Just a few decades ago, replacing plumbing required special precision, because it was important that the sewer outlet coincided exactly with the outlet. At the moment, the problem of selecting pipe radii has been solved thanks to a product such as toilet corrugation. A large number of advantages have led to its widespread use.

What is a toilet corrugation?

This name refers to a special type of pipe that acts as a transition element in the sewer system. The corrugation for connecting the toilet is made of polymer material, which simplifies installation. Its weight is light, which allows you to install it yourself and alone. To understand the popularity of a product, you need to know its advantages:

- Low cost compared to other plumbing parts.

- Easy to install, no professional skills or tools required.

- Installation speed – operation can be carried out almost immediately.

- Practicality due to the flexibility of the body.

- The versatility of the design allows it to be used in different device models.

- Reliability thanks to rubber seals.

The corrugation for the toilet also has negative aspects of the product:

- Low mechanical strength due to the design.

- Possibility of clogging if the product is not used correctly.

What does a toilet corrugation look like?

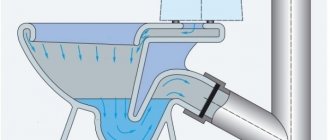

This name refers to a bend made of plastic and distinguished by its flexibility. In addition, an important indicator is the ability to stretch. They use products for installing various plumbing fixtures, selecting the appropriate pipe diameter. You need to know what parts the toilet corrugation consists of. A simple design includes several parts:

- cuff;

- corrugated pipe;

- seals.

Damage Prevention

Due to the high causticity of such products, it is necessary to observe safety precautions when working with them.

To increase the service life of a corrugated pipe, the following preventive rules must be observed:

- protect plumbing from exposure to high temperatures;

- periodically clean pipes from dirt and deposits;

- do not use potent products that contain highly concentrated acids;

- avoid mechanical damage.

A leak in the toilet, and in particular in the pipes through which it is connected to communications, is a rather unpleasant situation. However, in order to minimize the risk of its occurrence, it is necessary to pay attention to the correct installation of the corrugation, use suitable high-quality material, and follow preventive rules that reduce the likelihood of wear on the structure.

Common causes of corrugation failure

Ideally, the corrugation should be installed at a slight angle.

Various reasons lead to corrugation failure, including:

- absence or damage to the sealing ring in the socket;

- low quality adapter;

- absence or wear of the transition cuff;

- The corrugation is too inclined.

Depending on the cause of damage to the element, the appropriate method of repairing it is selected.

Types of corrugations for toilet bowls

There are different types of corrugated products on the market. To choose the right option, you should know what kind of corrugations there are for the toilet. Based on their rigidity, devices are divided into:

- soft;

- hard.

Depending on the type of coating, products are:

- unreinforced;

- reinforced with wire.

By size, toilet corrugations are divided into:

- short;

- long.

According to the direction of the bell, the products are:

- straight

– universal option; - curved at 90°

- for devices with direct release; - curved at 45°

- for connection to a horizontal socket.

- Manufacturer

. Almost all imported toilet corrugations are reinforced. - Hole size

. It is recommended to purchase the corrugation together with the plumbing fixture, which eliminates errors. - Rigidity

. This parameter is related to the material of manufacture. Plastic corrugations are softer and thinner. Reinforced pipes are rigid, but the thickness is the same. - Length

_ Here you need to focus on the distance between the drain and the plumbing. It is important not to stretch the pipe too much, as leakage may occur. - Reliability

. It is good if the corrugation for a toilet bowl with or without an outlet is equipped with reinforced wire, which will add rigidity and strength. - short corrugation for the toilet;

- long.

Dimensions of corrugations for toilet bowl

One of the important indicators when choosing is the length of the product. There are two categories:

Standard sizes that can be found on the market:

- length ranges from 230-500 mm;

- the cuff has a diameter of 135 mm;

- the size of the end connecting to the sewer socket is 100-110 mm;

- the diameter of the fastening nozzle is 50-70 mm.

Tips and tricks for use

In order for the product to last longer, you must follow some rules before installation:

- It is not recommended to stretch the corrugation too much, as this reduces its strength and wear resistance;

- It is also undesirable to pull out the reinforcement, since in the future this will lead to sagging of the product and the formation of blockages;

- Before shortening a reinforced drain, it is recommended to measure the distance to the pipe, and it is better to cut it with a small margin of length;

- when installing, it is better that the corrugated pipe channel be slightly curved - this will help water drain freely, without forming blockages or blockages;

- You should not press or put pressure on the drain or place anything on it, as the product is fragile and not designed for high loads;

- no additional elements in the bathroom should press the device, otherwise it will quickly lose its properties and fail.

These rules will help prevent premature failure of reinforced drains.

How to shorten the corrugation for a toilet bowl?

If there is no need, then it is better not to violate the integrity of the product, because leaks may occur due to future load. However, sometimes situations arise when this cannot be avoided. Straight and corner corrugation for a toilet bowl is shortened as follows:

- carefully cut off the accordion from the pipe;

- remove excess length;

- the end is installed back, running sealant along the seam;

- give time to dry;

- check the quality of joints.

When should you install a corrugated connector?

A corrugation or cuff for a toilet bowl is not always used when connecting to a sewer system. A plastic pipe is more reliable and will last much longer. But sometimes you can’t do without a corrugated connector.

For example, if it is impossible to install the toilet directly opposite the sewer outlet, or when the floor level has become higher after renovation.

The toilet corrugation can be stretched quite strongly, but it should be remembered that excessive tension reduces the strength of this element

This happens if new floor tiles are laid without dismantling the old covering. Sometimes the position of the toilet has to be changed due to rearrangement, for example, if additional elements appear in the bathroom: a washing machine, a shower stall, etc.

The corrugation is useful if the type of outlet of the new toilet does not match the existing sewer system. This problem is faced by owners of new plumbing fixtures who live in Soviet-built apartments.

The old sewer system is designed to be connected to a toilet with an oblique outlet, but in modern imported plumbing fixtures the outlet is usually made straight.

How to put corrugation on a toilet?

The installation process is simple if you follow the step-by-step instructions. Installation and replacement of the toilet bowl corrugation is carried out in the following order:

- Clean the toilet pipe, cover it with sealant and put the end of the corrugation with internal membranes on it. You need to make sure that everything is even and symmetrical.

- Give it time to dry.

- The edge of the toilet corrugation, which has external sealing rings, is connected to the pipe leading to the riser. It is important to insert it all the way. As with the other part, preliminary cleaning of debris and rust is carried out. For more reliable fixation, a sealant is additionally used.

- Leave for a while to dry completely.

- The installation of the corrugation on the toilet is completed by checking the quality of sealing of the joints. This is done by pouring a bucket of water into the toilet.

The easiest way out of roller shutters

The fastest way to solve the problem of hiding the sewerage is with the help of roller shutters. This design maximizes access to the pipes, while there are no doors cluttering the space. Hanging blinds requires no experience, and beautiful curtains do not require any additional finishing.

Plumbing roller shutters are not only beautiful, but also practical

In response to the increased demand, manufacturers produce special sanitary roller shutters, endowing them with noise-insulating and heat-saving properties. If desired, it is easy to choose a color that harmonizes with the decoration of the entire room.

How to seal a toilet bowl?

To get rid of voids, a silicone compound is used. This is done at the installation stage, the sealant is distributed in a thin strip over the seam, and then smeared over the surface. Installing the corrugation on the toilet with your own hands allows you to use the plumbing after just a few hours. When using quality products during the installation phase, reapplying sealant is more of a precaution than a mandatory process.

Sealant for toilet bowl corrugation

Among the range offered on the market, the following types are used for installing corrugations on a toilet:

- Silicone

. The most popular option, which has high resistance to humidity and temperature changes. It can be used for both external and internal application. For example, Ravak Professional and Ceresit Sanitary CS 15. - Polyurethane

. Elastic adhesive composition, characterized by strength, durability and wear resistance. Due to toxicity, it is recommended for outdoor use only. For example, Molder PU and PU 39 Bostik.

When figuring out how to lubricate the corrugation between the toilet and the pipe, we note that professionals recommend using silicone sealant. Popularity was achieved due to the following advantages of the composition:

- resistance to UV rays;

- suitability for working with all materials;

- resistance to temperature changes;

- creating protection against the appearance of fungus;

- high strength;

- resistance to household chemicals;

- environmental cleanliness.

Capital method plasterboard wall

The easiest way to hide the sewage system running in a technical niche is to use a false wall. Use plywood or chipboard as a material, but plasterboard is considered the best option. One sheet of dry plaster will be enough for the job; it must be green in color - this is what moisture-resistant drywall looks like, suitable for use in wet rooms.

A completely closed technical niche is difficult to see with the naked eye

The frame of the false wall is made of galvanized profiles (which is preferable) or wooden blocks. When marking the places where the profiles are attached, it is necessary to take into account that the distance between the partition and the riser must be at least 3 cm. First, the guide profiles are attached to the walls, then to the floor.

If you plan to decorate a plasterboard screen with tiles, then it is necessary to provide a distance between the rack profiles of no more than 40 cm. In cases where there are already ceramic tiles on the walls, drilling should be done in the joints between the tiles.

Drywall is cut according to pre-prepared drawings and attached to the frame using self-tapping screws. The finished wall is puttied and decorated taking into account your own wishes and the overall design. To make working with the inspection door easier and less noticeable, use a simple but convenient magnetic mount.

How to hide the corrugation from the toilet?

The choice of masking method depends on the size and direction of the pipelines, their location relative to each other, the presence of additional devices, and so on. After connecting the toilet to the sewer with corrugation, use one of the following methods for hiding the pipes:

- Box made of plastic panels

. A base is created from profiles onto which the plastic is attached. This method can be used when this material is present in the interior. - A plasterboard box on a frame

. The blank is made of wood, with water-repellent plasterboard attached on top. Finally, decoration is carried out with the material that covers the walls of the toilet. - Built-in sanitary cabinet

. It is a structure on the wall behind the toilet with doors. - Blinds or roller shutters

. Installed in the same way as a built-in wardrobe.

Actual work

Everything was tested, invented, materials were purchased. Now the work itself.

1. Installation of the frame.

If oriented strand board is used for cladding, then the frame is made of wooden blocks. For drywall we use a metal profile. How to cover the riser in the toilet with plastic panels? Better on a wooden frame.

- We install vertical guides according to the level.

- We attach crossbars to provide rigidity. The pitch is determined by the dimensions of the sheathing material, as well as taking into account the dimensions of the inspection hatch.

2. Sheathing.

For solid structures, plasterboard is more suitable. To create removable siding, it is preferable to use oriented strand board. She's stronger. And dismantling will not harm her.

3. Finishing.

Tile tiles are attached to the casing using glue, and plastic panels using staples. You can simply putty and paint.

If highly visible communications located in the bathroom spoil the interior of the room, then this is not a problem. Find out how to close the riser in the bathroom and get to work.

To avoid having to mask numerous and long pipes, draw up a diagram of all communications in advance and try to arrange them and plumbing so that, in the end, all utilitarian details remain as unnoticeable and hidden from view as possible. But this is not always possible, and often it is simply impossible to completely hide a boner. But such a problem is not as difficult as it seems if you know how to solve it.

How to clean the corrugation of a toilet bowl?

There are situations when the sewer becomes clogged, which is especially true for old buildings. Clogs form due to the accumulation of hair, dirt, grease, or insoluble detergents. Flexible and rigid toilet corrugation is cleaned in the following ways:

- Plunger

. It is installed as close as possible to the drain and pressed several times. A plunger can easily remove a small blockage. - A folk remedy is a mixture of soda and vinegar

. Proportion 1:1. Pour in the dry ingredient, then pour it in and give it a few minutes to react. Finally, use a plunger. - Chemicals for cleaning drains

. The product is poured inside, as described in the instructions on the package. The process takes up to 5 hours. - The resulting fossils are removed using a metal cable

. It is placed in a pipe and begins to rotate, moving deeper. - Remove the corrugation

. Shut off the water, place a deep container under the pipe, remove everything and clean it mechanically.

Tighten loose bolts

Another reason when a toilet leaks at the junction is the loosening of the tank mounting bolts. They are usually metal or plastic. While the former can rust and break, the latter simply burst over time due to static load or if someone rests on the tank.

The problem is solved by replacing the bolts with new ones, and to do this you need to proceed as follows:

- turn off the water supply to the tank and empty it;

- unscrew the flexible supply hose;

- remove the bolts (if they are rusty, this will not be easy, but be careful not to damage the fragile tank);

- insert new bolts with spacers into the holes and tighten (just do not overdo it).

If it is still leaking at the joint, you will need to tighten the bolts a little more to seal the toilet. The main thing is not to squeeze it so that nothing bursts or cracks.

Why is the toilet bowl dripping?

Sometimes situations arise when all the work was carried out at a high level, but problems with leakage are still present. The reasons why the toilet bowl drips may be as follows:

- The product is of questionable quality and does not adhere well to the pipe, forming unwanted folds.

- The skirt at the cuff is not straight, but cone-shaped. This is a problem that can only be corrected by replacing the corrugation.

The toilet bowl is leaking - what to do?

When plumbing malfunctions, it becomes the source of a large number of problems. To prevent the smell of sewage that leaks from being absorbed into the floor surface, you need to know what to do if the toilet bowl leaks. Before starting repairs, an inspection is carried out to identify the problem and only then a decision is made on how to correct the situation. The causes of leakage may be the following situations:

- pipe rupture;

- poor sealing of joints.

The corrugation for the toilet bowl is repaired according to the following scheme:

- The crack is dried and covered with a rubber patch. To do this, use only waterproof glue.

- You can soak a bandage in a cement mixture and wrap it around the pipe.

- The loose fabric is treated with sanitary silicone and placed on the toilet outlet.

Hiding sewer lines in the toilet

Preparatory work

Ways to hide pipes in the toilet

What is better to choose

Plumbing communications are unlikely to decorate the interior, so many during renovations wondered how to close the pipes in the toilet. We offer several ways to preserve the beauty of the room and not lose access to the water supply structure.

How to disconnect the corrugation from the toilet?

Despite the durability of the product stated by the manufacturers, there are cases when the corrugation for the toilet flush requires removal. There are different ways to remove it:

- Maximum stretched

. Remove it from the toilet pipe, and then from the sewer pipe. This sequence helps to easily remove remaining water. - Corner location

. Use the arc rule. Disconnection is carried out as in the previous method. - Maximum contracted state

. In this case, you will need to remove the toilet initially. Then the corrugation is disconnected, as in the previous versions.

Space saving hiding box

The wall completely covers the utility part of the room, but noticeably reduces the usable area. In order to save space, as well as to cover protruding risers, build a concealed box, hiding the sewer pipe. Making a frame for the box will be a little more difficult, since you will have to tinker with the corners. A strong corner can be easily obtained from two ud-profiles fastened together, with the shelves directed at right angles.

Depending on the location of the elements that need decoration, the protection system can be triangular or tetrahedral. When there are many protruding parts below, and only a riser is located at the top, you can build a multi-level box. This will create more space and create an additional shelf for storing small items.

Choose galvanized profiles for the frame. For a separate toilet, where the humidity is significantly less, it is allowed to use wooden blocks.

Features of silicone sealants

To glue the toilet to the floor and seal its base, it is worth purchasing a silicone compound. This is a one-component, one-pack product that seals all seams, cracks, defects, and holes as reliably as possible. Silicone sealants are divided into several types.

Acetic or sour

These sealants belong to the “economy” category: they are available, cheap, and quite reliable. One of the disadvantages is the sour smell, which indicates the presence of acid in the composition, so sealants cannot be used on marble and aluminum due to the risk of damaging the latter.

Neutral

Such products are based on alcohol components and metal oxides, which make them much stronger. They are suitable for any materials, do not damage them, but are an order of magnitude more expensive than the previous ones.

Sanitary

The sanitary category includes a group of silicone sealants that are used in residential areas. They do not contain toxic components, they have a minimal percentage of shrinkage, so the seams remain tight and durable for a long time. Due to their elasticity, the products are suitable even for moving joints and assemblies. Often plumbing fixtures are installed on them, including toilets, a substrate is installed, and joints are sealed with them.

Among other things, sealant can be used to fill tile seams where they are exposed to water, close the joints between structures and the wall, fix small glass items without bolts, and additionally secure mirrors.

Connection to plastic sewer pipe

Modern construction technologies involve the use of plastic pipes for sewer systems. And the question often arises about methods of connecting the toilet to the plastic part of the sewer system.

Types of connection of plastic pipe elements:

- Gluing method. This method involves connecting two parts of different diameters using special glue. But the difference shouldn't be big. The method involves degreasing the surface of the parts to be joined, then applying glue to the smaller part and inserting it into the larger one. Excess glue comes out of the gaps between the two parts.

- Application of welding technology. This installation method requires a professional approach. This method of connecting to a sewer riser involves the use of special equipment that heats plastic elements. The parts are heated, then pressed tightly against each other until the seam cools completely.

- Method of using fittings. This method requires the purchase of additional parts that are used to connect plastic elements.

Installation procedure

The operation of replacing a flexible fitting on a toilet consists of the following steps:

- removing old corrugation;

- preparing seats for installation;

- installation of a new flexible pipe;

- sealing joints from the outside.

How to remove the old connector

If the sewer system is installed from plastic pipes, then removing the worn-out corrugation is easy, even in a situation where this needs to be done without dismantling the toilet. To connect the fitting to such a fan system, additional sealants are rarely used, and dismantling the adapter is reduced to elementary operations.

First of all, you need to shut off the flow of water into the toilet and empty the flush tank. Removal of the fitting begins from the side connecting to the sanitary fixture. The corrugated section is compressed towards the sewer, after which the cuff is pulled off the toilet flush and the other end of the product is removed from the socket.

When the toilet is located close to the inlet neck, and the corrugation in the working position is already compressed, then to simplify dismantling it is cut across. If the old cuff does not pull off the pipe, it can also be cut with a hacksaw blade for metal.

On a cast iron fan system, the place where the corrugation is connected to it can be additionally coated on the outside with a layer of cement mortar or other sealing compound.

Here, when removing a fitting, only those methods are good that will not cause harm to the toilet - the solution can be carefully crumbled using a plumber's screwdriver and a hammer, and the silicone can be cut with a narrow knife. After exposing the connections to the sewer and toilet, the fitting is dismantled, and the opened seats are thoroughly cleaned of old seals and sealants, otherwise their fragments will interfere with the tightness of the new connection

After exposing the connections to the sewer and toilet, the fitting is dismantled, and the opened seats are thoroughly cleaned of old seals and sealants, otherwise their fragments will interfere with the tightness of the new connection.

How to install

Install the corrugation in the reverse order.

The pipe with transverse sealing rings is inserted into the receiving neck of the pipe. It would not be superfluous to apply sealant to the rings before this - this will protect against leakage when the riser on the lower floors becomes clogged. The folds of the fitting are pressed against the socket, after which the cuff is combined with the toilet flush and pulled onto the pipe - this will be easier to do if the rubber seal is lubricated from the inside with a soap solution.

With sewage systems made of cast iron pipes, the operation is complicated by the fact that the connection point to it most often needs to be additionally sealed or a special adapter installed from cast iron drain fittings to plastic ones.

How to shorten a corrugation

Sometimes it happens that the model of flexible fitting you like in the store is longer than necessary. The way out is to shorten the corrugation with your own hands, and this is done as follows:

the flexible part of the pipe is pulled out of the cuff (the factory connection is adhesive), and the vacated mounting groove is cleaned of glue residues;

- the fitting is tried on in place and a transverse cutting line is marked on the side of the free end;

- excess length is cut off from the pipe (in reinforced products, cut through the wire running in the folds of the corrugations in a spiral);

Fill the mounting groove of the cuff with sealant and insert the resulting end of the pipe there;

After the compound has cured, the corrugation is ready for installation.

After the flexible adapter is installed, to reduce the likelihood of leakage, you need to coat the outside joints of the cuff with the drain and the outlet end with the neck of the sewer with sealant. This will not make the corrugation stronger, but will increase the tightness of the connections.

Installation errors

The list of mistakes that are made when installing corrugations for toilet bowls is small, but all of them are fraught with troubles in the future:

Carelessness in arranging joints and neglect of additional sealing.

Excessive stretch of pipe in working position.

It increases the tensile load and over time leads, at a minimum, to sagging of the adapter, and rupture of the corrugation is not excluded.

Excessive compression of the corrugated part.

It complicates and sometimes makes it impossible to replace the fitting without dismantling the toilet.

Sharp corners in the pipe configuration after its installation.

Sharp bends cause blockages and destroy the corrugation on the outside of the bend.