Hello readers of my blog! Today we will talk about how to properly lay a self-leveling concrete floor with your own hands. It would seem that the matter is not tricky, but when you are faced with this problem, you have to think about how to do it correctly, what preparation to do, what materials to choose. Thus, I decided that this article would be useful to someone, and I am devoting my efforts to this subject. In it I will answer a number of questions that will arise immediately before How to properly lay a self-leveling concrete floor with your own hands, and some even after that. This topic is quite broad, because before work, thorough preparation is necessary, but how to do this? And this is a separate topic. You can learn about all this in great detail in the article below.

How to make a self-leveling floor

The technology for pouring a self-leveling floor may seem complicated and incomprehensible, but in fact this covering is no more difficult to install than laminate, linoleum or carpet. If you are interested in how to make a self-leveling floor at home, you just need to familiarize yourself with the basic technological rules.

If you follow these rules, without skipping a single stage of work, you can easily install a polymer coating in your home, and subsequently enjoy its outstanding performance and decorative qualities.

The first rule of laying a self-leveling floor is the preparation of a high-quality base, which must meet two requirements: dryness and strength. Ready-made materials for self-leveling floors can be purchased today at any hardware store. A huge range of rough self-leveling self-leveling floors and decorative final coatings for residential premises are present in the catalogs of almost all dry mix manufacturers.

Most often, in everyday life, people are interested in how to make a self-leveling floor for the final decorative coating in order to perfectly level the concrete or cement base.

For this purpose, a self-leveling screed is most often used, designed for small differences in the height of the base. The thickness of such a coating should not exceed 4-5 centimeters. Such screeds are a good choice if you want to install a heated self-leveling floor in a room, as they can be applied without problems to heating elements previously covered with insulating material.

Installation technology

At this stage you will need edging tape for the self-leveling floor.

It must be laid around the perimeter of the room, secured to the walls at the points of contact with the future polymer screed. The presence of tape will help to avoid deformations and cracks after the coating dries, as it compensates for the shrinkage and expansion of the material. The thickness of the damper tape must correspond to the thickness of the coating.

If you choose a thin self-hardening self-leveling floor, then the thickness of the tape should be small.

Ideally, it should not be visible after the coating has dried. If part of the tape is visible above the floor surface, you will have to cover it with baseboards.

After applying the tape and thoroughly cleaning and preparing the concrete base, you need to apply a primer to it. It is best to choose a deeply penetrating primer for self-leveling floors; it reduces the absorbency of concrete, removes dust and increases adhesion. Use a wide roller to apply the primer.

Before the next stage, you need to wait until the primer layer has completely dried. If the screed is old and porous, for reliability it is necessary to apply a primer in two or three layers. The new screed can become stronger after just one application.

Video description

The use of self-leveling mixture can be seen in the video:

Method 4 – dry screed

This option involves the use of gypsum fiber sheets. Such a screed is not monolithic. Sheets of material are mounted on expanded clay or other heat insulator with the same properties. Therefore, an insulated leveling floor screed is obtained.

At the beginning of work, the uneven base is cleaned of dirt and covered with waterproofing. Typically polyethylene is used. The film is laid overlapping and overlapping the walls. Therefore, polyethylene is used with a margin of 100 mm on each side. Additionally, edge tape is used. It is placed along the walls.

First, the expanded clay is leveled to the level of pre-installed metal guides, and then carefully compacted. Under linoleum, gypsum fiber sheets are laid in two layers. If the floor is finished with laminate, then only one row of gypsum fiber board can be installed.

The second layer of gypsum fiber sheets is fixed with glue and screws. In this case, the gypsum fiber boards of the top row are laid offset. The seams between the gypsum fiber sheets of the first and second layers should not match. Typically the offset is between 250 and 300 mm.

We install beacons

At this stage, you need to install beacons for the self-leveling floor. To do this, you need to prepare a certain amount of cement mixture, with which you will secure the beacons to the base.

It is convenient to use aluminum profiles as beacons, suitable for correcting various height differences. The installation of beacons must be done with a liquid or laser level.

In this case, the surface uniformity will be most accurate, and this directly affects the quality of the final coating.

If you are leveling the floor in the bathroom and plan to lay porcelain tiles or floor tiles on it, it is especially important to make the base level.

On a screed that is not too level, the tiles may subsequently begin to crack, break and peel off. After installing the beacons, level the cement mortar with a spatula, filling all the voids between the beacons and the base. Wait for the cement mortar to dry, and then begin preparing the dry polymer mixture for pouring.

Making a choice

We will make a choice based on the properties of materials and common sense.

Financial component

As we have already said, self-leveling floors and screeds solve the same problem of leveling the floor, but their approach is different. The main task of the screed is to produce a thick-layer, rough leveling of the floor.

The question arises, why can’t the same be done with a self-leveling floor? The answer is simple - financial costs. For a visual demonstration, we will make a conditional calculation.

Preparing the mixture

In order for the installation of the self-leveling floor to be successful, you need to properly prepare the mixture.

To do this, it is important to carefully study the instructions for the specific dry mixture that you purchased in the store. The amount of water must clearly correspond to the amount indicated by the manufacturer on the packaging. Excess liquid will cause the coating to become fragile, and the finished self-leveling floor may crack.

Measure out the required amount of water and add it to a large container. It is convenient to use a large bucket with a lid for this. After this, add the mixture from the bag to the water, stirring.

The resulting solution must be thoroughly mixed with a mixer attachment attached to a drill or hammer drill.

Mix the solution at low speed with the drill as long as necessary until it becomes homogeneous. Leave the solution for 3-5 minutes and then mix it again with a mixer. Do not leave the mixture for a long time, as this will simply harden it and become unusable for application.

Then the self-leveling floor is poured.

Carefully pour the solution from the container onto the floor, carefully leveling it with a wide spatula. A small bathroom can be filled in one go without the help of a second person, but if you are pouring a large area you will need a helper.

The layer of mortar on the floor must be rolled with a toothed roller to get rid of small air bubbles that impair the strength of the final coating.

If the room is large, do not prepare the entire portion of the solution at once.

It is best to knead the dry mixture in parts, filling the room with fragments. This will help prevent the solution from drying out, since after mixing it must be applied to the floor within 30 minutes. You should work quickly, because otherwise there will be visible seams between the fragments of the fill, and the self-leveling floors must be seamless.

After the entire floor area has been filled and leveled using a needle roller, you must wait for the coating to dry completely. You can walk on a fresh screed after a day, but complete drying will not occur earlier than after 5-7 days. Further repair work can be carried out only after the screed has completely dried and hardened.

Laying linoleum on a concrete floor

Linoleum is used very widely as a floor covering. And this is explained by the wide variety of all kinds of it, which differ in the degree of wear resistance, reliability, color scheme, texture, price and other indicators.

Features of coatings due to the compositions used

In addition to the main operational characteristics, when choosing the type of screed, it is necessary to evaluate other important parameters: time and method of preparation, installation, and other installation operations. These factors affect the final result, cost and time spent on floor repairs.

Cement-sand screed

The technological feature of this type of composition is its thick consistency and poor ductility. This necessitates the use of trowels, graters and rules, as well as significant physical effort to distribute the mass over the floor surface. In order to facilitate the application process, it is practiced to add modifiers to the mixture. If installation is carried out quickly and there are no factory modifiers, it is possible to add concentrated detergent to the composition - it also increases the plasticity of the mixture. When there are large differences in heights, the “beacon” laying technology is used; it is characterized by a general increase in the cost of work and additional labor costs. IMPORTANT: The cement-sand screed solution is prepared immediately before use using cement sand and a variable amount of water. The quality and composition of the solution is complete. It depends on the human factor and the skill of the performer - incorrect use of the proportions of materials when mixing the mixture can lead to its fragility and cracking.

Scope of application of cement-sand screed

Due to the pronounced roughness of the surface of the cement-sand screed, it is used as a basis for laying linoleum, parquet, laminate, floor boards, and carpet.

For technical or industrial premises, cement screed is sometimes used as a finishing coating. The top layer of the screed is strengthened for its further use using ironing technology, in which cement laitance is squeezed onto the surface of the mortar and dry cement or other powder toppings are rubbed into it, which compact the outer layer of the screed and strengthen it. The surface thus reinforced can withstand the use of heavy equipment, including forklifts.

For residential premises, the minimum thickness of the screed is 3-4 centimeters. To prevent mechanical damage and cracking, it is practiced to place a reinforcing metal or polymer mesh inside the composition. After 12 hours after pouring the cement-sand screed solution, it is possible to carefully move along its surface in soft shoes. Nominal strength is achieved after 14 days, after which installation of decorative finishing materials is possible. The final hardening of the solution occurs within 90 days. When using wood materials as a finishing floor covering, it is necessary to take into account the moisture content of the base, namely, the base must be completely dry.

Floor surface polishing machine

Screed using self-leveling floor

Installation of self-leveling floors is carried out without “beacons”; the filling technology is simple and does not require significant specialist efforts. Due to the fluidity of the solution and its ability to self-level and quickly dry, the installation process is fast and efficient.

Scope of application of self-leveling floors

The quality of the resulting surface of self-leveling floors allows you to lay absolutely any decorative coating on top. Often, self-leveling floors are left as a finishing coating due to its attractive appearance and the possibility of various decoration methods during the installation process.

Polymer self-leveling screed has a rich color palette; in addition, glitter, flock and other decorative decorations can be used. So-called 3D floors are gaining popularity. An impressive appearance and a variety of fantasy images are achieved by installing a high-resolution printed vinyl image in the middle layer, and filling it with a layer of transparent polyurethane or epoxy component on top. Tip: Using a similar technology, it is also possible to produce some interior items, in particular tables, whose design will repeat the design of the floors. Self-leveling floors are popular for food, chemical, and pharmacological premises, as well as in gyms and fitness clubs, public institutions, and kitchens in catering establishments, that is, where sterility and cleanliness, ease of maintenance and disinfection of surfaces are important.

For domestic premises, self-leveling floors are indispensable in bathrooms, kitchens - in areas where there are pronounced temperature fluctuations and high humidity.

After 3 hours after pouring the self-leveling mixture, you can already move on its surface, and after three days it is advisable to begin laying the decorative material.

The minimum permissible thickness for pouring the mixture is 0.5-1 mm, but generally, pouring is done at 3.5-5 mm. But with a minimum pouring thickness, floors are suitable only for home use, and for industrial use the thickness is calculated in accordance with the expected loads.

The process of pouring self-leveling floor

Selection of the “right” linoleum

According to technical characteristics, it is customary to distinguish between household, commercial and semi-commercial linoleum.

Household linoleum, as you might guess from the name, is laid in residential premises. Commercial – used in offices, shops, and various institutions.

Semi-commercial linoleum is an average option in quality and price between these two types.

Calculating the required amount of linoleum is not difficult.

You need to calculate the area of the room and add approximately 10 cm of margin on each side. When buying linoleum, it is very desirable to calculate everything in such a way as to avoid seams, but sometimes this is impossible, then you will have to resort to gluing the panels.

When buying linoleum with a pattern, the stock should be larger, since you will have to join the pattern, which means waste will appear. It is imperative to pay attention to the fact that the linoleum rolls are from the same batch (this can be seen on the labels).

No. 2. Semi-dry screed

Semi-dry screed is one of the varieties of the popular cement-sand screed. It is performed in virtually the same way as in the case described above, but the changes affected the process of preparing the mixture - a minimum of water is added to it , which is necessary only to hydrate the cement. Fiber fiber is added to the solution as a reinforcing agent. , many advantages were achieved

high density of the resulting screed, as well as the absence of pores and voids, because during the hardening process there will be no evaporation of moisture characteristic of a wet screed;- minimal shrinkage, because evaporation is almost completely absent. The screed can be laid without taking into account shrinkage;

- a cleaner installation process, since the solution is less wet and produces less dirt;

- it will take less time to completely harden, again due to less moisture and a faster process of evaporation;

- the level of humidity in the room after pouring such a screed does not prohibit carrying out associated finishing operations and storing building materials in adjacent rooms, which is strictly not recommended when a regular cement-sand screed hardens.

You should also not forget about the disadvantages of the method:

- Due to the higher density, the ability to spread worsens and sometimes difficulties arise in filling corners. However, experts advise combating this drawback by introducing plasticizers into the mixture;

- You can level only small surfaces with your own hands, up to 75 m2 in area; in other cases, you can’t do without a pneumatic paving machine.

The process of laying a semi-dry screed is almost identical in principle to the installation option for cement-sand screed described above, but some features require consideration. In particular, this is the process of preparing a solution . It is recommended to mix three shovels of sand and a shovel of cement in a container until the required amount of mixture is formed. It is mixed and a little water mixed with fiber is added (approximately 80 g is used per bucket of water, unless otherwise specified by the manufacturer). Water is added until the mixture has the consistency of sandy loam, sticky clay sand. If you compress the mixture, the moisture will not be released, and the lump will retain its shape. If you still go too far with water, you can add cement and sand in the same proportions, but in smaller quantities.

It is recommended to lay the mixture in two layers : the first slightly below the intended level and with maximum tamping, the second - with pulling and grinding. You need to act very quickly, because within an hour the mixture hardens. Some experts advise applying the first layer immediately around the perimeter of the room: this can only be done if the second layer is applied within one hour. A day after installing the screed, expansion joints can be cut along the walls to a depth of up to a third of the screed itself and a width of no more than 3 mm.

Preparing the concrete base

Whatever type of linoleum you choose, before you start laying it, you need to prepare the base.

The quality of the base directly affects the service life of linoleum. The slightest depressions and protrusions on the surface will cause the new linoleum to wear out quite quickly. It must be smooth, free of debris and old coating, have sound insulation and thermal insulation.

Since we are interested in a concrete floor, we will consider its preparation in more detail. If the differences in the heights of the base do not exceed 2 mm per square meter, then you can simply putty the depressions and eliminate the protrusions.

For larger differences, it is worth performing a new floor screed. For these purposes, both traditional screed (concrete or cement) and self-leveling mixtures are suitable.

The advantage of the latter option is that they make it easy to obtain a perfectly flat surface and, even with a fairly large thickness, they dry much faster than a regular screed. But even in this case, this process will last several days depending on humidity, air temperature and other factors. After the base has completely dried, if necessary, carry out thermal and waterproofing of the floor.

Hard subfloor

A rigid subfloor involves installing sheet material directly onto the floor slab or over a pre-installed cement screed. When gluing the joints of the sheets between each other and at the junctions with the walls, such a floor is suitable for traditional types of coverings: parquet, carpet or laminate.

On to the pros

can be attributed:

- Budget-friendly design. The minimum amount of materials allows you to significantly reduce construction costs.

- Saving room height in the absence of any heat insulator.

- A good option for ceilings of outbuildings, garages or attics, that is, where insulation and sound insulation are not required.

Cons

perhaps more:

- It will not be possible to correct a large difference in heights with such a screed. A significant difference will first have to be leveled with a cement screed.

- Complete absence of any heat and sound insulation.

- It is impossible to lay communications under a screed of this type.

- The need to treat sheet material with moisture protection and fire protection.

Technology for laying linoleum on concrete

In the room where linoleum will be laid on a concrete floor, a constant temperature of at least +18 degrees Celsius must be maintained. Humidity should not exceed 68%. Before laying, linoleum is spread in the room and allowed to level out and “rest.”

Next, the linoleum is cut, taking into account the location of the canvases in the room.

Be sure to carefully combine the pattern and leave a margin of about 10 cm on each side. In rooms that have complex floor contours, it is worth taking a particularly responsible approach to cutting the panels. Sometimes it’s better to do an approximate cut with allowances, and then do the final cut after gluing.

Seams, if any, should be placed in the direction of light from the windows, so they are less noticeable.

For styling you may need a knife, ruler, rollers or brush. For gluing, you need to prepare special glue, mastic or double-sided tape, depending on the chosen laying method. To seal joints tightly, you can prepare special glue.

There are several ways to lay linoleum. Let's look at the most popular options:

No gluing. The fastest way.

It is used for small rooms where there is no significant load on the floor. However, there is still a risk of wrinkles and waves forming. Gluing with tape. When using this method, linoleum does not wear out so quickly. Gluing with mastics or glue.

The last installation method is the most labor-intensive, but effective. For large premises it is mandatory.

What is the best way to proceed: whether to glue the linoleum completely or use the free-spreading method will depend on the size of the room and the loads. In living rooms, hallways, corridors, of course, it is better to glue it.

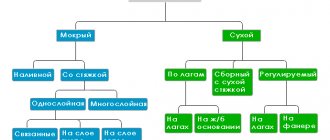

Alignment methods

You can make the floor level using several methods:

- cement-sand, which is used for high-quality foundations in private construction and industrial facilities. Advantages: porous structure, good sound and heat insulation, low shrinkage;

- dry, which when used creates a very smooth base for the finishing coat. It does not have high compressive strength, like the cement-sand method. But it’s great even for those rooms with a lot of traffic;

- from a self-leveling mixture, which is a gypsum or cement based composition with fine filler and special additives for hardening. The leveler turns an old cracked base into a perfectly flat floor in 10-15 minutes;

- scraping, which can be used to eliminate defects on wooden floors;

- correction of large differences in heights on floor slabs using polystyrene foam;

- an adjustable floor, which, thanks to its unique design, rises to a certain height above the base base for the purpose of laying engineering and cable systems.

Option #1 - mastics

As a rule, mastics are most often used for laying linoleum. They are characterized by high strength and moisture resistance, which allows them to act as waterproofing.

To glue fabric-based linoleum, dispersion adhesives or synthetic bitumen mastics are used. They are applied to the floor in a layer of about 0.5 mm. Linoleum on a heat-insulating base is glued using dispersion adhesives.

The thickness of the adhesive layer on the surface is 0.7 mm. For baseless linoleum, mastics made from resins and rubber of synthetic origin are used. They are applied in a layer of no more than 0.4 mm.

There are many recipes for making linoleum glue at home. But it should be noted that store-bought adhesive is more reliable, since if you prepare it yourself there is a risk of making mistakes or doing something wrong.

Installation of screed for heated floors

Warm floors are used for heating living rooms, bathrooms, large premises, verandas, and production workshops. But when deciding how to level a concrete floor or wooden floors under a warm floor, it is important to choose the right type of screed. It all depends on the nature of the heating elements:

- Water polypropylene pipes or electrical cable.

Floor slabs are lined with a waterproofing membrane. It is also laid out on top of the mineral wool. Directly under the pipes there is heat-reflecting foil. The screed for underfloor heating can be semi-dry or wet. If its thickness exceeds 50 mm, a reinforcing mesh will be required. There are no restrictions on finishing; - Infrared heating mats.

They are laid directly on concrete slabs. The best finish is tiles. - Film heating elements.

They are laid under plywood, drywall, fiberboard. Any finishing, except tiles and mosaics.

Option #2 - special glue

A good glue for linoleum is quite elastic, which does not allow it to peel off under load. According to the method of gluing linoleum, compositions are divided into two types: for fixation and continuous gluing.

There are five types of adhesives for continuous bonding: one-component, two-component, water-dispersed, polyurethane and solvent-based adhesive. Water-dispersed compositions are environmentally friendly and popular. At the same time, they are quite elastic and fix linoleum with high quality.

As a more economical option, use adhesive for fixation - a special composition that has moderate adhesive ability and constant stickiness. This glue is easy to apply and the consumption is not high. It is best to buy glue together with linoleum, which will allow the seller to give full advice and offer the best option.

Having chosen the adhesive composition, you can proceed directly to the procedure for laying linoleum.

The adhesive composition is evenly applied to the floor surface with a notched trowel, sequentially spreading the linoleum and pressing it to the floor surface with a roller or brush.

Drying times vary; to find out exactly, you need to read the label and instructions on it.

What tools will you need?

- Measuring instruments – rulers, tape measures, laser and bubble levels.

- Beacons or slats to set the level and direction of the screed.

- Waterproofing – liquid or roll.

- Spatula and rule for leveling the layer.

- Bucket or other large container for mixing the composition. Good amount of water.

- Construction mixture. Choose ready-made options that just need to be mixed with liquid.

- Workwear.

How to properly glue linoleum?

When gluing linoleum with double-sided tape, the procedure looks like this: first, the adhesive tape is glued to the floor, but the protective film is left. The linoleum is spread on top, then one half of the panel is folded back, the protective film is removed, spread again and smoothed thoroughly, moving in the direction from the center. Do the same with the other half of the cloth.

When laying linoleum with glue, the procedure becomes more complicated. After the panel has been folded back, glue is applied to the floor using a notched trowel (sometimes it is better to use a roller, depending on the type of glue), then the linoleum is spread and leveled. Same on the other side.

In a situation where strips need to be joined, they are laid overlapping. Bend the edges at the junction and apply glue to both panels.

At the place of application, use a sharp knife to cut through both layers and remove the trimmings, both edges are glued. This way you get an almost invisible joint. After drying, the joints are glued with a special glue for cold welding of seams, which gives them additional tightness and reliability.

We looked at various ways to lay linoleum on a concrete base. Each of them has its advantages, but the most reliable is gluing, which is carried out using special adhesives and mastics.

By following simple recommendations, you can lay linoleum yourself and get a reliable and aesthetic floor covering, which, moreover, is quite practical and does not require complex maintenance.

How to level the floor

We begin the renovation and look at the ceiling, walls and floor for a long time, and then, with a wave of our hand, we glue paper wallpaper and admire the new interior, stepping on the uneven surfaces that appear through the linoleum.

However, in our time of advanced technology, a wonderful material has appeared - self-leveling flooring. It allows you to perfectly level the surface. All that remains is to study the step-by-step technology for installing self-leveling floors with your own hands.

For modern floor coverings, and simply for the eye spoiled by today's realities, it is often necessary not just a flat floor, but a perfectly flat one.

Self-leveling is a dry mixture consisting of special components that provide good fluidity and viscosity.

In addition, self-leveling floors have extraordinary strength and durability, environmental safety and water-repellent properties. In other words, as soon as you pour the self-leveling floor solution onto the surface, it will take on the desired shape and horizontal position due to its unique components.

Also, unlike cement-sand and concrete screeds, it is enough to fill the self-leveling floor with even a minimal layer, which is usually equal to two to three centimeters. This layer will not crack and will be quite durable.

Specifics of working mixture compositions

The main difference in the implementation of cement-sand screed (CSS) and self-leveling technologies is already inherent in the physico-chemical properties of the materials used for them.

Cement strainer

A solution for a traditional “wet” cement plasterboard can consist of only three components - cement, sifted sand and water. Therefore, preparing it with your own hands is not difficult, even at home. If you take a ready-to-use mixture, then it is purchased in dry form and often contains a certain amount of profile modifiers. Their presence can significantly change the installation manufacturability and performance characteristics of the screed. For example, improve the mobility of the solution, increase the period of its initial setting or increase the moisture resistance of the finished floor, its strength, abrasion resistance, resistance to thermal deformation (a key characteristic for water-heated floors), etc.

Important! Laying cement-sand screeds, even those with high mobility, requires the processing of large volumes of materials, as well as the application of significant effort to obtain smooth, flat surfaces.

Self-leveling screed

A good composition for self-leveling floors (also known as self-leveling screed) is almost impossible to prepare on your own. Therefore, it is purchased in the form of dry mixtures or suspensions (liquids containing tiny solid particles). The working solution of the self-leveling screed has a mobile liquid consistency. This allows it to spread independently to form a horizontal plane along the surface of the base under the influence of gravitational forces. As the main binder, the floor screed can include both mineral and various polymer compounds, according to which their main classification is carried out, for example:

- polyurethane – have high moisture resistance and elasticity, withstand significant compression/tension loads. Resistant to chemical influences, temperature changes over a wide range, vibration and abrasion;

- epoxy - usually these are two-component compositions consisting of a base and a hardener. They are characterized by high moisture resistance and impact resistance. Epoxy self-leveling floor screed can withstand mechanical impacts of high intensity and force;

- epoxy-polyurethane - combine the advantages of both previous classes. Harmoniously combine high strength, resilience and elasticity;

- methyl methacrylate – characterized by a high drying speed, which allows you to walk on them in special shoes after just 2 hours.

Read more about the types, properties and choice of materials for self-leveling floors here.

Pouring self-leveling floor with your own hands

When working, be sure to use crampons (attachments for boots with steel spikes, see the picture on the left).

On the surface that you are pouring, move exclusively on them; only amateurs do not do this. Using crampons, your surface will be smooth. If you don’t have professional ones, then make something similar from scrap materials.

First add water to the entire volume of the dry mixture. To do this, you can run a bath.

When you start using the bath water, turn on the water to refill. This way, you will have enough water throughout the work and there is no need to wait for the bucket to fill. If there is no bathtub, prepare other large containers, such as barrels.

Pour water into the construction container according to the instructions on the package. Pour the dry mixture into the water and mix thoroughly with an electric mixer. The container should hold the entire bag of dry mixture at once in order to work as quickly and efficiently as possible. Wet the surface with water. Pour the resulting mixture onto the floor. Stir another volume of the mixture and pour it next to it again.

Mix and pour the solution quickly until you fill the entire area. The self-leveling agent sets quite quickly, so work with two people and at maximum speed. Then level the solution over the entire surface using a squeegee. Roll the entire surface with a needle roller to expel any air bubbles that have formed. Leave the self-leveling floor to dry. After the pot life period, the solution begins to set (polymerize and cement).

This process lasts from 3 hours to a day and ends with the solution hardening to such an extent that it can be walked on. It must be dried very slowly. Avoid direct sunlight, drafts and low temperatures. Full acquisition of working properties (strength, hardness, resistance to deformation, shock, friction, exposure to water, etc.) occurs within a month.

After a couple of days, you can lay the boards on the set mortar for indoor work. After a month, when it dries and gains the necessary strength, you can fully walk on it and lay floor coverings.

Under the influence of special components, the level levels the surface and becomes glossy. To do this, you need to make a high-quality mixture and fill the self-leveling floor correctly!

The ideal solution for your interior will be 3D decorative self-leveling floors.

Making a self-leveling floor with your own hands

The goal of developing self-leveling floors was to reduce the labor costs and installation time associated with outdated leveling and finishing schemes.

A wide range of compositions are excellent in solving both problems, allowing in a short time to create a durable, perfectly smooth, monolithic surface, pleasing with tightness and the absence of seams.

Technological priorities are justifiably added to the list of operational advantages, thanks to which a home craftsman who does not have a construction specialty on his track record can fill the self-leveling floor with his own hands, subject to scrupulous observance of the rules.

Pros and cons of screeds

Here is an analysis of the strengths and weaknesses of the screed types.

Wet

This method has long been considered classic. To prepare the working mixture you will need cement and washed or sifted sand in a ratio of 1:3. To reinforce the layer, you can add fiber fiber to the solution, as well as liquid soap or a factory-made plasticizer.

In addition, the trade offers ready-made dry fiber cement boards for “wet” floor screed. Simply pour them into a container and mix with water to the required consistency. Thus, already at the factory, plasticizers and modifiers are added to the dry working mixture for special conditions of work.

The main advantages of “wet” screed:

- affordable cost of necessary materials;

- strong, solid, durable base;

- the possibility of installing screeds in rooms with high humidity;

- The layer thickness allows height differences from 30 to 250 mm.

Flaws:

- long-term strength gain;

- large layer thickness and, as a result, significant weight loads on the base;

- the likelihood of cracks appearing when drying, the need for regular moistening when gaining strength;

- mandatory final leveling.

However, even with relatively little experience in construction work, you can do a “wet” floor screed with your own hands.

Semi-dry

It differs from the previous one by reducing the amount of water when mixing the solution by 2.5-3 times. This is quite sufficient for the cement hydration process, but the minimum thickness should be increased to 40 mm.

The solution turns out to be very thick; a concrete mixer is required to prepare it. In addition, the surface of the semi-dry screed is compacted and polished using a trowel.

This technology has a number of advantages:

- after completion of work, the surface does not require additional processing;

- short setting time;

- strength is almost the same as that of a “wet” screed;

- there is no shrinkage, no cracks form;

- minimal amount of water and no leaks;

- It is allowed to lay the mortar on a rough rough surface.

The disadvantages of the technology include:

- the need to use special mechanisms - a concrete mixer and a trowel;

- increased layer thickness;

- difficult DIY installation.

The advantages and disadvantages of semi-dry screed are discussed in more detail here.

Dry

The process of installing a dry screed involves filling a layer of expanded clay (perlite, vermiculite) and laying sheet materials such as plywood, chipboard, OSB on it. Builders note the following advantages in this technology:

- all work can be done manually, without special mechanisms;

- minimum weight load on the supporting base;

- backfilling can be done at any air temperature;

- no need to wait for the required strength to gain;

- improved thermal insulation properties with a backfill layer thickness of 5-6 cm.

Disadvantages of dry screed:

- impossibility of installation in rooms with high humidity;

- the need to install a waterproofing layer;

- large thickness of the system;

- poor resistance to heavy weight and mechanical loads.

The dry screed technology is presented in detail here.

Specific features of self-leveling floors

With some degree of misconception, we include the following in the family of self-leveling floors, popularly called self-leveling mortars:

Despite the fact that they work predominantly in a well-coordinated tandem, are produced by the same manufacturers, and have a similar base, they are different materials, both in purpose and in installation methods. Levelers, which differ from old cement-sand mortars in their optimized spreadability and plasticity, are applied to the floor in the usual way with leveling along the beacons. They do not have the ability to independently form a flat plane under the influence of gravity.

The class of finishing mixtures is called leveling mixtures for a reason. In fact, they are self-leveling floors, colloquially referred to as liquid linoleum.

It is not prohibited to use them to eliminate large base defects, but due to the impressive cost there are few takers.

The liquid consistency and the presence of plasticizers in the finishing options ensure the spontaneous formation of a perfectly flat surface without the use of levels or placement of beacons. Their advantages are less work with incomparably higher results.

Brief information about the features of concrete screed

Over time, cracks and scratches appear on the concrete surface, which inevitably leads to the need to level the flooring. It is impossible to efficiently install or replace laminated or parquet flooring or linoleum without restoring the concrete screed. The minimum thickness of pouring the concrete mixture when eliminating deficiencies in the existing concrete screed is 30 millimeters. TIP: The surface of the concrete screed must be additionally sanded if relatively thin linoleum is to be laid. However, sanding costs extra money. Specialists make concrete screeds using beacons; it is this technology that allows you to maintain the required level throughout the entire room. The need to use beacons and level the mixture manually with a special tool - as a rule - also makes the process labor-intensive and classifies the screeding process as low-tech.

IMPORTANT: Experienced specialists note the positive aspect of using a screed - elements of the “warm floor” system can be immediately laid inside it.

The advantage of a concrete screed: it can be used to install a heated floor system

Functions of self-leveling levelers

Levelers are needed to fill the base subfloor. However, their use as a rough basis is completely optional.

A double-primed cement-sand screed, plywood flooring or a plank floor covered with insulation would serve as a perfect base for the finishing polymer coating. It’s just that when paired, materials of the same brand work better, and there are no problems with compatibility. In addition, the polymerization of the leveler occurs 4 or more times faster than the hardening of a screed made of sand and cement.

In terms of thermal conductivity, progressive and outdated leveling materials differ slightly. Therefore, in order to increase the thermal insulation qualities of the floor, they are laid over the same insulation materials. And they are also used as a heat-conducting element in underfloor heating systems, if the manufacturer has indicated this possibility in the labeling.

Note. The “underground” water heating system is filled with leveling agent layer by layer, in at least two stages. The pipes are pre-filled with liquid at room temperature.

Bulk floor

The bulk floor is a layered cake made of film, which is laid on a floor slab, expanded clay, quartz sand or other non-metallic bulk material and sheet materials on top. Some manufacturers produce ready-made tongue and groove slabs designed for this type of floor.

Advantages

bulk floor:

- Expanded clay is a good heat insulator due to its porous structure. Even a relatively small layer of this material is comparable to a standard 50 mm mineral slab.

- Expanded clay is very durable.

- Sand and expanded clay are fire resistant.

- Environmentally friendly materials. The basis of expanded clay is clay, and sand is a natural material in itself.

- The physical characteristics of fillers for screed flooring allow it to be used in various types of premises and under different temperature conditions. And such a coating can be installed at low temperatures.

- Lightness of the entire structure. At the same height, the load with a loose screed will be 3 times less than with a wet screed.

- A budget option for implementing a subfloor.

Flaws

dry bulk screed:

- Despite the frequent statement that expanded clay is a good sound insulator, this is partly a misconception. The material is able to slightly reduce decibels in airborne noise, but does not cope well with shock due to the fact that it is not an elastic material. And as you know, elasticity is the key to successful shock wave damping.

- The minimum height to which the floor should be raised is 4 cm, ideally 6-8 cm. This is necessary for the strength of the coating and to avoid subsidence. A fairly high subfloor + finishing coat greatly reduces the height of the room.

- Sometimes unscrupulous manufacturers replace natural materials with synthetics, which can negatively affect the health of residents.

- Impossibility of use in wet areas. Natural fillers are usually hygroscopic material.

Secrets of using finishing mixtures

Thin-layer final fill mixtures can be applied over virtually any substrate. You just need to select products in accordance with the manufacturer's instructions regarding compatibility. The priority is still cement and polymer bases.

Leveling proudly appears among the functions of finishing compositions, but since they are mainly filled with a layer of up to 5 mm, it is advisable to exclude gross flaws in the “relief”. Even if the bumps and depressions can be smoothed out with a leveling mass, there is a strong argument in favor of first eliminating the defects.

Self-leveling floors of different thicknesses will harden unevenly, and strength indicators will vary significantly.

If previously the colorful range of finishing self-leveling compounds was dominated by dull gray and cream tones, now home craftsmen figuring out how to make a self-leveling floor can actively fantasize about their future decor.

The result can be a monochromatic color coating with the color specified by the manufacturer, or a 3D version with a unique pattern, covered with an epoxy transparent layer on top.

What to start from when choosing the optimal composition?

When choosing a specific composition, several evaluation criteria must be taken into account.

- Where will the floor be poured?

— In the living areas of a house or apartment, any mineral mixtures are suitable, taking into account the level of humidity in the room. Epoxy or polyurethane coatings, “self-sufficient”, that is, without subsequent finishing, are quite suitable. If a “warm floor” is planned, then this must be specified by the manufacturer.

Self-leveling polymer 3D floors have become widely used in residential premises. True, you need to carefully consider whether such a finish will soon become boring and whether it will become an irritating factor.

— In the bathroom, toilet, if you plan to cover it with tiles, then cement-based compositions (the use of combined cement-gypsum ones is allowed). Polymer compositions are also excellent - as an independent coating.

— In the kitchen, it is better to use mineral-based compositions if you plan to finish the flooring with laminate, linoleum, or tiles. Seamless polymer coatings, which can be given the necessary decorative effect, are also suitable.

— Bathhouse - the requirements are similar to the bathroom, but it is better to exclude the use of cement-gypsum mixtures.

— Porch, balcony, pedestrian area in front of the house, etc.: the characteristics of the mixture must necessarily indicate that it is frost-resistant. Naturally, compositions with a gypsum component are completely excluded. Polymer or polymer-cement compositions that are resistant to abrasion and have a rough surface are welcome.

— Garage – the optimal choice would be a polyurethane coating. As an option, leveling is done with a cement composition, and then a thin, up to 5 mm wear-resistant polyurethane layer is poured.

- What thickness of fill is expected?

Everything is simple here - the manufacturer must indicate the range of acceptable thicknesses. And violating these recommendations means risking the strength and durability of the floor.

The range of permissible thicknesses for pouring the self-leveling compound must be indicated by the manufacturer

In addition, the initial conditions and the cost of the material should be taken into account. Filling expensive finishing compounds with a layer of more than 5 mm is extremely wasteful. Therefore, for rough leveling of the surface, you can select “simpler” self-leveling compounds, and then, after such a base has hardened, perform the finishing fill. And it’s better if these mixtures are from the same manufacturer - they are maximally adapted.

- On what basis will the pouring be carried out?

— Any composition can be poured onto a concrete base (floor slab) after appropriate preparation.

- On a wooden base or on insulation (penoplex and the like) - preliminary pouring of a floating (not connected to either the base or the walls) cement-sand reinforced screed 40 mm thick is required. After this, a thin-layer finishing composition is applied. True, the manufacturer of the mixtures may stipulate other conditions - this must be clarified in the instructions for use of the compositions.

Special self-leveling mixtures are available for sale specifically for complex bases - wooden, bitumen, hardboard, etc.

— For waterproofing (bitumen), for old tiles, preliminary pouring of a reinforced floating screed is also required. For screed, by the way, a self-leveling mixture can also be used - compositions are produced specifically for such purposes.

- What kind of external floor finish is expected?

Any mineral compositions are suitable for tiles, but must take into account the degree of humidity in the room, as discussed above.

Under other coverings (laminate, parquet boards, linoleum, carpet, etc.) any, including polymer ones. The only question is how cost-effective it will be to use expensive polymer bases in such a case.

Laminate prices

laminate

- How quickly will the coating harden?

It should be correctly understood that the terms specified by the manufacturer usually only indicate the possibility of people moving along the poured surface without the risk of deformation. But this is still far from complete maturation of the coating. It will gain final strength and readiness for full operation much later - the period can be from one to four weeks.

The fact that you can move on the floor after just a few hours does not mean it is ready. For information on the timing of full ripening, see the detailed instructions on the packaging.

Be sure to pay attention to another time indicator - the viability of the prepared solution. That is, the time during which it is necessary to distribute the mixture over the surface before it begins to set. If you plan to work alone, and even with insufficient experience, it is better to choose compositions with the highest possible indicator - 40÷60 minutes, otherwise you can simply ruin all the results.

Find out when it is necessary to repair cracks in a self-leveling floor and how to carry it out from our new article on our portal.

- Mixture consumption.

A parameter showing how much material is consumed on average to fill 1 m² with a layer thickness of 1 mm (or 10 mm - different manufacturers may have their own “standards”, but converting one to another is not difficult). On average, this figure varies from 0.8 to 2 kg/m² with a layer of 1 mm.

The maximum consumption is observed for self-leveling cement-based compounds. But this is “smoothed out” by lower cost. Knowing the “certificate” consumption rate and the parameters of the room (its area, difference in floor level, planned minimum thickness of the poured layer), you can calculate the amount of material that will need to be purchased for the work.

Our online calculator below will help you with your calculations. It provides the ability to calculate both by the known area of the room (the area for filling) and by size (for rectangular rooms). The calculation result is shown taking into account the 5% reserve.

Calculator for calculating the required amount of mixture for pouring a self-leveling floor

Go to calculations

Why is composition information needed?

Regardless of the basic or final purpose, the mixtures include a similar set of components, these are:

The binding components of foreign mixtures are polymers, due to which the characteristics are improved along with a parallel increase in prices.

The formulas of dry mixtures also include dyes that determine the color of the future floor or base background for applying stencils, hand painting, banner images, etc. To increase the bonds between the hardening components of the self-leveling floor, microfibers are included in a number of self-leveling mixtures. Their chaotic direction firmly connects the ingredients in all possible directions, eliminating the possibility of cracks.

The main component that influences the choice of a mixture suitable for arrangement is its base.

Owners who want to install a self-leveling floor with their own hands need to deal with this issue before purchasing the material:

To install heated floors, you will need a leveling mass with increased elasticity, capable of expanding and contracting without forming a network of cracks.

If you want to complete finishing at an extremely high pace, you need to pay attention to fast-hardening products. There are also universal dry materials suitable for rough and final leveling; you can buy a mixture labeled “extra strong” for laying coatings without first strengthening the base. Information about specific properties is available on the packaging.

Differences in constituent components

The mixtures are packaged in bags and can be cement or gypsum. Cement leveler is used in all types of premises, regardless of the degree of humidity, although it requires more time to harden. Perfect for screeds 20-50 mm.

Gypsum composition is intended for use in dry areas because the substance swells when it absorbs moisture. The drying speed is quite high.

Along with the varieties discussed, you can find mixtures with other types of components on sale:

- polyurethane, characterized by greater ductility, resistance to damage and cracking, and therefore used for finishing;

- cement-polyurethane - guarantee a more durable and wear-resistant structure;

- methyl methacrylate - harden quickly, very durable and moisture resistant;

- epoxy - allow you to create a durable and smooth surface, also useful for finishing with visual effects.

Options for installing self-leveling floors

The layout of the floor using self-leveling solutions depends on the planned thickness of the fill, on the degree of destruction and on the material from which the base is made:

A thin finishing layer of up to 0.5 mm is poured into a fresh screed, the surface of which complies with technical regulations.

Thin-layer liquid linoleum must adhere firmly to the base. To increase adhesion, the rough base is coated with primer. Often, to improve adhesion, the underlying cement floor is pre-treated with a coarse abrasive or scraper, and then coated with a primer.

The self-leveling floor, cut off from the base by a separating layer, is placed above the wooden base and above any type of screed with a layer of 1.0-2.0 cm.

To form a separating layer between the wooden floor and the fill, oiled paper is laid with an overlap. The boundary between the screed and the self-leveling floor is created by treating the surface with waterproofing impregnation. In this case, the poured layer does not adhere to the surface of the rough base.

Thanks to the separator, the eternal movements of wood will not cause damage to the floor, and the cement screed will not draw out moisture, creating unwanted cavities and sinks in the body of the fill. By the way, according to this principle, 3D floors with a volumetric effect are arranged, only the separator is a banner with a pattern, a sticker or an original image made with acrylic paint. Floating type self-leveling floors are installed in the case of subsequent installation of laminate, linoleum, parquet flooring blocks - i.e.

coatings that tend to change in a linear direction with temperature fluctuations and unstable humidity levels. The reason for the preference for a floating floor may also be a thickness of 2.5 cm or more, which does not allow the self-leveling floor to harden without defects. The separating layer is created from polyethylene, rolled waterproofing or parchment, laid in strips with an 8-10 cm overlap.

It is necessary to lay the divider with 10-15 cm allowances on the walls. The floating layer is cut off from the walls with a damper tape used to ensure floor movement and for sound insulation.

The separator and damping material, which rises above the floor plane, is cut off before installing the baseboard and the seam is covered with it.

These are only the basic schemes for constructing self-leveling floors, which, if necessary, require modification and modernization taking into account specific conditions. In reality, there are many more options, but the principles are general.

Features of the use of various screeds in practice

The advisability of using one or another type of screed or a combination of them depends on several factors.

An indicator for the use of cement-sand screed is the complex terrain of the floor, namely:

- large differences in height between floor slabs;

- significant unevenness, potholes;

- large angle of inclination of the plates.

These defects require the installation of a thick layer of screed, therefore, the advantage of using cement-sand mortars in this case is undeniable.

If it is necessary to achieve significant heat-saving characteristics of floors, for example, interfloor, perilite, expanded clay or polystyrene foam balls are added to the cement-sand screed. Heat-saving functions are not characteristic of self-leveling floors and heat-saving indicators cannot be achieved by adding any additives. Advice: It is believed that you can make a self-leveling floor yourself, without resorting to the services of specialists. The stages of surface preparation for all types of screed can be characterized as follows:

- cleaning floor slabs or existing rough fill;

- surface dust removal;

- treatment with primer compounds to ensure better adhesion.

Ready-made concrete floor screed

Rules for pouring self-leveling mortars

You can pour the sealed leveling mixture onto the floor in rooms with equipped window and door openings. There should be no drafts; you should forget about ventilation using natural and forced ventilation while the floor is hardening.

The solution, without external coercion, needs to lose moisture during the ripening process. The temperature during this period should be stable without readings below 5º C and without rises above 20º C. Priority humidity is 60%.

We will assume that the leveling and climb to the planned altitude have already been completed, i.e. We have already created the base layer or we use an existing tiled, cement or plank floor as it. Next, we find out how to make self-leveling floors with our own hands and say the magic word “so.”

Preparing the surface for the upcoming treatment:

We repair a concrete or cement subfloor, widen the cracks to the width of a centimeter and fill them with a repair compound, cement-sand or a mixture intended for future filling. We cut off noticeable raised bulges with a puncher and remove unreliable segments. The cavities and small depressions remaining after removal are filled with mortar and leveled flush with the plane of the rough base.

We check the floor tiles for strength of fixation.

We treat unreliable elements like concrete hills. We fill seams and recesses with mortar. Wooden floors are repaired according to the rules for their restoration. We replace questionable elements, renew fasteners, foam the cracks, fill them with wood glue with sawdust or sealant.

We remove oil paint, grease stains, and residual detergents using solvents, then carefully remove dust and dirt from the floor with a damp cloth and a vacuum cleaner.

Depending on the chosen scheme for pouring the leveling mixture, we prime or cover the insulation layer. We place a damper tape around the perimeter if a floating floor is to be constructed.

Preparing and pouring leveler

Preparing and pouring leveler

Regardless of the type, all levelers are mixed in the same way: dry components are poured into a container with water and quickly mixed with a powerful drill with an attachment or a construction mixer. When the mass acquires a homogeneous structure, it is left alone for 2-3 minutes, then mixed again. After this, the mixture must be applied over a certain period of time until polymerization begins. Each leveler has its own hardening time, and it must be indicated in the instructions on the package.

Conditions for preparing the mixture

- When mixing and pouring the solution, the temperature in the room should be from +10 C to +25 C.

- The water temperature is not lower than +10 C.

- Air humidity is not higher than 80%.

- Windows and doors must be closed in the room to prevent drafts.

- Do not turn on the heating radiators until the floor is dry.

If the room is large, the solution is mixed in portions and poured into narrow parallel strips. The interval between filling adjacent areas should not exceed 10 minutes. Since it is very difficult to manage all the processes on your own during this time, you will need an assistant.

Filling process step by step

The solution must be mixed strictly following the instructions of the material manufacturer. Violations of proportions and deviations from instructions, entailing a deterioration in technological qualities and operational characteristics, are not allowed.

Important. Polymerization of the mixture for manual pouring occurs after 35-40 minutes. after cooking. Accurate data on the life of the solution must be indicated on the packaging.

Due to the short period of time when the solution is suitable for pouring, attempts to install a self-leveling floor without an assistant must be nipped in the bud. It is better to enlist two pairs of friendly hands and initially distribute responsibilities. One prepares the mass, the second pours it, the third distributes it with a spatula or a long-handled iron.

All that remains is to list the actions, following the sequence:

We install a limiter in the doorway - a rail, a piece of drywall or profile. We will do the same if it is not possible to fill in one step in a room that is too large or if you plan to install combined floors. We fill the mass prepared according to all the rules in strips no more than 50 cm wide.

The first lane runs along the wall opposite the entrance.

Avoiding any breaks, fill in the second strip, at the same time evenly distributing the solution with a spatula or iron. And we continue like this until the end of the work.

We treat the filled layer with an aeration roller, due to which the self-leveling floor will be free of air bubbles. During processing, we move along the surface in paint shoes - shoes with support spikes on the sole.

We cover the filling with polyethylene and wait the time required according to the instructions for the self-leveling mass to mature.

If the surface needs to be given anti-slip properties, the poured floor is sprinkled with washed sand or not too zealous, expelling air from the mixture with an aeration roller. The “craters” left from the bursting bubbles will interfere with sliding.

It’s not difficult to understand the technology of applying self-leveling flooring, and it’s also easy to do it with skill. You just need to find out all the important points in advance, take into account the technological specifics and plan your actions correctly. Knowing the nuances of pouring will not harm those who decide to entrust it to workers.

Well, now it's time to finish the article. All the material I wanted to share has been reviewed. I hope it will be useful to you, and you will use it if you need to lay a self-leveling concrete floor with your own hands. Improve your own practical skills and gain new knowledge, as they say: “It’s never too late to learn!” That's all, thank you for your attention, successful and easy repair!

What and in what case to choose

The comparison of operational characteristics allows us to make several recommendations.

- A screed made from self-leveling mixtures is effective in leveling differences in height at the base of the floor up to 2 mm. In other cases, other technologies are needed.

- For tiles and porcelain stoneware, a “wet” screed is optimal. Semi-dry and dry are used depending on the situation, but self-leveling flooring is completely excluded - a mirror surface is not the best material with which the glue has good adhesion.

- Dry screed is not suitable for linoleum, carpet and PVC tiles. It is also undesirable to use this technology on an open balcony, in a bathroom, shower and, with some reservation, in the kitchen.

- The self-leveling floor solves the problem of wear of the balcony slab - it creates small loads when pouring.

- A dry screed will help raise the floor by 10-50 cm. Other methods will either ruin or collapse the ceiling.

- The ideal solution for thin and flexible floor coverings (carpet, linoleum, PVC tiles) is a self-leveling floor with a mirror surface.

- In a panel house, self-leveling flooring can be poured onto a ready-made screed.

- If the angle of inclination of the floor base is large, a combined method must be used.

Instructions for creating a decorative coating

This task in itself is simpler, since a self-leveling floor made from polymer mixtures can only be poured onto an already leveled base. Otherwise, you will have to make a thick layer, which will lead to unreasonably high costs. In other words, a decorative self-leveling coating is created after all the steps described above have been completed.

If you need a single-color colored floor, then the selected and tinted mixture is simply poured over the primed surface and rolled with a needle roller. Since it is laid in a thin layer and has good fluidity, you can do without beacons. To ensure that the solution penetrates into corners and hard-to-reach places, immediately after pouring it, you can use a spatula or squeegee to initially distribute the mixture.

The plastic mixture itself spreads over the surface Source viprusstroy.ru