Active use of bathrooms leads to the formation of a special microclimate in these rooms. High humidity and constant temperature fluctuations contribute to the accumulation of condensation on surfaces, followed by the appearance of fungus and mold.

Especially often, fungal colonies grow in places that are difficult to reach for cleaning: tile seams, cracks, joints between plumbing fixtures and tiles. Special sealants can prevent destructive processes.

Previously, cement mortars were used to grout joints and plug cracks. However, practice has shown their fragility in conditions of high humidity, temperature and the presence of various kinds of microorganisms.

In modern construction, sealants are used for various external and internal works.

Advantages of Sanitary Silicone Sealant

A big advantage of silicone-based sealant is the ease of working with it and the ability to install plumbing fixtures yourself.

The product is universal, suitable for a wide range of actions in the bathroom, kitchen, sauna, bathhouse, swimming pool. Other advantages of sealants are:

- resistance to UV radiation, no fading in light;

- suitability for all types of materials that are used for the manufacture of plumbing fixtures: cast iron, earthenware, ceramics, acrylic;

- resistance to the influence of low, high temperatures, temperature changes, humidity, good tolerance to direct contact with water;

- the presence of a fungicide in the composition, protecting surfaces from fungus and mold;

- great strength, high adhesion force to the base;

- smooth, shiny surface of the seam after drying, aesthetic appearance;

- elasticity, the ability to stretch and shrink along with the base material;

- resistance to household chemicals and other aggressive substances that may get on the seam;

- safety for humans, environmental friendliness.

Manufacturers

Among the most popular companies producing sealants, it is worth highlighting four main ones.

- Ceresit. German products with European quality, standards and practicality. The sealants of this brand are known for their best adhesion to the surface being treated, excellent waterproofing properties and the presence of special additives that protect the room from mold and germs.

- "Moment". The brand, founded by a German chemical company in Russia, has a large number of necessary construction assistants. Among them is the very popular “Moment-Germent”. A large number of varieties of sealants from this company allows any craftsman to choose his own product. Unique products include frost-resistant, high-temperature and restoration options.

- Ciki Fix. The Turkish manufacturer is also among the top four leaders in the Russian construction market. A characteristic feature of this company’s sealants is its extraordinary ability to bond surfaces of different textures together. The seams are waterproof and elastic, but do not protect against fungus and mold.

- Makroflex. Another high-quality brand comes from Germany, but with Russian production. This is a modern and timely solution to any construction and finishing tasks. The company produces a variety of sealants that cope with both internal and external use.

When choosing a plumbing sealant from this variety, the main thing is not to forget its true purpose. And we must use this construction miracle correctly with maximum efficiency.

Connection to water supply

Is it possible to put new tiles on old tiles on the floor

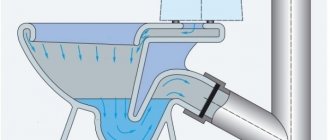

? Toilets have a different connection system to the water pipe:

- external connection,

- closed connection.

Despite the different connection methods, all joints must be sealed and prevent leaks.

With a hidden connection system, a copper tube or flexible water hose made of various materials can be used. If a copper tube is included with the toilet, then a flexible hose will have to be purchased separately.

The water pipe suitable for the toilet cistern requires special attention. It can be either with external or internal thread. If the thread is internal, then you will need to install an additional adapter and use a sealing winding.

After the connection is made, the operation of the drain tank and the possibility of leaks are checked. If everything works fine, then tighten the fastening bolts all the way and install the toilet lid.

canalizator-pro.ru

Useful tips

Plumbing materials, despite their strength, are very fragile. Therefore, maximum force should not be used when securing with screws or bolts. To reduce pressure, softening pads must be placed under the screw heads.

Important! When using glue, you need to thoroughly degrease the surface. If epoxy resin is used for fastening, the proportions of solvent and base substance are strictly observed.

The surface is covered with adhesive evenly, without the formation of bubbles.

Instead of wood, you can use high-quality multi-layer plywood as “taffeta”

It is important to ensure high-quality waterproofing so that the lining does not collapse prematurely

The best all-purpose liquid nails

Choosing a sealant for gluing and repairing an aquarium

Before you go to the store, decide on the type of liquid glue you need. It differs, first of all, in the type of glued material, price, and ease of use. Therefore, three main nominees for this category were selected. These are products of a company that has a high level of trust in the market, the most positive reviews and an affordable price for customers. 5 applicants participated in the selection, but only 3 were included in the list.

Moment Installation Express MV-50 universal

Moment liquid nails are good for gluing various building materials that are located inside the building. Best for fixing window sills and doors, installing profiles, baseboards, and decorative interior elements. Well suited for surfaces made of plasterboard, PVC material, and also serves as a good insulating layer. A characteristic feature is the absorption of moisture by at least one of the treated parts. Not recommended for use on Teflon coatings and polyethylene.

Advantages

- Not exposed to temperature changes or high air humidity;

- Suitable for many building materials, therefore it is considered a universal liquid glue;

- High adhesive strength;

- The composition contains a solvent, so the nails are environmentally friendly;

- Easily painted;

- Leftovers can be disposed of as general household waste.

Flaws

Hardens slowly.

In order for the workpiece to keep its shape, you need to fix it tightly for half an hour, and this is not always possible.

Makroflex MF 901 universal

Liquid universal nails are resistant to moisture and highly elastic. Products from the USA occupy leading positions and top the ratings of top quality products. Price and good technical performance bring Macroflex to the highest level, and if you add frost resistance and the ability to work both outside and inside the house, you get the perfect combination.

Advantages

- Versatility;

- Affordable price;

- Wide combination with multi-profile materials;

- After hardening it becomes non-flammable;

- It sets quickly and holds the glued surface firmly.

Flaws

- After just 10 minutes, it will be impossible to correct the glued parts.

- For high-quality gluing, you need to unstick the parts after 35 minutes, and then finally connect them.

Reviews say that this waterproof glue bonds well to wood. Resistant to moisture, they can be applied even to dried wood. Elasticity allows us to talk about reliability under strong vibration.

Kraftool craft Nails Premium KN-901 super strong

The products of the German manufacturer, which are packaged in Poland, are one of the strongest in their category. These liquid nails are characterized by a high degree of bonding of heavy materials used in construction. Craft Nails Premium super strong is not afraid of frost down to -30 degrees, and also tolerates heat up to +50 degrees.

The glue allows you to reliably glue the most problematic materials, such as brick, concrete, wet or frozen wood, metal and even slate. The highest level of adhesion helps to quickly bond heavy elements and not worry about the durability of the connection. Together with the affordable price, this is the main advantage of the product.

Advantages

- Water resistance, high grip strength;

- Convenient packaging in a soft 300 ml bottle;

- Withstands high loads;

- Resistant to sudden temperature changes, tolerates both heat and extreme cold;

- Easy to use;

- Does not require special skills to operate;

- Elastic, very durable.

Flaws

- Due to the rapid setting, after 5 minutes it is impossible to adjust the positions of the glued elements;

- Difficult to find in the market.

How to glue a toilet to ceramic tiles – Home Plumber

Choosing a flush cistern for a toilet: how not to get lost among the many models

In order to avoid cutting the tiles, when laying them on the floor in the toilet, the toilet bowl must first be dismantled. If a heated floor system is provided under the tiles, then further installation using fasteners that require drilling is undesirable. It is necessary to glue the toilet to the ceramic tiles. For this, certain adhesive mixtures are used.

Preparing to install a toilet on tiles

Before the gluing process, prepare the surface:

- The toilet is placed at the intended installation location and outlined with a marker.

- Draw out sewerage and cold water pipes. Provide for the pipes to exit above the surface up to 15 cm. This is necessary for a high-quality connection of the pipes with the toilet itself. This should not be neglected as a poor output will lead to the problem of poor connection and system build-up.

- The plane of the tile is sanded to give it roughness. The source material will stick better to such a plane. The same procedure is done with that part of the toilet that will be in contact with the floor. On which glue is applied.

- The floor surface and rim of the toilet bowl are cleaned of dust and degreased. To do this, use white spirit or a similar degreaser.

- To avoid applying excess glue to a clean surface, seal the outer side of the marked one with masking tape or regular tape.

Which glue to choose: review of the best

Gluing plumbing fixtures to tiles is done using silicone, liquid nails, special mixtures, and epoxy.

When using liquid nails, you should take into account the fact that subsequent dismantling of the product is difficult.

Gluing to silicone is less safe, since using only one product will lead to displacement of the product and possible damage. The quality of the installation depends on the product purchased and the skill of the installer. But this mixture allows for the fastest installation without difficulty or damage.

Gluing with epoxy will take a little time, but will be difficult to dismantle. Removable plumbing fixtures and tiles are damaged.

When choosing a silicone sealant, its components are taken into account: acetic (has an odor, low price), neutral (suitable for any materials, high price). The advantages of this product are: ultraviolet resistance, high adhesion of plumbing equipment, heat resistance, seam flexibility, beautiful surface. These include:

- Ceresit Sanitary sealant - suitable for sealing bathrooms and other equipment used in wet areas. Provides good grip. Prevents the spread of fungus and mold. UV resistant, long service life, flexible. Before application, the surface must be cleaned for better adhesion of the material to the base.

- Baumit Silicone is resistant to ultraviolet radiation, prevents the spread of fungus, the temperature used is from 5 to 35 degrees. Designed for interior plumbing and tiling work. Heat resistant. Available in a 310 ml tube.

When choosing liquid nails, their components are also taken into account: acrylic (water emulsion), neoprene (organic dyes). When choosing for a toilet room, preference is given to neoprene. It has a toxic composition, but is more durable for gluing. Liquid nails are impermeable to water and resistant to mechanical stress.

Liquid nails set quickly, so when installing, do not hesitate to make adjustments.

Liquid Nails Review:

- Belife is a unary polyurethane mixture. High initial grip strength. Environmentally friendly.

- LIQU >

Epoxy mixtures glue the surfaces of any materials. Adhesion is ensured by the ability of the mixture to penetrate into the structure of the materials being bonded. The compositions are available in several versions: transparent, heat-resistant, viscous liquid; paste; powder. Famous brands:

- EAF – two-component, low shrinkage, high strength. Used in damp areas. Affordable price, quality.

- Moment - has heat resistance, seals, glues and glues different surfaces. Plastic mixture. The dried component can be painted, polished, drilled.

- Contact – applicable in rooms with high humidity. The hardening time is up to two minutes, so the installation of plumbing fixtures is carried out immediately as accurately as possible, there is no time for corrections.

Which glue to choose: review of the best

Gluing plumbing fixtures to tiles is done using silicone, liquid nails, special mixtures, and epoxy.

When using liquid nails, you should take into account the fact that subsequent dismantling of the product is difficult.

Gluing to silicone is less safe, since using only one product will lead to displacement of the product and possible damage. The quality of the installation depends on the product purchased and the skill of the installer. But this mixture allows for the fastest installation without difficulty or damage.

Gluing with epoxy will take a little time, but will be difficult to dismantle. Removable plumbing fixtures and tiles are damaged.

When choosing a silicone sealant, its components are taken into account: acetic (has an odor, low price), neutral (suitable for any materials, high price). The advantages of this product are: ultraviolet resistance, high adhesion of plumbing equipment, heat resistance, seam flexibility, beautiful surface. These include:

- Ceresit Sanitary sealant - suitable for sealing bathrooms and other equipment used in wet areas. Provides good grip. Prevents the spread of fungus and mold. UV resistant, long service life, flexible. Before application, the surface must be cleaned for better adhesion of the material to the base.

- Baumit Silicone is resistant to ultraviolet radiation, prevents the spread of fungus, the temperature used is from 5 to 35 degrees. Designed for interior plumbing and tiling work. Heat resistant. Available in a 310 ml tube.

When choosing liquid nails, their components are also taken into account: acrylic (water emulsion), neoprene (organic dyes). When choosing for a toilet room, preference is given to neoprene. It has a toxic composition, but is more durable for gluing. Liquid nails are impermeable to water and resistant to mechanical stress.

Liquid Nails Review:

- Belife is a unary polyurethane mixture. High initial grip strength. Environmentally friendly.

- LIQUID NAILS LN-901 – used for interior and exterior work, in rooms with high humidity. It is acceptable to make adjustments within 10 minutes. Heat-resistant, can withstand temperature changes from -29 to +60 degrees. Complete drying is achieved within a day. Versatile, durable, light, easy to use, resistant to mechanical stress.

- Titebond Multi Purpose is universal and has significant technical properties. It has a viscous consistency and light beige color. The hardening time takes up to half an hour, then the parts can no longer be separated. The composition is moisture-resistant, frost-resistant. Disadvantage: toxic pungent odor. The work must be carried out using IZ.

Right choice

You can find silicone sealants on sale in different packages: cartridges, tubes, sprays. The cheapest ones are the usual formulations in tubes that have an elongated spout. Cartridge sealants require the additional purchase of a special gun. They are usually purchased for processing large areas.

Silicone sealant must not only be used correctly, but also purchased with a serious approach to the issue. To begin with, you should choose a composition that matches the color, although most often craftsmen prefer transparent or white products. There are also several other factors to consider.

Best before date

Sometimes sealants with expiring shelf life are sold at a large discount. You should not be fooled by tempting offers: usually the products are thicker, less elastic and may partially lose other beneficial properties, especially fungicidal ones.

Undamaged packaging

If there is even a small crack on the body of the product, it will quickly dry out from contact with air. When purchasing, you need to make sure that the integrity of the tube or other packaging is completely preserved. After uncorking, you need to cover all areas that require this in literally 3-4 days, otherwise the sealant will begin to dry.

Firm

Reliable, proven brands produce high quality products. The best proven sealants are Titan, Knauf, and Soudal. The downside is their higher price, because a well-known brand always has a slightly inflated price for the product.

Place of purchase

Sealants are sold everywhere, even in supermarkets. You should not buy them second-hand on the market; for this there are specialized departments or construction and hardware stores, where the goods are probably not expired.

Silicone sealants

When planning a bathroom renovation, choosing a composition, you need to know which sealant is best suited for working with plumbing fixtures.

Acrylic

There are waterproof and non-waterproof compounds. Both types are safe to use, have a choice of colors and adhesion. Despite their positive qualities, they are preferable to use for working with wooden surfaces (doors, frames, jambs, furniture).

We invite you to familiarize yourself with Flexible hoses for faucets and toilets

Polyurethane

Polyurethane-based compounds are durable, wear-resistant and elastic materials. Due to toxicity, they are not recommended for interior use.

Bituminous

Sealing agent based on bitumen. Such compositions are adhesive to dry, wet roofing materials (tiles, bricks, wood, aluminum and steel). They are UV resistant. They are used for filling roof seams, voids, gluing bitumen shingles, sealing gutters, chimneys, and ventilation ducts.

How to properly install a toilet on silicone

There is quite an active discussion on construction forums about how to install a toilet with silicone, and whether it is worth doing. There are plenty of both opponents and followers of this opinion. In fact, the toilet will stick, and it can even be used for its intended purpose, but silicone is designed specifically for sealing seams, and therefore its strength in a frozen state leaves much to be desired. It is more suitable for such cases as the need to seal a crack in the toilet. to prevent its further destruction.

If you are not sure that the toilet will be used carefully, and with small children it is simply impossible to be sure of this, it is better to choose a special adhesive composition for plumbing fixtures and components. It’s not every day that a situation arises when you need, for example, to stand on the toilet with your feet, but if this is necessary, the silicone will not withstand such a load.

As practice shows, installing a toilet without bolts is less time-consuming compared to installation work on installing a toilet using special fasteners. Moreover, if you don’t have a drill or a special drill bit to make holes, then glue allows you to quickly and efficiently install plumbing fixtures. The glue will dry in 12 hours, and the toilet can be used. If the plumbing is used carefully, there is no difference in fastening, so the method of fastening the pedestal must be chosen individually.

Advice from the experts

Experts advise placing the toilet (if possible) at a minimum distance from the sewer pipe, since in this case the corrugation stretches less and, therefore, sag less. A stretched pipe becomes deformed, deposits accumulate on its walls, which pull it down - this leads to potential blockages. There are times when it is impossible to dismantle a sanitary fixture. In this case, you can simply cut off the old plastic pipe with a knife and replace it with a new one.

Some disadvantages of a corrugated toilet pipe should be noted: it is easy to damage from the outside and inside. In the first case, this can happen from any mechanical impact, and in the second, from a sharp object, such as a piece of glass, being flushed down the toilet. Despite the fact that plastic is considered resistant to aggressive environments, exposure to various chemicals that are part of cleaning products still destroys it over time. From an aesthetic point of view, the corrugation does not look very nice, because unpleasant deposits inside are visible through its walls.

Open toilet installation sequence

Compared to the time and effort required with the closed method, the open method requires much less. But if you look from the aesthetic side, it is worse, due to the fact that the fasteners are visible from the outside of the toilet walls.

Do-it-yourself installation of a toilet with sealant using an open method is carried out in the following sequence:

- You need to place the toilet in the required place. It is also recommended to connect it with corrugation to the sewer pipe in order to calculate the location as accurately as possible. Toilet with sealant

- Using a pencil, make marks where the bolts will be located. Here you need to keep it level so that the holes do not move.

- You also need to circle the base of the toilet around the perimeter. This is where the sealant will be applied.

- Set the toilet aside and make sure everything is exactly the right size using a tape measure.

- Scratch the tile glaze with a core. This will make it possible to install the drill so that it does not “float”.

- Holes through the tiles are made with a glass drill. Be sure to turn off the impact mode in the drill or hammer drill so as not to break the tiles.

- Once you reach the concrete, change the drill bit with a pobedit tip and turn on the rotating impact mode on the tool. Carefully drill holes to the size of the fasteners (anchors or dowels).

- Thoroughly clean the holes from dust and debris. Seal them with sealant. It will act as a waterproofer to prevent water from accidentally penetrating under the tiles, and will more securely secure the elements in the holes. It is imperative to ensure that water does not get into the holes made, since then the sealant may simply not set and the seal will be destroyed.

- Along the contour that was outlined earlier, it is also necessary to apply sealant to avoid moisture getting under the base. Installing the toilet on the fasteners

- Place the toilet in exactly the right place and insert the fasteners. If everything is done correctly, they will go in without problems. It is advisable to place a plastic or rubber gasket between the head of the dowel or anchor so as not to overtighten and damage the base of the toilet. Tighten the nut or self-tapping screw. It is also recommended to use special plugs to prevent water from entering.

After installation, it is also advisable to immediately remove all excess sealant with a regular rubber spatula. When working with drills, try not to overheat them, as there is a high probability of “burning” them, which can lead to complete failure. This completes the installation of the toilet on ceramic tiles using the open method.

From plastic surfaces

The easiest way to remove sealant is from plastic building materials. All you need to do is buy Dow Corning OS-2. The liquid does the job well and does not damage the plastic.

To clean plastic coverings with this product you need to:

- treat the surface 30-40 minutes before removal;

- after the silicone becomes like jelly, it can be removed with a spatula, spatula or scraper;

- Wipe the plastic with a clean cloth.

Remove greasy marks with dish soap or plain soda.

Standard methods for attaching a toilet to the floor

How toilets were installed before. A piece of board was fastened to the floor, and the toilet was bolted to it through special holes in the platform. The wood was covered with cement and then painted over. So the wood did not rot. The floor was either painted or tiles were laid around this pedestal. By today's standards, the appearance is “so-so.”

For bolts/screws/studs

According to more modern standards, installation of a mortgage board is not required. You can attach the toilet directly to the floor. Concrete or wood - it doesn't matter. In the current SNiP 3.05.01-85 there are two ways to attach a toilet to the floor: with screws and glue. When using screws, the sequence of work is as follows:

We choose a place for installation, install the outlet in a riser or drainage pit, and connect it. Using a pencil or marker, mark the installation locations of the fasteners. What is needed is not a dot, but a circle, which should accurately show the edges of the hole

It is important. Holes are drilled in the floor at the mounting location

Their size is a couple of millimeters smaller than the size of the fastener

Holes are drilled in the floor at the mounting location. Their size is a couple of millimeters smaller than the size of the fastener

If there are tiles on the floor, take a special drill of the required diameter. It is also called “feather”. To prevent the point from slipping, you can punch the center of the mark (take a punch and hit it lightly with a hammer). The depth of the hole is equal to the length of the bolt. A rubber gasket is placed under the toilet pedestal. Bolts (or studs) with spacers are installed in the holes for fasteners, the fasteners are tightened one by one until they become immobilized.

The most unpleasant thing about this procedure is the rubber gasket. You need to find thin rubber, then cut a gasket out of it exactly to size. To prevent the rubber from glowing in the gap, coat the perimeter of the pedestal with sealant. If the toilet is white, it is better to use white sealant. Just choose a plumber. It comes with anti-mold additives, so it shouldn't turn black.

For glue or sealant

According to building and sanitary standards, the toilet can be glued to the floor. There are fewer requirements when installing with adhesive. There are only two of them:

- The temperature is important - not lower than +5°C.

- After gluing, the toilet bowl must remain stationary for 24 hours.

This is what is written in SNiP

In practice, it is important that both the floor and the toilet pedestal are level. So that when simply placed on the floor in the intended place, it will stand tightly and not wobble. If there is even a slight play, you will have to put it on bolts

If there is even a slight play, you will have to install it on bolts.

Another important thing: before using glue, you need to clean the floor and bottom of the toilet, degrease and dry. And then apply the adhesive composition to the sole. And the holding time in a stationary state must be checked according to the instructions for the glue

And also, more often they use sealant rather than glue. It is able to hold the earthenware in place and also seals the joint to the floor at the same time. So no additional sealing measures are required

And the holding time in a stationary state must be checked according to the instructions for the glue. And also, more often they use sealant rather than glue. It is able to hold the earthenware in place and also seals the joint to the floor at the same time. So no additional sealing measures are required.

How to do it right

The sequence of work when installing a toilet with sealant (glue) is as follows:

- Choose a location and install a drain into the sewer.

- Position the toilet so that it does not wobble.

- Trace around the pedestal with a pencil. We draw close to the edge.

- We turn the toilet over and clean the rim of the pedestal from sagging and possible dirt. You can scrape it with a knife or use fine sandpaper. Clean with a rag, then degrease.

- We clean and degrease the circled area on the floor.

- We apply silicone from the tube along the contour that we traced on the floor. The strip must have no gaps.

- We install the toilet from top to bottom.

- We immediately pick up the squeezed-out silicone. We level it until it dries. You can do this by wrapping your finger in cellophane. We simply take a thin packaging bag and use our finger as a tool, moving the film as it gets dirty.

- Leave it unmoved until polymerization is complete (look at the packaging).

How well does a glued toilet hold up? If the installation conditions have been met, it is difficult to tear off even during dismantling. There were no cases of “accidental” separation. And to remove the toilet, you need to cut the sealant and rock the earthenware, gradually lifting it off the floor.

Required Tools

The following tools are useful for cleaning hard surfaces:

- sponge;

- brush;

- knife (special corner knife, shoe knife, stationery knife);

- sandpaper;

- screwdriver;

- steel wool, usually used for pots;

- plastic scraper.

The sealant is heated with a construction hairdryer and then the softened material is removed with a plastic scraper. The method is ideal for mirrors, glass and aluminum surfaces.

While working, pieces of cellophane or bags will come in handy. With their help, you can easily get rid of dirt on your hands within a few minutes.

Button jamming

In case of such a breakdown, the drain is fixed in one position. That's why the toilet tank leaks. What to do in this situation? The cover is removed and it is checked why the mechanism is jammed. The drainage mechanism is often checked for the following reasons:

- System clogged. Cleaned from plaque.

- The rod is jammed. The cause of the jam is identified and eliminated. If necessary, replace with a new one.

- The return spring has weakened (the connecting ring on the lever has become deformed). To be replaced.

- The traction system is broken or deformed. It can be made from improvised means, for example, wire. But this will be a temporary solution to the problem. Because during subsequent use the wire will bend over time and you will have to repeat the procedure again.

Of course, before eliminating the breakdown, you should turn off the water supply system and drain the liquid from the drain tank.

Water supply

A common problem with the appearance of puddles near the toilet is the depressurization of the connection between the water pipe and the tank fitting. In modern models, plastic components are found. Therefore, during operation, the threads can wear off and thus the seal is destroyed.

This problem can be resolved very simply. Shut off the water supply with a shut-off valve. The hose is twisted and flax or fumlent is wound onto the thread. Screw it back. If the leak stops, the problem is resolved. If not, then you should repeat the procedure, increasing the layer of sealing material. Another reason could be a crack in the plastic fitting. In this case, it should be replaced with a new one.

Application when installing a toilet

In order for silicone sealant to display its properties as effectively as possible when installing a toilet and to retain them for as long as possible, it is necessary to follow a number of rules.

- The intended installation location must be dry and clean

- To ensure accurate distribution of the sealing composition, the base of the toilet is outlined along the contour on the floor. In this case, experts recommend covering the surface around the contour with construction tape.

- Anchor holes drilled in pre-marked places for installing a toilet are filled with sealant to prevent water from getting under the flooring

Cleaning clothes

How to dissolve sealant from fabric? In case of fresh contamination, you must immediately remove clothing and place it under running hot water.

Cured sealant cannot be removed from things without a special solvent. Aggressive chemicals can damage the structure of the fabric, so you need to do a test on an inconspicuous area of clothing. You need to saturate the contaminated area with solvent and scrub it with a brush after 20-40 minutes. Afterwards, wash the item as usual.

If after the test it turns out that you cannot use a solvent, then you need to clean the item as follows:

- spread the material on the table (ironing board);

- stretch slightly;

- with great care try to remove the contamination with a scraper and the blunt edge of a knife;

- wipe oily traces with vinegar, alcohol, having previously performed a test for suitability for use;

- After soaking the clothes for 2-3 hours, wash as usual.

The following methods exist:

- Place the item of clothing in the freezer for 2-5 hours, then remove the silicone sealant with a scraper.

- Apply hydrogen peroxide to the stain until the stain is removed.

What kind of cistern do you have?

The correct installation of a toilet cistern directly depends on its type. The division into types corresponds to the location and method of installation of the equipment.

There are three main types:

- The element of the toilet set located below is a compact toilet. The toilet bowl has a wide shelf to which the drainage container is mounted. The water is released by pressing a lever or button.

- Autonomous. It is located at the top, suspended from the wall, and is connected to the toilet using a drain pipe. To drain the water, you need to pull the chain (or rope) hanging down.

- Built-in. A special model designed for wall-hung toilets. The toilet is attached to the wall, the water tank is located inside it. Draining is done by pressing a button in the wall. To save water, use two buttons: for complete or partial drainage.

Installation of a toilet cistern-compact

Before installation, you should prepare the necessary parts:

- drain fittings that will be located inside the tank;

- gasket for sealing between the main parts - the container and the toilet;

- flexible hose for connecting to a water pipe;

- a set of fastening bolts, nuts and cone-shaped rubber gaskets;

lubricant to prevent corrosion on fasteners.

The compact toilet cistern is sold as a set and, after installation, forms a single unit with the toilet

After preparing the parts, it is necessary to gradually attach the flush cistern to the toilet. A self-adhesive sealing gasket is placed on the shelf of the bowl, which will prevent leakage. A drain container is placed on it and attached to the shelf with fastening bolts, which are secured on the reverse side with nuts. The fixed tank is connected to a pipe with cold water using a flexible hose. The gasket in the washer also prevents leakage. After completing the work, you should draw water and perform a test drain. The absence of leaks and proper operation of the drain fittings indicate correct installation.

Installation of a stand-alone mounted model

The tank is located separately, installation is carried out to the top of the wall. The tank and toilet are connected to each other by a drain pipe.

An autonomous flush cistern is installed above the toilet: either at the level of the classic design, or very high - under the ceiling

Installation procedure:

- attach the pipe to the toilet, marking the location of the lower fastening on the wall;

- we calculate the height of the tank by lifting it on the pipe;

- mark the mounting points, check their horizontal position using a level;

- we attach the container with the pipe to the wall using brackets and dowels;

- connect the pipe and the toilet;

- connect the tank to the water pipe.

At the end of the work - a test test.

Installation of a tank in the wall

The built-in container comes complete with a wall-mounted toilet. The tank, made of durable plastic, is hidden in a wall made of plasterboard panels.

This set takes up less space and looks aesthetically pleasing. Often, a hanging model is purchased in conjunction with a bidet. The big plus of the built-in tank is its safety. The only negative of the whole set is the high price.

The installation of the toilet cistern ends with mounting the wall so that only the buttons on the decorative plate are visible from the outside

Fasteners for installation (mounting frame, bolts) are usually included in the kit. How to install a toilet cistern is described in detail in the installation instructions, which are also usually included. The tank is hung on the frame, then the drain volume is adjusted. Two buttons allow you to select full or partial drainage, for example 6 l and 3 l. This is designed to save water.

Leak at the junction between the bowl and the tank

One of the common reasons why a toilet joint leaks is a misalignment or damage to the gasket. If you just bought a new toilet, and there is dripping at the junction with the tank, it is due to improper installation or a defective rubber gasket.

If the toilet has already been in service for some time, the reason is probably a cracked gasket or a misalignment of the tank (for example, someone pressed hard on it from the side). It should be clear to you what to do if the joint between the bowl and the tank leaks due to the gasket - the rubber seal needs to be replaced. The algorithm of actions is quite simple:

- turn off the water supply and drain the water from the tank.

- blot the remaining water at the bottom with a sponge or rag, otherwise it will flow out onto the floor;

- unscrew the water supply hose from the tank;

- Unscrew the screws that hold the tank on the toilet shelf, after which it can be dismantled;

- unscrew the locknut that holds the drain;

- install a new gasket, coating it with silicone (gaskets differ in shape and size, so it is better to choose according to your own example);

- put everything back together in reverse order.

Fill the tank with water and make sure there are no more leaks at the junction.

Adhesives and their benefits

Gluing a toilet is easier and simpler than installing it on dowels. Using a drill can damage the tiles. Glue allows you to quickly and efficiently install plumbing fixtures with minimal financial and physical costs. There are enough options for adhesives to make a choice in favor of the most suitable composition.

Epoxy adhesive

You can buy epoxy glue ready-made in a store or prepare it yourself in strict accordance with the proportions:

- 10 parts epoxy resin;

- 20 parts cement;

- 2 parts solvent;

- 3.5 parts hardener.

The resin is heated to 50°C, a solvent is added to it, then a hardener and only at the end cement. The mass is thoroughly mixed and can be used within 1-2 hours. The adhesive provides a high level of adhesion strength.

Silicone

A common fastening method is silicone. Its advantage is that the subsequent dismantling of plumbing fixtures is carried out quickly and without significant effort. There will be no damage or chips on the tiles or toilet. But if you use only silicone during installation, the body of the plumbing fixtures may move during operation.

It is necessary to select a sealant that matches the specific installation option.

Liquid Nails

Liquid nails will help you cope with the task. The surface of the floor tiles and the connecting part of the plumbing fixtures are lubricated with the compound, connected and pressed against each other with force. Then the toilet is removed from the floor and placed on its side, kept for a certain amount of time indicated in the instructions on the packaging of liquid nails, after which the final installation is performed. After the nails harden, the structure will be strong and reliable.

Cement mortar

By choosing a cement mortar, you don’t have to worry about the reliability of the installation; the plumbing fixtures will be firmly fixed. But if you ever need to dismantle the toilet, it’s unlikely to be without damage. Overall, this option is very effective. On the tile at the future location of the toilet, small notches are made using a chisel and hammer. They are necessary for strong adhesion of surfaces with cement composition. Then the joints are generously covered with the solution, the toilet is installed and pressed into the solution. Excess cement is collected with a spatula. Allow the solution to completely harden for 12-24 hours.

Use of adhesives

One of the most versatile methods of attaching a toilet to a tile floor is gluing. Modern industry offers a whole line of products designed for reliable fixation of plumbing fixtures. Often these are simple products that are applied immediately (liquid nails, sealants); there are also two-component compositions, the most famous of which is epoxy resin.

For those who want to achieve excellent results and are not afraid of work, we can recommend an adhesive composition based on epoxy resin, which has been used for decades. Its composition:

- 100 parts epoxy;

- 20 parts solvent;

- 35 parts hardener;

- 200 parts of cement.

First, take the resin and bring its temperature to 50 degrees in a water bath. The solvent is introduced, followed by the hardener. The mixture is stirred all the time. Cement is added last. The resulting mass has sufficient fluidity; when it hardens, it firmly fixes the mating parts.

While the glue is being prepared, you need to prepare the surfaces. To do this, simply sand the base of the toilet and the tiles with coarse sandpaper. An adhesive mass is applied to the base. The layer must be at least 4 mm, otherwise it will not be possible to completely fill possible irregularities in the tiles and the base of the bowl. Place the toilet in place, press down firmly and leave until completely hardened.

Even a novice repairman can install a toilet on tiles with his own hands. The main thing is not to rush and not to forget that you are doing this for yourself. Just try, spend a little time and everything will work out, and another useful skill will appear in the home master’s collection of skills. Related article: How a toilet cistern works