Metal entrance doors have two main tasks: to reliably protect owners from intruders and to create comfortable living conditions. Comfort, in turn, is always associated with warmth in an apartment or house. Therefore, insulating the doorway of the front door is the owners’ primary goal after installing a new door block. After all, it, along with windows, is the main conductor of cold into the room. It is necessary to insulate the frame, door leaf and slopes.

In this work, we will consider in detail all the stages of thermal insulation of the frame and door leaf. The nuances of the process of insulating slopes are discussed in detail in the material “Finishing the slopes of the front door,” which makes it possible not to touch on this topic here.

Choosing a material for insulating a metal entrance door

You cannot begin work without it, which is why you first need to decide on the best option, having previously examined each of them in more detail and purchase it. There are a large number of different insulation materials on the market, making it quite easy to choose the one that suits the cost and technical parameters. For thermal insulation, you can use not only hard but also soft materials.

Mineral and stone wool

Mineral wool is in quite significant demand on the market among consumers, which has an affordable price, perfectly absorbs noise, has the ability to restore its original dimensions after compression and, due to its soft structure, is easy to use. This insulation withstands temperature fluctuations, providing complete protection of the building from the penetration of cold into it, and it is also environmentally friendly, non-flammable and allows you to vary the installation height without the need for additional cutting.

Mineral wool is supplied for sale in rolls and sheets, which makes it possible to cut blanks of the required size, which are placed in cells created by the stiffening ribs of the door structure itself. To obtain the required thickness of the insulation, you only need to press it down (pressure), which in the end will in no way negatively affect the technical performance.

The disadvantages of mineral wool include softness, which leads to shrinkage over time, but this disadvantage can be easily eliminated by creating stiffening ribs in the door structure, which prevent the material from slipping over a long period. Its significant disadvantage is its poor resistance to the influence of moisture, often acting as condensation, which occurs due to a shift in the dew point inside the door leaf. To perform high-quality insulation and avoid this drawback, it is better to give preference to stone wool.

Unlike mineral wool, it withstands its impact and allows for effective thermal insulation even of the entrance doors of private houses. In another situation, mineral wool may be a suitable option only when insulating structures that are installed in heated vestibules or corridors of apartment buildings, as well as when additionally installing a waterproofing film inside it.

Foam plastic and penoplex

Preference is given to it quite often, since the insulation has insignificant weight, which does not lead to significant weighting of the door. The material has an optimal level of strength and excellent wear resistance, and due to its hygroscopicity, it does not require additional waterproofing. In addition, polystyrene foam has high soundproofing and thermal insulation properties, thanks to which it is possible to reduce noise levels and increase heat retention inside the house, as well as prevent the penetration of cold from the street. When choosing it, you should give preference to penoplex, which, unlike ordinary material, has a higher density, which is why such insulation, even of a finer thickness, has similar qualities as ordinary sheets of standard polystyrene foam. When using it as thermal insulation, it is advisable to additionally seal all seams with polyurethane foam to prevent the formation of cold bridges.

Note! It is not recommended to use ordinary polystyrene foam for insulation, since when heated it can release substances hazardous to health.

Polyurethane foam (polyurethane foam)

Not quite a traditional option for insulating doors, but which also has a number of positive qualities and even surpasses other materials in some respects. Initially, in order to obtain an effective result, you need to be able to correctly use a spray foam gun or the tube supplied with the container, thanks to which you will not only be able to complete the work fully, but also avoid spraying an excessive amount of excess.

The material itself, due to its airy structure, does not significantly increase the weight of the door leaf, withstands temperature changes and exposure to moisture, and if you know certain nuances, it is quite simply applied and evenly fills all voids, including hard-to-reach areas.

Entire door trim

With normal sealing of the door leaf around the perimeter, freezing can occur along the entire plane of the enclosing element. This situation occurs when the insulation inside the fabric is insufficiently effective, or when it is completely absent. In such cases, the door surface is completely insulated using the following algorithm:

- The door leaf is removed from the supporting frame.

- The product is placed on a flat horizontal surface.

Removing the front door

- Typically, a door consists of two layers of sheet metal or one layer and an MDF panel. One of the elements is removed to provide access to the interior of the canvas.

- Insulation is laid in the internal space - polystyrene foam or mineral wool, which is pre-cut to size. It should be noted that basalt materials have a high degree of elasticity, and they should be cut to a slightly larger size than the landing size.

- All joints between sheets of insulation are treated with polyurethane foam from a container.

- The top panel of the door is fixed in its previous position using self-tapping screws or rivets.

Laying mineral wool into the canvas

- The canvas is hung back on the frame, and the master tests its performance.

When insulating a wooden door, it is necessary to install insulation on either side of the door - external or internal. Insulating the structure from the cold side is considered the most effective. When installing a soft insulating layer, it is also necessary to provide a finishing coating made of polymer film, genuine leather, MDF or leatherette.

Insulation of the door frame

Insulation of a metal entrance door should begin with the elements of the frame. If the box is made from a corner, then insulation is possible only in the places where the box adjoins the doorway. In this case, the gaps are filled with foam, and the excess insulation is cut off with a construction knife. If the box is made of a rectangular or square pipe, the insulation is placed inside the profile.

The better to insulate

To insulate the door frame, use foam or bulk insulation (sawdust, expanded clay).

Polyurethane foam is used to eliminate gaps between the frame and the doorway, as well as to fill the cavities of frame elements made from profiles.

Bulk insulation is used only for profiled frames. The profile is filled through a technological hole drilled in the upper part of the box. The diameter of the hole should allow the largest fractions of filler to pass through.

This method has a significant drawback: it is impossible to ensure that the entire internal space of the box is filled with bulk materials. As a result of uneven filling, voids are formed that freeze. Therefore, the use of bulk insulation is possible only in production conditions, when assembling the box in the workshop.

Materials and tools

To insulate the box you will need the following tools and materials:

- electric drill;

- metal drills with a diameter equal to the diameter of the nozzle of a cylinder with polyurethane foam;

- polyurethane foam;

- construction knife.

Insulation instructions

To fill the door frame with foam, you will need to prepare technological holes with a pitch of 500 mm. Through these holes, the internal space of the profile is filled with polyurethane foam. Excess foam coming out through the holes must be removed with a construction knife.

The gaps between the door frame and the doorway are cleaned of old insulation, moistened and filled with polyurethane foam. Excess foam is removed using a construction knife, after which the contact point between the box and the wall is masked with putty.

Materials and tools

Each type of insulation requires its own materials and tools.

For technological gap

To seal the space between the door block and the wall you will need:

- polyurethane foam in tubes;

- masking tape;

- polyethylene film;

- knife or scissors;

- construction gun for foam supply.

FYI: Each foam can has its own spray nozzle. But in many cases it is difficult to work without a pistol. Therefore, professionals take their use for granted.

For door frame

The following will help you perform a thermal break in the box profile:

- an electric drill with a drill of the same diameter as the feed tube of a construction gun;

- polyurethane foam;

- construction gun;

- knife with removable blade.

For the porch

You can fix the problem called “blowing from the cracks between the door leaf and the frame” using:

- seal in one piece;

- universal or special glue;

- scissors or construction knife.

For internal insulation

Replacing the door leaf filler requires the following materials and tools:

- thermal insulation material;

- polyethylene film for waterproofing insulation;

- wooden blocks;

- self-tapping screws;

- glue;

- metal corners to give rigidity to the box of bars;

- electric drills with a set of metal drills;

- construction knife;

- scissors;

- fine-tooth wood files;

- screwdriver or Phillips screwdriver;

- an awl or thin nail;

- sandpaper P60.

Attention: how to insulate a metal entrance door in an apartment using upholstery is discussed in detail in the article “Do-it-yourself door upholstery with dermantine.” Therefore, it is not practical to consider the technology of external insulation in this material.

Eliminating Gaps

Heat loss occurs not only through a metal leaf or door frame. During the installation of the structure, a so-called technological gap is created - a gap between the wall and the box, usually its dimensions are about 2 cm. For insulation work, it is best to use polyurethane foam. Simply covering the cracks with cement is not a solution, since such a mixture is not a heat-insulating material. It does not protect the room from the cold, but shrinks over time.

Thermal insulation of the technological gap must be carried out in the following sequence:

- From the side of the room, remove the casing in the place where the box comes into contact with the wall. Secure the polyethylene film.

- Remove the casing from outside the apartment. Moisten the space in the crack with water. You can use a spray bottle. This is necessary so that the polyurethane foam hardens much faster.

- Apply the first thin layer of foam. Its path should be uniform, without breaks or omissions.

- After about 20 minutes, when the first layer of foam expands, apply a second ball of it. It is necessary to ensure that the substance does not bleed beyond the perimeter of the door frame.

- When the foam has completely hardened, remove the polyethylene film that served as protection from inside the apartment.

- At the end of the work, install the platbands in place.

If the foam appears a little outside the box, it’s not a big deal. It must be carefully cut with a construction knife.

Execution of work

Let's look at how you can do the insulation work yourself. You need to start by removing the door leaf from its hinges, removing all parts attached to the surface: handles, linings, locks, etc.

Attention to the box

It is worth starting insulation measures by inspecting the box. When installing the front door, the gap between the frame and the opening is often filled with foam. This material is easy to use, but deteriorates quite quickly when exposed to light. To perform high-quality insulation you need:

- remove the layer of old foam, clean from dust and other debris;

- carefully fill the gaps again with foam;

- wait for the foam to harden and use a knife to remove any protruding excess;

- cover the foam with a layer of ready-made putty, this layer will protect it from destruction.

We insulate the canvas

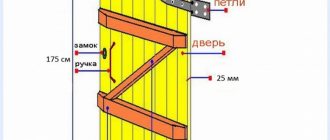

To insulate the canvas, it is necessary to assemble a frame, in the spaces of which insulation will be laid. The frame is made of wooden blocks, securing them around the perimeter of the door and along the stiffeners with self-tapping screws.

Next, do the work with your own hands in the following sequence:

- Insulation is placed between the ribs of the assembled frame so that there are no gaps. The material can be fastened with glue or spaced between the bars;

- After the glue has dried, you need to carefully inspect the installed insulation. If large gaps are found, they are filled with polyurethane foam, followed by trimming off the excess. Small cracks are filled with thin strips of polystyrene foam, which are attached with glue;

- Now you need to trim the door from the inside. Since the sheathing will not only cover the insulation layer, but also perform decorative functions, you need to be careful when choosing the material. Most often, laminated chipboards are used, but you can take moisture-resistant plywood and cover it with artificial leather or cover it with self-adhesive film;

- Having secured the inner lining, all that remains is to return the fittings to their place - lock linings, peepholes, handles, etc.

So, if your house has an uninsulated metal door or you plan to buy an inexpensive Chinese model, then you should definitely think about insulation. It is quite possible to do this work with your own hands and thanks to the efforts made, the house will become much warmer and more comfortable.

Seal installation

Another weak point in the design in terms of heat loss is the area where the sash comes into contact with the frame. If it does not fit very tightly, a draft will appear. This problem can be eliminated by installing a seal. It is produced in the form of a self-adhesive tape, which can have a different profile (section).

If the gap is small, then an oval or round seal will be useful.

If the gap is more than 3 mm, then it is worth buying a tape with a cross-section in the shape of the letter P.

Before insulating a metal entrance door, in addition to the seal itself, for insulation work you will need to acquire scissors and some kind of solvent to degrease the door.

The scheme of work is as follows:

- If an old seal was installed on the door, it must be removed and the surface thoroughly cleaned.

- Degrease the area for the tape using a solvent.

- Glue the seal around the perimeter of the sash, retreating approximately 3 mm from the outer edge. In this case, the tape must be pressed well to ensure good adhesion (without waves).

Do not pull the tape too tightly while gluing. Otherwise, it will not adhere well to the surface of the door and may come off. It is not recommended to purchase a seal that is too thick, as this may cause the door to open and close poorly.

Causes of heat loss

A modern front door is a complex system consisting of several layers of different materials. One of its main purposes is to retain heat indoors. But in a private home, thermal energy leaks often occur. There are several factors that cause this phenomenon:

- Cracks. These damages often occur as the home settles. At the same time, first of all, they appear in the most “thin” places, among which are doorways.

- Wall thickness. A single-layer structure has much worse heat retention characteristics than surfaces made of several layers.

- Technical openings. This includes both windows and old doors. The latter type of structure is one of the most common causes of heat loss.

Therefore, when insulating an apartment, you should first pay attention to the door. The disadvantage of an iron structure is poor sound insulation and high thermal energy conductivity

A single-layer Chinese door has a rather small protective layer and is not always complemented by high-quality thermal insulation.

Before you begin insulating such structures, you should identify the real reasons for the penetration of cold. If this is not done, then such an operation simply will not give optimal performance.

This is interesting: How to change the cylinder in a door lock: let's look at it in detail

How to insulate a door frame?

Many people think that to insulate a metal entrance door it is enough to insulate only the leaf. But in fact, the box also needs insulation. If it is made of a metal corner, then insulation can be done only along the perimeter where it adjoins the opening. To do this, just blow out all the cracks with foam. When the substance hardens, the excess can be cut off with a knife.

In the case when the box is made of a square or round pipe, then insulation can be placed inside it.

Suitable for these purposes:

- Polyurethane foam. It is convenient to seal the gaps between the wall and the frame, as well as fill all the cavities of the door frame.

- Bulk materials. This could be expanded clay, sawdust. To do this, make a hole in the profile and fill it with filler. If you perform this procedure yourself, then not all voids can be filled with material. Thorough insulation is only possible when the box is manufactured in a factory.

But you can try to do the insulation yourself. To do this, you will need a drill and suitable metal drills, the insulation itself (spray foam), and a knife.

Completing of the work:

- Holes are made every 50 cm.

- Using them, the cavity inside the box is filled with foam.

- All of its excess that has emerged through the holes is cut off with a knife.

- The gaps between the opening and the box are also filled with foam.

- When the substance becomes hard, it is cut and puttied.

Internal and external insulation of a metal door will reliably protect the room not only from thieves, but also from frost. You can carry out insulation work on your own by placing suitable material on the outside or inside of the sash. You should also take care of insulating the box and gluing the seal. Only a set of measures will prevent heat loss.

How to deal with this?

Protection against freezing of a metal entrance door is a set of measures, which include:

- Organization of insulation. If the insulation is already installed, you need to check it. Perhaps its quality is insufficient to provide adequate protection against freezing, or it does not exist at all. In any case, if it freezes, you will have to replace the insulation with an effective one. For these purposes, it is recommended to choose high-density foam - it is resistant to temperature changes and prevents the formation of condensation on the surface and inside the structure.

- Interior finishing device. The thermal insulation is good, but are there still signs of freezing on the surface of the canvas? We need to check the interior decoration. If the thickness does not exceed 10 millimeters, you should take care to increase this value to 22-25 millimeters. Sometimes a thicker layer is required, which will become an obstacle to temperature changes.

- Installation of an additional door. To protect your home from low temperatures, it is recommended to take radical but effective measures - installing an additional door opposite the main one. The chamber formed in this case creates an air gap between the doors, which acts as a buffer. Even if the outside freezes, the inside will get rid of the negative impact, and the premises will not be exposed to cold weather.

- Checking the door frame. The door hatch (a frame that is installed in the opening and serves as a place for attaching hinges to secure the door) plays an important role in protecting the front door from freezing. It is responsible for the tightness and tightness of the canvas. A properly equipped metal box copes best with external influences. For greater protection, it is recommended to install slopes.

The above methods are effective and practical. If possible, be sure to install an additional door. It will create protection against freezing and contribute to the thermal insulation of rooms and contribute to the interior.

In order not to encounter problems with the operation of the front door in winter, you should immediately take care of high-quality and durable insulation during installation, check the correct installation of the door frame and the door itself, and prevent the formation of gaps and other vulnerabilities. It is better to cut a problem at the root than to solve it in its prime.

Do-it-yourself insulation of a metal entrance door

The process begins with the selection of the optimal thermal insulation material, which determines the effectiveness of insulation and its duration.

How to insulate a metal door

Types of insulation:

Penofol

Thanks to the reflective ability of the foil layer, it retains almost all the heat in the room. Used only as additional material.

Insulating a metal door with penofol

Rigid insulation

These include polystyrene foam and expanded polystyrene (penoplex). Their advantage is ease of installation and relatively low price. Since it is not hygroscopic, it does not require additional films. This is the only suitable option for installation in a cottage, country or rural house. Indeed, in this case, the door serves as a barrier to low temperatures and wind, which is not observed in apartment buildings where the door opens into the entrance.

Insulation of a metal door with polystyrene foam and polystyrene foam (penoplex)

Note. When choosing thermal insulation material, give preference to penoplex (expanded polystyrene). It is an order of magnitude denser than polystyrene foam and will provide the door with much more effective insulation.

Soft insulation

This category includes glass wool and mineral (basalt) wool. Their difference is only in the raw materials; in terms of their thermal insulation characteristics, they are not very different. Mineral wool is characterized by environmental friendliness, fire safety, and the ability to vary the installation height without additional trimming.

Cotton wool is sold in rolls or sheets, which makes it possible to cut blanks of the required sizes from it and place them in cells formed by the stiffening ribs of the door itself. To ensure the required height (thickness of insulation), simply press down the material (press cotton wool), the thermal insulation properties will not be affected.

But cotton wool has a drawback that prevents it from being recommended for installation in iron doors for private homes. Because There are different temperatures on different sides of the door, and sometimes the difference is up to 40 °C (-15 outside and +25 in the house). This leads to a shift of the dew point inside the insulation, and the wool gets wet. The effect can be neutralized by installing a hydrobarrier film.

But, nevertheless, professionals do not recommend insulating an iron door with cotton wool in a private house. It can become an acceptable option only if the entrance door to the apartment is insulated, since in this case there is not such a big difference in temperatures (it is much warmer in the entrance than outside).

Insulating a metal door with mineral wool

Inflatable insulation

Presented with polyurethane foam. Spraying makes it possible to fill all the cracks, but has a high price.

Insulation of a metal door with polyurethane foam (PPU foam)

Thermal insulation of luxury metal doors is carried out using three types of materials: foam plastic (main material), penofol (additional), polyurethane foam (filling the voids of the stiffeners and frames).

Note: a set of materials that can be found in stores is of little use for insulating an external metal door, because They use dermantin, foam rubber or synthetic winterizer as insulation.

How to insulate an iron entrance door from the inside?

Fibrous materials

These include mineral fiber wool, which is sold in the form of rigid tiles or rolls. It has excellent heat and sound insulating properties, does not burn and is easily mounted into the canvas. However, when wet, such material shrinks, which is why all the pleasant characteristics are sharply reduced. Because of this, it is recommended to use it in heated entrances.

Image from balkonhelp.ru

Expanded polystyrene

Expanded polystyrene is a foamed polymer material whose bubbles are filled with nitrogen, which is why it practically does not burn and retains heat well. It is available in the form of slabs of various thicknesses, which allows you to choose the best option for insulating a specific metal door. Expanded polystyrene has an analogue - polystyrene foam - in which instead of nitrogen there is air in the bubbles. This increases the risk of fire, but reduces the cost. Both of these materials do not get wet, so they can be used in any conditions.

Before you insulate a metal entrance door in a private house with your own hands, you need to prepare the following tools and materials:

- wooden beams, laminated chipboard or plywood for arranging the interior of the door leaf;

- polyurethane foam;

- plaster;

- self-adhesive microporous sealing tape;

- universal glue.

You will also need power tools: a jigsaw, a screwdriver, a spatula and a knife for cutting material.

Step-by-step instructions for insulating a wooden door in a private house

The work is carried out taking into account the characteristics of the entrance group and the installation technology of the selected insulation.

Tools and materials

In the process of working, the following set of tools, devices and materials is required:

- nail puller, pliers;

- screwdriver, hammer;

- hacksaw, jigsaw;

- tape measure, stationery knife, scissors;

- construction stapler.

It is also necessary to prepare the estimated amount of insulation, sealant, sheathing material and fasteners.

Preparatory work

At the preliminary stage, the following work is performed:

- remove the door leaf;

- unscrew door fittings and hinges;

- remove the casing, if present;

- remove old insulation and sealant residues.

Next, the canvas and box are checked for structural defects, distortions and other defects are eliminated.

Cutting and laying insulation

Based on the measurements, blanks of the required sizes are made. When arranging a frame structure, the voids are tightly filled with layers of insulation. The material is fixed using a construction stapler.

Door trim

Dermantin is mainly used as a finishing layer. The upholstery fabric should be cut taking into account a margin of 10 cm on the sides in order to create the necessary thickening around the perimeter. The upholstery is secured with decorative nails and cord to form a distinctive raised pattern. Next, install the door hardware.

The surface of the door leaf is lined with artificial leather from the inside

Seal installation

To eliminate gaps, use self-adhesive strips or install a harpoon seal. Thanks to the special shape, the product fits as tightly as possible to the base, ultimately eliminating the risk of drafts and reducing the level of heat leakage from the room.

Additional measures and means of hydro- and thermal insulation

For maximum quality insulation of a street door in a private house, the joint around the perimeter of the frame is equipped with dermantine rollers with a foam insert inside. It is recommended to line the surface of the entrance sheet with artificial leather from the inside. From the outside, the structure is sheathed with a material that is highly resistant to aggressive atmospheric influences.

Insulation of the Chinese model

Insulation will help increase the level of comfort in an apartment or house. The technological process of insulation is relatively simple.

Thermal insulation is carried out by covering the canvas with insulating material from the inside.

- Before starting insulation, it is necessary to free the canvas from fittings and upholstery material.

Important! If you cannot carefully remove the structural elements from the surface, there is no need to worry, since the surface is updated with fiberboard strips.

- Wood slats are installed around the perimeter and secured with screws. The size of the slats is adjusted to the corresponding parameters of the canvas. Their immediate thickness can reach 2 cm.

- The space between the slats is filled with foam. Glue is used to secure the material. Large gaps become foamy.

- use fiberboard to sheathe the inside. Fastening is done using metal screws.

Standard insulation

Important! Holes for fittings are pre-drilled in foam plastic and fiberboard panels.

- Foam rubber is glued to the fiberboard panels.

- The insulated structure can be covered with vinyl leather.

- The final stage is the installation of fittings.

Stages of plating an iron model

The sequence of actions when covering an old door depends on its design. If the design is more modern and the metal panels are attached to the base with screws, the insulation is done internally. When starting internal insulation, we remove the metal structure and place it on a work surface. Unscrew the screws and remove the metal panel (to ensure that the screws unscrew well, lubricate them with machine oil). Using a tape measure, take the dimensions of the internal cells of the door.

Carefully measure the insulation material and cut it off. Be sure to cut out a place for the door lock and peephole. For old doors, polystyrene foam or foil-lined stone wool are great. We treat the inner surface of the old structure with glue (liquid nails) and glue the prepared insulation. If there are any gaps between the old door and the insulation, fill them with foam. You must work carefully, squeezing out the mounting foam in small portions. It is important to ensure that it does not get on the bolt lock mechanism. For additional sound insulation, we lay foil insulation between the insulation and the metal sheet. We cover the structure with a metal sheet and screw in the screws.

If the old door is made by fixing metal panels by welding, then we proceed to insulate the old door using the external method. We prepare wooden blocks 20 (30) x 20 mm. We measure the parameters and cut the slats to the required length. Using a drill, we make holes for future fastening in the metal sheet. We assemble the base from prepared wooden blocks and fasten it to a metal sheet with self-tapping screws.

We prepare insulation according to the specified dimensions. We line and glue the insulation into the cells between the slats. We fix the MDF panel or board with screws. Additionally, for sound insulation, the door can be treated with leatherette from the outside or inside. To do this, we bend the leatherette and fix it with staples. Lubricate the lining and hem of the leatherette with glue (liquid nails) and press firmly against the metal sheet. This work is painstaking. At the last stage, we install door locks, handles, and a peephole. We return the finished door to its place.

When covering a single-layer metal door, it is necessary to measure the cells between the stiffeners. We cut the inner material to the specified size. We quickly glue the insulation into the cavity. We eliminate cracks and small gaps using polyurethane foam. We decorate with MDF panel.

Choosing a method

The entrance iron door is insulated in two main ways:

- internal filling with a heat insulator, when steel sheets (panels) are attached separately to the frame;

- external insulation - if the fabric is monolithic and it is impossible to disassemble it into its component elements.

The first method is more preferable from an aesthetic point of view. In this case, insulated metal entrance doors for the house in the apartment will look as beautiful as they do from the inside. The second option - with external works - is more a measure of necessity, although they can be decorated beautifully. For this, additional finishing is used - wooden or plastic strips, non-woven materials, etc.

Materials and tools

Regardless of whether you decide to insulate the front door from the inside or on both sides, you will need:

- screwdriver (you can also use a screwdriver, but it’s faster with a power tool);

- drill with metal drill bit;

- stationery knife;

- a hacksaw with the smallest teeth;

- awl;

- fine to medium grit sandpaper.

Next comes the turn to choosing insulation. For this purpose, you can choose one of the following:

- Mineral wool

The porous structure of the material retains heat well and does not give rise to condensation, that is, the metal does not rust on the inside, but is gradually knocked down, due to which voids are formed. To avoid such “dripping” down, you need to fill grates with a side of 15-20 cm on the canvas and fill them with mineral wool.

- Basalt slabs

The advantage of this material is the stability of its structure; it retains its shape even after 10 years, and when ignited, it does not emit toxic substances.

- Expanded polystyrene

It costs a little more than polystyrene foam, but at the end it gives an excellent thermal break, since it has zero thermal conductivity. A door with a thermal break is essentially a thermal bridge that reliably separates both layers of the door and completely isolates the access of cold.

You can mention synthetic winterizer, foam rubber or wool batting as insulation, but these are, say, exotic options that give minimal effect. There is no point in dismantling the door to insulate it with padding polyester. As a last resort, you can upholster it from the inside with this material, but, we repeat, this will not fundamentally solve the problem of heat loss.

- a sheet of fiberboard or fiberboard for decorating the interior fabric;

- isolon strips 7-10 cm wide;

- liquid nails for fixing the insulator;

- screws;

- one cylinder with polyurethane foam;

- sealant.

How to insulate a metal entrance door

Here we will tell you how to insulate a metal collapsible entrance door.

- To do this, it is first removed from the hinges, laid horizontally and the sheet is unscrewed from the inside (usually it is secured with screws).

It is easier to insulate entrance street structures in a horizontal position

If the screws do not unscrew after a long time, drop some machine oil on them, after which the process will go much easier. There is no point in tearing off the caps; then you will have to drill out the body.

If it is not possible to remove it from the hinges, the sheet is unscrewed gradually, starting from the bottom side and gradually rising up. The order of work will be exactly the same, you will just need one more person to support and help.

- Next, cut the insulation to size. If it is polystyrene foam or polystyrene foam, it is better to cut it with a fine-toothed hacksaw. Mineral wool or basalt slabs are cut with a stationery knife.

Entrance door filled with mineral wool

You cut the mineral wool 3-4 mm larger than the required size - it is literally pushed inside so that it covers the corners perfectly accurately.

- Apply liquid nails to the inside of the canvas and the insulation around the perimeter and lay it tightly into the frame, simultaneously pressing the edges and the central part.

When preparing the insulator, take into account the need for space for the bolt system and the lock - this part does not close and remains free.

- Blow out all voids and irregularities with polyurethane foam. But again, be careful not to touch the working area of the crossbar system. When squeezed out, the foam expands greatly and can move the working mechanism, and at the same time squeeze out part of the insulation. After hardening, cut off all excess with a knife.

The voids are filled with foam

- Along the perimeter, degrease the edge, squeeze out liquid nails or sealant and glue the isolon to move the dew point inward.

- Next, mark the size of the canvas and cut off the required part of the fiberboard or laminate sheet, depending on how exactly the canvas will be decorated from the inside. Use a thin drill to make holes in the same place where the screws were previously attached.

- Degrease the surface again and place the laminate on the sealant. Screw it loosely around the entire perimeter.

- Return the metal door to the opening on its hinges and tighten all the screws. Separately, the edge should be treated with an adhesive-based rubber seal. This is a guarantee that the door will close softly, tightly and keep the cold out.

High-quality joints are ensured by a rubber seal

This is the simplest and most convenient method, on which you will spend at most 2 hours, and the result will be an insulated metal street entrance door.

VIDEO: It is clearly shown exactly how the front door is insulated from the inside

The situation is somewhat different with a non-demountable structure, but even here you can manage it on your own in a few hours.

How to properly insulate a non-demountable structure

In this case, you can choose one of two options:

- pouring dry insulator into the cavity.

- external internal or external insulation;

For the first option, granular foam is perfect - it is sold in most hardware stores. This method cannot be called ideal, since a private house requires a door with a thermal break, and in this case, cold bridges are preserved, but in any case it is better than just an empty sheet.

Beautiful ideas

The appearance of the front door always emphasizes the status of the owner. Therefore, in a private home the requirements are especially high. Here it is important to take care of a decent image. The market for metal doors is saturated with a variety of products. Another good thing is that doors can be ordered according to a personal project.

And yet, how nice it is to work on the design yourself! We offer several ideas for decorating metal doors with your own hands. The design of a door in an apartment is interesting because the outside can be decorated so as not to attract other people's attention. The simplest, most affordable way is to decorate a metal door with bright fittings. You can attach new numbers to the outside, add stylized handles, hinges, and locks.

For those who prefer natural materials, we can recommend covering the inside of the door with MDF panels or simple wooden slats. The design and color of the metal door of a private house, as well as the shape, depend on the style in which the house or cottage is built. For fittings, you can use forged parts, stained glass windows, glass inclusions. And instead of a modern bell, you can hang a knocker or gong.

We insulate non-dismountable iron sheet

It happens that the design of the canvas cannot be disassembled. But it is still possible to insulate a door leaf of this type and it is not at all difficult as you might think. This is even somewhat simpler than insulating collapsible metal doors. So, how can you insulate an iron door if it can’t be taken apart?

Several holes with a diameter of 20-25 millimeters should be drilled in the upper end of the door leaf. Subsequently, these holes will need to be welded or sealed in another way. Insulation will be installed through these holes. For these purposes, dry, granular insulation should be used. To thermally insulate the canvas with such material, it does not need to be laid or secured.

Granulated polystyrene foam or foam balls are simply poured through holes drilled in the upper end. It is not advisable to use sawdust for this, since they do not have such high thermal insulation characteristics as modern materials.

Laying and compacting granular insulation is done by shaking the door leaf and tapping on it.

Improving the characteristics of Chinese products

The Chinese-made door is a non-demountable structure. To insulate it, remove the door and place it horizontally. We remove the handles, peephole, locks. Then we begin to attach the frame and stiffeners to it, both from the inside and from the outside. Therefore, we choose a wooden beam with a thickness of 20 * 20 mm, or more (we start from the thickness of the insulation material). If desired, you can weld a metal base, attach it with self-tapping screws or weld it to the door leaf, and fill the joints with polyurethane foam.

The next step is laying insulation. If fibrous materials are selected (mineral wool, stone wool), we lay out a water-repellent material larger in size than the base cavities, approximately 200 mm, secure with glue (liquid nails) and line the wool, having previously cut out a canvas slightly larger than the size of the base cells, and cover with another layer of water-repellent material. We fold the edges of the film tightly onto the top layer and secure with tape.

We cover the insulation with foil isolon or penofol with the foil side facing the room. This will improve the soundproofing qualities of the door. Polystyrene foam, expanded polystyrene, polystyrene, foil-coated isolon do not need waterproofing, since they themselves have water-repellent properties. Next, use a tape measure to measure the distance between the stiffeners, cut the insulation a little larger than necessary to avoid the formation of a cavity between the insulation and the base of the door. We glue the insulation into the cavity with glue (liquid nails).

We coat the base attached to the surface with mounting foam at the joints. The next step is to decorate the structure with an MDF sheet, panel or alternative material. It is important to remember that the decorative panel must be attached from the bottom up. We secure it, install locks, a peephole and handles, and hang the door. Now the door keeps the house warm and also protects from noise.

Common mistakes when insulating

Insulating metal doors is a fairly simple and straightforward process, so it is not necessary to involve professionals to carry out the work.

Having decided to remake it yourself, it is important to adhere to the described algorithms. To avoid unnecessary mistakes, take note of these simple tips:

- When insulated, the door becomes thicker than it was originally. This fact must be taken into account when selecting accessories - locks, handles, peepholes.

- You should not carry out insulation work while the door is in a vertical position. This will not only complicate the process, but will also lead to displacement of the insulation.

- When using polyurethane foam to fill joints, it is worth considering its ability to expand. When dried, its volume increases 2-3 times, which can compromise the integrity of the structure.

- When installing a new iron door, it would be useful to leave the old wooden one. Thus, the air space formed between the canvases will help enhance the heat and sound insulation properties.

- If, after laying the insulation in the cells of the frame, gaps have formed, they can be eliminated using pieces of polystyrene foam or polyurethane foam.

Following these tips will help you achieve good results and avoid annoying mistakes when insulating your home. Knowing how to insulate an iron door yourself, you won’t have to turn to the help of professionals.

Tips and tricks

The following recommendations should be followed:

- It is best to insulate a plastic door with glass, using an additional double-glazed window;

- it is necessary to pay equal attention to both the insulation of the canvas and the thresholds and the perimeter of the doorway;

- standard Chinese metal doors immediately need to replace the insulation.

The front door requires special attention when protecting from the cold. The entire perimeter should be insulated, and the door should be closed tightly and quietly using a seal. The insulation process for doors made of plastic and metal with wood is different.

External method

In addition to internal insulation, you can also resort to external insulation; this will not only help achieve the best result, but will also transform the old door. For this purpose, you will need a piece of dermantine slightly larger than canvas and several strips, with the help of which sealing rollers are made around the perimeter.

Using glue, it is necessary to glue pieces of soft sealing around the perimeter of the door. Next, sheets of isolon, polystyrene foam or mineral wool are attached.

The final point is fastening the dermantine. The edges must be folded and attached with glue on top of the rollers, then install the fittings.

Why does heat pass through the door?

It happens that the canvas has high-quality insulation, but for some reason the heat leaves the room. What is the reason? Common causes of heat leakage include:

- Presence of cracks in the canvas. These defects may appear due to inaccuracies during the installation of the structure, subsidence of the structure, or, for example, such unfavorable factors as sudden temperature changes, etc. Sealing compounds or putty will help solve the problem.

- Insufficient fit of the front door to the frame. This is associated with deformation of the canvas or damaged loops. Replacing elements or adjusting the dimensions of the door will help correct the situation.

- Large space between the threshold and the bottom of the canvas. This situation can be changed by replacing the worn threshold with a new one.

Another possible reason is the insufficient thermal insulation properties of corrugated cardboard or other thermal insulation material. Sheathing, upholstery or the construction of a vestibule will help to cope with the problem.

Characteristics of insulation

All door insulation must have the same characteristics. First of all, low thermal conductivity. This quality is extremely important when insulating dachas, garages and private houses - places where the doorway quite often opens directly onto the street.

Also valued is high resistance to adverse factors, such as changes in humidity, temperature, fire resistance, etc. In addition, the insulation should not lose its qualities over time. It is important that the material is elastic and easy to install. At the same time, its accessibility is not the least important. Good material should not be expensive so that doors are available to a wide range of consumers.

Door seal

Very often the cause of drafts is a large gap between the door frame and the leaf. Rubber seals can solve the problem. This element has a sticky base, due to which it is securely fixed in place. It can be found on sale in various profiles and widths. If desired, you can add glue to the adhesive part.

Rubber seals are available in stores, but if desired, you can make them yourself. For this purpose, take strips of foam rubber, the thickness of which corresponds to the size of the gap, and wrap them in upholstery material, for example, dermantin (it is desirable that the shade matches the shade of the door).

The resulting rollers are nailed along the perimeter of the canvas. Perhaps the look is not entirely aesthetic, but the quality of such work is beyond doubt.

Threshold insulation

Sometimes front doors release heat at the threshold area. This can and should be fought. There can be several ways:

- Replacing the threshold with a new one, with a clearly adjusted height and high-quality work.

- Creating a roller, similar to the one described in the insulation of the door contour. The object is fastened using nails to the bottom of the canvas.

- A special sealing brush, which, like the roller, is attached to the bottom of the canvas using nails.