Faucets - devices that allow you to regulate the flow and temperature of water, consist of a large number of parts, each of which performs a specific function. In such a system there cannot be any unnecessary or insufficiently important elements, and a part such as a nut ensures the functionality of the entire valve as a whole.

Tips for selecting nuts

If you need to find a nut separately due to loss or damage to the complete one, then you should not forget a couple of simple rules:

| The best selection option is by example | It goes without saying that if you have an old element, then buying a new one instead is much easier. It is enough to compare two products and make sure that they have similar parameters and are interchangeable. But not always an example is at hand, so it is possible to take with you a faucet part that requires a fastening element |

| Study the quality level | If there is no example, then you need to take measurements very carefully and meticulously, and when choosing, select the option that is made better: there are no burrs on the thread, it is rolled evenly and carefully, there are no stains or cavities on the surface. Every little thing matters, because it is possible to draw conclusions from it about how well the element is made |

| Consider the type of tap cover | Putting a copper nut on a chrome-plated structure, as well as the opposite, is not the best solution, since it does not look very attractive. It goes without saying, this point does not apply to cases where the fastening is hidden and simply will not be visible; in such a situation, any color will do |

Advice! Another reason that speaks about the quality of the product is its mass. High-quality options weigh much more than fragile elements made of powder alloys, so it is better to choose those that are heavier.

What to look for when choosing

Since the gander is an integral and far from the most important part of the mixer, the faucet itself is chosen first, paying attention to the following factors:

- The material used to make the vast majority of faucets is brass; copper is sometimes found; the cheapest models are made from stainless steel, but they are visually different from the two previous ones with chrome plating due to their less intense metallic luster. To find out exactly what a chrome-plated faucet is made of. Look at the inner surface of the non-chrome-plated fastening union nuts or gib, in which the aerator is first unscrewed. Compared to copper ones, preference should be given to more durable brass faucets.

- If you plan to use separate faucets for the bathtub and washbasin, it is better to purchase a model with a fixed gooseneck to fill the bowl - this will prevent leaks due to abrasion of the gasket at the point where the tube is attached to the faucet body.

- It is clear that if you have a washbasin in a bathroom without a mixer, choose a model with a long swivel spout. Before purchasing, you should determine the middle distance from the center of the bathtub on the wall to the sink drain hole and select the length of the gander accordingly. If the distance from the bathtub to the sink is too large and it was not possible to find a mixer with suitable parameters, the faucet body is shifted from the bowl towards the sink so that its aerator is located above the drain hole of the washbasin.

Faucets made of different materials

- When purchasing, you can unscrew the aerator in the spout and look at the thickness of its walls, comparing it with other models - the larger the cross-sectional area of the tube, the more reliable the selected faucet is in operation.

- The diameter of the spout does not matter much and can only be important if the user has a rare habit of filling the bath faster. Typically, the circumference or perimeter dimensions of all jibs are standard and correspond to the internal channels of faucets from specific manufacturers. Expensive models of wall-mounted mixers from German manufacturers (Hansgrohe, Grohe) of the avantgarde, hi-tech styles have the highest passage channels of the ganders.

- When choosing a suitable spout from any manufacturer, you should keep in mind that the vast majority of expensive or cheap models are made of brass with a chrome finish. In not a single budget Russian or Chinese gander will the chrome coating peel off from the brass, and the metal will not rust over decades of use. Therefore, there is no point in overpaying for a product from a more well-known brand if a similar cheap one is practically not inferior to it in terms of technical characteristics.

Structural design of bath and washbasin faucets

Types of products and basic installation tips

As noted above, the design may contain different nuts; we will consider the most popular of them, since the number of models is huge and the design may contain atypical elements.

Types of nuts

Much more often during installation and repair work you have to deal with the following components:

- Elements for fastening to the water supply, they are located on the inlet lines and in most cases are visible . Much more often they are rigidly fixed to the structure and replacing them is unrealistic; you need to buy a new mixer. Based on this, when working, be careful and do not apply too much force, so as not to break the element; in addition, watch the position of the rubber gasket, it must be level.

- The nut to the faucet body under the spout helps to fix the faucet gooseneck . Its main highlight is that the spout must not only be well fixed, but also move left and right; for this, there must be a plastic expansion washer under the nut. Tips for securing such units are simple: you do not need to apply too much force, but you need to tighten the system carefully so as not to scratch the outer decorative coating.

- A clamping nut is also needed for systems installed on a sink or sink; it is located at the bottom and is not visible from the outside . The price of these elements is low, but it is better to buy a version made of brass or brass, so as not to worry about the unit being damaged by corrosion. It is possible to tighten the system with your own hands, without using a key, since too much force is not needed.

- Another type is nuts that secure the cartridge in lever valves . They are hidden under a decorative ring and can only be reached by removing the handle. The design is enormous in size; in the upper part there are turnkey edges, and in the lower part there are threads of a certain size.

Features of the work

The installation instructions tell you the assembly procedure, but you will need to learn how to disassemble the system yourself.

Let's look at how to change the nut on a faucet if it cannot be unscrewed:

- The first thing to do is to carefully tap the joint with a hammer on all sides; you do not need to apply too much force so as not to damage the edges and the threaded connection.

- Another option is to treat the structure with liquid key; this composition dissolves plaque and makes unscrewing much easier. In very difficult cases, this operation can be repeated 2-3 times.

- How to unscrew a stuck nut on a faucet if the above methods did not have the desired result? You can use a hairdryer and heat the connection; this method also allows you to cope with difficult problems.

Advice! You should unscrew the fasteners carefully, since if the edges are torn off, it will be much more difficult to carry out the work and you will need to make cuts on the structure.

Purchase

- Which jib is better - rotating or non-pivoting?

From a reliability point of view, it is, of course, non-rotating , which is part of the mixer body.

A device with a fixed jib is more fault-tolerant.

There are two reasons:

- Even if you accidentally hit it with noticeable force, this will not lead to deformation or breakage of the spout. The brass of the body is thick enough. In addition, the short length of the non-rotating gander makes the deforming force at its base minimal due to the minimum lever arm to which it is applied;

- The design with a fixed spout does not have a movable joint with the body, which is why the faucet in the bathroom so often leaks from under the gander. The swivel joint is sealed with an annular rubber gasket, which wears out quickly with frequent turns of the spout.

However: if one faucet serves both the bathtub and the washbasin located next to it, willy-nilly you will have to choose a faucet with a movable gander.

The washbasin and bath share a mixer tap with a swivel spout.

- Which location of the swivel spout is more practical - at the bottom or at the top of the faucet body?

It all depends on the purpose of the plumbing fixture.

If it is installed above the bathtub, it is more convenient to have a gander located below . The shorter the distance from the spout to the surface of the bathtub, the lower the noise level will be when water is drawn into it.

For a faucet designed for a washbasin, the choice is small: the gib can only be located on top . Simply because the body is pressed against the sink shelf from below.

Washbasin mixer. The gander is located on top.

- The gander design of a bathroom faucet often includes an aerator. Is it needed?

If you have water meters, you definitely need them. The aerator creates a larger jet with less water consumption. Thus, it allows you to significantly reduce its average monthly consumption.

The aerator saturates the stream with air, making it more voluminous.

Private houses with autonomous sewage systems - septic tanks and cesspools - deserve special mention. The wastewater flow in them has to be strictly controlled: the frequency of calling the sewage disposal truck depends on it.

The price of clean drinking water and wastewater disposal of the same volume can vary significantly. At the time of writing this article (July 2016), in Sevastopol, four cubic meters of drinking water cost the consumer about 100 rubles, and removal of the same amount of liquid sewage costs 1000.

- What to look for when buying a gander to replace a damaged one?

- To the diameter of the nut . Old-style domestic faucets used 1/2-inch threads, modern and imported fixtures used 3/4-inch threads. If in doubt, take the faulty unit with you as a sample. To remove the gib, just unscrew the nut at its base with an adjustable or open-end wrench and turn the spout out of the mixer body;

Old mixer of domestic production. The thread size of the union nut is DN 15.

- On the cut of the aerator . Sooner or later it will have to be cleaned. It is quite difficult to unscrew a round aerator with your own hands without a tool, and trying to use pliers or a gas wrench will deform the aerator and damage its chrome coating;

External turnkey slots will simplify the dismantling of the aerator.

- For wall thickness. It can be roughly assessed by tapping the spout with a fingernail. The thicker the walls of the gander, the less likely it is to accidentally damage it. In addition, the thickness indirectly indicates that the manufacturer did not skimp on product quality. Therefore, we can also hope that the gander is equipped with a strong nut, a durable aerator filter, and that the decorative coating on its surface will not peel off in the coming months after purchase;

- The material from which the spout is made. Brass should be hidden under the chrome coating, not silumin - a plumber’s terrible horror, a material with extremely low mechanical strength;

Hint: brass and silumin are easy to distinguish by weight. The density of silumin is three times lower - 2.5 - 2.9 g/cm2 versus 8.4 - 8.7 for brass.

- The length of a gander. Ideally, the stream of water from it should fall exactly into the outlet grate of the washbasin or bathtub. In this case, the amount of splashes, which, when dried, will leave untidy streaks on the walls, will be minimal. First of all, the size of the gander is important for shallow washbasins: the splash problem is especially acute for them.

Types of faucets

Based on functionality, they can all be divided into two types: valve and ball. The first ones are well known to customers, since they are most often used to work with hard chlorinated water, which is supplied to apartments. Repair of this option usually consists of one replacement of the seal.

Ball ones are more common than single lever ones. They appeared on the domestic market recently and are distinguished by their ease of use and elegance. To adjust the temperature and pressure of the water supply, the lever is simply raised or lowered and then turned in the desired direction. A significant disadvantage of this model is the low tolerance of salt deposits in the water. Over time, they clog the mixer module, which negatively affects its further operation. Its repair consists of completely replacing the ball module. The cost of work is much more expensive than that of valve devices.

To reduce the risk of plaque on the ball system, special filters are installed. As a result, already purified water is supplied to the tap. Thanks to this mechanism, the mixer works much longer.

- Single lever mixer.

A device that has a lever that allows you to control the pressure and temperature of the water. It's easy to use. Its cartridge is usually ceramic or metal and serves as a seal and also distributes the water stream.

- Two-valve mixer.

In this case, the water supply is adjusted using two handles, which are placed on the sides of the tap with a bend. Each of them contains faucet axle boxes, where there are also rubber gaskets or special ceramic rings that act as seals. In case of a sharp drop in water pressure, this model is more stable and convenient.

- Thermostats.

This is a panel with handles that help you quickly adjust the temperature and pressure. This model is more modern and convenient. In addition, it combines all the advantages of previous types of mixers.

After studying all the offers on the market, you should pay attention to installation options.

Installing faucet cups close to the wall

In the sanitary area (in the bathroom or shower), everything must be brought to perfection - the absence of seams and significant gaps here plays not so much an aesthetic, but a protective function. The less significant the seams and gaps are, the less moisture can be retained in them and the less likely it is that black fungus, familiar to many, will appear in these areas, which is almost impossible to remove.

In order to prevent water from entering the areas connecting faucets, heated towel rails and other plumbing fixtures to the water supply system, special decorative cups (reflectors) are used - round metal plates that are screwed onto the eccentric fitting until it touches the surface of the tiled cladding.

Types of faucet mounting

It is according to this characteristic that all models can be divided into four groups: for a bath, for a sink, for a bidet, for a shower.

- For Bath.

In this situation, there may also be two separate mounting options - on the bathtub or on the wall. In the first option, there will be only adjustment knobs and a spout on the surface. Most often used for acrylic bathtubs.

But still, most owners prefer the second mounting option. This is true in small bathrooms, where the bathtub is very close to the sink, so you can save on buying two taps and limit yourself to one with an extended spout and a swivel mechanism. But their significant disadvantage is unreliability. They often leak at the mounting points because the mechanism wears out quickly.

- For the sink.

The mixer can also be mounted either on the wall or on the surface of the washbasin itself. But still, most buyers give their preference to the second option.

- For shower.

These are models that do not have a spout. Instead, they are equipped with a hose for a watering can, as well as knobs for adjustment. They are mounted exclusively on the wall. The attachment points are masked with special reflectors for greater aesthetics.

- For bidet.

These faucets are similar to sink models. Most are installed directly on the side thanks to special mounting holes. Additionally, it is equipped with an aerator. This design is equipped with a ball joint that allows you to adjust the direction of the water.

Faucet installation methods

- Flexible connection.

The first thing you need to take care of is turning off the cold and hot water.

Next, you need to unscrew the clamping nut using a wrench and remove the fastening screw with a screwdriver. The mixer is removed and the installation site is cleaned. If installation is taking place for the first time, then it is necessary to consider the location and make marks if necessary.

The installed equipment must first be assembled and the reliability of the connections checked. A seal is pre-installed on the faucet.

Connection to the pipeline is made using adapters and union nuts. Flexible hoses are inserted into the holes in the sink. Then the mixer is fixed in place.

Additional fixation is provided by a gasket and a pressure washer underneath the sink. The faucet is then reliably “tightened” without any effort. As a result, its stability is ensured. In the event that the input axes of the coupling and the device do not fit together, eccentric adapters are used for connection, which have different threaded diameters at the ends.

Flexible hoses are used to supply hot and cold water. The nuts are first tightened by hand, and then using an adjustable wrench. When choosing a size, it is important to remember that you cannot twist, bend or stretch them. The strength of the thread connection is achieved using FUM tape or linen sealant.

The check is carried out with the mixer turned off, but with water supplied. First cold and then hot. This way, it will be possible to notice a leak if it occurs. If drops of water appear on the threads, then you just need to tighten the nuts a little with a wrench.

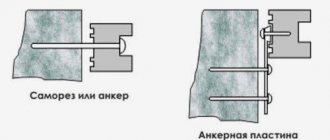

- Rigid connection.

It often happens that flexible hoses do not “reach” the entrance. In such situations, a fitting nut acts as an alternative for connection.

A rigid installation is more durable, but if it breaks, it will be more difficult to repair than a flexible connection.

The preparatory period during installation is not fundamentally different from the previous version.

To access the collet, an angled needle is screwed into one of the entrances to the mixer in such a way that its direction is oriented towards the free area. This will make further work easier.

Next, a hydraulic seal is made between the sink and the mixer using a gasket. Installation is carried out through the mounting hole.

Having determined the length of the pipe, the remainder is removed with a pipe cutter. The pipes are secured using keys and clamping couplings.

Types of pipes used for flexible and rigid connection

Depending on the financial capabilities of buyers, the quality of the required connection, pressure power, and size of the sink, connecting pipes are divided into three types:

- Chrome plated copper tube.

Used for rigid and high quality connection. During installation, high-precision and careful bending is required, which takes a lot of effort and time. But this connection is the most stable. It is also possible to place pipes in a wall cavity or in concrete.

- Flexible bellows hose.

The cheapest option, the most accessible type. It is a metal hose without rubber internal inserts made of stainless steel, completely flexible. A tube shaped like an accordion. Used for flexible connection of water pressure fittings with a mixer.

- Heat-resistant metal-plastic pipe.

Mount connections of medium rigidity. Provides for the mandatory use of additional needles for transitions to metal-plastic pipes, as well as end caps with internal threads. This type of connection is used less frequently, only when it is impossible to use any other fastening option.

Mixer spout device (photos, diagrams)

Let's look at the most common and inexpensive type of spout, tubular. It consists of a curved tube, usually circular in cross-section.

To make such a spout, no expensive, complex equipment is required, since there is no soldering and few parts. In fact, it differs from more expensive spouts only in appearance, but otherwise it performs its function in the same way and lasts quite a long time.

Let's see how a tubular spout works.

At the end that fits into the body there are grooves into which two rubber bands and a plastic split ring (white here) are inserted.

The plastic ring serves as a stop for the union nut and thus secures the spout.

Ring rubber bands help to secure the spout tightly and also block the flow of water past the hole.

A low-quality spout can be easily identified by one rubber ring instead of two: it not only wears out faster, but also does not secure the spout well, which is why it begins to dangle and leak.

Sometimes, to facilitate sliding, a thin and flexible plastic ring is added between the nut and the spout tube. With our water quality, such a gasket “hardens” over time; the small gap between it and the spout becomes overgrown with dirt, which ultimately prevents rotation. Therefore, taking into account the two rubber rings, there is no point in such a ring.

The diameter of the tube and the hole in the body where the spout is attached is usually about 18 or 19 mm (two main standards). When purchasing a spout, keep in mind that these two types are not interchangeable. Varion uses the 18 mm standard. When purchasing a Varion spout, you can be sure that it will fit the Varion body.

At the other end of the spout there is a thread for the aerator:

Soldered spouts

Soldered spouts are usually more expensive, but more interesting in appearance.

Rubber and plastic rings in them are put on a separately machined nipple.

The nipple is screwed into the body, the spout is inserted into it and secured with a nut, usually larger in size.

In soldered Varion spouts, the plastic split ring has a special shape and its protrusion fits into the hole of the nut.

Sometimes, instead of a nut, a screw is used, screwed into the body perpendicular to the axis of rotation of the spout.

This design prevents the nut from unscrewing during operation.

Varion soldered spouts use a profile of an interesting shape (not just round).

On the left is a D-shaped Varion spout. On the right is a spout from another company.

Nuts for the aerator and nipple are soldered into the ends of the spout, all this is polished and assembled.

There are more parts, operations, and the tube thickness required with this manufacturing method is greater.

To obtain a shape with a diameter that varies from the base, the workpiece can not only be bent, but also “inflated” (sometimes this allows you to save on material).

The wall thickness decreases, but, as a rule, this does not impair the quality of the spout.

Cast spouts

The most expensive. The body is cast entirely and without soldering, only threads for the nipple and aerator are cut. The wall thickness is already about 3 mm, the shapes can be very different. Such spouts can be identified by weight.

What are spouts made of?

Cast spouts are made from brass for casting LS-59, the rest are made from brass L63, L68 or analogues - they are more suitable for the manufacture of products by plastic deformation.

The cheapest products have stainless steel spouts; they may not be coated with nickel and chrome, but simply polished. As a rule, they have a very small wall thickness (for high-quality spouts the wall is ≈ 0.8 mm, for high-quality cast ones ≈ 3 mm) and, contrary to the name, they can rust.

Malfunctions

The most common spout problems (in descending order):

- the nut has come loose;

- vomited due to a clogged aerator;

- rubber rings worn out;

- The plastic ring broke.

The most common problem (not counting problems with a clogged aerator) is unscrewing. If you do not tighten the spout tightly enough during installation, the union nut will gradually loosen and sooner or later will unscrew completely, falling out along with the spout.

The spout can vomit under pressure due to a clogged aerator, because it (the spout) is not designed to withstand network pressure; water must flow through it. In such cases, the owner usually loses the rubber seals, puts them and the plastic ring on in the wrong order, winds the FUM tape for some reason (which is completely pointless), everything leaks and dangles, although he should have just tightened the nut in time, because nothing is broken.

If the rubber rings are torn, or the plastic ring is bent, it is enough to buy new ones in the store, since they are quite inexpensive. Some types of lubricant can cause the rubber bands to dry out or swell - we recommend using plumber's Vaseline.

It often happens this way: people hang a bucket on the spout and fill it with water (in addition, they can also lean “slightly”). Most often, in this case, the nipple or tubular spout breaks (along the groove). The problem can be solved by simply replacing the broken part.

Varion produces spouts of different lengths. You can choose the one you need. If the store does not have a spout of a suitable length, it can be replaced free of charge at our service center.

Installation of the mixer on the nut

Installing faucets on a nut is not so difficult if you know in advance the algorithm of actions and some nuances that should be taken into account. If all rules are followed, the installation process takes no more than 15 minutes.

- Preparatory work. Take the hose and mounting pins that come with the standard kit and install them on the faucet. Tighten the studs carefully, since they are the main fasteners. The hose, on the contrary, should not be tightened too much, since too much twisting can break the tightness of the hose.

- Installation. Place the faucet on the sink and lightly tighten the fastening nuts. Now you can install the second hose. Make sure that the faucet completely covers the hole in the sink, and also check the position of the taps when turning on the hot and cold water.

- Main fastener. Carefully secure the faucet, controlling its position relative to the sink, and secure the other end of the hoses at the junction with the water pipe.

It is possible to install faucets where nut mounting is the main type of fastening without involving professionals.

Advantages and disadvantages of installing a mixer on a nut

Nut-mounted faucets, which are offered by any online plumbing store, are extremely easy to install. Therefore, the owner of the premises can perform all the work himself, saving on the services of a plumber.

The disadvantages of such a device include frequent damage to components during the installation process due to carelessness. Therefore, if you decide to buy a nut-mounted mixer and intend to carry out the installation work yourself, be sure to control the tightness of the nuts. After all, tightly tightened fasteners can break the tightness of the system, and loosely fastened ones can lead to leakage.

What do mortise bathtub faucets look like, and can you install them yourself?

The functionality and unusual appearance of the bathroom is due to the use of practical accessories. The mixer is an indispensable element that is installed not only on the wall, but also on the central side of the bathtub. How to do this, and whether it is necessary, is further in the article.

A non-standard look at familiar things – a side-mounted bathroom faucet

When buying a faucet or mixer with a shower for the bathroom, most consumers focus on qualities such as practicality and reliability.

But if you want to diversify the interior of the room with non-standard parts, you can mount the plumbing fixture directly to the side of the bathroom.

This type of installation has features, advantages and disadvantages.

On-board faucets - flow of water with a stylish and unusual solution

Many of us are accustomed to the standard solution for placing a faucet in the bathroom - on the wall near the shower or on the washbasin. However, recently another decorative solution for using a faucet has gained popularity - on the side of the bathtub. A special feature is that the water spout is located in the central part of one of the sides, as well as an unusual external solution for the style of the room. In this case, the mixer can be mounted anywhere on the product.

What's good

The advantage of attaching the faucet to the side of the bathtub is that it is an unusual decorative solution and practical for daily use. It is also worth noting a number of other advantages:

- There is no need to drill into the wall near the bathroom, which is convenient when the bathroom is purchased and installed directly after repairing and finishing the walls of the room, when changing the stylistic direction.

- They hide communications and pipes under the bathtub if it is in the middle of the room.

- Accessibility during water procedures - no need to reach for a watering can or tap, such elements are easily accessible by hand.

- The original appearance of the bathroom is perhaps the main advantage. By placing the mixer in the center of the wide side of the bath, you decorate the interior of the room with unusual notes.

Features of the design of a mortise mixer

Built-in bathroom faucets have an extensive list of advantages relative to their wall-mounted counterparts:

- strength and long service life due to the use of solid injection molded parts in the production process;

- quick collection of water without splashing on the walls;

- original lines and shapes combined with interesting modern design allow you to decorate the space with additional gloss;

- compactness – there is no need to create additional space in the bathroom during installation;

- static design, which does not allow the use of individual components, the installation does not break down;

- simple operation and use at home;

- solution to the problem of masking the connecting hose with a mixer or watering can.

Convenience also lies in the fact that the entire length of the hose from the shower head is usually hidden in camouflage frames from the bottom of the bathtub. Therefore, only the top part of the mixer without its connectors is visually visible.

The order of installation and installation - the main differences

Installing the structure on the side of the bathtub is basically no different from conventional mounting, but there are certain installation features.

For the most part, the differences in mounting depend on the type of faucet - single lever or with a shower head.

Single lever built-in spout without shower

The easiest installation option. The installation method consists of choosing a mounting location for the installation, cutting a hole on the side of the bathtub and attaching the faucet. As a rule, designs are used in which control is carried out by an adjustment lever from above. Therefore, a separate hole for fixing the control unit is not required.

Built-in faucet into the side of the bathtub - what tools are needed?

To install the structure you will need the following tools:

- Drill.

- Flexible hoses.

- Adjustable wrench.

- Milling.

- Fastenings.

- Screwdriver.

Cascade with shower

Mounting a cascade mixer does not require special skills. Installation and connection of the pipeline is carried out as in a conventional mixer, but with some differences. You will need several holes for the control unit, faucet and shower head. The only difference in control is the water supply: a cascade of water flows through an existing hole in the spout of the faucet, the appearance of which can be completely different.

Installation - sequence of work, how to install it yourself

Attaching the faucet to the side differs slightly, depending on what material the bathtub itself is made of - cast iron, acrylic or ceramic.

In this case, the thread of the hole always follows the same principle - a Forstner drill with a diameter of 35 mm is selected. Such a drill has one central point and 4 notches, which will be used to cut out the material.

Selecting a location to drill 1 or more holes

If you plan to install only one top-control faucet, you will need to cut one hole on the side of the bathtub. Preliminary markings are made along the central part of the surface. If there is not enough space on the side, there are special side covers for mortise mixers. They will be required if the side of the bathroom is too narrow, almost flush with the diameter of the hole for the mixer.

If it is necessary to mount the unit (water supply tap, control unit and watering can), the most practical place for placing the accessories is selected.

Is it possible to drill a hole in an acrylic bathtub at the edge from the corner?

The peculiarities of drilling an acrylic product consist in choosing the necessary tool that would not damage the base.

The material (acrylic) itself is soft, and therefore no special effort is required to insert the tap.

Sequence of actions:

- The drill is set to minimum speed - 300 rpm. Do not put pressure on the structure, otherwise it will burst.

- Mark the place for drilling with a sharp object so that the drill does not “lead” at the entrance; even a simple nail will do. Kernim without impact, screwing the nail into the acrylic.

- The drill is installed strictly vertically relative to the surface of the bath.

- Acrylic is a very soft and pliable material, so there is no need to cool the drill during work.

Drilling for mortise installation on enamel and other materials

The hole for the cut-in on the side of the bathtub is drilled in the place where it is most convenient. For example, you don’t have to stand up to reach the tap if you install it in the center. And the watering can and shower hose can be attached in a corner so that they do not interfere with the usual collection of water.

An ordinary drill copes with the task of drilling a hole in a metal or cast iron base. The only condition is to determine the correct degree of sharpening of the cutting tool. The optimal angle range is considered to be 116-117 degrees. The use of a drill with steel tips (more often - it will win) is also justified by the need to make holes in large volumes.

During the drilling process, pressure and force are not used, so the material can burst and deform not only at the thread, but also in the central part of the bead. When using a forstner drill bit on acrylic, you need to twist slightly from side to side.

Connecting communications and flexible hoses

After the holes are cut, they begin to attach flexible hoses and communications.

- There are three holes at the bottom of the mixer - for hot, cold and mixed water. First screw the hose into each hole. The largest one is the central one. Do not tighten the hoses while we are just planning.

- The faucet is placed at the top of the bathtub rim, and a plastic stand is attached below to further secure the faucet, firmly locking it in one position.

- The spout and shower head are attached alternately. In this case, the hose from the watering can is first threaded through the seat ring, since after fastening it will be impossible to install.

- Connect hot and cold water.

How to install a faucet on the side of a bathtub so it doesn't wobble

Attach the faucet to the side of the bath in the same way as to the wall. To prevent it from wobbling, use a plastic gasket on the bottom. Without this, it is impossible to tighten the faucet and install it tightly on the bathtub. Additionally, sealants are used to treat the lower parts of the seals.

Are mounting panels and strips required?

The use of mounting panels or strips on the side of the bathtub is advisable in situations where the quality and strength of the base of the product are not impressive. If there are doubts that fastening the mixer will negatively affect the operation of the structure, play it safe by choosing side covers. The faucet and watering can are subsequently attached to them.

Disadvantages in using a built-in mixer

Among the many advantages of using this plumbing installation, there are also disadvantages, among which the main one is wear and damage to the hoses located inside the built-in structure. With constant extension, the shower hose rubs, becomes deformed and leaks over time. At the same time, the spout lasts a long time because it does not move.

Tips for a successful installation

Installing a mixer and shower head on the edge of the bathtub is a practical solution. The work does not require professional plumbing skills; you just need to choose the correct drill size and insert the device. But some tips are worth considering:

- The distance between two holes does not exceed 25 cm.

- It is better to choose a place for drilling on a wide part of the side.

- Do not drill into acrylic using force.

- It is advisable to install the gander or spout in the central part of the bath, and the shower hose in the corner.

- Calculate the diameter of the hole so that the side edges of the bathtub are against the wall if the installation is not in the center of the room.

- Additionally, silicone sealants are used to seal the exit from the hole from the inside. To do this, apply the composition to the inside of the seal.

Attaching the faucet to the side of the bathtub is a practical solution that allows you to enjoy the benefits of civilization without the slightest discomfort. In addition to impressive performance characteristics, this fixation method has visual advantages - the bathroom looks extravagant and original.

Source: https://santehnika.guru/smesiteli-i-krany/smesiteli-s-dushem-na-bort-vanny.html

When is replacement required?

The obvious reasons for replacing the faucet are physical damage: the body has cracks, chips, replacing gaskets does not eliminate the leak. Restoring the tightness and integrity of the case while maintaining aesthetic qualities and reliability is unrealistic. The faucet seat or axlebox of hot or cold water often wears out. Damage can be repaired by grinding with a roller cutter. However, the process is lengthy and the result is not guaranteed. Some defects are accurately determined only after dismantling. The replacement also occurs after renovating the kitchen and changing the interior.

If necessary, you can call a specialist or work with the tools yourself. The process is not difficult if you take your time and do everything carefully.

Preparation and necessary tools

First of all, you need to shut off the water line on which the mixer sits. To do this, close the tap or valve.

The second stage of preparation is to select a tool for the plumbing operation. In most cases, you won’t be able to get by with just one device. Typically, in order to unscrew a rusted nut, you need:

- wrench - adjustable or gas, cap, open-end, socket;

- screwdrivers;

- pliers;

- metal brush;

- hammer.

Faucet selection

Choosing the right mixer is not as easy as many people think. The market offers products from several dozen manufacturers and more than a hundred models. Don't be overwhelmed by such a wide variety of choices. The main thing is to understand the differences between them.

Internal organization

Mixers are divided into several types depending on the internal structure:

- With two-valve system. The classic scheme, familiar to many from childhood: a spout between two axle boxes. The water flow is regulated by valves. Although models of this type do not cost much, their popularity is falling. Internal components, especially gaskets, wear out quickly.

- With single lever system. Many buyers prefer this type of faucets. It allows you to adjust the intensity and temperature of the water with one movement.

- With contactless system. Modern design and comfortable construction. When you bring your hand to the sensor, water begins to flow. The device significantly increases the cost of the mixer.

Spout

The height of the spout determines the comfort of using the mixer. With a high spout, splashes can scatter to the sides, and with a low spout, it is inconvenient to wash dishes. Preference should be given to the average value.

The spout must match the sink. It is better to choose a ready-made set of faucet and sink from one manufacturer. It will be equipped with additional accessories to solve possible problems.

Modern models may have a pull-out spout. It extends 0.6-1.2 m from the nest. High quality materials will ensure durability and hygiene.

Nozzle design

There are two types of nozzle:

- aerator;

- shower head

The “shower” mode is convenient for washing greens and berries without damaging their integrity. Caring for the sink is much easier.

Material

The material will determine the duration of the work. Today there are faucets made of metal, plastic and ceramics. Let's take a closer look:

- Metal.

The most common is silumin - an alloy of silicon and aluminum. Mixers belong to the budget price category; there is no high aesthetics and durability.

Another material would be bronze and brass. Their reputation is much better: they do not interact with water, are strong, durable. This is the best category of kitchen faucets.

- Plastic.

Modern plastic is chemically resistant, durable and lightweight. The cost of a product made from it is low. A significant drawback is low thermal conductivity, which causes strong heating of the parts. Longer service life than metal. - Fake diamond.

The production technology is based on low tide. It has high decorative characteristics.

Attaching the eccentric to the pipes

To attach the device to the pipes you will need:

- keys of appropriate sizes;

- insulating material, which can be linen thread, a special compound, FUM tape, and so on.

Installation is carried out according to the following scheme:

- determining the optimal position of devices for connecting the mixer. At this stage, it is necessary to calculate the number of eccentric revolutions that must be made for correct installation of the equipment;

- fitting of a mixer;

- insulation of threads using the selected material;

Thread sealing with linen thread

- installation of the eccentric.

To protect the eccentric coating when tightening the device with wrenches, it is recommended to use a gasket or union nut.

Necessary equipment and materials

Before replacing the mixer, make sure that all components and tools are available. It will be sad if you have to run around and buy the missing materials, and the household will languish while waiting for the water supply to be restored.

- Mixer.

Before installation, check the flexibility of the hoses and their length. As a rule, the product is equipped with 30 cm hoses, which are not always enough. In “market” faucets, the quality of the hoses is very low. It is recommended to replace them immediately.

When purchasing hoses, you should pay attention to the length of the fittings. It is better when it is different, as this will make assembly easier - the hexagons for clamping will not interfere with each other.

Before going to the store to buy a mixer, you need to look at the threaded connection in the water pipe (diameter, male/female). The most common female hoses are ½ inch. However, other options are also possible when there is a “female” ball valve or a manifold comb is present.

The length of the hoses should not be minimal. During switching on/off, a pressure drop occurs, the hoses jerk, and the rubber tube inside quickly wears out.

Corrugated stainless steel hoses have the highest reliability. Their cost is higher, and installation is more difficult, but high rigidity ensures the preservation of the original shape.

Sometimes plumbers use metal-plastic pipes, excluding the use of flexible hoses. Then you will additionally need to buy special fittings. Their installation is the most difficult, but in the future there will be no questions regarding the installation of pipes.

- To work you will need tools:

- Wrench 10, 22x24. If it is attached to the sink using a large nut, then an adjustable wrench is required. Often studs require an 11mm wrench.

- Pliers.

- Screwdriver with different tips.

- Gas key.

- An electric drill and a 35 mm hole saw if the installation is on a new sink or countertop.

- A flashlight for illumination, since under the sink it is quite dark and the joints are difficult to see.

- Materials:

- Seals for threads. Often it is necessary to install a coupling or adapter on a water pipe.

- If you intend to dismantle the sink, you will need silicone sealant and a syringe for extrusion.

- Universal lubricant WD-40 in a spray bottle is used to disassemble “stuck” threaded connections.

You should not choose fum tape, as there is a low guarantee against leakage. It is better to give preference to a proven sealant - sealing paste and flax tow.

After preparing all the materials, you can begin work on dismantling the old mixer.

Installation

If the fitting shows that the eccentrics are too long, they need to be shortened. It is better to shorten from the ¾ thread side - it does not hide into the wall. In particularly severe cases, both threads are shortened. You need to remember one important rule - the thread should be enough for at least three turns

, otherwise shortening is fraught with leaks.

If there is a strong deviation from alignment, it is better to “saw” the eccentrics in place. It is more difficult to guess the final position of the eccentric in advance. Also, replacing the “native” rubber gaskets with silicone ones can help with the solution - they are softer. As a last resort, you can try placing two gaskets in one connection.

The eccentrics are packed with a sealant and screwed into water sockets; more details about sealing threaded connections are in this article. It is good to check the positions of the terminals to each other with a level - then the mixer will fit clearly and evenly. By adjusting the eccentrics, you need to achieve the required distance between them - both union nuts should fit without effort or friction.

Screwing in eccentrics with a gas or adjustable wrench is not very convenient; for this it is better to use a regular open-end wrench, hooking it onto the square transition between the threads. Some products have an internal hex structure - a hex wrench will help.

Most of these products have four edges in the middle. Therefore, it is convenient to tighten them with an open-end wrench. You may need a different key number: in some places it will fit “14”, and in other places the number “17”.

The hardest part is over, all that remains is to screw on the reflectors and the mixer with gaskets. Be careful when tightening the union nuts

– they are quite fragile and can burst if too much force is applied. The tightening force should be slightly stronger than if the nut were pulled with bare hands.

All prefabricated parts of the mixer are twisted together manually, without the use of keys. The assembly of the spout and shower is so primitive that it is not covered here.

This completes the installation. All that remains is to supply water and check the connections for leaks.

How to replace a faucet with a nut yourself

Before installing a faucet with a nut in the kitchen, you first need to remove the old one. Then they install a new one and connect it. It is also necessary to have keys of a suitable size on hand (usually 10, 11, 22 and 24) and some auxiliary materials. To dismantle the union nuts of the mixer, you will need two adjustable wrenches.

There is a good chance that new hoses will be required. As a rule, kitchen faucets with a nut come with hoses, but they are only 30 cm long. Therefore, before starting work, make sure that this length will be enough for you.

It is important to consider the distance from the mixer with a nut to the cold and hot water pipes. The hoses should sag a little, since when the tap is turned on/off, the pressure changes sharply, causing the hoses to twitch. If the tension is too high, the connection will soon leak. Thus, if the distance from the pipes to the mixer inlet is no more than 25 cm, then the existing hose is enough; if the distance is longer, buy a new one.

It is necessary to choose only high-quality flexible hoses made of stainless braided or corrugated stainless pipe, as they will last a long time.

Before you go for a hose, you need to determine the size of the “needle” (the tip that is screwed into the mixer with a nut), the diameter of the pipe and the type of its end (male-female) - in order to choose the right fittings.

When connecting hoses or supply pipes, you should adhere to the following diagram: on the left is hot water, on the right is cold.

There are times when difficulties arise when dismantling an old mixer: the nut may become stuck. If you encounter such a problem, then use universal lubricant in WD-40 cans. This liquid seeps well even into the most microscopic cracks. Apply the lubricant to the stuck joint and wait 10–15 minutes.

If no methods help to unscrew the nut, then use a grinder to cut the body along with it. However, this can only be done if the mixer is to be disposed of.

If the faucet is fixed on the countertop, then you need to act “from the inside” - unscrew the nut while in the closet and illuminate it with a flashlight.

Installation begins with attaching the mixer to the sink with nuts. The mixer always comes with a rubber sealing ring, which must be placed in the groove located at the end of the body.

The cylindrical part with thread is inserted into the hole in the sink. The rubber ring should not move.

The kit should include a wide rubber gasket, which also needs to be installed at the bottom.

Now screw on the brass fixing nut with a “skirt”. The “skirt” is an extension in the form of a washer, thanks to it the tightest clamping of the installed rubber gasket is created.

The nut is tightened with an adjustable wrench so as to ensure that the mixer does not move on the sink. It is important that the spout is positioned so that the sectors of rotation to the left and right from the central position are equal, and the switch lever or valves are level with respect to the sink. If the mixer is installed at an angle, then the spout position is selected diagonally.

In order to level the mixer, loosen the nut, perform the necessary manipulations and fix it again. Now install the hoses, first the one with the short fitting, and tighten them with a 10mm wrench.

If the sink has been removed, it must be reconnected to the sewer by replacing the siphon and inserting a corrugated hose with a sealing collar into the outlet of the sewer pipe. Now you can turn on the water supply and check the operation of the mixer with the nut.

Please note that you first need to spill water without the aerator tip in order to avoid clogging it with small particles accumulated in the pipes, faucet, and hoses. It is enough to drain a few liters of water, and then you can put the aerator in place.

It is also important to check the tightness of all connections during the first descent. If leaks are suspected, the connections must be tightened immediately.

There is no need to wrap the threaded part of the fitting with FUM tape or solder it, since it has one or two O-rings that ensure the required tightness of the connection. The fitting is screwed in until it stops, but you should not overtighten it, as you can damage the rubber ring. All you need is hand effort and one turn of the key.

Now you can install the hose with an extended fitting. If water will be supplied through a metal-plastic pipe, then the fittings with fittings are screwed in in a certain sequence: first the one that has a bend, and then the straight one. When the hoses (fittings) are screwed in, the sink must be secured in place.

The faucet is one of the important attributes of the kitchen and bathroom. It creates comfort for the owners and guests of the house and performs an aesthetic function. Modern sets are created from various materials that fit harmoniously into any interior.

The plumbing market today is quite extensive, so an inexperienced person will most likely get confused. In addition to choosing the right option, you should pay attention to installation. If you have never done this yourself, then it is better to call a plumber, and for a small fee he will do everything carefully and quickly. After all, in this matter everything depends not only on the availability of tools, but also on the type of fastening of the mixer. Skills, knowledge and availability of required components are required.

Various models and design options, a wide range of product prices give the potential buyer the opportunity to choose the right item.

First you need to understand the types of mixers and find out how they differ.

The initial parameter during selection is the length of the spout. Most often, shorter options (20-25 cm) are chosen for bathrooms, but elongated ones (30 cm or more) are well suited for the kitchen. There are also shortened versions that are compact and neat. You should also immediately decide what will be more functionally convenient: if the tap is rotary or fixed.

According to the form, there are two main options: cascade and traditional. They differ only in the size of the liner section. The most common pipe shapes are oval, triangular and round.

It is important to pay attention to the placement of the faucet in the bathroom. For example, if the sink and bathtub are adjacent, then the best option may be one elongated swivel faucet, which will be located right in the middle. In general, the choice is individual, and everyone decides for themselves.

Bathroom faucet distance: marking correctly

Repair work in the bathroom often requires complex measures, including installation or replacement of mixing equipment, which you can do yourself. Due to the fact that the work requires specific skills, the installation of plumbing fixtures should only be entrusted to a specialist. The main task of the master is to select tools that allow you to accurately determine the center-to-center distance of the bathroom faucet in order to place water pipes.

How to choose the “right” eccentric?

Inexpensive faucets made in China or Turkey are often equipped with shiny chrome-plated adapters. The quality of such products usually raises doubts, and deservedly so.

This is due to the fact that, despite their attractive appearance, inexpensive chrome parts also have several negative qualities. During the operation of such products, rust often appears.

But this is the case if it comes to operation in principle, since even during installation work the unreliable eccentric head often breaks off. Therefore, experts recommend that you still purchase an eccentric separately, making sure that it is made of brass and using solid cast technology.

The cost of a product made from pressed brass is too fragile and will break and fall into pieces at any time. Solid brass adapters are much heavier and more expensive. But the characteristic golden color of the eccentric does not at all indicate the quality of the material from which it is made.