Here you will learn:

- What does boiler efficiency depend on?

- How to calculate the efficiency of a heating boiler

- Reasons for reducing the efficiency of heating boilers

- How to increase the efficiency of a gas boiler

- Installing radiators for maximum efficiency

- What should an energy efficient boiler be like?

- Which gas boiler has the highest efficiency?

In order to define the concept of an economical gas boiler, it is necessary to clarify that such a boiler will heat the room at minimal cost. This is a boiler that is correctly calculated in terms of power in accordance with the heating area, with high efficiency, with good regulation of operating modes, and with optimal gas consumption. If we generally define the criteria for boiler efficiency, then we should pay attention to the following:

- Optimally suitable power;

- High efficiency;

- Optimal design and additional equipment;

- Reliable, well-established manufacturer.

Let's consider these and other criteria that affect the efficiency of the boiler. In details.

What is efficiency

Nowadays, many companies, both domestic and foreign, produce gas boilers. When choosing such equipment, owners of private houses in Russia, unfortunately, mainly look only at its price and power. Meanwhile, a very important parameter that allows you to choose a good heating unit is efficiency. A gas boiler, among other things, must be highly efficient.

The higher the efficiency of such equipment, the less home owners will subsequently need to pay for blue fuel. The efficiency of gas boilers is called the ratio of fuel consumed to thermal output.

Criterias of choice

When choosing a condensing device, it is recommended to give preference to a manufacturer with a good reputation among customers and who produce products using innovative technologies with increased operating comfort.

Regarding the technical characteristics of boilers, you need to pay attention to the following points:

Performance. Too much power may not always be a good option, and operating at half capacity will soon lead to equipment failure. Therefore, before purchasing a device, it is necessary to calculate the optimal power for heating the house. To do this, you need to calculate the area of the building, height and level of insulation. You can even use special tools to explore a private home. They will help identify existing heat losses. The optimal power of condensing devices depends on the climate zone. For example, for Moscow, for a 10 m2 house, the equipment power should be in the range of 1-1.5 kW. Thus, for a private heating system with an area of 200 m2, you need equipment with a power of at least 20 kW.

The speed of heating response to external factors largely depends on it:

- Silumin, or an alloy of silicon and aluminum, is designed to combat aggressive condensate. In this case, the heat exchanger must be seamless, since the presence of seams increases the risk of corrosion.

- “Stainless steel” is considered an inexpensive material compared to silumin. The advantages of stainless steel include resistance to corrosion, lack of inertia and immunity to thermal shock. Therefore, the rating of materials for the manufacture of heat exchangers is headed by “stainless steel”.

- Environmental friendliness. Conventional turbocharged boilers, when burning fuel, emit vapors with acidic impurities into the atmosphere, and in condensing devices the vapors dissolve in condensate and are neutralized.

- The operating temperature affects the efficiency of the equipment. As the temperature decreases, the intensity of condensation increases. Thus, at a vapor temperature of 30 to 40 degrees, the rate of condensation formation is highest. In this case, condensation occurs in a constant mode.

- Control. Modern condensing devices are equipped with an automated control system. Automation allows you to monitor and manage temperature, flow and pressure in the circuits. The most advanced boiler models are regulated through a special application on a smartphone.

- Installation method: on the floor or on the wall. Floor-standing models with one circuit are available with a power of more than 100 kW and are easily connected to boiler equipment using pumping units. For intensive use of hot water, a floor-standing boiler is an excellent solution. If the house area is small and much less water is consumed, it is recommended to give preference to wall-mounted models with two circuits. They are compact and have low power - up to 100 kW, are easy to install and do not require a special chimney.

- Pricing policy for condensing type gas boilers.

All equipment models are divided into the following classes:

- Premium boilers are usually produced under German brands. They are easy to use, safe in all respects, silent, made of high-quality materials, efficient in operation and meet environmental requirements. However, they have one drawback - high cost.

- Medium-cost boilers are produced by the Baxi brand and are distinguished by comfort, efficiency, environmental friendliness and a variety of models. Devices of this class also meet European requirements.

In the next video you will find a review of the Vaillant EcoTec condensing boiler from ABC Heat.

Formula for calculating average efficiency

The efficiency is also indicated in the technical data sheet of the boiler. However, in this case, the consumer is provided with only an average indicator, which is calculated by companies involved in the manufacture of such equipment using the following formula: n=(Q/Qo)*100%.

Here Q is the heat that was released, accumulated and used to heat rooms; Qo is the total amount of thermal energy released when fuel is burned.

Unfortunately, using this formula, you can only get ahead of the average efficiency. Gas boilers with high performance indicators are presented in a fairly large assortment on the modern market. For some modern brands of such units, the efficiency can reach 98%. This is, of course, a lot. However, in practice, modern gas units, unfortunately, often do not demonstrate such efficient operation. During the operation of such equipment in private homes, various types of heat loss occur, which has the most negative impact on efficiency. That is, when installed in a house, gas boilers usually lose performance.

How to take into account the height of ceilings when calculating?

The formula below is suitable when the ceilings in the house are of standard height.

Those. do not exceed 2.6 - 3 meters. If the ceilings are higher, calculation by area will not work.

You need to use volume.

Knowing the volume of the room, you can calculate the predicted heat loss (HL) using the formula:

PT = V (volume) x Pt (difference t) x k: 860.

Pt – difference in average temperatures outside and indoors. Example: in winter the average temperature is -30 C, but in the house you want it to be 22 C. Pt = 52. The higher this indicator is, the more the building will lose heat.

k is the dispersion coefficient. It depends on the building materials from which the structure is made:

- Wood or corrugated iron, no insulation = 3–4.

- Single brickwork, regular windows and roof, average thermal insulation = 2 – 2.9.

- Double brickwork, good thermal insulation, few windows = 1 – 1.9.

- Excellent thermal insulation, plastic windows, well insulated floor and ceiling = 0.6 - 0.9.

Now that all the basic data is known, you can calculate the boiler power using the formula:

M = PT x kz.

Kz in these calculations is the safety factor. It is equal to 1.15 - 1.2 (that is, 15 - 20%)

Example. Brick house with good thermal insulation, area 60 m2. And the ceiling height is 3m.

- Let's calculate the volume. 60m2 x 3 = 180m3. Pt = 52, k = 1.5.

- We substitute the data into the formula: PT = 180 x 52 x 1.5: 860. PT = 16.32.

- We multiply this indicator by the safety factor: 16.32 x 1.2 = 19.58.

- We round up and get a boiler with a capacity of 20 kW.

Actual efficiency - formula

On site, the efficiency of such equipment is usually determined using the following formula: η = 100 - (q2 + q3 + q4 + q5 + q6).

Here:

- q2 - heat losses due to heated combustion products going into the pipe;

- q3 — losses due to incorrectly chosen proportions of the gas mixture (underburning);

- q4 - losses due to soot inside the boiler and mechanical underburning;

- q5 - losses due to fluctuations in outside air temperature.

It is believed that the boiler efficiency is most strongly influenced by the q2 indicator. That is, to the greatest extent, the performance and efficiency of a gas heating unit depends on how much heat it induced literally “flies down the drain.”

How to calculate how much heat is needed to heat water?

To calculate heat consumption in this case, you must independently add the heat consumption for hot water supply to the previous indicator. To calculate it, you can use the following formula:

For example, the average family consumes 150 liters of warm water. The coolant that heats the boiler has a temperature of 80 °C, and the temperature of the water coming from the water supply is 10 °C, then Δt = 80 - 10 = 70 °C.

Then you need to do the following:

- Let's say you need to heat 150 liters of water at a time, which means the capacity of the indirect heat exchanger is 150 liters, therefore, 12.25 kW/h must be added to 28.58 kW/h. This is done because the Qzag indicator is less than 40.83, therefore, the room will be cooler than the expected 20 ° C.

- If the water is heated in batches, that is, the capacity of the indirect heat exchanger is 50 liters, the figure of 12.25 must be divided by 3 and then added independently to 28.58. After these calculations, Qzag is equal to 32.67 kW/h. The resulting indicator is the power of the boiler, which is necessary to heat the room.

Which boilers have greater efficiency

Domestic manufacturers currently produce quite powerful and reliable gas heating equipment. However, in our country, unfortunately, too much attention is still not paid to saving resources. Therefore, today imported gas boilers have the highest efficiency. This is especially true for low-temperature condensing models, in which the heating rate of the coolant does not exceed 70 °C, and the exhaust gases - 110 °C.

The most productive brands of gas boilers, the efficiency of which is very high, on the modern market are:

- "Buderus."

- "Wissman."

- "Baksi."

- "Vailant."

De Dietrich is also considered a very good brand of heating units with high efficiency.

Choosing a torch for soldering

Soldering or cutting cannot be done using ordinary gas torches. For this purpose, powerful and productive devices are needed, equipped with an air blower or an injector. By adjusting the composition of the supplied mixture, you can achieve the flame of the required strength and perform the necessary work related to soldering metals or other materials. Professional torches used for soldering are expensive, and therefore they are needed by a narrow circle of specialists. The power of such devices is 10-15 kW.

Attention! This material is the subjective opinion of the authors of the project and is not a guide to purchase

How to increase the efficiency of a gas boiler: basic methods

If the boiler in the house does not work with proper performance, its owners will have to overpay for gas consumption, which, of course, will have a very negative impact on the family budget. To increase the performance of the heating unit and thereby avoid unnecessary expenses, you can:

- modify the chimney or improve the conditions for exhaust gas removal;

- clean the combustion chamber;

- clean or replace the lines of the home heating system;

- make changes to the boiler design;

- adjust the proportions of the gas mixture in the combustion chamber using a damper.

Using such techniques, it is possible to increase the efficiency of both a double-circuit gas boiler and a single-circuit one. Such methods are also suitable for wall-mounted or floor-mounted gas heating units.

Insulation of windows and doors

This step does not directly relate to either the boilers or the system, but it directly affects the performance of the work. If you open the room to all the winds, then it will be warm only if you sit with the boiler in your arms and you can forget about energy efficiency. A properly insulated room will retain the heat given off by the radiators inside, the boiler will not have to be started again and less gas will be consumed.

Preparing for winter a house with an installed gas heating appliance is no different - it means installing plastic windows, and if they already exist, then switching to winter mode. In regular window frames, the cracks are plugged and sealed with tape.

It all starts with insulation

What to do with the chimney

The performance of boilers is greatly influenced by the condition of the combustion products discharge pipe. If the chimney becomes clogged with soot, this will reduce its diameter and, accordingly, draft. Experts recommend checking the condition of the pipe that discharges gas combustion products at least once a year.

To increase efficiency, it is best to connect a closed-type boiler to a coaxial chimney. In this case, the air will begin to enter the combustion chamber through the outer cavity of the two-cavity pipe, already slightly heated. This, in turn, will reduce the initial heat costs by several percent.

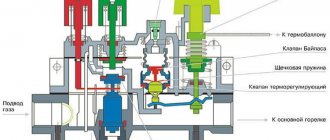

Adjusting the proportions of the gas mixture

In the design of any modern heating unit, among other things, there is such an element as a damper. By correctly adjusting its position, you can significantly increase the efficiency of a gas boiler.

If the boiler damper is opened too much, too much air will enter the combustion chamber. In this case, a draft will form in the firebox, drawing some of the blue fuel out into the street along with the combustion products.

An even more serious decrease in the efficiency of a gas boiler can be caused by closing the damper too much. In this case, little air will enter the combustion chamber. As a result, some of the gas simply will not burn and will also exit into the chimney along with the smoke. The efficiency of the heating unit with this position of the damper can decrease by as much as 7%.

It will not be difficult to adjust the proportions of the combustible mixture inside the boiler firebox yourself. This can be done experimentally. The home owner simply needs to pull out and close the damper until the boiler thermometer shows the highest heating of the coolant in the heating system.

Heat loss when removing flammable gases

The most significant heat losses occur as a result of the evacuation of flammable gases into the chimney (q2). The efficiency of the boiler largely depends on the combustion temperature of the fuel. The optimal temperature pressure at the cold end of the water heater is achieved when heated to 70-110 ℃.

When the temperature of the exhaust combustible gases drops by 12-15 ℃, the efficiency of the water heating boiler increases by 1%. However, in order to reduce the temperature of the exhaust combustion products, it is necessary to increase the size of the heated surfaces, and, therefore, the entire structure as a whole. In addition, as carbon monoxide cools, the risk of low-temperature corrosion increases.

Among other things, the temperature of carbon monoxide also depends on the quality and type of fuel, as well as the heating of the air entering the firebox. The temperatures of incoming air and exiting combustion products depend on the type of fuel.

To calculate the heat loss rate with flue gases, use the following formula:

Q2= (T1-T3) × (A2 ÷ (21-O2) + B), where

T1 – temperature of evacuated flammable gases at a point downstream of the superheater;

T3 – temperature of air entering the furnace;

21 – oxygen concentration in the air;

O2 is the amount of oxygen in the exhaust combustion products at the control point;

A2 and B are coefficients from a special table that depend on the type of fuel.

Cleaning the combustion chamber

Blue fuel is distinguished primarily by the fact that its combustion does not produce too much soot. Of course, it is necessary to clean the furnace of a gas-fired boiler less often than of solid fuel equipment of this type. But it is still necessary to wash the combustion chamber of such heating units from time to time. Experts believe that owners of gas boilers need to do such cleanings at least once every 3 years.

Scale in pipes

In order not to spend a lot of money on gas, it is imperative that owners of private houses also monitor the condition of the heating system lines. The boiler's performance can also be reduced by regular clogged pipes. Experienced owners of country houses, for example, do not advise changing the coolant in the heating system circuit too often. It is not advisable to drain water from the mains even after the end of the cold season. The fact is that any water from a well, a well or a centralized system contains a huge amount of dissolved minerals, which subsequently fall out in the pipes in the form of sediment.

Rule of successful statistics

What is the point of bringing a tank onto the field? Of course, the goal is to remain in a combat-ready state for as long as possible and at the same time accomplish something useful, for example, inflict incredible damage, illuminate enemy tanks, prevent the capture of a base, and so on.

You should not immediately merge, even if your nickname is at the end of the list. You need to be patient and wait. As soon as it becomes clear what positions the tanks occupy, you can begin to plan your actions.

It also happens that players on a team merge, and you have to be left alone with enemy vehicles. Just don’t give up right away, even if it seems like you can’t handle it, continue the game. Sometimes such tactics help to increase the number of unfinished tanks and recapture HP.

What changes can be made to the design?

To increase the efficiency of wall-mounted or floor-mounted gas boilers, special turbulators can be installed between the combustion chamber of the unit and its heat exchanger. This is the name for special plates that can significantly increase the area of heat energy extraction.

The operation of the boiler can also be controlled using temperature sensors. Such devices are installed in the premises of the house and turn on/off the burner of the heating unit depending on the air warming up to the temperature set by the owners. When using sensors, it is important to correctly configure and synchronize the operation of the boiler in accordance with the latter’s readings.

The burner of gas heating units is turned on when the air temperature in the premises drops below the specified parameters using a special “lighter”. This is the name given to a small burner whose gas never goes out. Such a “lighter” cannot burn a lot of blue fuel. However, during the season, due to its operation, several cubic meters of blue fuel are often burned. To reduce losses, the usual “lighter” in the boiler can be replaced with a “piezo”. Such a device will work no worse than a traditional one, and the savings from its use are quite significant.

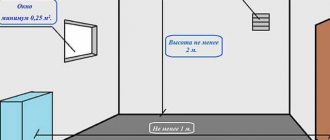

Heating system requirements

Regardless of whether an old system is being modernized or it is being designed from scratch in a newly built house, the first thing to start with is becoming familiar with the regulatory documentation. It describes in detail how the equipment is put into operation and describes the subtleties and features of its further use.

After spending some time on this, you can be sure that the heating system will last for many years. From year to year, the requirements are adjusted and updated. But there are some principles that every cottage owner should know. The first thing that needs to be ensured when installing a heating system is explosion and fire safety.

For safe operation during the installation process, you need to ensure free access to the equipment for cleaning and regular checks.

The list of rules that will help make a private home not only cozy, but also safe to live in, should include the following aspects:

- The temperature of open heating system elements should not be higher than that recommended by the manufacturer.

- Equipment and all appliances should be properly insulated. This will avoid burns, eliminate the formation of moisture and reduce heat loss. In addition, hot elements can ignite dust, gas or aerosol in the room.

- When using a coolant, the temperature of the latter must be 20 degrees Celsius lower than its evaporation or self-ignition temperature. For example, if the system uses water, then it must be prevented from boiling. An excellent solution would be to raise the pressure.

There are also operational requirements for the heating system. After all, any equipment must be as strong, durable, easy to operate, silent and easy to repair as possible.

It is better to order equipment from trusted manufacturers. Such companies produce truly high-quality products, since they stand behind them with their own name.

By choosing a boiler, radiators and pipes that best meet the listed criteria, you can save yourself from many problems.

Other changes

Among other things, gas heating units equipped with modulating burners also have very good performance indicators. Modern boilers from the best European manufacturers are initially supplemented with similar two-level or fully modulated elements. Burners of this type are able to independently adapt to the actual operating parameters of the heating system installed in the house. Thus, the percentage of underburning in boilers of this design is reduced to a minimum.

In conventional heating units, home owners can, among other things, try changing the position of the burner. Installing this element closer to the water circuit allows you to increase the efficiency of the boiler by several percent. In this case, the heat balance of the unit increases significantly.

Condensing boilers

Thus, increasing the efficiency of a gas boiler will be relatively easy. But of course, it is better for owners of country houses to immediately purchase economical and productive equipment of this type. Condensing gas boilers, as already mentioned, have the highest efficiency.

Such equipment appeared on the domestic market relatively recently. The efficiency of these boilers is determined primarily by the fact that they additionally use the energy generated due to the condensation of water vapor from the exhaust gases. The efficiency of such equipment is an order of magnitude higher than that of conventional heating units.

Many manufacturers of such boilers even claim that they produce gas boilers with an efficiency of 100% or higher - 108-109%. Of course, such statements are disputed by experts. After all, as you know, the efficiency of any equipment rarely reaches 100%. Such an indicator cannot exceed this figure at all. Of course, even the most advanced heating unit is not capable of increasing the amount of heat when burning the same volume of blue fuel.

But still, the efficiency of gas condensing heating boilers is much higher than conventional ones. According to experts, it can reach 98-99%.

In terms of gas consumption efficiency, condensing boilers are thus significantly superior to simple ones. However, unfortunately, such equipment also costs much more than traditional equipment. Whether or not to purchase such a unit is a matter of choice for the owners of the gasified house themselves. Most likely, during the operation of a gas boiler with a high efficiency condensing boiler, the difference in cost will eventually pay off. But this will not happen too quickly, for which buyers should be prepared in advance.

How to increase the efficiency of heating equipment running on solid fuels

Today, many consumers, having at their disposal a solid fuel boiler, are trying to find the most convenient and practical way to increase the efficiency of heating equipment. The technological parameters of heating devices set by the manufacturer lose their nominal values over time, so various methods and means are being sought to increase the efficiency of boiler equipment.

Let's consider one of the most effective options, installing an additional heat exchanger. The task of the new equipment is to remove thermal energy from volatile combustion products.

In the video you can see how to make your own economizer (heat exchanger)

To do this, we first need to know what the temperature of the smoke at the outlet is. You can change it using a multimeter, which is placed directly in the middle of the chimney. Data on how much additional heat can be obtained from evaporating combustion products is necessary to calculate the area of the additional heat exchanger. We do the following:

- we send a certain amount of firewood into the firebox;

- We measure how long it takes for a certain amount of firewood to burn.

For example: firewood, in the amount of 14.2 kg. burn for 3.5 hours. The smoke temperature at the boiler outlet is 460 0 C.

In 1 hour we burned: 14.2/3.5 = 4.05 kg. firewood

To calculate the amount of smoke, we use the generally accepted value of 1 kg. firewood = 5.7 kg. flue gases. Next, we multiply the amount of wood burned in one hour by the amount of smoke produced by burning 1 kg. firewood As a result: 4.05 x 5.7 = 23.08 kg. volatile combustion products. This figure will become the starting point for subsequent calculations of the amount of thermal energy that can be additionally used to heat the second heat exchanger.

Knowing the value of the heat capacity of volatile hot gases as 1.1 kJ/kg, we make a further calculation of the heat flow power if we want to reduce the smoke temperature from 460 0 C to 160 degrees.

Q = 23.08 x 1.1 (460-160) = 8124 kJ thermal energy.

As a result, we obtain the exact value of the additional power provided by volatile combustion products: q = 8124/3600 = 2.25 kW, a large figure that can have a significant impact on increasing the efficiency of heating equipment. Knowing how much energy is wasted, the desire to equip the boiler with an additional heat exchanger is completely justified. Due to the influx of additional thermal energy for heating the coolant, not only the efficiency of the entire heating system increases, but also the efficiency of the heating unit itself increases.