Wooden houses are considered thermally efficient, since wood conducts heat poorly. However, in practice, everything turns out the other way around. The material dries out and cracks, causing the cold to penetrate inside faster.

Floors are made mainly using frame technology, so layers of insulation must be laid inside them. The thickness of the floor insulation in a wooden house depends entirely on the selected heat insulator.

Laying mineral wool - not the best quality work

General information

The thickness of the material is selected depending on the climate of the region. One indicator is provided for the northern republics, and another for the southern republics.

Firstly, the thicker the insulation, the better the heat is retained, and the less energy is spent on heating. Secondly, insulation also saves you from heat. Thirdly, insulation is a good sound insulator.

The thickness varies depending on the type of floor and its location. The floor of the first floor is the coldest, especially if the house is on stilts and is ventilated from below. But it can be earthen if the foundation is strip, and concrete if it is slab.

The floors between floors are heated on both sides. Insulation is used only as sound insulation.

The attic floor is also a floor. It must be insulated, especially if the attic is unheated. Otherwise, the heat will go outside, and in addition condensation will appear on the ceiling.

Insulation thickness under a heated floor system

Each material has its own thermal conductivity coefficient. This parameter is of primary importance when determining the thickness of insulation.

Thermal conductivity of insulation of different densities

The effectiveness of insulation also depends on the density. The higher it is, the more difficult it is for the insulator to retain heat.

Comparison of thermal conductivity of materials

12 cm of polystyrene (density, however, not indicated) will retain heat as effectively as 210 cm of solid red brick.

Overview of polymer materials

It is important to study specific insulation materials and compare them with each other.

Polystyrene foam thickness

This material is usually called polystyrene foam, but this is not entirely true, since foam plastics are a huge group of polymer foam materials.

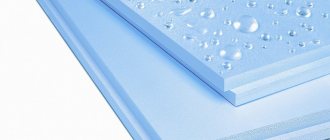

Expanded polystyrene boards are one of the most effective insulation materials

Kinds:

- Pressless, suspension - marked as PSB. The most inexpensive of the others. The price per square meter with a thickness of 20 mm is only 40 rubles. The structure consists of large granules glued together. When broken, it begins to crumble. Such expanded polystyrene is not dense, you can’t make a screed on it, it is flammable and can easily be turned into dust by rodents. It can be used as insulation for the floor of a wooden house, but low quality will not give the desired result.

- Pressed polystyrene foam (PS) has closed cells. During production, some brands of latex PVC and blowing agents are added. It retains heat perfectly, has a stronger and denser structure, and is not afraid of mold. But it is not used primarily for insulating floors, but the next type.

- Extruded polystyrene foam (EPS) - is obtained by squeezing the molten mass through holes of a certain shape. It has a dense structure, all cells are closed, which means the material does not absorb water and tolerates mechanical loads - it can be used for plastering and concrete screeding.

Each type of polystyrene foam has a different density and thermal conductivity, but in general, as insulators, they are all effective.

The material can be purchased in different thicknesses - from 5 to 100 mm. If you need to install 10 cm of material for insulation, take not a slab of comparable thickness, but two layers of 5 cm each, and install them overlapping. This approach eliminates cold bridges formed at the seams.

Expanded polystyrene boards 10 cm thick

Individual slabs have profiled edges for easy joining. Heat loss is also reduced.

Advice! When installing expanded polystyrene boards, it is additionally recommended to coat the seams with polyurethane foam. By the way, this material also belongs to foam plastics.

The thermal conductivity coefficient of pressless polystyrene foam is 0.05 W/mC. The extrusion indicator is lower - 0.04 at a density of 40 kg/m3, despite the higher density.

Harm to human health from polystyrene foam

It is difficult to give a definite answer to this question. There is a strong belief among the general public that polystyrene foam is capable of releasing a considerable range of substances that are potentially hazardous to human health. At the same time, the history of the use of polystyrene foam dates back to the middle of the 20th century, and during this time scientists were unable to identify at least one disease that would be directly related to the use of this material for insulation. Moreover, it is successfully used not only in the construction industry, but also in food production.

It is known for certain that polystyrene foam can emit a carcinogen called styrene that is dangerous to humans. The process occurs only when exposed to direct sunlight or high temperatures. But standard operating conditions of the material do not imply the influence of these factors, since some kind of coating is applied on top of the foam. Under such conditions, the concentration of styrene in the atmosphere does not exceed standard values, which means it is completely safe.

To be completely sure of absolute safety, you should pay attention to the styrene content in the selected type of expanded polystyrene. The highest quality materials from foreign brands contain no more than 0.05% of this substance. In types of foam that are not of high quality, this figure can be up to 0.2%.

Insulation class mineral wool

It is profitable and safe to insulate wooden houses with mineral wool.

Mineral wool is more often used for wooden houses

If we compare mineral wool with expanded polystyrene, with a comparable density, the thermal conductivity coefficient of the former will be on average 50% higher.

Where 5 cm of polystyrene foam is enough, 7.5 cm of mineral wool can replace it. There are several varieties of mineral wool with different characteristics. Products from different manufacturers vary significantly in quality.

Comparison of the characteristics of mineral wool from well-known Russian manufacturers

Types of mineral wool:

- Glass wool is the most affordable, containing harmful formaldehydes. It generates a lot of dust, so it is practically not used for residential premises.

- Slag wool is also a material harmful to health due to phenol-formaldehydes. There are composite models that contain up to 20% wool. Slag wool retains heat more effectively. It can be used for the floor of an unheated attic.

- There are several types of stone wool. They have the same disadvantages as the previous types, but to a lesser extent. Basalt wool does not burn even when heated to +1000 degrees.

Foil-coated basalt wool

Such insulation costs on average from 100 to 160 rubles per square meter with a thickness of 5 cm.

Mineral wools are vapor permeable, which is considered a great advantage and disadvantage. When wet from steam, they lose thermal efficiency; glass wool suffers more than others.

Therefore, they must be protected with vapor barrier films.

This need not be done in interfloor ceilings when all rooms are heated. The steam simply passes through, the moisture evaporates, and the insulation dries out.

Wool with a density of more than 150 kg/m3 is used as a base for screed, although it is better to use extruded polystyrene foam.

To insulate frame floors, you can use wool with the lowest density, which will make insulation more effective.

The frame floor and walls are insulated in four layers

If we average the layer thickness for structures facing the street, the average thickness of mineral wool is taken to be 15 cm.

The floors are also insulated in layers. For mineral wool, a rigid base is required, since low-density material cannot support its own weight without sagging.

Slab size

Foam boards are produced mainly in three sizes: 0.5 * 1, 1 * 1 and 2 * 1 m. It is immediately worth noting that this insulation is easy to cut, so no problems should arise during the installation process. So, it is better to choose the material that is most suitable for the area of the insulated surface. As a rule, for insulating balconies, loggias and apartments in apartment buildings, the choice is made on slabs measuring 0.5 * 1 m : they are most convenient to work with, they are more economical, and it will be easier to insulate all kinds of complex facade details with such material. But if you need to insulate a private house, the walls of which have a regular flat surface, then it makes sense to use slabs measuring 1 * 1 m. The largest material, slabs measuring 2 * 1 m are used least often for particularly large buildings.

Foiled insulation

There are many manufacturers producing insulation materials. Someone is developing unique technologies that make products more energy efficient. Therefore, relying on average indicators is not always productive.

It is worth noting products supplemented with a layer of aluminum foil on one side. Aluminum reflects heat. Its thin layer allows you to increase the efficiency of the entire “pie” and reduce its thickness.

The foil layer is always located on top.

Foil penoizol

Some polymer insulators and mineral wools also have this addition.

Foiled mineral wool

The use of a foil layer is especially effective when installing heated floors. The reflection of energy will not allow the street or ground to warm up.

Also, structural materials can be supplemented with substrates and slabs made of rigid materials to simplify installation.

Thanks to the textile backing, it was possible to secure low-density mineral wool under the ceiling

Substrates increase the resistance of materials to loads. It is profitable to buy them if the insulation is from below, from the basement or lower floor.

Dense insulation materials, such as extruded polystyrene foam, can serve as a foundation in a wooden house (example in the photo).

The subfloor is assembled from insulation

The combination of mineral wool and expanded polystyrene reduces the overall thickness of the ceiling, making it maximally protected.

Other materials for insulation

Internet users often ask what the expanded clay layer should be for floor insulation. This indicates a lack of understanding of the purpose of some materials.

The use of expanded clay for insulation

Expanded clay

Over time, this bulk material will shrink and its thickness will decrease.

The thermal conductivity coefficient at a minimum density of 200 kg/m3 is 0.1 W/mC, which according to GOST is sufficient for insulating the external structures of a single-family residential building.

But this is 30% worse than mineral wool.

Expanded clay significantly loads frame floors. It can only be used in a wooden house on floors built on the ground, as a base for a screed.

Ecowool

Another material that belongs to the controversial category is ecowool.

Laying ecowool on a wooden floor

This material is free-flowing and is made by recycling waste paper.

The thermal efficiency coefficient is only slightly inferior to penoizol, but only when using wet spraying.

It does not burn, does not rot, does not attract rodents and is inexpensive. The average price per kilogram is 60 rubles.

If you simply pour ecowool on it, it will not retain heat as effectively. If it is sprayed, the moisture contained in the material will evaporate within 1-2 months, which will lead to rotting of wooden structures.

Our country has not yet developed a unified standard for this material. As a result, manufacturers sell whatever they want. There is no need to talk about any security. And the final cost is high.

For high-quality insulation of a wooden house, you can use natural insulation materials, which are made from flax, coconut, wool, and various trees. They are very effective, environmentally friendly, but expensive.

We recommend reading: insulating the floor of a frame house on stilts.

Penoplex screed: technology

Let's consider the simplest case - Penoplex for a floor under a screed on a concrete base. This can be concrete preparation in a floor structure on the ground, or a concrete floor in a high-rise building or private house. The procedure is as follows:

Local irregularities larger than 5 mm are leveled. The manufacturer does not specify the alignment principle. That is, it can be a leveling screed (if there are too many irregularities) or local filling of potholes and cracks with a solution. In the second option, it is necessary to trim/cut/knock down the strongly protruding fragments. Sometimes they even level it with sand. This method is also not excluded.

Standard scheme for using Penoplex under screed

You can level the base with sand, but do you really have a lot of unevenness

? Actually, the whole technology. All clear. Only questions may arise regarding the minimum thickness of the Penoplex screed. The manufacturer recommends at least 40 mm. When laying floors in wet rooms, it is advisable to cover the slab with waterproofing. Choose the type of waterproofing material yourself. The rest of the technology is the same.

Calculation of floor insulation thickness

The norms for climatic conditions are as follows.

Standardized resistance by country's republics

3 values are indicated for each region. The second is for floors.

The temperature resistance of the material is calculated as follows: R=h/λ, where h is the thickness of the material, and λ is the temperature coefficient. Accordingly, by rearranging the values, you can derive the thickness formula: h=R*λ.

But the floor does not consist only of insulation. To reach this value, it is necessary to calculate the heat loss resistance of all installed materials, subtract it from the standardized value, and leave the rest for the insulation.

The floor of a wooden house in several layers

The simplest example. The bottom of the floor is lined with 25 mm thick boards. Top – 30 mm. Total 55 mm layer of wood. Specify the type of wood, find its heat loss coefficient, and calculate the value of Rder. Then 3.13-Rder, and you get R for insulation.

We recommend reading: insulating a frame house from the outside.

What you need to know

Foam plastic tolerates moisture well.

Before starting work on arranging thermal insulation for a house, it is necessary to think through some points so that you do not have to correct mistakes later. First we define:

- what material to use;

- size of the thermal insulation layer;

- insulation method: internal or external.

There are many materials for these purposes, but one of them is polystyrene foam. This building material copes with all the tasks quite well. It can be used for both external and internal work.

Most often it is used for external insulation of home walls.