The socket for the hob and oven must meet all safety requirements and must be installed following all installation rules. Such household appliances are now in great demand in any kitchen; you will learn how to connect them to the mains later in this article.

You need to take the choice of electrical installation devices and wiring seriously, because now any equipment “eats” a lot of electricity and the issue of saving should be one of the first places. To do this, you need to select separate lines with a special design for sockets.

Next, we’ll find out how to connect the socket for the oven and hob with your own hands.

Origins of the problem

Often in the kitchen of an apartment or private house there is only one electrical outlet at the equipment connection point. This is how the living space was designed, especially for old houses.

At the same time, we are faced with the task of ensuring the connection of two independent loads simultaneously, each of which has its own electrical input.

This situation becomes critical when the electrical equipment:

- has high power, which does not allow solving the problem through a multi-socket extension cord or tee;

- due to its purpose, it was not initially designed for frequent connections and disconnections.

An additional complicating factor is that the electrical appliances located at a given load point, in our case the oven and hob, must function simultaneously, and the problem cannot be solved by alternatively connecting one of the devices to another point.

How to connect a built-in oven to the mains

Now that the cabinet is in the right place, it needs to be connected correctly. If the house was built a long time ago and it uses aluminum wiring, you will need to lay a three-core copper wire from the panel to the device socket.

- There are several ways to connect the oven to the mains:

- Via a power cord connected to the oven outlet. You can start it:

- to an outlet of the required power (the cord must have a suitable plug);

- to a machine installed nearby in a separate plastic box (cord without plug);

- to a terminal block mounted on the wall near the equipment (machine on the panel).

- Connection without a cord, directly to the line that comes from the electrical panel (the machine is installed on the panel).

Here you need to do everything correctly and without errors, since this is an extremely important process. With a device power of 3.0-3.5 kilowatts, the current consumption will be 16 amperes. A separate 25 ampere circuit breaker is set in the panel for just turning on the device. Next, a VVG - 3x2.5 wire is pulled from it in the cable channel to the socket.

Devices with a power of more than 3.5 kilowatts are also produced - what to do with them? We carry out the same process, only the machine should be set to 40 amperes, since the current consumption will be approximately 32 amperes. You also need to choose a slightly different wire - VVG - 3x4.0 will do.

All that remains is to connect the built-in oven to the power supply.

When installing an electric oven, things are a little easier - there are no gas hoses, and there is practically nothing to be afraid of. But this does not mean that you can relax and not follow electrical safety rules.

Here everything is just the opposite, and an incorrectly connected electric oven can cause a lot of problems for the owners, the most serious of which is a short circuit and, as a result, a fire. Be sure to do everything right - in particular, follow a few simple rules.

An electric oven is a powerful consumer of energy, and it must be connected with a separate branch of wire with a cross-section of at least 2.5 square meters. Naturally, the wire must be solid and not have any twists, even well-soldered ones.

The branch that provides power supply to the electric oven must be equipped with a separate circuit breaker - its power must be calculated based on the current consumption of the oven you purchased.

As a rule, this is 16-20 amperes - if an electric hob is also connected in conjunction with the oven, then the machine is selected based on the total power consumption.

Grounding is a must. The safe operation of an electric oven depends on grounding. In private houses there are no problems with this, but sometimes in apartments there are problems - as a rule, in old buildings there is simply no grounding.

You will have to do it yourself by extending an additional wire strand to the common panel in the entrance and connecting it to any metal element.

In all other respects, installing and connecting an electric oven is no different from installing a gas oven. The only additional thing you need to do here is to equip the oven wire with a plug - everything is very simple here.

The cable has three wires, one of which is the ground wire - usually a yellow or green wire. They must be connected to the ground terminal.

The remaining two wires are screwed to the other two terminals of the plug - which one and where it doesn’t matter. The contacts must be crimped tightly so that they do not heat up and the insulation of the wires does not melt - this, again, can lead to a short circuit.

You will need a three-terminal (“phase”, “zero”, “ground”) “Euro-socket”, that is, you need to take care of purchasing it in advance. It must be connected to the wire laid to the kitchen.

Some apartments use a two-wire wiring diagram in which there is no ground, and this becomes a definite problem. However, as you know, there is no way out only from the grave, and in our case, the solution would be to call an electrician. He will have to supply ground from the main access power supply panel.

Today, ovens are produced in a variety of configurations, parameters, and characteristics. Some products have a 3-pin connector on the back that allows you to connect a 3-wire cable.

Others are deprived of this benefit - on them you can only find a terminal block with screws. With such cabinets you will have to tinker a little extra - you need to tighten the cable with screws and connect a Euro plug on the other side.

And the final stage of installing any oven is checking its performance and the first idle start. We simply turn on the oven according to the instructions, first check the indication, then the heating, and when we are sure that all the heating elements or burners are working, we start it at full power.

Set the temperature on the thermometer to 150 degrees and burn off the factory grease inside the oven. Perhaps, or rather certainly, smoke will pour out of it. There is no need to be scared, this is why the concept of the first start exists - after the smoke stops coming out, the oven can be fully used.

Justification for separate connection

The PUE states that to power household loads whose power exceeds 3.5 kW, a dedicated cable with a separate circuit breaker must be used. This means that for power supply a radial circuit must be implemented.

In our case, the hob often has a power that is higher than one kilowatt. Despite the fact that the oven is a less powerful device, there are models that consume one and a half kilowatts or more.

Therefore, these two devices can be considered as a single whole not only from the point of view of functional purpose: cooking, but also load.

Preliminary remarks

When connecting the oven and hob, a number of requirements must be met regarding wiring and circuit breaker:

These include:

- the wire is known to be in good condition;

- withstands prolonged maximum load;

- contains the required number of working conductors, neutral and grounding;

- complies with all safety standards.

When choosing a machine, it makes sense to be guided by the values of 25 A with a total load power of up to 5 kW and 32 A with a higher power (see table below).

Table. Limit parameters of 220-volt single-phase wiring for cables with a core cross-section of 4 mm2.

| Exposed wiring or box | Closed wiring (in a groove) | |||

| Core material | Copper | Aluminum | Copper | Aluminum |

| Current, A | 41 | 32 | 27 | 21 |

| Power. kW | 9 | 7 | 5,9 | 4,6 |

Cable selection

To connect the oven, a three-core cable of the required cross-section . It is necessary to choose a copper cable with single or multi-core wires. Aluminum is installed only with a current strength of 50A or more, for reasons of economy - such loads will require very thick conductors, and aluminum is cheaper than copper.

VVGng-cable-3x2.5

VVGng-cable-3x4

VVGng-cable-3x6

Most often, flat power cable VVGng-LS 3x2.5 is chosen. External width - 10.3 mm. It has three single-core copper wires with a cross-section of 2.5 mm2. Color marking of cores eliminates erroneous connection. Usually the wires are blue, brown and yellow-green (phase, neutral and ground, respectively).

Other core color options are possible. The order of connection is not of fundamental importance, since all wires are exactly the same.

The main requirement is not to mix up the wires and not allow, say, a phase wire to end up on the grounding terminal.

Selection of household appliances based on the possibility of existing wiring

Let's go a little deeper into the topic so that everything is clear.

If you are just planning to buy an oven and hob, then it is important to understand whether the existing wiring will withstand the total power of both devices, and not a short-term, but a long-term load.

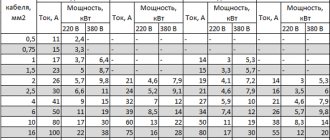

To do this, you need to find out what cross-section of wires the wires have and based on this, make calculations or use ready-made tables.

To measure the cross-section of the wire, use a caliper. An ordinary ruler will not work, as the measurements will have a large error.

Do the following:

- Disconnect the cable.

- Strip the insulation of one core to at least 1 cm.

- Take measurements using a compass.

Next, use the formula from the school course: S=π×d²÷4.

Where:

- S is the required cross-sectional area.

- D – measured diameter.

- Π = 3.14.

For example, measurements showed a core diameter of 2.4 mm. We carry out the calculation: 3.14x2.42÷4=4.52mm2. The recommended value is from 4 to 6 square millimeters.

In new houses built after 2001, the conductors are usually copper, in old ones they are mainly aluminum.

Further, using the table below, you can find out how much power this cable can withstand.

Self-installation

To connect an automatic protective switch in the electrical panel, first install the upper part of the switch on the DIN rail . Use a screwdriver to pull out the eyelet and press the lower part. The lower grip is released and snapped into place.

Then the contacts are connected. If stranded conductors, crimped with lugs, were previously connected, they are inserted back into the upper and lower clamps and the screws are tightened. If the core was without a tip, it is better to remove and clean the old end, then use a screwdriver to make a fresh, undeformed conductor.

After connecting the wires, voltage is applied to the machine and its operation is checked. If everything is in order, connect electrical appliances and make sure that no sparks, crackling, heating or other undesirable effects appear at the switch contacts. Heating is checked with a pyrometer.

It is important to choose the correct ratings of the circuit breakers, the diameter of the copper conductors, and install the breaking phases and not the neutral wire. The machines are installed in the operating position by sliding the switch buttons up.

This is interesting:

Connecting the hob and oven to the same outlet and is it possible to do this?

Connecting the plug to the hob

About the demand coefficient

The demand coefficient is calculated using the formula Ks = Рр/Рн, where:

- Рр – design power.

- Рн is the total power of electrical consumers, in our case the oven and hob.

In simple words, if the demand coefficient is 1, this means that it is possible to simultaneously use all electrical appliances on one network at maximum capacity. But in practice this rarely happens.

For example, 0.7 indicates that electrical appliances are used separately or simultaneously, but not at maximum loads, provided that they are connected to one point.

Below is a table for calculating the power consumption of an apartment taking into account the demand coefficient.

What do we mean by this? And the fact is that if with a wire with a cross-section of 4 mm2 and a load it can withstand of 5.9 kW, you can purchase electrical appliances that in total consume more power.

For example, you liked certain oven and hob models that consume a total of 8 kW at maximum load. But you do not plan to use these electrical appliances in this mode.

We multiply 8 kW by the demand factor of 0.7 (you can take less, but this figure is the most optimal), we get 5.6 kW, which suits you quite well.

Connection options

You can connect electrical appliances to the network using detachable and permanent methods.

Options for connecting the panel and cabinet to the electrical network

A detachable connection is based on the use of a plug and socket, which are pre-mounted on the cable: the connected equipment and wiring, respectively. It's convenient and practical.

Permanent connections are made through the terminal block. The advantages of this connection method are a strong and reliable connection of contact pairs and lower cost.

Connection via socket

In practice, the following main versions of sockets are used, which are shown schematically in the figure below:

- assembly of two single sockets with a separate cable for each of them;

- assembly of two single sockets with a common cable;

- monoblock socket with two seats for plugs.

Options for the end section of wiring for connecting the hob and cabinet, from top to bottom:

- with individual cable and circuit breaker for each socket;

- with the installation of a monoblock double socket and a common circuit breaker;

- using a daisy chain connection of two sockets and a common circuit breaker.

Taking into account the high power of electricity consumed, monoblock sockets with three or more seats are not used in this connection method.

The type of socket used is significantly limited if the panel and/or oven cable is reinforced with a plug. You cannot change it for another one, since in this case, at a minimum, the factory warranty will expire.

When connecting, it is advisable to use socket modules with different form factors, which are also available in a double monoblock version.

Dual power socket with different form factors and the option of lateral cable supply to it in a brick wall groove

Common mistakes

Common problem: the panel is connected, but turns on and off spontaneously. The cause of this behavior is not necessarily due to incorrect installation.

The problem is caused by a variety of factors: child lock is turned on, water gets on the touch parts of the equipment, or accidentally pressing the wrong buttons. Some models are equipped with a cookware recognition function, and until there is a pot or pan on the panel, the stove will not heat up.

Another common problem: only two of the four available burners are functioning. Burners that are not working show residual heat (indicated by the letter H). The situation is caused by blocking that occurs when three-phase models are connected single-phase. The blocking is done programmatically.

Therefore, before tampering with the connection terminal block, it is recommended to study the documentation for the equipment in advance.

Connection via terminal block

This connection is made in two cases:

- if the connecting cable of the hob or oven does not have a plug;

- if a terminal block is installed on the device itself as an element of connection to the network.

Figure 4 shows both of these cases in schematic form.

Options for connecting the cable to the panel and oven

In the latter case, to connect, connect two terminal blocks with a cable: the device itself and the linear one, and the cable itself is not included in the delivery package of the device and must be purchased separately.

This option is labor-intensive to implement, but does not limit the distance between the cabinet/hob and the power cable exit point, and also allows you to very accurately select the length of the connection cable and avoid the formation of loops.

Most often, the functions of a linear terminal block are performed by a so-called barrier block.

One of the barrier block options

This type of terminal block got its name due to the presence of a protrusion-barrier separating the fastening components of the input and output sides of the device.

The block can be installed openly on the wall or mounted inside a cutting box, for which it is provided with appropriate mounting holes for screws or screws.

Installation operation

Under the hob lies the concept of an ordinary electric stove. Despite the small area of the stove, it must be installed in the kitchen furniture using all the safety measures provided. To ensure that nothing interferes with the production process, it is better to prepare the necessary tools in advance in the form of:

- electric drills

- jigsaw

- screwdrivers

- knife

- ruler, square, pencil

- sheet of cardboard

To cut out a space for the stove, you need to make a template on cardboard and transfer the parameter data there - the width and length of the stove body. You can measure them yourself or take them from the product data sheet.

On the countertop of the cabinet where the stove will stand, cut out the desired hole configuration along the lines of the template. Sometimes kitchen units include special floor cabinets into which a standard oven and stove can be inserted.

The next step is to create a kind of niche where the panel will be installed

Along the marked rectangle, starting from the corners, carefully so that unnecessary chips do not form, make holes with a drill, finish the work by cutting out with fine teeth with a jigsaw

The result is a window, the cooking panel is lowered there, the joints must be treated with special substances. You can choose a sealant or the seal needs to be silicone. To conveniently fit the equipment into the place created for it, it can be adjusted - expanded or narrowed with a tool. The kit should include clamps for more secure fastening of the panel to the tabletop. Finally, excess processing material must be removed.

Features of connecting the panel and cabinet to the barrier block

There are two things to consider during the connection process.

The first of them is that the connection of the panel and cabinet to the linear terminal block, regardless of the design of the connection block of the device itself, is always performed according to a star circuit, which is shown in schematic form on the left side of the figure.

Connection diagram of line terminal block, hob and cabinet

The use of a loop circuit on the right side of the figure is not recommended due to the fact that the fixing elements of the hob terminal block are not initially designed to connect two wires to it.

The second feature is that, given the large currents flowing through the socket, it is necessary to ensure low contact resistance in the area where the panel/oven cables connect to the terminal block.

To achieve this effect do:

- reinforcement of individual cable wires with lugs (an example of such a component is shown in the figure below);

- the use of a special crimping tool for their installation.

Fork-type tubular cable crimp lug

The correct connection is additionally checked by the color of the insulation of the individual cable cores, their purpose is additionally controlled by the accompanying documentation of the device.

Connection diagram to the machine.

Connecting a Gorenje electric hob

Before starting work, be sure to study the technical characteristics of the selected model with the connection diagram.

Make sure there are jumpers.

Install jumpers between pins 1 - 2, 4 - 5.

Unscrew the cable clamp, pry it with a screwdriver and remove it.

We connect the wires according to the diagram.

We fix the cable with a clamp.

Next, pump up the hob using the methods described above.