient are devices with automatic control of closing and opening drain holes.

If necessary, you need to press on the plug, which will close the hole and open it the next time you use it. However, due to the somewhat high cost of this option, the traditional siphon is more popular, which involves manually closing all the holes.

Some types of siphons are equipped with a special handle. She alone regulates the opening and closing of all holes. This is also a kind of automatic system.

The choice of plumbing fixture should be based not only on automation. The main parameters of siphons are dimensions.

Bottle-type devices are considered the most voluminous. This option is suitable if there is enough space at the installation point. If you plan to install a washing machine under the sink, then such a device will not work. The flat version is more compact. In this case, it will have to be placed under the sink.

Bottle siphons perform best in maintenance. It is this type of product that is considered suitable for a round double stone sink. A flat siphon, which is often installed in the bathroom, may not be suitable in size.

By the way, connecting other elements to the device requires the presence of additional connecting outputs. The device must have at least a pair of inlet fittings.

The siphon outlet can be made in the form of a regular lattice mesh. There are also technical devices with adjustable valves. Decide in advance whether you need this improvement so as not to overpay for it.

If the diameter of the siphon outlet pipe does not match the sewer pipe, you can use special adapters. However, this statement is only relevant if the size of the nozzle is smaller than the size of the pipe. Large-diameter pipes cannot be connected to the drain outlet.

Purpose and design features

A sink drain in a bathroom or kitchen with an overflow is a curved structure, the key purpose of which is to redirect excess water into the drain, thereby preventing the sink bowl from overflowing.

The design of the bathtub drainage system is almost identical to the design intended for the sink.

Structurally, the overflow drain for a sink or sink consists of the following elements:

The main secret of the functionality of the siphon is in its design. Due to the bending, the water does not completely leave the pipe. The formed water seal acts as a barrier to the penetration of sewer “ambre” into the drain hole.

Such designs are convenient because if they become clogged, they can be easily removed and cleaned mechanically or chemically.

Do you want to install a more durable device that is less prone to clogging? In this case, it is better to purchase a design in the form of an overflow drain for the sink. It differs from traditional models in that it is equipped with an additional tube.

This device connects a hole made in the upper side of the side of the bowl with the elements of the drainage system located in front of the siphon. Thanks to this, the overflow drains liquid from the sink, thereby preventing the bowl from overflowing.

From the outside, the drain hole is covered by a grill. It performs a protective function, trapping small debris and hair, thereby protecting the system from clogging.

Main types of drain devices

There are several types of drain systems. One of the most common options is a design in which the drain is secured with a large locking nut. This method of fastening can be found even in the bathrooms of houses built more than two decades ago.

Classification by device principle

Drain siphon systems used when connecting sinks come in three types: flask-shaped, elbow and combined.

They differ according to the type of construction:

In bottle-type devices, the waste, entering the siphon, moves down through an internal pipe of smaller diameter. Having reached the bottom, the wastewater rises through the cavity between the inner and outer cylinders and is discharged into the sewer pipe.

Bottle siphons are advantageous in that even with rare use of the plumbing fixture, the water seal in the sewer system does not dry out for quite a long time. This effect is achieved due to the fact that the outlet from the siphon is located approximately in the middle of the flask.

Many owners prefer bottle siphons for the reason that, if necessary, they can always connect several drains. To do this, the structure only needs to be equipped with an additional element.

Siphons of mixed type have proven themselves to work well. The corrugated siphon, used when arranging a mixed-type drain structure, is a modified version of a conventional curved tube.

Unlike analogues of bottle and pipe versions, among the combined options there are no models with bells, and therefore they cannot be connected to overflow systems and household appliances.

Division by material of manufacture

There are two types of sink drains available for sale, depending on the material of manufacture: those made of polymers and those made of metal alloys.

Polymer products are famous for their low price and ease of installation. Structures equipped with a corrugated pipe can be conveniently adjusted in length.

But the service life of PVC structures is relatively short. And the sealing properties of the assembled structures leave much to be desired. Therefore, all joining elements must be equipped with rubber gaskets during assembly.

In terms of reliability and durability, metal elements of drain systems are more beneficial. The models made of non-ferrous metals: brass and bronze are most in demand in everyday use. The harness made from such materials often has a chrome coating, due to which it acquires a rather presentable appearance.

To prevent the accumulation of dirt deposits on the inner surface of the walls during the manufacturing process, manufacturers coat metal products with a protective film of chromium.

Installation of metal structures does not present any particular difficulties. A hitch can only arise at the stage if you need to shorten the outlet pipe.

Siphons for non-standard equipment

For non-standard models of double “pair” sinks, siphons equipped with two outlets are used. Such siphon devices are connected to the drains of both sinks, and a little lower along the flow of waste water they are combined into a common flask.

Do you need to connect a sink located on an open shelf to communications? Then choose a model that offers hidden installation. Yes, the price will be somewhat more expensive than traditional options, but it will allow you to completely hide unesthetic elements of communications.

Drain systems of such designs will not be difficult to hide in a niche, covered with a decorative screen. But it is worth remembering that if the bend of the outlet pipe is too short, there is a high risk of an unpleasant sewer “aroma” appearing.

Types of structures

When choosing a siphon for a sink, pay attention to the shape of the device. The practicality of operation, installation method and price of the product depend on the structure. Manufacturers offer 4 types of designs, each of which has strengths and weaknesses.

Bottle

The shape of the model resembles a glass with an oval base to which pipes are connected. Such a device can be mounted to the sewer using either a straight or flexible tube. Due to the structural features, it is easy to adjust the distance between the drain pipe and the neck. Pros:

- takes up little space;

- simple installation technology;

- There is always liquid in the shutter.

If a small object (decoration) gets into the sewer drain, it can be easily removed by unscrewing the bottle siphon. The design is easy to maintain. Due to its rigid structure, the device does not fail for a long time. The only negative is the possibility of leakage with a large number of connections.

Glass-shaped model Source shopsalamat.satu.kz

A flat siphon is a modification of the bottle design that is suitable for compact sinks. The modified flask has a small throughput, so no additional equipment is connected to the model. The devices rarely become clogged, which makes operation easier.

Corrugated

The design consists of a corrugated pipe made of soft plastic. One end of the structure is attached to the sink, the other to the sewer inlet. Due to its flexibility, the part can be bent in any position, adapting to the plumbing features, or changing the angle of inclination.

The siphon is easy to install in confined spaces, and the water seal system is adjusted manually. The folded model has only one knot. The design has a simple structure with a minimum of connections, so if installed correctly, there are rarely leaks.

Flexible plastic construction Source master39.net

Due to the uneven surface of the sewer pipe, it often becomes clogged. To remove debris, the part will have to be completely disassembled and reassembled. Corrugated plastic deforms when exposed to high temperatures, so it is forbidden to pour boiling water into the sink. The product cannot be installed in an unheated country house, otherwise it will freeze and crack.

Tubular

The model is made in the form of an S-shaped tube, which can be collapsible or hollow. Liquid accumulates in the bend of the structure, acting as a water seal. At the bottom of the siphon there is a removable lid through which accumulated debris is removed. Due to its compact size, the device fits perfectly under small sinks.

S-shaped siphon under the sink Source aksu.satu.kz

Technology for installing a drain with overflow

There is nothing difficult about installing an overflow drain on your own. Each device usually comes with instructions. It contains information about the order in which the structure should be assembled.

The simplest path will be taken by an independent craftsman who installs a sink with an overflow channel provided in the design of the sink:

Step 1. Preparation of necessary materials and tools

With all the variety of models of drainage equipment, the technology for installing siphons is almost identical. Therefore, even if your plumbing fixture had a drain system installed, for example, a bottle type, you can easily replace it with the same combined option.

The standard siphon package includes the following elements:

To better understand the sequence in which you need to assemble the structure, lay out all the elements of the siphon on a table or on the floor.

Device installation

Anyone can install a siphon, even those who have not previously had such experience. The instructions included with the product provide an action plan that must be followed to properly install the device.

The sequence of actions is as follows:

- Take the grate and check its fit by placing it on the drain hole. Make sure that this element does not ride up. When the grille is installed correctly, it should be slightly recessed. If the grate is too high, the liquid will not drain completely, resulting in a puddle forming near the drain hole. When the drain hole in the washbasin has a small stamping, then this model of the device should be replaced. Otherwise, you will have to install the grille without a gasket, using only sealant.

- Install a thick rubber cuff into the outlet pipe. In this case, it must be treated with a sealant in advance.

- Check the thread mating surfaces on the parts. If there are burrs on them, you need to take a sharp knife and remove all defects.

- Install the grate into the washbasin using a white gasket. The exhaust pipe will be placed on the reverse side. After this, tighten the docking screw.

- Insert the gasket into the groove of the sump and rotate the bottom of the glass to the top. Install the outlet pipe, and then the cone gasket. Position the gasket so that there is a gap of 5 mm between it and the edge of the pipe.

- Insert the pipe into the siphon flask and tighten the nut. This can be done using your hands or a wrench, but it is important not to overtighten so as not to damage the siphon.

- It is worth installing a rigid exhaust pipe to the siphon body. After this, connect the exhaust pipe and the sewer socket. If the diameters of the installed parts do not match, you can use transitional connecting rubber cuffs.

The video explains how to install a siphon on a sink: