Pros and cons of using parquet boards in the kitchen

The main advantages of this type of flooring include:

- environmentally friendly material of natural origin, which ensures a high degree of safety for human life;

- practicality, indicated by a long service life from 10 to 35 years;

- heat transfer of natural components, protecting the home from high temperatures without additional costs;

- noise sound insulation;

- the ability to maintain its original shape under external mechanical influence of surrounding objects;

- ease of assembly, ensured by an adhesive base or special connecting locks;

- high degree of compatibility with different styles of design art;

- the presence of additional factory protection of the top layer, providing increased wear resistance;

- the possibility of carrying out restoration work on damaged areas by scraping (up to 5 times);

- presence on the market of a wide range of color shades, allowing to satisfy the needs of even the most sophisticated customers;

- Possibility of use when laying a “warm floor” heating system;

- distinctive design properties that allow you to avoid coating defects upon completion of the parquet laying process;

- The smooth surface of the floor, eliminating the possibility of debris accumulation, makes cleaning easy, quick, and hygienic.

Among the disadvantages inherent in parquet, the following parameters are noted:

- high price category of the product, exceeding the cost of other flooring materials;

- exposure to alcohol-containing substances, chemical reagents, active coloring pigments;

- lack of resistance to high temperatures;

- tendency to the harmful effects of large amounts of moisture;

- sensitivity to large overloads that occur during constant rearrangement of furniture structures (roller wheels made of plastic are especially dangerous);

- lack of possibility of original decoration;

- the need to use special detergents designed to care for these products.

Important! If the parquet lamella is damaged, it will need to be replaced. This can happen several years after the repair; such material may no longer be available in stores. It’s worth taking care of this right away and purchasing parquet boards with a reserve.

Positive properties

To lay parquet in the kitchen, you should first find out about the properties of the material. The flooring must be durable and meet the specific requirements for this room.

Advantages of parquet:

- it goes harmoniously with a kitchen decorated in any style;

- meets environmental requirements;

- made from natural material;

- easy to install with glue or using locking connections;

- suitable for creating a “warm floor”;

- excellent sound insulator;

- is not subject to deformation after installation;

- features a varied color palette;

- during restoration, damaged areas can be restored;

- has a protective coating;

- strong and durable.

Combined flooring in the kitchen

But parquet flooring for the kitchen also has negative aspects:

- the cost is much higher than other coatings;

- special formulations are required for care;

- it is impossible to create a unique drawing;

- the coating does not like high humidity; when left in water for a long time, the boards swell and become deformed.

Choosing a wood species

The flooring of the kitchen should be reliable and as practical as possible. When purchasing a parquet board for laying on the floor, it is important to correctly determine the quality of the material and its characteristics.

Among the most popular types of wood used for the production of parquet panels are the following:

- oak - elements created from it are extremely strong, have a long service life, are not subject to drying out, cracking, and are resistant to temperature changes;

- beech is a soft wood with a bright color and beautiful pattern, easily susceptible to external influences;

- walnut – has good hardness, massiveness, has an aristocratic background color, is not subject to temperature fluctuations, and is easy to care for;

- ash is a material of light shades, technical characteristics are similar to those of oak;

- maple - its wood is used to produce high-strength products made in warm colors, characterized by stability in preserving the original geometric shapes;

- cherry – a distinctive feature of this type of raw material is its recognizable shade of pinkish color.

The financial capabilities of the consumer allow you to expand the range of wood you choose and consider exotic wood species:

- wenge is a rare dark-colored raw material with a distinct natural pattern, endowed with durability and endurance;

- merbau is a hardwood of a bright brown hue that does not require additional treatment with antiseptic agents;

- Jatoba is a super-strong raw material with a mirror surface, characterized by the absolute absence of knots;

- kempas is a solid material of high texture density of golden color, not subject to external mechanical influence, but sensitive to temperature changes and high humidity.

The general requirements for kitchen flooring can be outlined in a number of points:

- Water resistance. Such products have special signs indicating the presence of moisture-resistant properties.

- Thickness. The minimum size should be 20 cm.

- Parquet flooring. It should be varnished and contain a small amount of wax.

- Type of wood. The properties of the flooring in the kitchen may differ from the parquet installed in the sleeping room.

- Correct manufacturing. The edges of the boards should be cut at an angle of 45 degrees, which makes it possible to avoid damage to adjacent planks. Such bevels are called chamfers.

- No nicks, cracks or knots on the wood. This is a guarantee of a smooth surface and external beauty of the floor.

Is it possible to lay parquet on a kitchen floor?

It’s not enough to want a kitchen with parquet flooring; you also need to understand that wood is afraid of moisture, which means the floor must be moisture-resistant. To make a parquet floor, you will need to purchase material treated with moisture-repellent impregnation. Such panels have reinforced ends to prevent liquid from getting inside the parquet.

According to the craftsmen, such material does not deform when water hits the surface. But only for a while. Do not forget that parquet is made from natural materials, and over time, wood, no matter how it is processed, begins to absorb moisture and deteriorate.

Kitchen surfaces are required to be highly hygienic. In this regard, parquet boards are a suitable option. The surface of the material is smooth, so dirt does not accumulate on it, which cannot be said about ceramic tiles laid with thick seams.

Today, stores sell a variety of cleaning products. They perfectly polish natural wood flooring. After this treatment, the parquet board takes on its original appearance.

The strength and impact resistance of parquet is much higher than that of tiles. If glassware falls on such a floor, it may break and leave scratches on the parquet that are easy to remove. But if the floor is laid with ceramic tiles, it will break along with the dishes. Replacing it will require costly repairs.

Self-adhesive vinyl panels with imitation parquet for kitchen tiles

If you treat your parquet floor carefully, it will remain attractive for a long time. Natural wood creates comfort and coziness in the room. This floor can be used for many years.

From the above, it becomes clear that you can create parquet flooring in the kitchen. Even with minor shortcomings, such material has many advantages. You just need to choose the right type of board.

How to protect parquet boards in the kitchen

There are a number of techniques to ensure a longer life of the coating in the food preparation room. One of the modern protective technologies for parquet is the application of a special impregnation (Protection aqua floor), based on natural wax. It is safe, easily sprayed with a spray bottle, leaving no traces or specific odor. The liquid substance is evenly distributed on the surface and fills the seams. After rubbing the impregnation, you need to warm up the treated area with a special thermal device. This will create a durable floor covering and ensure its durability. The procedure time in a standard two-room apartment takes about 2 hours; the floor will be completely ready for use 12 hours after impregnation.

Along with special means, you can additionally protect the parquet by applying several layers of varnish to it. This procedure will extend the life of the coating and prevent damage from water, dirt, and scratches.

Alternative solutions

The kitchen floor made of pressed bamboo is also an interesting solution. Compressed bamboo boards are very moisture resistant and incredibly durable. Its surface is covered with several layers of durable varnish. There are also several colors of bamboo board to choose from. This is also a product for people who don't like the classic look of bamboo and the characteristic texture of this type of wood. Compressed bamboo slabs can be sanded and refinished, giving us the ability to renew the floor. This purchase will serve you reliably for many years.

And finally, we can buy laminated panels. Currently, there are products that imitate wood; they are made of fiberboard, HDF or chipboard and are distinguished by abrasion-resistant protective layers. When choosing this type of flooring, you need to pay attention to the abrasion class suitable for the kitchen.

How is the price of moisture-resistant parquet for the kitchen determined?

Product pricing depends on several factors:

- the amount of financial costs for the production of parquet boards (the cost of natural wood, equipment costs, wages and other indicators);

- consumer demand for the product;

- production technologies;

- number of manufacturers in this segment;

- buyer trust in a particular brand (rating);

- ways to sell products;

- after-sales service;

- advertising expenses.

The production of moisture-resistant parquet requires additional costs and the use of a specialized board, which gives the final product water-repellent properties.

Modern technologies are designed to satisfy the population’s needs for new opportunities, expanding the scope of usual applications. Such products always cost an order of magnitude higher. Thanks to moisture-resistant technology, natural parquet can be installed in any room of the house, including the kitchen and bathroom, where there is a high degree of humidity and additional loads on the floor. These points must be taken into account when choosing quality products; they cannot be cheap!

Quality, reliability and prestige

If you prefer quality things, even despite the high price, parquet is your choice. And here you need to make a note. Do not confuse the concepts of parquet and parquet boards. The latter is multi-layered:

- 1 (bottom) – veneer;

- 2 (middle) – wood planks that are laid perpendicular to the other two layers, together with lamellas;

- 3 (top) – valuable wood. This layer determines the service life and appearance of the product. Therefore, it is usually impregnated with a special composition.

The value of wood is its naturalness and warmth. It can improve the interior of virtually any style. And thanks to the characteristics of the species, the artistic reserves of parquet boards are very wide. Wood on the floor is warm and comfortable. But we must not forget that if the parquet is varnished, the natural properties will be leveled. To preserve the quality of the board, wax should be used. At the same time, the texture and beauty of the wood will remain.

According to the design of the product there are:

- single-lane;

- two-way;

- three-lane.

The first group of products are made in such a way that there is a solid piece of wood on top. The rest are made of lamellas in several rows, making the design original. It looks like parquet.

The pattern depends on the types of material, cutting option and processing methods. Thus, the color of the product can be any.

An important advantage of parquet boards is ease of installation. After all, the material is supplied ready for this process. Moreover, if such a need arises, the coating can be removed and then installed again.

Customer Reviews

Six months ago we renovated the kitchen. The choice fell on Scheucher parquet boards. Its top layer is protected by special oil with the addition of wax. It is pleasant to walk on the floor even with bare feet. Natural material guarantees safety for all family members. We don't regret our choice at all.

Ksenia, Moscow

We laid light parquet flooring and it has been in use for 1.5 years. During this time, a children's bicycle, a stroller, rocking toys and other child's joys were driven around the apartment, but the floor stands up to everything without the slightest hint of deformation. Very pleased, I recommend.

Maria, St. Petersburg

As a specialist who has been laying floors for 12 years, I recommend parquet boards as a high-quality and safe material. It is important not to save money and choose proven brands, otherwise you will have to pay twice.

Nikolay, Voronezh

Composition of parquet flooring

Parquet panels are made of three layers using natural wood. They are glued together in a cross pattern. To create an impact-resistant material, the boards are compressed under pressure, creating a single piece without seams.

Each layer of parquet panel has its own properties:

- the top layer of the material is made of valuable wood, its thickness is within 4 mm;

- the middle layer consists of coniferous wood - the layer is placed perpendicular to the tiles of the first layer;

- the last layer is made from a sheet of plywood 2 mm thick.

Note! The parquet board for the kitchen should be quite thick. Its wear resistance and strength, as well as its further service life, depend on this parameter.

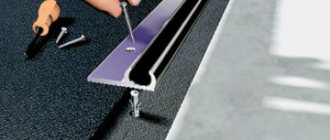

Installation of parquet boards

How to distinguish genuine waterproof parquet from a Chinese copy?

The rating of parquet flooring is traditionally led by European manufacturers. Reliable brands guarantee that the stated characteristics correspond to the actual state of affairs. However, high-quality water- and wear-resistant parquet is not cheap. Therefore, in an effort to save money on purchasing parquet, you can purchase a Chinese counterfeit that passes off as waterproof parquet. To prevent this from happening, you should adhere to the following rules for choosing quality material:

- Checking parquet for chemical odor. Cheap parquet is environmentally unsafe - formaldehyde is used in its production. High-quality coating has class E1;

- The packaging of waterproof parquet must bear all the necessary markings: a drop of water, the word Aqua or an image of an umbrella. The company and country of manufacture must be indicated in full, without abbreviations;

- The size of parquet boards produced in China is 1215*12.3 mm. These are the settings of the equipment of Chinese factories. European manufacturers produce parquet in other sizes;

- The pattern repeatability on laminated panels must be no less than 1:6. The higher the quality of the parquet, the higher this indicator will be. Chinese manufacturers, in order to save money, diversify the pattern by no more than 1:4. A large number of repeated elements is a sign of cheap parquet.

You can check the water resistance of parquet experimentally. If you cut off a small piece of board and place it in water for a day, the thickness of the parquet should not increase by more than 18%. Exceeding this indicator is evidence of low quality parquet.

Laying parquet in the bathroom

It is preferable to install waterproof parquet in the bathroom. When choosing parquet you need to follow some recommendations:

- It is advisable to give preference to well-known brands that specialize in the production of waterproof parquet;

- When purchasing, make sure that the locking joints are treated with wax or silicone;

- The integrity of the packaging with parquet boards should not be compromised - any chip on the panel may compromise the water resistance of the floor.

Parquet flooring in the bathroom should be installed in accordance with the brick (checkerboard) pattern - so that the transverse seams do not coincide. Laying should be done from left to right, with special attention paid to the first row. It should be laid especially carefully, since the quality of installation depends on it.

After connecting the panels, it is advisable to coat the locks with sealant. This will provide additional protection against moisture ingress. Where the pipes enter the lamellas, a hole with a diameter exceeding the size of the pipe is drilled and a corresponding cut is made. After installing the panel, the gap is closed with a special lining and treated with sealant.

If the installation of parquet is carried out after installing doors that open inwards, then professionals advise starting installation from the door threshold.

It is recommended to leave a thermal gap of 8 mm wide around the perimeter of the bathroom. When laying the last lamella, as a rule, it needs to be trimmed to fit the size of the room. To avoid unnecessary gaps, you need to accurately measure the distance to the wall on both sides. The installation of parquet in the bathroom is completed by installing the baseboard. The gaps between the floor and the baseboard also need to be sealed.