Building the walls and roof of a house is only half the battle. It is necessary to make the built space comfortable for life. To do this, most often the house is insulated from the outside or from the inside, and sometimes both options are used simultaneously.

Do you want to insulate your home, but don’t know what technologies exist and where to start? We will help you deal with this problem - the article discusses the main options used for external thermal insulation. The procedure for performing the work is also considered, thematic photos and useful video recommendations on the nuances of insulation are selected.

Types of insulation: external and internal

Why is home insulation so important? The question may seem stupid, but some novice masters may ask it because they do not yet fully understand the importance of this event. And if the insulation of a garage or country house can sometimes be neglected, as well as the insulation of a building located in southern latitudes, then it is imperative to take measures to increase the level of thermal insulation of the walls of a house located in a harsh climate .

Insulation of house walls from outside

So, firstly, it is worth noting that insufficiently insulated walls of any building cause large losses of thermal energy . About 45% of the heat is lost through them and goes to “heating” the street, which means that approximately the same 45% of the heat needs to be taken from somewhere to keep the house warm. And this is a significant increase in the amount of expenses for heating and heating the house, and annually. It is enough to install the insulation once during construction and forget about replacing it for many years. And the cost of heating the building will be significantly lower. Moreover, it is also very important to lay the insulation correctly so that cold bridges do not form, otherwise the loss of thermal energy will still be quite large.

It is very important for residents of private houses to know how to insulate the outside of the house themselves.

On a note! Nowadays, home insulation is mandatory in accordance with the standards for building insulation work. Thus, a building project may not even be approved without meeting the requirements of SNiP 02/23/2003 , which state that the house must be insulated from the outside.

In general, insulation can be done using two methods - both from the inside and outside the room. Deciding which method is better is quite simple. Thus, it is extremely rare to resort to laying insulation on walls from the inside, since this method has many disadvantages compared to the method of insulation from the street.

How to properly insulate walls - outside or inside?

If the house is insulated from the inside, then the wall of the building from the outside is completely unprotected from external factors, which means that the materials will be subject to attack by sunlight, cold, moisture, etc., which will significantly reduce their service life. It is also worth taking into account the so-called dew point - the place where condensation collects. When installing insulation from inside the house, it will be too close to the inside of the rooms, which means that the walls will dry out worse , dampness may form and, as a result, mold, mildew, etc. It is also important to understand that insulating the walls from the inside will “eat” some of the free space, and the rooms will be smaller.

Dew point

If you insulate the house from the outside, then all these negative factors can be avoided. That is, the wall from the street will be well protected from cold, light and water, and the room inside will be freer, and the quality of insulation will not suffer at all.

Advice! You should insulate a house from the inside only if it is impossible to insulate the structure from the outside of the building, and also if there is a good layer of vapor barrier from the inside of the house.

Insulation of house walls from the inside

Materials that can be used for insulation

Previously, mineral wool was used to insulate various buildings. It is still used today, but a fairly large number of alternative materials have appeared on the market that may well replace it. You will have to choose yourself, taking into account their service life, composition, cost and a number of other factors. Materials may differ from each other in the degree of moisture resistance, tendency to deformation, level of thermal conductivity, etc. When choosing insulation, you should take into account all their technical characteristics and be sure to focus on the climatic conditions of the region in which the house is being built.

To insulate with foam plastic, you do not need to build a frame. The plates are attached with special glue and fixed with dowels

Expanded polystyrene and extruded polystyrene foam

One of the most commonly used materials is expanded polystyrene or foam. It can be used in the form of large slabs or as bulk insulation. Its thermal conductivity is low and depends directly on its density, but a sufficient level of thermal insulation can be achieved due to its cellular structure (that is, the material has a mass of cells filled with air).

Expanded polystyrene

Expanded polystyrene is an inexpensive material, easy to install, does not absorb moisture, and is a low-flammable material. It can be bought at almost any hardware store. As part of the wall pie, it has a sufficient level of strength.

Important! When burning, foam releases very toxic fumes. There are, of course, types of material that are capable of extinguishing on their own, but... That is why such insulation is used only for insulating the outside.

Thermal insulation of the house outside

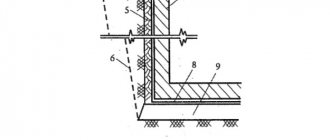

Extruded polystyrene foam - a “relative” of polystyrene foam - has a certain difference from the standard material associated with manufacturing technology. Its percentage of water absorption is also low, its thermal conductivity is low, but its compressive strength is higher. This insulation is perfect for installing thermal insulation at the base or foundation level. It costs more than standard foam.

The installation of these materials is the same: you need to clean the walls of debris and level them. Then you just need to glue the slabs of material to the wall, using adhesives designed specifically for such materials; they can additionally be fixed with anchors with wide caps - mushrooms. By the way, before attaching the EPS, it needs to be made somewhat rough before applying glue - the surface of the material is too smooth. After installation of the insulation is completed, the walls can be plastered or covered with other facing materials, having previously laid a reinforcing mesh.

Types of XPS

You can also install these types of insulation using wooden sheathing. Wood slats are fixed on the walls. Moreover, their thickness should be equal to the thickness of the insulation or slightly exceed it. Then between the external finishing material and the polystyrene foam there will be a small pocket with air for ventilation. The slats are fastened from each other at a distance equal to the width of the insulation element itself.

On a note! You can also attach facing material to the sheathing after installing the insulating elements.

Insulation of timber house with polystyrene foam

Prices for foam plastic

Styrofoam

Mineral wool

Traditionally, you can insulate a house with ordinary mineral wool. The material is based on rocks, usually basalt. This fibrous insulation has a low level of thermal conductivity, inferior to foam plastic, and low density. But the main advantage of the material is its absolute non-flammability. Mineral wool also “breathes” perfectly.

Mineral wool

Installation of mineral wool is carried out using a frame, because this insulation is too soft compared to expanded polystyrene and does not hold its shape as well. You can additionally secure the cotton wool using anchors on which the cotton wool is placed, or dowels with wide caps.

The main disadvantage of mineral wool is its tendency to absorb moisture. So waterproofing cannot be neglected when using it. A layer of moisture-proofing material is laid on top of the installed insulation. If this measure is neglected, the mineral wool will lose all its properties when saturated with water.

Insulating the gable of a house from the outside

Advice! When constructing a sheathing for mineral wool, it is recommended to make the distance between adjacent elements of the sheathing slightly less than the width of the layer of wool. Then the sheets will stand tightly between them.

Prices for mineral wool

Minvata

Polyurethane foam

This material is new to the insulation market. It is already quite widespread. The material can be used both in the form of slabs and in the form of sprayed substances (the latter option is more common).

Polyurethane foam (PPU) – advanced thermal insulation technology

On a note! By the way, polyurethane foam is also known as polyurethane foam.

Some tiled types of such insulation already have an external decorative layer. So in this case, insulation can be combined with the cladding of the house. Such polyurethane foam is attached to dowels or to a special fastening system, if we are not talking about a sprayed composition.

The main disadvantage of sprayed insulation is its high cost. But polyurethane foam carefully closes all the cracks, does not require the installation of vapor barrier materials, has high strength, perfectly insulates noise and does not let heat out of the house.

Application of polyurethane foam

The application of sprayed insulation can only be trusted by professionals. It is not recommended to carry out the procedure on your own, since in the process of applying it to the walls you can inhale toxic substances, which cease to be released only when the material hardens.

Expert recommendations

For thermal insulation of residential buildings, it is worth giving preference to materials that are environmentally friendly, which allow the walls to “breathe”. These include:

- foam glass;

- mineral wool;

- stone wool;

- ecowool.

It should be taken into account that the high thermal protection characteristics of such materials are combined with a high degree of hygroscopicity. They are able to quickly absorb a significant amount of moisture, hold it inside, and when the temperature drops below zero degrees they can freeze and lose their valuable insulating qualities.

To protect the insulation layer based on natural materials, hydro-vapor barrier membranes should be used, which isolate moisture and steam, preventing them from penetrating into the insulation layers, and promote ventilation of the wall surface.

Thermal insulation based on foamed polymer materials, unlike insulation made from natural raw materials, is almost unable to absorb moisture and has a long service life. If laying mineral or basalt wool slabs on walls is accompanied by certain difficulties and requires strict adherence to safety standards, then installation of polymer types of insulation, which include polystyrene foam, polystyrene foam or polyurethane foam, can be done without unnecessary labor and time. The thermal insulation qualities of such insulation materials are in no way inferior to the properties of mineral wool.

Which is better to use?

Choosing the right material is quite simple for an experienced craftsman, but it will not be easy for beginners to decide. You can rely on ready-made recommendations, for example, depending on the materials with which the house will be faced.

Table. The choice of insulation depends on the material from which the wall cladding will be made.

| Wall/façade type | Recommendations |

| Facing brick | If you have such a facing material, it is important to ensure that there is a small layer of air, otherwise the wall materials will get wet. Here it is recommended to make a wall structure consisting of three layers. |

| Ventilated | Finishing is done along the lathing. The easiest way to insulate is with mineral wool - ideal for hanging facades. |

| Wooden house | Such buildings are insulated only with mineral wool; the technology of the so-called hinged method of facade installation is used. |

| Wet | Typically, insulation is done with mineral wool, but sometimes polystyrene foam is used, but it is important to leave a gap for air. |

Insulation of the facade of a wooden house

The question about the number of layers of thermal insulation will be answered by a regulatory document. You can insulate a house from the street in two or three layers. In the latter option, finishing with panels or plastering does not take place as a separate layer, so in a three-layer wall, the third layer needs to be laid with structural material.

On a note! Whatever one may say, most often the choice of insulation comes down to the fact that you need to decide what to buy - mineral wool or expanded polystyrene.

How else can you insulate the walls of a house from the inside?

- Alternative materials . This group includes insulation materials forgotten by time. These are straw, reeds, linen mats, cork, sawdust, clay and gypsum panels. Today, not only craftsmen, but also manufacturers practically do not remember such insulators. The main difficulty for the owner of his home is to find such natural materials.

- Additional materials . Additional materials include vapor barrier and means for creating a ventilated gap. So, galvanized rolled metal or timber with wood boards (preferably solid) can be used for lathing. The latter are subject to mandatory treatment with long-lasting protective compounds (the composition must contain antiseptics and fire retardants).

Calculation of insulation thickness

Calculating the amount of insulation is not easy, even if you know the dimensions of the walls and follow the recommendations of SNiP, SP and GOST. You can make the calculations yourself, or use the services of a special company that deals with such calculations, or look for online calculators. It is worth understanding that in order to correctly determine the thickness of thermal insulation, it is important to take into account all possible options for heat loss at home, the power of the heating system, climatic conditions, etc.

Important! Each building has certain parameters, and the thickness of the material must be calculated for each house individually.

Insulation of external walls is more effective than insulation from the inside

Polyurethane foam

Polyurethane foam is a type of plastic that has a cellular-foam structure, due to which its thermal conductivity coefficient is one of the lowest. It has a high level of adhesiveness, so it can be used on any surface, creating an airtight coating.

High level of moisture resistance, resistant to temperatures, can be used for a long time. Does not deform, does not contribute to the formation of fungus. Creates an additional soundproofing layer.

It is applied using a compressor and a hose, therefore it is indispensable for complex structures and frame houses, being a blow-in material. The disadvantage is its high price and the fact that special equipment is required for application.

Fixing thermal insulation

Prices for dowels for fastening insulation

Dowel umbrella

Installation of standard types of insulation such as mineral wool and polystyrene foam is carried out on walls that have been thoroughly cleaned of old materials, if any. Whatever one may say, you need to remove all dust, noticeable dirt, remove all hanging elements, remove any signs, etc. Next, the entire surface must be dropped, cleaned and primed. Moreover, it is better to apply deep-penetrating primer.

Photo instructions

You can make the walls smooth and suitable for further work using an adhesive composition. You can check their evenness using a long level or rule. So, with level differences of up to 5 mm, the adhesive composition can be applied to the entire surface of the wall plane; if the unevenness is larger and the difference is 5-20 mm, then the glue is applied in sheets along the edges and on the entire surface of the insulation element.

In order to fix the first row correctly and evenly, it is recommended to install a starting strip above the base, and the slabs will rest on it. Subsequent rows of insulation are installed with some row shifting so that the joints between elements in adjacent rows do not coincide with each other. Each insulation board must be secured with dowels so that there are 5 pieces per 1 m2. fasteners.

Features of installation of insulation based on mineral wool

Important! If the facade is finished using the “wet facade” system, then there should be only one layer of insulation.

Ecowool

Cellulose fiber material is applied to the walls using a special installation. Used in two formats:

- fills the space between the wall and the cladding;

- is sprayed onto a wall with sheathing, and subsequently façade panels are placed on it.

This wool is safer to use and install than glass wool.

Insulation with polystyrene foam

Step 1. The first step is to do the preparatory work. That is, the walls need to be cleaned of dirt and debris.

First you need to clean the walls

Step 2. Next, you need to apply a deep-penetrating primer, which will increase the level of adhesion of other materials and also rid the walls of dust. It must be applied over the entire surface of the walls using a brush or roller.

Applying primer

Step 3. After this you need to mount the starting bar. It is fixed above the base of the building using dowels, after carefully leveling it, focusing on the building level. The starting strip will allow you to properly glue the polystyrene foam.

Installation of the starting bar

Step 4. Next, you can begin gluing the insulation panels. It is important to use specialized formulations. The adhesive solution must be prepared immediately before use strictly according to the instructions.

Preparation of adhesive solution

Prices for Ceresit glue

Ceresit glue

Step 5. The adhesive solution must be applied to the polystyrene foam board using the “side-flat” method - a strip of glue is applied around the perimeter of the board, and then 3-5 cakes of the adhesive composition must be placed in the middle. In this case, the glue will cover about 40% of the surface of the slab.

Applying glue to insulation

Step 6. Next, you need to place the panel with glue on the starting profile and then attach it to the wall, pressing it tightly.

The plate is applied to the wall

Step 7. You can determine whether the panel is glued evenly using a building level. You need to check the evenness of the panel in three planes - on the sides and on top.

Checking the evenness of the slab

Prices for building levels

Construction levels

Step 8. Now you can glue the remaining panels in the first row. By the way, in subsequent rows the panels are glued in a checkerboard pattern.

Panel gluing process

Step 9. After installing the slabs, you need to wait 12 hours for the glue to set, and then fill the wide gaps between the slabs with polyurethane foam.

Filling gaps between slabs

Step 10. After drying, excess foam must be cut off with a sharp knife, and the panel joints must be sanded.

Removing excess foam

Grinding joints

Step 11. When installing polystyrene foam in the area of window and door openings, it is important not to forget to reinforce the corners of the insulation with strips of reinforcing mesh. This will strengthen them. The mesh should be laid at an angle of 40-45 degrees. This measure will help avoid cracking of walls in these places in the future.

Installation of expanded polystyrene in the area of window openings

Strengthening corners

Step 12. At the corners of the house, the panels still need to be laid in a checkerboard pattern, joining the sections from different sides of the house (shown in the image). Here, by the way, you also need to use a mesh for reinforcement.

At the corners the panels are laid in a checkerboard pattern

Using reinforcing mesh

Laying mineral wool

Step 1. In this case, you need to attach steel brackets to the front part of the walls of a wooden house. The length of the bracket will depend on the thickness of the insulating coating. The brackets can be fixed using self-tapping screws.

Steel bracket

Fastening steel brackets

Step 2. You need to place a paronite gasket between each bracket and the wall.

Next you need to lay the paronite gasket

Step 3. Next, you can attach the insulation. The mineral wool sheet simply needs to be placed on the previously installed brackets.

Fastening mineral wool

Step 4. Additionally, the cotton wool must be secured using self-tapping screws and wide plastic fasteners, screwing the screws into them.

Additional insulation fastening

Step 5. In this way you need to lay the first row of cotton wool. It is important to attach the second row on top of the first so as to cover all the joints between the sheets of cotton wool in the first row.

Insulation with mineral wool

Laying the second row

Step 6. When the second layer of mineral wool has been laid, you can begin installing the wind-waterproofing layer. The brackets need to be threaded through the film.

Installation of a wind-waterproofing layer

The brackets need to be threaded through the film

Step 7. You can also fix the protective film using self-tapping screws and wide plastic fasteners.

Fixing the protective film

Step 8. After completing the installation of the insulating material, you can begin the construction of the ventilated facade, that is, the installation of the frame and the finishing material itself. The guides, by the way, are attached to the same brackets.

Arrangement of a ventilated facade

The result of the work done

Video description

We will dwell in more detail on insulating a house with polystyrene foam. Find out how safe polystyrene foam is in our video:

Foam insulation Source beton-house.com

- Installation of foam plastic . It is placed in the spaces between the frame elements, additionally secured with foam or glue.

- Fixing the slabs . The foam sheathing is additionally reinforced with plastic dowels (metal dowels are not suitable, as they create cold bridges).

- Decorative finishing . A primer is applied to the foam layer, a fiberglass mesh is fixed on top, then reinforcing glue is applied. After the glue has dried, finishing is done with decorative or warm plaster.

See also: Catalog of projects of houses made of aerated concrete blocks presented at the exhibition “Low-Rise Country”.