An eccentric for a toilet bowl is a cuff that comes in different types, allowing installation for direct and complex connections.

When installing a toilet, it is necessary to ensure that the entrance to the sewer is sealed.

Connection requires a set of parts:

- accessories;

- float;

- siphon;

- eccentric (cuff).

Due to the design of the cuff, there is no need to use sealed means, with the exception of old cast iron communications.

An eccentric for a toilet bowl is a mandatory part when installing equipment.

What is a cuff?

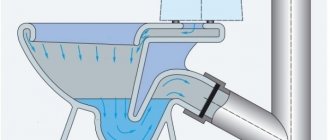

The element is made in the form of two cylinders. One of them is adjacent to the outlet of the device, the other is adjacent to the sewer pipe. Between these parts there is a smooth or corrugated internal cavity.

The part is an integral part of the drainage group adapter. The flexible hose is a pipe through which waste waste flows.

It can have a length from 25 to 50 cm, the diameter of the corrugation on the riser side is 10 cm, on the outer outlet - 13.5 cm, on the inner outlet - 7.5 cm.

The manufacturer offers several types of devices:

- rubber;

- polyethylene;

- polypropylene.

The first option is considered obsolete, as it was used mainly for cast iron communications.

Such an eccentric is short-lived, after a certain period of operation it bursts, becomes unusable, and requires replacement.

There are long and short elements for all types of installation. But when choosing, it is recommended to accurately measure the distance from the socket to the equipment so that the fastening does not work out, as this will cause leaks in the future.

Toilet outlet direction

It is not difficult to carry out minor repairs on your own; you need to know exactly the technology and procedure for connecting both external and internal parts to the sewer system. Since toilets are produced in various modifications, the cuffs also have the appropriate sizes.

In some cases, it is necessary to take into account that the outlet and the receiving part may not coincide with each other. For this purpose, offset eccentrics are made, when the longitudinal axes of cylindrical surfaces are shifted relative to the center of the device.

Since there are rubber seals at both ends of the cuff, the use of sealant is considered impractical.

Types of sealing products

Known types of sealing products differ both in their configuration and in the size and material from which they are made. Each of these signs has its own characteristics.

Seal shape

In accordance with this feature, toilet cuffs are divided into the following groups:

- oval, resembling a regular ring;

- trapezoidal seals;

- cone products;

- gaskets of complex multi-circuit configuration.

Toilet O-rings are the most common type of seal used to connect the bowl and cistern.

They are used in most classic old-style designs. In modern models, gaskets of a more complex shape, resembling a truncated cone, are usually installed.

Recently, trapezoidal seals, which look like a triangle with cut off corners, have become increasingly common in foreign-made products.

In addition to the shape of the cuffs, all of them are characterized by another important property that determines the performance characteristics of the product. It involves classification according to the type of material used in the manufacturing process. https://www.youtube.com/embed/WoI7fB1HCqo

Material

Based on this feature, all known samples of seals are divided into the following types:

- elastic cuffs, which are among the most popular and cheapest products;

- silicone blanks, characterized by increased elasticity and higher cost;

- polyurethane seals, which are the most expensive in their class.

Rubber cuffs are easy to produce and have a relatively low price. This comes at the cost of poor wear resistance and the need for frequent replacement. In contrast, expensive polyurethane products are very elastic, retain their shape well and have a long service life.

Types of eccentrics

The device is necessary when installing the toilet for the first time. But it may also be required during emergency repairs. A signal that the device is out of order is leakage of varying intensity from the back and bottom of the plumbing.

There are several reasons for failure:

- poor quality connection;

- rupture of a dried out rubber eccentric;

- broken plastic.

To connect the appropriate eccentric to the sewer, it is important to know which part is needed for a particular connection.

Toilet connected to the sewer with an oblique outlet

There are three types of cuffs:

- A straight or conical element has standard parameters and configuration. Its function is the usual connection of a plumbing fixture with a sewer system with tightness.

- An offset eccentric is designed to align the toilet with the riser when the inlet and outlet pipes are at different levels.

- Corrugation is a more complex spare part with specific shapes. It is flexible and elastic, allowing you to connect anywhere. Its versatility lies in the fact that the bowl can be moved and mounted at the required angle, regardless of the location of the internal elements.

Corrugation can be reinforced or simple. In the first case, a high level of rigidity is ensured through the introduction of anti-corrosion wire with a small diameter.

Also interesting: Plumbing repair: water is leaking from the tank, what should I do?

Silicone sealants

Silicone sealants are used to fill cracks and cavities to seal and protect against various environmental factors, as well as to glue different surfaces together.

At room temperature, the sealant hardens and turns into rubber. This sealant is waterproof!

What kind of sealant is needed for a toilet?

If the toilet is white, then it is better to use white sealant rather than transparent. The sanitary sealant contains special anti-fungal additives that prevent the appearance of fungus, mold and other microorganisms on its surface.

How long does it take for silicone to dry?

Silicone sealants are neutral and acidic. The most common are neutral, they dry for about 24 hours at a temperature of 5-40 degrees Celsius and at normal humidity. Acid sealants are cheaper and dry faster (4-6 hours).

How to remove old sealant?

The cleaner will soften the sealant and its residue can be removed either with a spatula (plastic) or a glass scraper. Instead of Soudal cleaner, you can use pure gasoline (Galosh), white spirit, vinegar + warm water. After removing the sealant, wash off its remains with soapy water and finish with clean rags + water.

Installation Features

Corrugations for the toilet bowl and internal parts are low in price, so there is no need to save in this sense. But before choosing suitable elements for connection, you should take into account the compliance of the model of the plumbing fixture and the eccentric.

Based on the location of the drain pipe directed into the sewer, three types of installation are distinguished.

Type of connection depending on design

Vertical release

This is modern equipment in which the pipe and siphon are directed downwards. It can be mounted at any angle. The work is quite simple, there is no need for the help of a specialist.

After calculations and markings on the floor, you need to connect a flange screw with a lock. A sewer pipe is inserted into the inner round hole in the center of the part.

Then the toilet is installed, turning it until it fits snugly. In this case, the outlet pipe automatically fits tightly onto the end of the communications due to the eccentric design.

Horizontal release

Features of connection in domestic systems. Involves the nuances of installation in multi-storey buildings. The earthenware is placed against a specific wall according to a traditional pattern, the same for all apartments.

To fix it in the floor, the legs of the bowl are equipped with special holes. The corrugation, directed towards the base, is connected to the sewer using a straight or conical cuff.

Custom release

An inclined connection implies a freer discharge of waste waste. This has its advantages: such toilets rarely become clogged, cleaning is done in exceptional cases, if the operating rules are violated.

Instead of one standard elbow at a right angle, two elements with a 45-degree turn are used here.

There is no need to adhere to a specific fixation point; the socket can be shifted, which does not affect the quality of connection and operation.

These types of plumbing fixtures are manufactured in various modifications to reduce splashing when draining water.

Customer Reviews

Vanya, Moscow : “The cascade eccentric came to the rescue when we bought a toilet, not taking into account the height of the drain hole: it was 6 cm higher than the sewerage inlet. Installed without problems, looks aesthetically pleasing, does not leak. No sealant was used."

Roma, Moscow : “After the expiration date, the cuff had to be urgently replaced. Previously there was a rubber one, I took a combined eccentric one with corrugation at the ends. The flexible corrugation helped to quickly deal with the problem. I protected myself with silicone sealant, no leaks were observed.”

Zhenya, Moscow : “Some are afraid that flushed solid waste may get stuck in the eccentrics due to the bends. I can say for sure that their statements are baseless. A year of using this cuff did not reveal any complaints: the flush is good, there are no blockages. Maybe they flushed something that doesn’t dissolve down the toilet?”

Connection technology

After a certain period of operation, the eccentric may fail. Therefore, in addition to the initial installation of the toilet, after a while you will need to replace the cuff.

Damaged and burst elements are unable to cope with their functions, which leads to leaks.

Easy connection

If the system is old, a straight or tapered piece will do in most cases.

The work is easy to do with your own hands, in several stages, including preparation:

- Cleaning the outlet pipe and outlet. You can use special products designed for thorough treatment of plumbing fixtures and its internal parts. It is better to choose soft compositions, without aggressive substances that can corrode the material. All devices must be degreased.

- The prepared devices must be allowed to dry, otherwise it will be difficult to achieve high-quality sealing.

- After preliminary measurements, a suitable cuff is purchased. If the pipes are old, cast iron, it is recommended to additionally treat the internal and external surfaces of the adapter with silicone acriplast.

- One part of the eccentric is put on the bowl drain. There is no need to apply force, as the seal will automatically create a maximum seal. If a sealant is used, you need to give it time to harden.

- The second end is inserted into the drain.

With correctly selected parameters and modification of the cuff, a fixed position is quite easy to achieve.

Connection for multi-level releases

If the outlet from the equipment and the entrance to the riser are at different distances from the floor, only an eccentric corrugation is suitable, since it can easily combine the two elements due to its flexibility.

Also interesting: Toilet cistern flush mechanism: device, replacement features

The installation principle is identical to connecting a straight cuff. Involves preparation, cleaning of internal surfaces and fastening.

In this case, you will need to handle the adapter carefully. When inserting, you need to bend the device carefully so as not to damage it.

Work is carried out before attaching additional elements. This will help you install the device quickly and without interference.

Connection for low tank height

In modifications of the toilet with the location of the flush equipment at a short distance from the floor, installing the eccentric will be difficult. But if you wish, you can also do it yourself.

The adapter is put on the front part of the tank attachment plate from the end of the smaller diameter, approximately a third of the length. The remaining cavity will include the neck of the bowl and the inter-end step.

In this place, careful fixation is required, for which steel wire is usually used. The corrugation must be slowly rotated and bent to the specified position.

The shelf is mounted to the toilet using fasteners.

The device is combined with the sewer outlet pipe. Despite the tightness of the internal seals, it is recommended to additionally tighten them with wire for reliability.

If the tank is low?

There are also cases when the tank is located too low. This is a problem, but not so strong that it cannot be solved.

- The first step is to put the cuff between the tank and the toilet on the end of the toilet extension shelf.

- Then, using a wire, we fix the eccentric in a stationary state.

- After this, we unscrew the rubber part and attach the attached shelf to the toilet with bolts.

- We pull the eccentric onto the outlet pipe of the sink. Using sealant, we coat the joint with it and, tightening it with wire, fasten the cuff.

- After this, you should perform a test run to make sure there are no leaks. As with any plumbing connections, the bathroom must be installed hermetically.

Recommendations for urgent repairs

If the eccentric has become unusable and there is nothing to replace it with, you can temporarily repair the device to stop the leak.

There are two options for this:

- The first involves the use of dense fabric, such as canvas or canvas. Cut a tape wide enough to cover the damaged area. The strip is impregnated with slightly thickened oil paint. Carrying out the work requires the participation of two people: the first must lift the bull, the second must wrap the material in the area of the defect formed. For strength, the fabric is secured with twine and coated with sealant. After this, the drain device is fixed with bolts. Do not use the equipment until the paint has completely hardened.

- The second option is to use a meter rubber band 50 mm wide and 2 mm thick. The strip is stretched and wound with force onto the broken corrugation. The end is secured with steel or copper wire. The advantage of this method is that there is no need to remove the adapter from the pipe. To push the tape into the inside, it is better to take a pencil or a long, smooth wooden stick. The screwdriver is useless in this case because of the handle.

Please note that both methods are temporary repairs. After a short period, you will need to purchase a new eccentric and install it in place of the damaged one.

Sequence of actions when installing an eccentric

What are gaskets for?

The toilet and cistern must become a single system after installing the hygienic device in the sanitary area. This is the only way to avoid leaks and other unpleasant issues associated with plumbing. Everything must function smoothly and clearly. This can be achieved by using a special gasket. Such a product lasts a long time (for several years), and after wear it is easily replaced.

The importance of the gasket can hardly be overestimated; when installed between the toilet bowl and the flush cistern, it provides:

- creation of one coherent “toilet-cistern” system;

- tightness of the connection of these elements;

- organizing a soft, elastic insert between two contacting ceramic parts;

- eliminating leakage problems between the tank and the toilet.

Over time, this seal loses its elasticity, cracks, dries out and begins to leak water - these characteristics are signs that it needs to be replaced. Don’t be upset – you can replace the gasket yourself, without the help of an experienced plumber.

The price of this product is also low, so you just need to decide on the appropriate type of gasket and study the sequence of installation work.

Installation of rubber seal

The rubber cuff is a short and dense element that is inserted into the socket of a cast iron pipe. This is a seal or gasket that ensures maximum tightness. In addition, this part protects the toilet from various chips and damage.

First of all, measure the diameter of the socket and purchase a seal. Most often this is a 110 mm toilet cuff. Then the product is installed in a cast iron pipe. Then you can proceed directly to the installation of the plumbing product itself.

Advantages and disadvantages

Corrugated toilet flush is in demand among consumers due to a number of positive qualities:

- easy installation: no special tools are needed, as well as extensive experience in performing such work;

- light weight of the product: installation is done by hand;

- low price;

- when displaced or in an area of complex configuration, a flexible pipe makes it possible to connect the sewer riser and the toilet outlet;

- corrugation helps to join elements of the sewerage system that do not match in diameter;

- resistance to corrosion;

- no need to dismantle the toilet;

- significant permeability due to the device: when stretched, the stiffening rings that make up the walls of the flexible pipe acquire a certain volume, which slightly increases the diameter of the product in the area between the cuffs.

Corrugation for the toilet: advantages and disadvantages.

This product also has disadvantages:

- low strength: when a sharp object, a splinter, gets into the pipe, the risk of damage to the walls increases, which may result in a leak that cannot be eliminated;

- Do not use a pipe that is too small or large, as it will sag under the weight of the contents;

- installation errors (installation at an inappropriate angle, significant bending) can lead to clogging;

- rapid clogging is also determined by the ability of the pipe to retain contaminants on the walls;

- insufficiently long service life;

- In terms of attractiveness, such a product is inferior to smooth-walled analogues;

- installation restrictions: it is impossible to cover the toilet outlet with plasterboard, as well as install it inside the floor.

The prohibition on installation in the thickness of the wall is due to the high probability of leakage. It is difficult to detect damage in time; as a result, sewage will enter the premises.

How to seal pipes

Rubber sealant for sewer pipes is used most often.

The sequence of installation work depends on whether the internal or external sewage system is being installed. When arranging an internal pipeline, installation consists of the following stages: The connection is sealed, now the pipeline is ready for operation. It should be remembered that if silicone sealant is used, it should not be applied to the outside of the sewer pipe.

If sealing of the external pipeline is required, installation work is carried out in the following sequence:

- the sealing compound is applied to the inner surface of the rubber cuff;

- the fitting is put on the pipe;

- When the sealant hardens, you can connect the pipeline.

Sealing sewer pipe connections is an important step when performing sewer installation work. It is at the joints that blockages, leaks and other unpleasant problems most often form, which help reduce the service life of the sewer system. You can prevent any problems if you follow the advice of professionals and carry out all work carefully and diligently.

In order for the sewer system to function efficiently and effectively, it must be installed correctly. It’s easier for residents of multi-storey buildings who install only an internal pipeline. But owners of country mansions will have to take care of laying external sewerage and arranging an autonomous system.

Sewage installation consists of several stages:

- drawing up a sewer system project;

- procurement of materials;

- pipe connection;

- sealing joints;

- sealing connections.

Sealing sewer pipes is necessary to avoid leaks and breakthroughs during system operation. Most often, rubber cuffs are used to seal the joints of plastic sewer pipes. Seals prevent water from getting in or out and protect the sewer from the penetration of insects and small rodents. High-quality sealed connections are a guarantee of long-term and efficient functioning of the sewer system.

Important parameters

All parts that are commercially available today differ from each other in materials, shape, and diameter. Before purchasing, you should know important nuances. So, pay attention to the diameter of the sewer pipe to which one end will be attached. The standard diameter is considered to be 110 millimeters. However, the dimensions may vary in some homes.

Also, before choosing, you should clarify what type of outlet the particular toilet has and the diameter of this hole. The second end of the cuff will be attached to it. It may happen that the sizes will not match. Then you will have to purchase a non-standard model.

Corner release

In old houses where the pipes have never been changed, the toilet is installed using a rubber cuff. This is most often a conical toilet cuff. It is connected to a cast iron pipe. If the input/output axis is shifted, then an eccentric is purchased. Suitable for smooth or corrugated tube. If there is a significant distance to the pipe, you can use corrugation, stretching it to the desired length. An eccentric is also needed to obtain a more tight connection.

The principle of installation of products made of rubber or plastic, corrugated or smooth parts is very similar. But there are some nuances. Next we will look at three options for connecting a toilet.

How to solve the problem of choice

Before purchasing a corrugated connector, you should check the dimensions of the holes with which it will be connected. The likelihood of errors will be less if you buy the corrugation at the same time as the toilet. The second important indicator is the length of the pipe. There are models of different types and purposes.

For example, for a small combined bathroom, a corrugated outlet with an outlet can be a very convenient option, allowing you to connect two objects to one sewer outlet at once. Sometimes it is more convenient to use a special rubber cuff for the toilet.

To connect the toilet to the sewer system, you can use not only the corrugation (2), but also a special rubber cuff (1) and a plastic outlet (3)

It makes no sense to purchase cheaper corrugation, since the cost of even the most expensive option is low. The connector may be a little more expensive, but it meets the expected level of quality. Imported products have good strength and durability characteristics.

Western manufacturers additionally strengthen their products with reinforcing metal wire. Such models are more rigid, they sag less and resist mechanical stress better.

To install the corrugation, you may also need the following elements:

- coupling, straight or eccentric, for connecting to the sewer pipe of the toilet, which is located right next to it;

- a pipe with a cuff or a plastic outlet intended for installing a toilet bowl, the position of which is shifted relative to the entrance to the sewer system;

- the corrugation is hard or soft, allowing you to bypass small obstacles that prevent the direct connection of the toilet to the sewer.

When choosing a suitable corrugation for a toilet, you should remember that problems can arise not only when using an element that is stretched too much. It is also not recommended to use an excessively short pipe.

Strong compression or sharp bending will soon lead to breakage.

With such a bend in the corrugation installed on the toilet, liquid will most likely accumulate at the bottom. It is necessary to change the position of the toilet or choose a different connection method