According to the sad statistics of injuries when working with power tools, the grinder ranks first among the causes of major and moderate injuries. The design and power of the cutting tool are to blame, namely a violation of the operating rules. Instructions with traditional rules on how to properly work with an angle grinder are included with each copy, but there are specific features and advice from professional craftsmen on combining effective working techniques with maximum protection.

Recommendations for the safest methods of working with an angle grinder

First of all, experienced specialists, in whose work there is a constant need to cut metal, ceramics, stone and other materials, never neglect personal protective equipment. The kit for proper work with an angle grinder should include:

- goggles or mask; respiratory protection (petal or piglet masks); overalls; thick gloves and closed shoes.

Inappropriate bragging or neglect of protective equipment can result in injuries to limbs, eyes, and head, especially when removing the protective casing, which is strictly prohibited! Lack of understanding of how to use an angle grinder and failure to comply with basic operating safety rules will certainly be “punished by an accident.”

To ensure that the work is truly safe, the circles are checked for integrity before turning on the tool. Deformed cutting wheels with cracks and chips almost always fly apart. In this case, various nozzles should be used only in the speed mode recommended by the manufacturer and marked on the nozzle itself.

Treatment of eye burns

Further therapeutic strategy is determined by the nature of the lesion and complications that have developed. In different situations, antibiotics and anti-inflammatory drugs, antioxidants and vitamin therapy, regeneration stimulants, detoxification measures, and analgesics may be prescribed. In more severe cases, surgical removal of necrotic tissue, partial or complete transplantation of the cornea and/or conjunctiva, plastic surgery in the presence of a disfiguring eyelid defect, etc. are necessary.

Methods and techniques on how to work with an angle grinder correctly

1. The work area should be completely clear of foreign objects that may interfere with your free movement and cause clumsy movement.2. The grinder must be held firmly with both hands due to the risk of jerking when starting and during operation.

Do not let go of it until the rotation of the wheel or sanding brush has completely stopped.3. The question of how to cut correctly with a grinder is one of the most discussed in professional recommendations, but at the same time, many people forget, due to the inconvenience when carrying out work in confined spaces, that according to safety rules, cutting can only be done when the disk moves in the direction away from you. Position The workpiece to be sawn needs to be cut transversely with maximum prevention of the disk jamming during the cutting process. If you work with the disk positioned tangentially or bending, there is a risk of clamping, which is accompanied by a sharp kickback of the tool and breaking of the cutting wheel. In such cases, the grinder is often torn out of your hands, which completely eliminates control over the tool. Before using the tool for the first time (turning it on), in order to understand how to hold the grinder correctly, you need to manipulate it in front of you to ensure that the cutting trajectories are likely to pass outside your body. Cases of the tool “moving” to the side, forward, or backward must be considered. A sheaf of sparks serves as a sure guide for determining how to properly saw with a grinder.

Sparks should not be directed upward or towards the master. Do not forget that sparks and a directed dust flow are small particles of material that, due to the high ejection speed, can easily damage not only leather, but also other easily destroyed materials. A large cutting depth increases the likelihood of the cutting disc jamming due to misalignment, therefore massive parts use wider discs.4. It is unacceptable to use replaceable wheels and attachments for purposes other than their intended purpose: The cutting wheel is used only for cutting off parts, and not for grinding surfaces, because

pressure on it at an angle or on its side surface deforms the wheel with an increased likelihood of destruction. The grinding wheel is not suitable for cutting parts due to its large width. Depending on the model of the grinding wheel, it is unacceptable to carry out grinding on non-working surfaces that do not have a grainy structure, like emery. Additional attachments must have operational features on how to properly use the grinder when installing them. Before using the attachment, it is always recommended to clarify its working surfaces and the direction of movement of the tool. Due to the large structural and raw material differences, cutting and grinding wheels have different, non-interchangeable purposes. The use of additional accessories and attachments that modernize the purpose of the tool on an angle grinder is not recommended for novice operators. is a simplified name that has long become popular for an angle grinder. It is used everywhere: in construction, in agriculture, and in private household work.

Designed for grinding and cleaning surfaces of various kinds, for cutting metals of any thickness, stones and other materials. This power tool received its unofficial name thanks to its country of origin - Bulgaria. The working element of the grinder is a special disk, the configuration of which is selected depending on the material being processed. The disk attachment moving at a huge speed of rotation, at the slightest careless movement of the master, can lead to at least wounds or cuts, and in more serious cases - to severe injuries. Non-observance of safety precautions makes the angle grinder an extremely dangerous tool, therefore the rules defined for working with it must always strictly followed.

Rules for cutting tiles and porcelain stoneware

We asked a specialist how to properly cut tiles and porcelain stoneware with a grinder. There are two options.

- Using an abrasive wheel for stone (usually these wheels are marked accordingly), and the abrasive is silicon carbide grains, which have a less aggressive shape than electrocorundum, which is used for cutting ferrous metals. The powder of this abrasive is mixed with a binder bakelite resin and a circle is formed from this mixture using one or several layers of fiberglass mesh, which plays a reinforcing role.

- Diamond wheels, where the cutting elements are grains of industrial diamond, and the binder is cobalt.

Sergey Nemkov, director of the marketing and advertising department,:

If everything is clear with the first option and there are no special options, unless someone wants to take a grinding wheel (unlikely, but there will be no danger) and cut with it, then diamond wheels can be smooth (the so-called crown), segmented (there is a cutouts, which accelerate the removal of cutting products from the cutting zone) and “turbo” circles, where there are notches on the sides of the abrasive layer, which also allow for more efficient removal of products from the cutting zone. Any advantage must be paid for, and all cuts or notches cause increased vibration of the wheel in the cut, and vibration causes chipping. Therefore, for clean cutting of durable tiles or porcelain stoneware, you need to take diamond wheels with a continuous cutting edge - in this case, the number of chips will be minimal. Of course, it would be more economical to make a dozen cuts using an abrasive wheel on a stone. When cutting tiles, it is better to secure the angle grinder in a stand. Holding it with your hand to prevent vibration is much more difficult.

Before work

Before proceeding to direct work with the tool, you should make some preliminary preparations:

- You should not work with any power tool (not only with an angle grinder) if you are unhealthy, tired or intoxicated - loss of clear control over the body leads to negligence in actions, lack of the required reaction speed and uncoordination of movements. Mandatory components for safe work with an angle grinder are closed safety glasses (preferably reinforced) for reliable protection of the organs of vision from sparks or scale flying along an unpredictable trajectory, as well as a protective casing that guarantees that no fragments of the material being processed or sparks enter the worker.

You should definitely wear gloves or work gloves made of thick leather on your hands. Work clothes should not be wide and at the same time should not restrict movement.

Its parts should be carefully tucked and dangling or dangling elements should be excluded: ties, fringe, etc., which could be pulled under the moving disk of the instrument. When working with rocky materials without organized suction of rock dust, you should use a dust respirator to avoid problems with the respiratory system. The tool must be fully operational; it is prohibited to use a deformed or damaged working disk, the use of which could cause a kickback.

Introductory part. Young fighter course

Grinder, also known as angle grinder (angle grinder). Brief information for those who hold this capricious instrument in their hands for the first time.

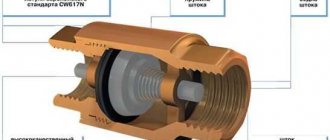

1.1. Grinder device (angle grinder)

- On/off button

- Spindle stop button (spindle rotation is blocked when the tool is turned off when replacing abrasive discs)

- Lever. Rubberized as in the photo. An angle grinder produces noticeable vibrations during operation.

- Protective cover. Removing it is strictly prohibited!

- Air channels. Try not to overlap them with your palms so as not to overheat the angle grinder.

- Abrasive disc. In this case, grinding.

Do you know why the Bulgarian is called the Bulgarian?

The proper name “grinder” appeared in the 70s of the last century, when the first representatives of this type of instruments, produced in Bulgaria, arrived in the USSR. They were called "Fortune".

Bulgarian, now Sparky, was the first in CMEA to begin production of this type of power tool, purchasing an AEG license in 1966.

1.2. Actions with an angle grinder. What can you twist and change?

Some models provide the design ability to change

1.2.1. Handle position

1.2.2. Guard position

But never remove it completely!

Very conveniently made by the Japanese (Kawasaki). In a couple of seconds you can rearrange without a key.

The click system also looks interesting, but I personally have not had to use it.

Attention!

If you found it in a garage, received it at a factory, borrowed it from a neighbor, or somewhere else you came across a used grinder without a protective cover, then refuse the job or arrange for it to be available. Never work without a protective cover!

1.2.3. Speed adjustment

There are excellent angle grinders on sale with a speed controller. I use it myself and highly recommend it. Economic considerations are also useful here - the consumption of abrasive wheels will be 2-3 times lower.

If your grinder does not know how to regulate the speed itself, then look for an adjustable autotransformer (LATR), many people use homemade ones. With this device you can overcome the frantic speed of the grinder and even turn it into a polishing machine.

1.2.4. Replacing the drive

We change the disk as follows:

- We de-energize the tool (you can simply unplug it from the socket)

- Press the spindle stop (see the grinder device above)

- Use a special wrench to unscrew the lock nut.

This not the most convenient option will be on your grinder by default. When you get tired of turning with a wrench, purchase a modernized nut with a spring-loaded base that clamps the disk. Chinese junk, pay once for AEG, BOSCH or Makita .

How to hold an angle grinder while working

The correct grip of an angle grinder will largely ensure competent and safe work with the tool:

The handles of the grinding machine must be held firmly with both hands, without transferring its center of gravity to any one. With a secure grip, even in the event of a kickback, there will be no serious displacement of the tool, much less tearing it out of your hands. The power cord should be located away from the rotating disk: its grip will create the danger of a short circuit and a sudden stop of the tool with the possible occurrence of a kickback. Line The cut should be positioned in such a way that the grinder faces the master, and the person should not be in the plane where the disc is likely to fly apart. In this case, the direction of the sparks is possible both away from the master and under him - everyone decides for himself.

There are no options for left-handed people - when gripping an angle grinder, the only way convenient for a left-handed person is that the sparks will flow “under themselves”. And a mandatory rule is that there should always be a bucket of water nearby to extinguish a possible fire from sparks. It is forbidden to put the tool anywhere until the rotation of the working disk is completely stopped, otherwise objects and planes not intended for processing may become caught. If it is necessary to move the grinder, one place of work to another, it should be turned off, since any careless movement of the master (stumbled, swayed, fell) can lead to unpleasant consequences: injuries, seizure of foreign objects, clothes, etc. The working disk heats up significantly during work, and, of course, , do not touch it until it has cooled completely.

How to cut wood, plywood, chipboard

Despite many questions and attempts to cut wood products with a grinder, many experts do not recommend using this tool for such work, but using other tools for these purposes - jigsaws, circular saws, etc. This is explained by the high degree of danger in the process of performing such work.

Among the reasons for increased danger, the most important are:

- There is a possibility that the teeth of the disc will catch a large amount of wood, which will lead to the tool suddenly slipping out of your hands;

- Heating of the disc during the cutting process, which leads to its fragility. In this case, even a slight misalignment causes destruction of the disk, causing its small pieces to fly apart;

- There is a high probability of solder detachment, which can lead to injury to the technician.

Now there is a wide variety of special tools for woodworking. So why risk your own life?

Backlash

The most common and dangerous moment of working with an angle grinder is the occurrence of a kickback, which is characterized by an instant and very sharp throw of the tool towards the operator. The force of the impact can be so great that it is simply impossible to hold the grinder in your hands - this is especially dangerous if work is carried out at head level. Kickback injuries can be so severe that they are sometimes fatal.

The cause of kickback may be the use of a non-working (deformed or damaged) working disk and/or its jamming in the material. Very often, a kickback occurs at the final stage of cutting, when all that remains is to modify the last layer of material connecting the parts being cut. In this case, it is recommended not to complete the cut on the same side, but to complete it on the other. Safety precautions to prevent the occurrence of a kickback or at least minimize its consequences for a person contain several simple rules: It is unacceptable to use equipment not intended for an angle grinder: a circle of a larger diameter, since to install it you will have to remove the protective casing and during use the linear speed of the cutting edge will exceed; a saw blade that is completely unadapted to the rotation speed of the angle grinder - a carbide solder flying off its tooth at cosmic speed can become a fatal bullet for a careless craftsman. The operator must stand steady with both feet stand on a hard and level surface - this will make it possible to withstand the impact energy. You should be as careful as possible when processing sharp edges, edges of material and any corners.

You must be prepared for the possible kickback of the grinder and the body to move away from the intended location of damage as a result of a reverse strike. If the working disk is jammed, the grinder should be turned off and the cutting disk removed from the cut. Safety precautions and an understanding of the principles of working with the grinder guarantee high-quality performance of the assigned tasks without receiving any injury or harm to human health. In the wrong hands, an angle grinder can lead to great disaster. Safety precautions and instructions for working with an angle grinder must not be neglected. The specialist must use all necessary protection methods, be collected and concentrate his attention. This will protect not only the technician, but also people nearby from injury.

The simple design of an angle grinder does not prevent it from being one of the most popular and necessary tools in the household. The principle of operation is an electric motor that drives the shaft through an angular gearbox, onto which a special disk is attached.

The main advantage of this technique is its versatility, because when using various discs, cutting, polishing or grinding off excess material is performed. There are discs designed for working with wood, but they cannot be used for metal. Discs with an abrasive base of different grain sizes are used as polishing consumables.

Bulgarians are classified into several types:

- Professional; Low, medium and high power; Without handles; Household; With one or two handles.

Low-power equipment is powered from a simple household socket of 220 V, but powerful angle grinders are connected to a network with a voltage of 380 V. Regardless of the power, all machines perform manipulations such as cutting, grinding and polishing wooden, concrete, metal and plastic materials.

The only difference is the operating time.

Powerful equipment can work longer without overheating, but household equipment must be given a rest. If necessary, an angle grinder serves as the basis for creating a small machine. To do this, the grinder is fixed permanently and parts, drills, cutters are turned and knives are sharpened.

The grinder is an indispensable equipment for construction and rescue work in auto repair shops and economic activities.

There are several reasons why an angle grinder is classified as a dangerous tool:

- Working with an angle grinder often takes place on an unstable surface, where it is impossible to find support for a stable position. Despite the protection, most of the rotating disk is not protected. Abrasive polishing disks often break during work into medium and small parts, which fly apart at great speed in different directions .

Types and features of using angle grinders

The popularly known grinder is nothing more than an angle grinder. This power tool, according to ordinary people, is necessary for every owner who has the slightest bit of self-respect.

It is not surprising, because in addition to grinding, the device is capable of performing high-quality cutting of various types of materials, ranging from simple wood to metal corners and fittings.

Most often in everyday life, this tool is used not for grinding operations, but specifically for cutting materials.

Image gallery

Photo from

Metal pipe cutting

Cutting bricks with a grinder

Working with a grinder on a concrete wall

Cutting wood blanks

Main types of grinders

This useful and almost universal power tool can not only saw and cut, but also grind the surface with emery wheels, clean off rust with metal brushes and, if you have a special diamond wheel, carefully cut glass.

But not every angle grinder model has a wide range of capabilities. And technical characteristics, such as power, revolutions per minute, recommended disc diameter and the list of possible operations, vary.

In addition, all grinders presented on the power tool market can be divided into the following categories based on operating time and endurance:

- For domestic use - this type involves use strictly at home to perform simple tasks. The operating time of such models is up to 40 minutes.

- For professional use - this category of power tool is designed for a daily load of 3-4 hours. Similar models are used by craftsmen performing “turnkey repairs” and other types of repair work.

- Industrial - machines, it’s even awkward to call them simply “grinders,” designed for continuous use by an angle grinder operator all day long.

While the first two types are common among the population, the latter are used exclusively in large enterprises working with serious objects. And increased demands are placed on an employee applying for the position of operator.

In particular, knowledge of the design of a power tool, the principle of its operation, the technology of performing work with its help, and knowledge of and compliance with personal safety rules.

The device of a household type grinder. It is useful for a beginner who has received an angle grinder as a gift from friends to become familiar with its main parts. After all, for high-quality cutting and grinding, it is important to use this power tool correctly

In addition, devices can be classified according to the type of power supply: mains-dependent and rechargeable. And also divide into groups according to cost and other criteria.

Subtleties of using power tools

Before you learn how to make an even cut, you need to figure out how to use a household grinder correctly so as not to damage yourself.

First of all, you should read the manufacturer's recommendations specified in the instructions/user's manual. Although it is precisely this moment that often causes a storm of protest in the souls of newly minted owners

But you shouldn’t ignore the instructions, because an angle grinder is not only a useful tool in the household - an angle grinder is also extremely dangerous in the hands of an inexperienced operator .

There are frequent cases of serious injuries to the face, limbs, and torso due to careless handling of the device. Eyes are even more likely to suffer from scale, sparks and other foreign objects if they are not properly protected.

Moreover, no one is insured against an accident - even experienced users who have been working with an angle grinder for 20-25 years, by coincidence, find themselves visiting the emergency room.

Therefore, it is important, first of all, to protect yourself with personal protective equipment (PPE).

Image gallery

Photo from

Face shield

Respirator and headphones

Overalls for working with power tools

Hand protection gloves

Another item that guarantees a certain level of protection, which the manufacturer insists on using, is the protective cover supplied with each type of cutting wheel. It is important to put it on before installing the appropriate attachment and adjust it well.

Terms of use

The main danger when working with technology lies in the principle of its use. To cut, the disc must be in contact with the surface of the material, while the master holds the grinder suspended, relying only on his own experience and attentiveness.

One awkward movement and the disk breaks or the machine jerks when it comes into strong contact with the work surface. That is why when working with powerful units it is better to have basic skills. For beginners, a household grinder with low power and a disc diameter of 115-125 mm is more suitable.

If you thoroughly understand the instructions for the safe use of angle grinders, then you don’t have to worry about your health. In terms of safety when working with an angle grinder, there are several important notes:

- During cutting, the grinder is held firmly with both hands, but is not pressed into the surface of the working area; The master must stand firmly on his feet or knees. This will protect him from injury when jerking the tool; The power cable must be at a safe distance from the cutting disc and the platform where hot sparks fly; Movements around the working area are carried out with the device turned off; If the power is turned off, the angle grinder should be de-energized; The thickness of the blank should not exceed cutting disc diameter. Here it is important to calculate the grinding of the circle during operation.

Error 6 – Fasteners are not tightened properly

The fastening nut is responsible for good fixation of the working disk. If it is not tightened properly, the circle may become loose while the disc is operating, and this in turn may simply rupture the disc. This can happen when changing disks, or when a person is in a hurry because work is idle. Rush in this case is unacceptable.

To check whether there is a deviation from the axis or not, take the edge of the disk and move it from side to side. If deviations exceed 3 mm, then the nut must be tightened. There is another way to check the deviation from the axis: place the circle on the grinder and start the tool. Without touching the metal, bring it to the pre-designated cutting line and inspect the operation of the disc from above. If the backlash is large, it will be noticeable against the background of the cutting line.

Conclusion: Check the disk for large gaps. Always check the nut for tightness before turning on the device.

Precautionary measures

An angle grinder is a dangerous tool. When working with it, a number of conditions must be observed:

- It is forbidden to use the tool without safety glasses; Before cutting or polishing, check the suitability of the disc at idle speed; Clothing must cover your hands and protect from hot sparks; You cannot remove the protective cover from the grinder; When cutting on a plane, the master and assistant must be at the side of the tool; The unit cuts material under its own weight, and excess load will lead to deformation or jerking; Working without a break leads to overheating of the equipment and fatigue of the master, who must hold the grinder firmly in his hands, observing the cutting angle; The workpiece must be firmly secured; You cannot grind the side parts side of the cutting disc, because there are specialized circles for such work; Within the work area there is a master and his assistant. All other people move to a safe distance; The radius of the cutting wheel should correspond to 1/6 of the thickness of the workpiece.

Processing metal with a grinder

Processing metal with a grinder is the most difficult.

This is mainly due to the large number of hot sparks that appear when cutting this material. Manipulations are carried out only in fireproof protection. In addition, the work area should be cleared of objects that could ignite if struck by a spark.

Cutting metal products requires care, patience and basic skills. This will help keep the grinder suspended, which will prevent jerking and sucking of the disc into the hole.

When cutting metal products, a number of rules should be followed:

- All workpieces are securely fixed and free of rust. Before cutting, it is better to cool the metal. The disk can be pinched by the workpiece, so it is better to gradually increase the depth of the slot. There is no need to press the grinder, as it calmly cuts under its own weight.

The grinder is an indispensable assistant in any household or in large construction works.

It helps to process any material with minimal effort and time. Initial experience and advice will be enough for successful manipulations with this tool. The main thing is to follow safety precautions while working, which will help avoid serious injuries.

https://youtube.com/watch?v=jeIdF1xlLb8rel%3D0%26amp%3Bcontrols%3D0%26amp%3Bshowinfo%3D0

- aquagroup.ru

- proinstrumentinfo.ru

- tokar.guru

Working with defective discs

A health hazard often comes from a deformed cutting disc. Even a minor defect at high speed reveals itself in unexpected ways.

Chips, cracks, or the absence of a small piece of the disc lead to its loosening, which is why the grinder often simply flies out of your hands. Therefore, before starting cutting, it is better to pre-check the consumables for defects, and do this immediately before starting work, because damage could appear after a fall or external impact on the disk. Sometimes the plate can be stepped on, and the master simply will not notice it.

Despite numerous warnings that it is impossible to work with defective disks, situations arise when the technician simply did not visually see the defects. Such situations occur all the time and therefore it is necessary to follow a number of rules in order to protect your health as much as possible:

- Before each installation or start of cutting, it is necessary to check the consumables for defects; Work exclusively in personal protective equipment: gloves, goggles or a protective mask.

The grinder is most often suspended in the hands of the master and does not have a fulcrum, so the cutting or polishing process should be approached with extreme concentration and sobriety. People with an unbalanced psyche or poor health are prohibited from starting to work with an angle grinder.

Error 2 - Using budget “non-native” drives

As often happens, to save money, they install a cheap disk on the device. Quite often such circles are curved or made of soft material. In any case, the disk breaks during operation and scatters around the room.

To protect yourself and avoid damage, you need to use high-quality diamond and metal discs. It is preferable to buy branded wheels from a well-known brand - better than the same company as the grinder. For example, for Bosch devices with a maximum cutting wheel size of 125 mm, the Bosch Standard for Metal universal disc 125 × 1.6 × 22.23 is suitable.

Conclusion: It is best to use original discs to eliminate the possibility of injury.

The principle of woodworking

The angle grinder was originally designed for polishing and sanding surfaces, and therefore it can easily cope with operations on wooden workpieces. At the same time, there are some nuances and rules of work that will not only protect the craftsman, but will also help him better cope with wood processing.

First, you should dwell on the types of nozzles, among which are:

- Sanding pads are a multi-layer compound disc where rubber and plastic alternate with foam rubber, sandpaper or wool flannel. The structure helps to extend the life of the wheel and polish the surface. Flap discs are designed for rough processing of wood at the initial stage. Sandpaper flaps of different grits are attached to the surface of the circle, which polish the surface, removing all imperfections. A wire brush is used to remove old paint from a wooden surface.

Operations involving polishing or sanding wood are considered relatively safe. During operation, the disc does not get stuck in the cut, there are no jerks, short circuits or deformations of the wheel.

Device and capabilities

All grinders, regardless of manufacturer, are made the same way. The difference may be additional design elements through which the brand wants to stand out. A standard grinder (for example, Makita GA5030) consists of:

- durable shock-resistant case that is not afraid of falls;

- an electric motor, which includes a rotor, stator and electric brushes;

- gearbox and coupling;

- two handles for holding the machine;

- lever for quick disc replacement;

- button that starts the engine.

Often this button operates very smoothly, which allows the angle grinder to gradually pick up the pace, thus reducing the load on the motor and reducing the risk of possible injury.

Wood cutting

Only one type of cutting wheel is used to cut wood material.

With its side teeth it resembles a circular saw blade, but they are not so long. The teeth help cut deeper into the material, but you need to cut the boards carefully, as the grinder may jerk. Boards about 40 mm thick are sawn off.

The use of circular discs instead of cutting wheels is strictly prohibited, because they are designed to operate at 3 thousand rpm.

The grinder does not produce even half this speed. Accordingly, circular circles are deformed at best. The use of circular wheels can cause serious injury.

What dangers does an angle grinder pose?

In addition to the fact that there are many life hacks with an angle grinder, an angle grinder is a dangerous electric tool.

This is due to the following reasons:

- High speed of rotation of the working nozzle – capable of exceeding a speed of 10,000 revolutions in 1 minute.

- Openness (the casing is not protected) of most of the disk.

- The ability to break the abrasive disc into fragments of different sizes, which will fly away on all sides at great speed.

- Partial lack of ability to properly organize the workplace.

- Formations when cutting metal (or other materials), when grinding small particles.

If the disk begins to jam, even due to a slight misalignment, the grinder will be almost impossible to hold in your hands, since the tool is powerful. This is due to the fact that the rotation speed is quite high. For this reason, it is better for beginners to work with models that have low power, which are equipped with discs with a diameter of 11.5 to 12.5 cm. By the way, the latter should in no case have defects that can lead to unexpected destruction and tearing of the angle grinder out of hands with irreparable damage. consequences.

Polishing ceramic tiles

In the construction industry, the grinder occupies a leading place among tools. Using special discs and attachments, ceramic products are cut and polished, preparing them for installation. A diamond-coated grinder requires special consumables, because cutting ceramics with a regular cutting wheel will lead to breakage or cracks in the tiles.

Dry cutting discs for tiles are divided into segmented and solid. Both types do not require constant cooling - which is why they got their name.

Solid discs are cooled only after 1-2 minutes of operation by lowering the circle into cold water.

The segmented type cools itself due to the slots, but they are not always suitable for cutting ceramic tiles due to the formation of chips on the surface of the material. A segmented or solid disc processes ceramic material and any natural stone. Sometimes, with high-quality work, it is possible to cut paving slabs with a household grinder without deformation or process the edge part of the cut.

How to cut tiles, ceramics, granite, tiles

A feature of these materials is a large amount of dust and the possibility of chipping during the cutting process.

It is important to approach the preparatory process correctly. If it is impossible to avoid the formation of dust, then minimizing the risk of chipping is quite possible.

To avoid chipping while cutting the tiles, you need to moisten them in water. This step in time reduces the temperature of the material, which is the main cause of destruction. This will also allow you not only to cut the tiles without chips, but also to cut out the necessary fragments. Approximately this principle is used to cut tiles.

There is an alternative way. In this case, you will need to use a stone cutting wheel. The use of such a circle practically eliminates the formation of cracks and chips.

Cutting porcelain stoneware is more difficult, as this material is thicker and stronger. The best solution in this case is to use a stone circle:

- make a contour cut along the contour line. Then again, until the uncut thickness of the product becomes less than the cut thickness;

- move the product to the edge of the table;

- With a sharp, but not strong movement, break the porcelain tile.

Straight line cutting

Unlike cutting wood, ceramic is a brittle and demanding material that easily deforms under high loads. Therefore, the discs are pre-selected depending on the density of the stone. The speed must be higher than when processing low density materials.

It is most effective to cut ceramic tiles using circles with a diameter of 115 mm at a speed of about 6-8 thousand revolutions per minute. Not every household grinder produces such power, so you will have to find a tool with the necessary characteristics.

The procedure for working with the material is divided into several stages:

The tile is laid on a flat surface with a clamp attached and marked in the cutting area. Cutting begins gradually along the surface of the entire tile.

First you need to make a rut with a depth of 1-1.5 mm, gradually increasing it. Move the grinder while cutting evenly and slowly. You cannot put pressure on the unit, because it itself goes deeper into the tile under its own weight. It makes no sense to completely cut the material. Most often, they place a nail under the tile and simply press it to break it.

The nuances of cutting certain materials

When cutting concrete, use the following recommendations:

- Before starting work, check the concrete for the presence of embedded fittings, pipes, and electrical wiring (using a metal detector to find wiring).

- To reduce dust, moisten the work surface with water (for example, spray it with a spray bottle or brush).

- From time to time it is worth cooling the cutting element with water or air.

If you don’t have a tile cutter, you can also use a grinder to cut tiles. Specialists are able to cut even a perfectly even circle in tiles. Stone and tiles can be cut in two ways :

Wet (wet the work area with liquid).- Dry (no moisture).

When using the first option, cooling improves, but there will be a lot of dirt, and with the second there will be a lot of dust. The wet method is used for large volumes of upcoming work, and the dry method is used for one-time cutting. The material should be cut smoothly so that the disc sinks in with slight pressure, almost under the influence of the angle grinder’s own weight. This is required in order to prevent disk distortions and reduce the likelihood of jamming. If the process slows down, you should change the nozzle to a new one. And let's look at other life hacks for an angle grinder with your own hands.

- When you cut with a grinder, sparks often fly at you. If clothing is flammable, it may cause injury. To avoid the problem, take a regular insole (used sandpaper or a piece of rubber), as well as silicone glue (alternatively, use double-sided tape) and glue it all to the protective casing of the angle grinder. The advantage of the silicone adhesive composition is that it can be easily peeled off from the casing, and the result will be an interesting design. This way you will have a flexible extension of the casing. Such a splash guard will provide good protection from sparks, the main thing is that you choose a non-flammable material.

- Very durable profile pipes are usually coated with oil, which helps prevent rusting. If you have MDF in your workshop, then you can make a device for stripping the profile pipe (and any other metal) of grease, as well as paint or rust. To do this, take a regular grinder disc and transfer the outer and inner diameters to an MDF sheet. The circle can be cut with an electric jigsaw, but you can also use crowns with a suitable diameter. Next, attach the homemade disk to the device and you can clean the wires. If you take car polish, you can polish the metal.

- The key to the grinder is annoying because it is sometimes difficult to find when you need it. There is a fairly simple way to disassemble a drive without a key, and we note that it is better to do everything with gloves and with the device turned off.

To begin, spin the grinder disk in the direction opposite to the movement (on the back of the grinder, an arrow indicates the direction of rotation of the disk), make three turns with a sharp movement of your hand. Then sharply twist the disk in the opposite direction. The nut that holds the disk will unwind, and you can easily unscrew it by hand and remove the disk.

- The method is useful for cutting off the edge of a profile pipe, so that the bottom wall is cut at the same angle as the top (we do everything at an angle of 90 degrees). Take a piece of metal with a thickness of 0.1-0.2 cm and drill a hole so that it stands 0.2-0.3 cm away from the cut disk and screw it with an M8 bolt. Next, make a mark with a square, it should be marked at a right angle, and then cut off the tip of the profile pipe. Please note that this method has two drawbacks - the bolt limits the length of the cutting part, and the size of the disk limits its height.

- An excellent life hack if you need to cut a round pipe at a strictly right angle using a grinder. You will need a sheet of paper with straight edges, tape, a pipe and a power tool. Wrap the sheet around the pipe, tightly, and after you have made one circle, the edges should meet perfectly. Next, cut everything along the edge of the sheet with a grinder, and get a perfect 90 degrees.

Use an angle grinder only when you know all the operating and safety rules. The working part must rotate in the direction of movement of the tool. Before starting the process, be sure to turn on the device at idle speed. Also, vibration, heating of the angle grinder, and also extraneous sounds should be absent. Wheels should be used without defects, and the most dangerous part may be kickback. To avoid this, try not to jam the wheel when cutting to a fault.

Three simple facts

Accept three simple facts and think:

The official instructions from the manufacturer that you will find in the box have nothing to do with pressing safety issues that arise in practice.

One (most likely Chinese) made a cutting metal disc for woodworking, which fits like a native one onto the mounting diameter of your angle grinder. Another (the owner of the outlet), through an oversight or taking advantage of a hole in the laws, put this product on the shelf and hung a price tag.

But this does not mean that the third one (you) should trust both of them, purchase and work with this product. We talk about this separately in another text.

Not a single sales consultant will tell you, and most likely he himself does not know, that all the shields and protective masks (including visually reliable ones made of steel mesh) on the shelves of hypermarkets and hardware stores are not capable of protecting the face and head of an angle grinder operator in the event of a break. abrasive disc.

In a separate article, I described in detail, with calculations, why this is so, and also summarized sensible information from specialized construction forums and my own practical experience. Read the material and find out how to work with an angle grinder effectively and, most importantly, safely.

Site navigation

Quotes from specialized Internet resources

When Sergei Lovtsev was brought to the thoracic (chest) surgery department of hospital No. 12, he was pale from blood loss. He was examined by an experienced surgeon, Olga Statsenko, and just looking at the patient made her feel sick. https://www.eletos.ru/articles/129/2519.html

The last time I used an angle grinder without protection with a circle on wood, it turned out to be an unscheduled vacation for 2 months

There are many such cases. On every major construction forum you will find threads that are exactly alike: “consequences of safety violations when operating an angle grinder,” “death from an angle grinder,” etc. Here are some typical remarks, preserving the vocabulary and spelling of the authors:

I had to cross paths at work.. The man got TB while working with an angle grinder.. I took photographs on the steel.. A piece of disk in the temporal bone (penetrating), brain damage, a removed eye.. Deep coma, mechanical breathing.. 33 years old, wife pregnant alone will remain.. Follow safety precautions.

A friend was buried a month ago. the disk flew into the neck. and a friend had his hip stitched up three years ago, the surgeon was surprised that the artery was not touched. worked without a casing. Another centimeter or two and there would be nothing for the children to do.

The task was to cut scrap metal into pieces for loading into a Volvo. These are normal pieces. He climbed into this pile and started cutting. It’s time for lunch - we’re heading towards the town - there’s blood everywhere. What happened? - That guy is standing there with a claw instead of his right hand. Shock.

Today, a guy from a construction team died in our hospital building. I removed the protective cover from the angle grinder and installed a larger diameter disc. The scattered pieces of the disc broke the blood vessels and nerve plexuses of the neck. Injuries incompatible with life. In shock, he went up to the floor above, to the working department. Everything along the way is covered in blood.

A friend of mine, working with an angle grinder without a casing, knocked out his eye, they treated him, his blood pressure began to rise, he lost interest in everything, became sour, began to eat a little, died a few months later, aortic rupture, I think it’s all connected. Before this he was a healthy, strong, energetic and cheerful man.

And another friend, also working as an angle grinder without a casing but with “cool” expensive glasses, broke his carotid artery. I ran around the yard a little in front of my wife and children and ended.

Several times I observed wounds inflicted by a grinder (a fairly common injury in the departments of maxillofacial surgery and ophthalmology), and some of the victims were wearing shields themselves and had protection on their grinders. According to my statistics, most of these problems occurred when using a saw with an object that was taller than human height.

No TB. Death from an angle grinder

This article is not written for entertainment purposes. As stated in the brief description preceding the article, evidence of the consequences of working with a traumatic tool in violation of safety regulations . The basis for this material was a forum topic called “Death by an Grinder”, which appeared back in 2006 (the reason was the tragic mistake of a worker, witnessed by one of the participants in our forum) and since then has continued to be actively replenished with more and more dramatic stories from the lives of both professional workers and ordinary amateur builders. As you will see from the examples below, in most cases the tragedy could have been avoided by observing the basic safety requirements, but negligence, excessive self-confidence, and sometimes simple stupidity often lead to irreparable consequences. Mostly, the authors of the posts below were experienced builders who either themselves received any injuries at work or became unwitting witnesses to such cases, so the article was written primarily for those who rarely use tools and therefore often do not even realize, what danger can a tool that seems quite harmless at first glance carry?

In the process of collecting material, we gave a draft of the article to some of our editorial staff for an experiment. There was not a single one of them who would not vow to work in the future without observing safety regulations. And we, of course, hope that the article will be useful to you! Art: Today a guy from a construction team died in our hospital building. I removed the protective cover from the angle grinder and installed a larger diameter disc. The scattered pieces of the disc broke the blood vessels and nerve plexuses of the neck. Injuries incompatible with life. In shock, he went up to the floor above, to the working department. Everything along the way is covered in blood. Neither experience nor self-confidence can replace TB.

Specky: A guy brought a 230mm angle grinder from work with a disk from a circular saw. He says to his wife, let’s go and cut some wood. As soon as he touched the log, the log was torn out of his hands and cut across his shin. He died right there in front of his wife’s eyes from loss of blood - the wife went nuts and couldn’t really stop the bleeding.

There will be many such cases. Let's give a few examples of exactly how safety conditions are violated when working with an angle grinder. most common errors can be identified : operating an angle grinder without a casing, operating an angle grinder with a disk larger than the diameter intended for the model, operating an angle grinder with a saw blade on wood or concrete, working without proper protective equipment (in particular, without glasses).

This photo shows

“modified” killer angle grinders with saw blades . And this is not so bad when a careless but experienced worker deliberately takes risks by installing such discs on an angle grinder. But when manufacturers and stores openly offer deadly devices (often who do not pose any danger) , this is already too much:

Dmitry T: Today, when purchasing another device, I saw THIS. Moreover, THIS is offered for the 230 mm angle grinder in all seriousness. I won’t say what will happen when the grinder can escape from your hands. But if the chain breaks... and it hits you in the balls... or in your head... BRRRRRR...

SOL: Diold burns... I saw the catalog: they offer an angle grinder in a case already with a saw blade for wood.

The scan is attached. And one more example, in terms of danger comparable only to Russian roulette:

glazkov_ro: The master works with 115 grinders, 230m and 400m disc.

The casing, of course, is not installed. Vlad_31: I was doing repairs, removing floors - chipboard on joists. To make it quicker, I put a saw blade for wood on a grinder - there was no jigsaw then. At first there was a terrible vibration, then the fear dulled, I remember nails being cut or simply being pulled out, and delight in the power appeared. Then there was a moment when I caught myself sitting on my haunches and drinking at myself... I realized with horror that if I don’t hold this terrible thing in my hands now, I’ll open up all the childbearing and other things that come after it. I turned it off and broke out in a cold sweat. I didn’t work that day—I just drank beer. And I threw the disk away out of harm’s way! Now, if I’m working, I wear a protective shield, leather gloves, and I do everything to comply with safety regulations.

kotenok: This is my first work with an angle grinder-900 - I bought a new one))) My finger was dragged under the notorious protective casing.

Thin diamond sector disc for concrete. In principle, I seemed to comply with the safety regulations, sawed the wall in the corner, stumbled a little, leaned on the wall, but unsuccessfully. val102: I put a metal disc from a circular saw on a large grinder and started sawing plywood. At first there was euphoria because... I cut like butter, then a severed hand and 7 operations in a year... Unfortunately, I can’t describe the details - I don’t remember the moment from the painful shock. By the way, I also cut my other hand. I think so, the teeth, clinging to the material, with great pressure or when skewed, give a strong forward movement to the tool, and it goes for a walk in the hands.

Yuriki: Photo of a man happy with his life Alex___dr: Why shouldn’t he be happy?

Survived. Commentator: I was sanding old paint from a house at the dacha. I put a grinding wheel on a 115 mm grinder. He took off the protection, stupid... In the process, he extended his hand while standing on the stairs and the grinder was thrown (he hit the head of a carnation) onto his chest. The sweater quickly wrapped itself around the disc and began sanding my chest :-)))... I didn’t have time to turn it off or jump off—it took a split second. But! I know that when working with email. the tool requires two people - the son below was belaying. I screamed at him, and he managed to pull the cord out of the socket. He left only a little of his skin on the disk from the chest.

Well, and, of course, you can’t ignore disk ruptures:

Konstantinn: The other day, a friend told me that they asked her stepfather at the dacha to sharpen a hoe with a grinder (as I understand it, 230), and so, the disk broke into two parts, one part cut off the cheek, so much so that the teeth and everything else are visible, and the other part a piece of meat was cut off from the leg. Blood flowed like a fountain. In the heat, we barely managed to get from the dacha by ambulance to the hospital. Several operations. They say if he weren't 140 kg. weighed, then definitely not a tenant. This is such a sad story.

aragon_sp: I sawed a corner of 50 today. Quietly, peacefully, didn’t bother anyone... Grinder 1200W, 150. Disc 150 “Attack”. All of a sudden, and just like that (see photo). The disc is almost new, it has not been bitten. It’s as if it just exploded on its own. I remained intact because I held it correctly (with a strong grip and the cutting plane did not intersect with the body). Otherwise, the glasses probably wouldn’t have been saved.

Summer resident Me: Today I started sharpening the blade of my rotary lawn mower.

I clamped it in a vice, put a sanding disc on the grinder and off we go! I sharpened it carefully, especially since there’s nothing special to sharpen there anymore. Suddenly, something rattled into the protective shield, right in front of the mirrors. Next is a photo report. But at first I just wanted to put on glasses. The scratch may not be noticeable, but if it’s on the forehead, let alone in the eye. In the last part of our article we will not comment on anything, but will simply clearly demonstrate how the work can end if you neglect safety precautions.

kinburn: ...with a cleaning disc behind the cheek.

Dmitry888: “The grinder is a terrible tool.”

The saw blade shattered. Katz: Yesterday I almost became crippled too. And in gloves, and in a protective mask, and with a casing, and was in no hurry, but it jerked - apparently, the disc slightly perturbed - and hit the leg in the shin, and it smelled like fried pork. About 5 centimeters long and 1.5 cm deep somewhere. But, surprisingly, there was little blood and almost no pain, I disinfected it and applied a bandage.

kinburn: But this is what happens when a disc fragment gets into the face; a person seems to have even survived and ended up in neurosurgery.

ovn83: I myself saw how a drunk man, a reserve colonel, lost 2.5 fingers on a woodworking machine and didn’t even notice it until he finished sawing the board to the end. After the dressing, I trudged to the store for anesthesia. A friend told me that while working at one factory, he saw how, during a “drunk” shift, a man lost both hands while trying to push a stuck log into a sawing machine. After that, the machine was protected. A month later, the men took it off, saying it was interfering with work. And so many “specialists” walk around without fingers, etc. We have never taken safety precautions into account, and people drink at work regularly.

Dmitry888: This is a brush VS a circular.

Alexander RZ296: When, during a labor lesson at school, the teacher in front of us planed himself on an electric planer (an option with a drum with knives up, some Soviet one), then after treatment he said that injuries happen when you stop being afraid of the tool. For example, he got tired of feeding the workpiece with a plank - he fed it with his paws, and ended up planing the back side of one... For example, I have the most traumatic tool - LSM Interskol 75. Well, the sandpaper and the sandpaper... But I often finish small parts with it by turning them over its ribbon up and holding the parts with your hand. A couple of times, when it broke, my fingers got caught between the back of the aluminum frame and the tape (where the sawdust gets pulled in). Broken nails, finger injuries. Once I tightened my T-shirt and almost sanded my face... I will try REALLY not to do this in the future, but in the process of work you relax.

Let’s end the article with a quote from one of the forum members:

BigMC: It’s not in vain that they say that the [TB] rules are written in blood.

Follow safety rules and stay healthy!