Thermal insulation of the foundation is no less important than the thermal insulation of the walls, especially in areas with a harsh climate. Frozen soil cannot protect the foundation of a house from moisture and cold, and the foundation itself, after repeated freezing, begins to collapse faster. To get rid of these problems and reduce the cost of heating your home, you need to know how to insulate the foundation of a house from the outside, and how you can do it yourself.

How to insulate the foundation of a house from the outside

Foundation insulation is a one-time investment that will increase the lifespan of your home

Why insulate the foundation

Thermal losses of the building through the foundation are small - from 5% to 15%. Its position and the peculiarities of the “physics” of heat transfer affect it.

About 15% of losses remain on the foundation and floor, but how much this is in absolute value depends only on the owner of the house Source ps-b.ru

There are only three ways to transfer thermal energy: radiation, convection (for gas and liquid media) and thermal conductivity.

Radiation is clearly not “about the foundation”, but about the heating system devices. They have a higher temperature compared to air and surrounding objects and serve as sources rather than “receivers”. But the walls of a heated room during the cold season emit energy in the infrared spectrum to the street. To see this background, just look at them through a thermal imager. It is especially bright in uninsulated areas and “cold bridges”.

It’s so easy to see how heat escapes through uninsulated walls Source rte-france.com

Natural convection is characterized by an upward flow of warm air and a downward flow of cold air. Of course, the temperature of the foundation cannot affect this process. It is important here to insulate the roof and ceiling so that they do not quickly “cool” the warm air.

Of the above three methods of transferring thermal energy, it is “thanks to” the thermal conductivity of structural materials that a cold foundation affects heat loss and heating costs of the house. And the thermal conductivity of reinforced concrete, from which the foundation is usually made, is quite high, so its low temperature is transferred to the walls and load-bearing partitions.

The air in the room cools due to the enclosing structures, which release heat to the environment. For the underground part of the foundation it is soil, for the base and walls it is air. Insulating the foundation reduces these losses.

Requirements for insulation

The foundation of any building is constantly exposed to high humidity, excessive loads and temperature changes. When the temperature drops below zero degrees, the moisture accumulated in the material turns into ice, contributing to the destruction of the material. And through cracks in the concrete monolith, cold air penetrates into the home. Because of this, the temperature of the floors in the rooms decreases, the baseboards may become damp, and drops of condensation appear on the walls of the basement, and in severe frosts, frost crystals.

To increase the efficiency of thermal insulation, it is important to know the list of key characteristics of insulating materials:

- low thermal conductivity;

- impermeability to moisture;

- resistance to mechanical stress;

- resistance to sudden and significant changes in temperature.

The requirements for the vapor permeability of insulating materials are less stringent, but in combination with concrete it is recommended to use insulation materials whose vapor permeability is as low as that of the foundation itself. The flammability of the material in this case is not decisive, since the underground part of the house is less susceptible to fire.

Video description

The heat loss of a building and the purposes of insulating the foundation are described in detail in the video:

But there is also another function of thermal insulation of the foundation of a house - increasing the service life of the foundation. Building materials have such a criterion as frost resistance. Its numerical expression means how many freezing cycles (assuming water saturation) must pass before signs of destruction appear. Therefore, for regions with cold and long winters, insulation and waterproofing of the foundation is a prerequisite to ensure the strength and durability of the structure.

How to organize water drainage from the base?

Melt and rain water lead to the destruction of the foundation over time. Often even proper insulation cannot save in such a situation. Therefore, it is important to organize the drainage of liquid from the base of the house. For this purpose, an open or closed drainage system is made.

The easiest way to do it yourself is open drainage. It consists of ditches about 0.5 meters wide and 1 m deep, dug along the entire perimeter of the building. The walls of such a trench are beveled at an angle of 30 degrees for better water drainage. Liquid from the pits should move to the drainage well. Therefore, the efficiency of such a system is much higher if the site has a slope.

Closed drainage has recently become the most popular. It consists of pipes that are dug into the ground outside the building around the perimeter. They are laid at an angle to allow water to flow independently into the drainage well. Pipes must be wrapped with geotextiles.

Technologies and materials

There are only two types of foundations that need to be insulated: slab and strip. For columnar and pile foundations, we can only talk about thermal insulation of the floor of the first floor and the insulation (basement) - a kind of screen that protects the subfloor. But piles and pillars do not directly insulate.

Plate

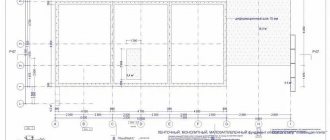

The technology for insulating a slab foundation is no different from the thermal insulation of concrete floors on the ground:

- a solid base of compacted soil;

- geomembrane as protection against capillary rise of groundwater;

- crushed stone-sand cushion to improve the bearing capacity of the soil and proper load distribution;

- roll waterproofing;

- sheet insulation (expanded polystyrene or EPS);

- plate.

Eps is the best material for insulating slab foundations Source rmnt.ru

See also: Catalog of companies that specialize in foundation repair and design.

The Swedes have slightly improved the technology and already at the stage of pouring the base they install a “warm floor” into the slab. In our country it is often done the old fashioned way - in a screed or under the finishing floor covering. Scandinavians are “boring” people and already know in advance where not only the partitions will be located, but also how the furniture will stand (one of the conditions for the correct operation of the “warm floor”). Our people have a different character - they are not only furniture, but also interior walls are often moved from place to place.

Strip foundation

Insulation of this type of base has a wider selection of materials and technologies:

- permanent formwork;

- fastening sheets of foam plastic or extruded polystyrene foam;

- spraying liquid polyurethane foam;

- filling of expanded clay.

Among foundation insulation materials, only one popular thermal insulation material is missing - mineral wool. When saturated with water, any type of water loses its thermal insulation properties. And although it not only easily absorbs, but also easily releases moisture, it is impossible to create conditions for its weathering for the foundation.

Places for foundation insulation Source anticafe-sandbox.ru

Features of applying polyurethane foam

Insulating the foundation base from the outside with polyurethane foam requires special equipment. It is often not advisable to purchase it for finishing a private house. It is more profitable to seek help from professionals.

The work is divided into several stages:

- A trench is dug along the perimeter of the building. The foundation is cleaned of contaminants. There is no need to apply primer or mastic to it. Liquid polyurethane foam will independently fill all cracks and voids.

- The surfaces are dried. Remove crumbling fragments.

- Polyurethane foam is applied. The thickness of the coating is maintained in the range from 3 to 5 cm. In some cases, applying a second layer of polyurethane foam is allowed.

- Wait for the insulation to dry completely. After this, a trench is dug. Finishing work is carried out on areas of the foundation that rise above the ground surface.

If the surface to be treated has a small area, then you can use polyurethane foam, available in cans. It resembles polyurethane foam and is applied in a similar way.

Technologies for insulating strip foundations

Each type of insulation has its own characteristics, which dictate the methods of its application.

Permanent formwork

This is the only method of insulation that is possible only at the stage of construction of a monolithic strip foundation. In fact, this technology can be called “two in one”, when the formwork made of thermal insulating materials remains as part of the structure upon completion of construction. Moreover, permanent formwork solves two problems - how to insulate the foundation of a house from the outside and from the inside.

Structurally, there are two types: block and panel. When pouring a strip foundation, shields are used. The blocks have walls and wide transverse bridges, which reduces the strength of the reinforced concrete base.

Ready-made kits have a set of polymer jumpers that can be used to adjust the width of the foundation Source visualizepicture.com

Installation of a foam insulation layer

Let's start insulating the foundation with penoplex by choosing the material. Penoplex slabs are available in two standard sizes: 0.6 m x 1.2 m and 0.6 m x 2.4 m. We do not give any specific decision on thickness - everything is purely individual and depends on the thickness of the wall and the material, from which it is folded.

Penoplex is glued to the base with a special glue; it is sold in bags in the form of a dry mixture. We will not dwell on glue brands - every self-respecting company producing dry mixes necessarily produces glue for penoplex foam.

- While the mastic was drying, its surface was covered with dust, so we treated the waterproofing with a primer. The primer increases adhesion and improves the quality of gluing.

- Apply an even layer of adhesive mixture to the foam board. We also apply glue to the wall. Press tightly. And so on until the entire surface is sealed.

- At 4-5 points of each sheet we drill and hammer in additional fasteners - a dowel-fungus.

Note! With a planned insulation thickness of 10 cm, it is better to take twice as much material, but 5 cm thick, and glue it in two layers so that the slab of the second layer overlaps the joint of the first.

Decorative finishing of the outside of the foundation

Video description

You can get acquainted with the features of polystyrene foam insulation technology in the video:

Insulation with sprayed polyurethane foam

Among all polymer insulation, sprayed polyurethane foam is the most expensive type. Its advantage is that the thermal insulation layer has no seams, and foamed polyurethane has very good adhesion to all types of building materials.

Application of polyurethane foam to a surface cleared of dirt is very quick. There are two types of materials: two-component and one-component.

In the first case, professional equipment is needed, the work of which is to supply both components under pressure to the working head, where they are mixed and foamed.

Single-component polyurethane foam is produced in liter aerosol cans, and even an untrained beginner can handle them correctly. But this technology is good for a small area of work, or when it is necessary to apply a small layer up to 2 cm thick.

Spraying polyurethane foam is similar to painting with a spray gun, so it is better to cover the cladding of the house. Source ppuspb.ru

If the soils are dry, the water level is low and proper drainage work has been carried out, then waterproofing of the foundation and base need not be carried out - there are no seams, and the water absorption of hardened polyurethane foam is small (no more than 2%). When finishing the base with plaster, reinforcement is not necessary - there are no joints, like with foam plastic slabs, and, therefore, there are no prerequisites for cracks to occur.

In addition to the price, polyurethane foam has one more small drawback, which is a consequence of its advantage - good adhesion. When carrying out work on insulating the basement, it is necessary to protect walls that already have finishing (or do not require it) - this is easier than cleaning off hardened foam.

Insulation with expanded clay

Recently, this bulk material is rarely used for foundation insulation. Its use is limited by two factors: quite high, compared to polymer insulation, water absorption and thermal conductivity.

The thickness of bulk thermal insulation can reach 60 cm Source obustroeno.com

The first indicator lies in the range of 8-20% of the volume. Moreover, such water absorption is typical for “fresh” expanded clay - over time it becomes even higher. For comparison, for ordinary polystyrene it is no more than 4%. Therefore, waterproofing of both the foundation and the entire insulation layer is necessary.

It is impossible to ensure complete “tightness” of expanded clay, and it will take a long time to dry underground, wrapped in film - its use is not recommended in conditions of high seasonal rise of groundwater.

Thermal conductivity also does not meet modern requirements for thermal protection of buildings - 0.07–0.18 (W/m*°C) versus 0.02–0.04 for polyurethane foam, 0.03–0.04 for EPS/EPS. Therefore, the recommended thickness of bulk thermal insulation for our middle latitudes lies in the range of 40–60 cm.

The insulation scheme looks like this:

- dig a trench of the estimated width (or clear the cavity of the pit) to the heel of the foundation;

- lay a waterproofing film over the entire area of the trench - foundation-bottom-wall;

- fill and level expanded clay;

- cover with film on top;

- pour a layer of sand;

- make a blind area.

Typical scheme for insulating a foundation with expanded clay Source sevparitet.ru

The advantage of expanded clay is its environmental friendliness and low price. Although, taking into account waterproofing and a large volume of materials, the cost of work in the end will not be so low. In addition, the base will have to be insulated using one of the above methods.

Mandatory insulated blind area

Thermal insulation of the blind area can significantly increase the efficiency of foundation insulation.

To arrange it, the following work is carried out:

- Along the perimeter of the base you need to dig a recess about 30-40 centimeters deep and 80cm-120cm wide.

- Next, drainage pipes are laid along the entire outer contour. They are connected to a common drainage system.

- A pillow about 15 centimeters thick is made from sand, compacted and covered with black film.

- Reinforced polystyrene foam slabs 1200*600mm are laid; their thickness can vary from 40 to 50 millimeters. The sheets are installed along the short side to the wall so that the width of the blind area corresponds to 120 centimeters.

- On top of the thermal insulation, a dry slag-cement mixture (proportion 5k1), 5-10 centimeters thick, with a slope of 1.5 cm from the house is poured and compacted.

- The final stage is the installation of curbs and paving slabs, with abundant irrigation of the entire area to form a screed under the slabs.

TISE

From the title it is not immediately clear what we are talking about. In fact, an abbreviation of these words refers to a foundation built using this technology. Its “trick” consists of piles that expand towards the bottom, so that the soil cannot push them out when freezing or heaving. Another feature of the TISE foundation is a grillage raised above the soil by 10 - 15 cm, which allows it not to experience loads during the above-mentioned phenomena. It is this part of the base that is subject to mandatory insulation.

Carrying out work with a grillage is to some extent easier, since there is no need to dig a pit around the base. The same materials as in the previous version are suitable for insulation: polyurethane foam, EPPS, etc. The only thing is that in this case, cladding is needed, which is not necessary underground.

A separate issue concerns the gap, which we have already discussed. There is still debate on this issue. Someone suggests placing glass-magnesite sheets under the grillage and, screwing them to it, covering it with external finishing. Some people advise not to touch this gap, especially if there are floods in the area. As in any controversial cases, it makes sense to consult with specialists.

Extruded polystyrene foam

Extruded polystyrene foam (EPS), with a smaller sheet thickness, brings more benefits, since, compared to standard foam, it is harder, completely resistant to moisture penetration, and has minimal vapor permeability and thermal conductivity.

Expanded polystyrene made by extrusion is significantly superior to polystyrene in all respects

For complete thermal insulation of the base of a house in latitudes with a temperate climate, a sheet with a thickness of 40 mm is suitable, for cold regions - 60 mm, it is better to lay it in 2 layers of 30 mm. To simplify installation and increase packing density, a tongue-and-groove connection is used. For fastening, an adhesive solution and dowels with a disc-shaped surface are used.

Installation of slabs is allowed both vertically (for strip and columnar bases) and horizontally (for slab bases).

Due to the high strength of the material, it can withstand loads from concrete well, the sheet does not flatten and prevents shrinkage, unlike polyurethane foam and polystyrene foam. When choosing an EPS brand, it is better to purchase Technonikol and Penoplex.

Main characteristics:

- density: from 15 to 35 kg/m3;

- operating temperature: from -50°C to 75°C;

- sheet dimensions: 600x1200 mm and 600x2400 mm;

- sheet thickness: 20-100 mm;

- service life: over 40 years.

Possible mistakes

A novice workman must know all the difficulties of working with heat-insulating material. Having assessed all the possible risks of incorrect installation, he must decide for himself whether to do the thermal insulation of the base with his own hands or invite specialists.

The main mistakes made when insulating the base:

- Use of cheap material installed with low pressure.

- Failure to comply with the temperature regime: below 5 or above 25 C.

The work was carried out during rain or high atmospheric humidity.- Violation of technology and preparation of the working surface.

- The starting bar is not set.

- The installation of the tiles was not carried out in a checkerboard pattern.

- Incomplete fastening of thermal insulation to the surface of the base. The dowel was sunk into the thermal insulation with excessive indentation, which resulted in the formation of cold bridges.

- Exposing thermal insulation for a long time without a protective coating outdoors in bad weather.

- No primer was used before decorative plaster.

How to eliminate them?

Most mistakes in the process of insulating the base cannot be corrected; you will need to start the work completely from the beginning. Correction can only be done if the plinth lath is poorly secured, for example, only at the ends, or it was in vain covered with plaster from the plinth side. This has led to the fact that the plaster easily falls off due to its low adhesion to the metal.

To correct the error, it is necessary to increase the number of base rail connectors . For this purpose, the lower border of the sheets is cut off to open access to the rail. Then knock down 10 cm of plaster above the removed part.

After which it will be possible to determine the place where there are not enough screws and install them. Next, fix the insulation, lay the new mesh overlapping 10 cm with the old one.

You will find a lot of important and useful information about basement insulation in this section.

What are the consequences of his absence?

To avoid any questions about what will happen if you skip this stage, let’s consider the possible consequences. This is what can happen if you do not insulate the foundation of a private house:

- The foundation may freeze, that is, its temperature will drop to minus. It’s especially scary if groundwater is nearby. Then the concrete absorbs moisture, which freezes at sub-zero temperatures and breaks it.

- The base may suffer from temperature changes, which negatively affects it.

- If the waterproofing of the foundation is weak, then moisture will still affect it one way or another. Thermal insulation additionally prevents water penetration.

These arguments are usually enough to understand why insulating the foundation. Therefore, let's move on to the next point.