However, if the moment of inertia of the existing beams is 6000 cm 4, then you simply need to select the cross-section of the reinforcing beams, based on the fact that the missing moment of inertia is 2000 cm 4. For example, you can specify a beam width of 5 cm and then the required height of the beam will be. An example of calculating a reinforcing beam is given separately.

For example, if, according to the calculation for deflection, the required moment of inertia I tr is 8000 cm 4, and the moment of inertia of the existing beams is 4000 cm 4, then it is necessary to strengthen the overlap with beams of exactly the same section or beams with the same moment of resistance. When the cross-section of wooden beams is taken without calculation, either by eye or on the basis of the authoritative opinion of a neighbor, then problems may arise with the strength or deflection of such beams when calculating for all acting loads. As a rule, this is discovered already at the operation stage, when simply replacing old weak beams with new ones is too expensive, and technologically it can be quite difficult. In such cases, the question arises: how can you strengthen a wooden beam? However, a similar question may arise when redevelopment is being contemplated.

Install additional wooden beams

This method is good because it requires a minimum of calculations, and they are also quite simple (the basics for calculating wooden floor beams are given separately). However, from a financial point of view, this method may be the most expensive. For example, if, according to the deflection calculation, the required moment of inertia Itr = 8000 cm 4, and the moment of inertia of the existing beams is 4000 cm 4, then it is necessary to strengthen the overlap with beams of exactly the same section or beams with the same moment of resistance. However, if the moment of inertia of the existing beams is 6000 cm 4, then you just need to select the cross-section of the reinforcing beams, based on the fact that the missing moment of inertia is 2000 cm 4. For example, you can set the width of the beam to be 5 cm and then the required height of the beam will be h = 3 √ 12I/b = 3 √ 12 2000/5 = 16.87 cm Of course, the height of the beam should be taken larger, most likely it will be 20 cm, however, to order you they can make 17 cm. That’s the whole calculation in this case.

The use of overlays for strengthening and repairing floor beams is used when there is damage in a certain area. The point of restoration work is to install wooden overlays on both sides of the problem area, which are attached to entire parts of the beam with bolts complete with nuts and washers. If a section of the floor beam is damaged to such an extent that there is practically nothing left of it, overlays must be installed over the entire beam length: from one wall to another. Metal profiles should be used at junction points. In particular, a steel prosthesis, which is a metal strip or metal rod of the appropriate diameter bent at 90º.

Application of overlays.

The methods proposed in the article for strengthening wooden floor beams will extend the service life of structures where such beams are present. This process is very important, and in some cases simply necessary. After all, floor beams made of wood become completely or partially unusable over time, threatening the destruction of the entire structure. There are many reasons for this: dampness, rodents, sudden temperature changes, and simply natural wear and tear from carrying loads.

Content

- Application of overlays.

- Metal reinforcement.

- Increase in cross-sectional area.

- Carbon fiber reinforcement.

Room correction options

Logs are a universal tool that allows you to adjust and improve any home. They can be placed over the entire surface or partially, choose clear shapes or unusual designs. There are many styling options, you can always find your ideal option. European design is very popular these days, in which the joists are moved to the wall.

Floors are subjected to the following types of treatment:

Brushing. In this case, a realistic imitation of wood texture is created. They even make marks from the bark beetle. This method is used when you need to create a spirit of antiquity in a room.

Textured processing is another method of artificially aging wood. This effect is achieved by treating the wood with special brushes and a special planing technique.

Vintage style - ceilings are treated with paints and varnishes, also giving them an antique look.

Traditional style combines simplicity and lightness. A room decorated in this style is especially cozy and comfortable. For this effect, a varnish or oil-wax coating of the floors is done.

Metal reinforcement

Continuing the topic of ways to strengthen wooden floor beams with the help of a steel prosthesis, it should be noted that metal is used not only in the places where the beam adjoins the wall.

It can also be successfully used as overlays instead of wooden ones. In this case, any metal profiles must undergo anti-corrosion treatment before installation. Simply put, they are painted. In addition to strips and round profiles, you can use a channel, a corner, or simply sheet metal as overlays. All metal profiles are attached to sections of wooden beams using the same kit: bolt, nut, washer.

When deciding in favor of reinforcing wooden beams with metal, it is necessary to take into account the fact that metal is more expensive than wood. In addition, it has more weight, which can be an additional load on the beam itself.

Another good solution is the construction of prefabricated beams from three wide boards of small thickness (25 - 50 mm). And in this case, the butt joints of the boards inside each beam and between adjacent beams are spaced apart; the boards are glued along their length and additionally tightened with pins. To determine the condition of the load-bearing beams, it is necessary to calculate the maximum permissible deflection of the element. The norm is 1/300 of the length of the beam. That is, with a length of 3 meters, the deflection in the central part should not exceed 10-12 mm. If the value is greater, repairs are required - strengthening and strengthening the load-bearing component of the floor.

And one more important point: when making wooden attic floors, you do not need heavy lifting equipment, especially a concrete pump.

Today's:

- Flowers attract men to the house. Indoor flowers that attract men to the house; they have powerful love energy

- Why are window shutters needed? History. Why were shutters needed in houses in Rus': wowavostok

- And we are settling into our new kitchen.

- Dressing room with washing machine. Washing machine in the pantry/dressing room - to do or not to do?

- Two-room apartment in loft style, 60 m

- From our subscriber:

- The weight of one solid red brick is 250x120x65. Weight of 1 red solid brick.

- Strengthening wooden beams. When to strengthen wooden floor beams

- Repair of wooden floor beams. Attic flooring using wooden beams: a review of the best designs and tips for choosing beams

- Reinforcement of floor beams with plywood. Splicing and strengthening

- Strengthening a wooden beam with a corner. Strengthening wooden floor beams

- Reasons for weakening the load-bearing capacity of the floor

- Ways to strengthen a wooden floor beam

- What to do if strengthening floor beams is not possible?

- Video of simple strengthening of wooden floor beams in your home

General information

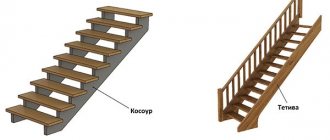

A beam is a structural element, which is a rod that is subject to forces in a direction perpendicular to its axis. Under the influence of these forces, any beams, including wooden ones, are deformed.

A slight deflection is completely acceptable. For example, when walking on a wooden floor, we often feel how it springs slightly. But if the deflection exceeds the permissible values, this can lead to breakage of the part.

Acceptable deformation is one that meets the following requirements:

- Does not exceed the calculated values.

- Does not interfere with comfortable use of the home.

To find out how much a part will deform in a given case, it is necessary to perform some calculations for rigidity and strength. It should be noted that such work is usually carried out by civil engineers. However, in private construction, after familiarizing yourself with some formulas, you can perform them yourself.

Minor deflection of floors is allowed

It must be said that calculating the deflection of a wooden beam is a very responsible job, because any building must meet certain strength requirements. Therefore, beams must have a certain stability and rigidity so that the structure can withstand the planned loads with a certain safety margin.

Increase in cross section

For this purpose, wood overlays are used. Use boards and timber. The cross section is selected depending on the degree of damage and the planned load. It is worth noting that increasing the section on the sides is not effective. To understand this, just look at the formulas by which the elements are calculated. The width in these calculations is taken to the first power, and the height to the second. When the dimensions are doubled in the first case, the load-bearing capacity doubles, and in the second it quadruples. Tightening an existing beam with an overlay using bolts, staples or studs. Professional craftsmen prefer the latter option. When tightening the nuts, be sure to use washers to avoid damaging the wood. An insulation layer is provided between the metal parts and the wood, for example, Technolast EPP. The damaged area is treated with an antiseptic before performing work.

Design norms and standards differ for reconstruction, redevelopment or other types of work. At the initial stage, the designer determines the following points: Specialist comment. The result of design and construction work depends on the completeness and accuracy of the surveys. Without objective expert conclusions, it is impossible to choose the necessary options and solutions for reinforcing floors. Therefore, the Smart Way company always pays special attention to the pre-design stage of the survey and involves all the necessary specialists in the work.

Design of project sections, description of solutions for strengthening floors. Reading time: 5 minutesWhat is a floor - this is a horizontal internal structure of a building, which has load-bearing functions, ensures the strength and reliability of the object. Consequently, the main purpose of strengthening floors is to increase the strength and permissible loads of this structure. Various methods of strengthening floors, as well as other structures, are used in reconstruction, redevelopment, redevelopment and major repairs of buildings. Read in this material how reinforcement of floors is carried out in practice, whether it is necessary to design and approve this type of work, what is examined in the building before developing a project .

"Little blood"

Most homeowners will prefer to reinforce the floors in such a way that it remains possible to live within the walls of the building. In most cases this is indeed possible. If the wood of the load-bearing beam is damaged, but it has not yet crumbled into dust and retains its main characteristics, some kind of prosthetics can be installed on the element. And from different materials.

- Deflection of beams can be eliminated by applying wooden prostheses. The pads are fixed as tightly as possible on both sides of the damaged element, either on both sides, or on top and bottom. Maximum strengthening of floor beams is achieved by fastening the lining along its entire length. In this case, it is important to treat both the prosthesis and the element being strengthened with an antifungal compound.

- Reliable reinforcement of the overlap can be achieved using metal overlays or rod prostheses. Steel plates are used on the same principle as wood linings, only they are treated not with antibacterial, but with anti-corrosion agents.

- Reinforcing floor beams with carbon fiber has recently become much more popular than wooden overlays and metal prostheses. Carbon fiber is available in the form of tapes, fabrics, plates and strands, so it is not difficult to choose the option that is most convenient to work with in specific conditions. The material is glued in several layers until the desired degree of reinforcement is achieved. Working with carbon fiber is simple: it is light, plastic, attached with glue, which greatly facilitates installation, and is non-flammable, which increases the fire resistance characteristics of wooden beams and other structural elements made of wood. Carbon fiber becomes especially relevant in cramped spaces where there is not much freedom of movement.

Note that strengthening floor beams using the listed methods only makes sense if the deflection of structural elements is not accompanied by significant deformations. Strengthening beams that have significant mechanical damage in this way is only suitable as a temporary measure.

What kind of work and projects require reinforcement of floors?

If a building or premises undergoes cosmetic repairs, additional loads on the floors or other load-bearing structures will not arise. If the main characteristics or configuration of the object change, reinforcement of the floors may be required:

- when reconstructing a building, i.e. when replacing or restoring load-bearing structures, increasing area and height, constructing extensions and new floors;

- during redevelopment, when the configuration of a room or building changes, work is carried out on door and window openings, and other types of changes;

- during reconstruction, since changes in utility networks and equipment may also be accompanied by additional loads on the floors;

- during major renovations of buildings, when the project may include partial replacement or restoration of floors.

For each of these types of work, design is carried out. Also, to obtain initial data on the condition of the object and its structures, a commission inspection is required.

There are three ways to strengthen structures: replacing wooden beams, increasing their number, strengthening existing ones. It is necessary to change the supporting elements if there is damage along the entire length. Damaged beams are dismantled, and new ones are installed in the same seats. The carbon fiber layer should be from 1 to 5 mm. Its value depends on the condition of the crossbar and its future load.

Damaged wooden beams, worn out by loads and time, or not strong enough initially according to the design, are the first reason for the weakening of the load-bearing capacity of the floors, the appearance of vibrations and creaking floors on the upper floors of the house.

Our company is often asked the question of what to do with sagging wooden floors and how to fix and strengthen the floors in the house. This situation is mainly faced by the happy owners of ready-made houses and cottages built hastily, without respecting the dimensions of the house design. The fact is that unscrupulous builders try to save on materials and time, reducing the use of expensive wooden beams. The future owner of the house cannot visually assess the strength of wooden floors, since they are covered with floorboards and floor coverings. After the purchase, disappointment sets in - the floors creak, and vibration is felt when walking around the room. There are extreme cases when it is simply dangerous to be around, much less place heavy furniture, due to the threat of the wooden floor beams collapsing.

The main mistakes builders make when installing wooden floor beams:

1. Raw wood is used. In this case, after natural drying, the owner of the house begins to notice cracks in the floor covering and a squeak that gets worse every day. 2. The timber used is of insufficient thickness. In this case, increased floor vibration and creaking are felt. 3. Beams with an increased span (the distance between the beams) are installed. This is a fairly common mistake among builders and finishers. The floor without load (furniture, flooring, etc.) is quite stable and it is difficult to identify poor-quality floors. As soon as, say, parquet boards are laid and furniture is brought in, the wooden floors begin to sag and vibration appears. 4. Beams assembled from two or more parts are installed. The most unpleasant option. When the beam is knocked down with nails. With such installation of beams, there is a real threat of collapse of the cottage floors. If you are faced with the above problems, then think about strengthening the wooden floor beams. It is advisable that an experienced team of builders, finishers and finishers deal with the defects.

Necessary tools and materials for strengthening wooden floor beams in a private house:

A. Retractable construction jacks “telescopes” – minimum 4 pcs. Racks can be purchased at prices ranging from 400 rubles to 1000 rubles. You can look for a used one. racks priced from 200 rubles. The size of the rack depends on the height of the ceilings of the room being renovated. From 2 m - to b m. b. Several boards at least 4 m long and at least 3 cm thick - for lining the base and the top of the racks. Boards are necessary to distribute the load between the racks and prevent damage to the floor. V. Threaded studs, at least 50 cm, with a set of nuts and washers. d. A wood drill with a diameter matching the diameter of the tie rods and a length no less than the thickness of the beam. d. Chopped blocks for linings when leveling wooden floor beams. e. Sand-concrete cement mortar.

Eliminate sagging floors in the house by adding a wooden or metal beam.

So, let's start solving the problem. Decide which material to choose for installation: Wooden beam - additional beam 200X200 or 200X150 (on edge). This is the cheapest, but no less durable option. The metal channel is very durable and reliable. When choosing this option, prepare for the high cost of the material and the inconvenient “sewing up” of the ceiling, because... It is much more difficult to fix a ceiling in metal than in wood. The technology for installing reinforcement is identical, no matter which option you choose.

Procedure for strengthening wooden floors

1. Take telescopic stands and place them at an equal distance from each other, pointing towards the ceiling or beams. NECESSARILY! We place a board at least 3cm thick under them (on the floor).2. We rest the racks close to the sagging ceiling through the spacer board and begin to twist (jack) one by one. You must have an assistant to tighten the “telescopes” simultaneously and evenly. 3. We determine the installation location of the reinforcing beam. The ideal option is in the center, between the existing beams. 4. Using a hammer drill, we hollow out holes opposite each other with a depth of at least 100 mm in the places where our reinforcement is attached. 5. We lay the bottom of the prepared hole with roofing felt and lay a little 2-5 cm of mortar. We insert the prepared beam first into one hole, then into the other (opposite).

7. If the beam does not rest tightly against the ceiling, then we drive wedges under the beam in the holes.

8. The final moment, we remove the “tension from the ceiling.” We remove the jack stands. The ceiling should “lie” on the new beam. That’s all). We hope that our advice will help you solve problems with floors. Strengthening the floors of buildings. Projects of one-story cottages.

Timber laying algorithm

During the construction of walls intended for laying timber, they are covered with their own hands in several layers of roofing material. 1 day before laying, the timber is treated with a fire retardant solution to protect it from fire.

The ends of the wooden beams are wrapped in waterproofing material and placed in niches. The distance from the ends of the beam to the walls of the niche must remain at least 4 cm. This device is filled with foam plastic or mineral wool.

Do-it-yourself ceilings in a timber house

If the wall is brick and the thickness of the wall is less than two bricks, the space is filled with cement mortar. Every third beam is fixed with an anchor protruding from the wall by 20 cm, laid during the construction of the wall. First, a device for an anchor corresponding to the diameter and depth is drilled into the beam with your own hands.

The beams are laid from the walls to the center, checking the evenness of the laying with a level. Having discovered an unevenness, it is eliminated using tarred boards adjusted to the width. It is forbidden to cut the timber or place it under wood chips, as this will lose the strength of the structure.

Note

The outer beams are never placed close to the wall, leaving at least 10 cm. The beam is never installed directly next to the chimney pipe.

How to strengthen wooden floor beams

Damaged wooden beams, worn out by loads and time, or not strong enough initially “according to the design” are the first reason for the weakening of the load-bearing capacity of the floors, the appearance of vibrations and creaking floors on the upper floors of the house. Let's figure out how to strengthen wooden beams and make the structural elements of the floor stronger.

Reasons for weakening beams

The need to strengthen beams may arise in a number of cases:

- natural wear and tear of a correctly installed product;

- damage to the beam due to errors in manufacturing and installation;

- change in the purpose of the room associated with increased load on the floors.

Let's consider these reasons in more detail. So, the beam may fall into an unsatisfactory condition due to the influence of various factors, including increased levels of humidity, sudden temperature changes, as a result of pest activity, as well as simple physical wear and tear with the further appearance of cracks. The dishonesty or incompetence of the builders should not be discounted. The owner of the house is not able to check the quality and correct installation of hidden installation elements. Problems are identified later - already during the operation of the room, when walking on the upper floor, the floors vibrate or creak. The main errors at the stage of manufacturing and installation of beams include the following:

- using insufficient or incorrectly dried wood. After such beams dry, they become covered with cracks;

- using too thin timber, which leads to vibration of the beams;

- too large spans between beams;

- assembly of beams from several parts.

If we are talking about changing the purpose of the room - for example, the attic is planned to be turned into an attic or a residential unit, then in this case the load on the floor will increase. Obviously, this will require an increase in the load-bearing capacity of the beams. A non-specialist can determine the need to strengthen the beams. The main indicator in this case, in addition to the mentioned vibrations or visible damage, is the level of deflection that occurs both under load and under the beam’s own weight. Deflection can increase after increasing the load - installing parquet on the top floor or after the delivery of furniture. In this case, the beams begin to sag, which not only leads to vibration of the floors, but can also threaten their collapse. The maximum permissible deflection of the beam is easy to calculate independently. The simplest method is to calculate the indicator depending on the length of the beam. In particular, the level of deflection should not exceed approximately one three-hundredth of the length of the product. For example, if the deflection is 8–10 millimeters with a beam length of 2.5 meters, this is the norm. If it turns out to be large, then it is time to strengthen or replace the beam.

Increasing the cross-sectional area of a beam

One of the most popular ways to strengthen floor beams is to increase their cross-section by installing additional wooden overlays. This method is mainly used in cases where the material of the beams becomes loose due to natural aging or as a result of the activity of wood-boring beetles. An increase in the cross-sectional area is achieved by installing wood overlays with a thickness of at least 50 mm on the weakened or damaged area. Some experts argue that it only makes sense to increase the cross-section along the horizontal sides, that is, at the top and bottom of the beam, and increasing the thickness of the product along the width does not give a useful effect. Before installing the overlays, as in the case of other work on strengthening beams, weakened beams should be treated areas with antifungal agents. After antifungal treatment, it is necessary to reduce the level of deflection to a minimum using jacks. It is more efficient to directly install the linings along the entire length of the beam. Attachment is carried out using bolts or studs through and through. Not only wood, but also metal can be used as a reinforcing element. In this case, channels or metal strips are used. The latter are less reliable than the channel and can only be used to strengthen small areas of damaged beams. Reinforcing the span of a beam with the help of metal overlays is carried out according to the same algorithm as in the case of wooden overlays, but it has some features. In particular, before installation, metal linings are treated with an anti-corrosion compound. In addition, a waterproofing layer should be installed between the metal and wooden parts.

Rod prostheses

In cases of severe damage to sections of beams, it is practiced to remove such areas and install bar prostheses made from steel reinforcement in their place. This method is used mostly when replacing end elements, which most often become unusable. The role of prostheses is played by scraps of reinforcement with a cross-section from 10 to 25 mm. The length of the prosthesis is selected with the expectation that it should be 10% greater than the double length of the damaged section of the beam. There is also a limitation on the length of the prosthesis - it can be no more than 1.2 m. Before performing work, you should support the area that will be strengthened with a stand to prevent possible collapse of the structure. The racks and support run are placed at a distance of one to one and a half meters from the load-bearing wall. After such temporary strengthening, the ceiling is dismantled, and the rotted section of the beam is sawed off. The prosthesis blank is inserted vertically into the ceiling, and then rotated to a horizontal position. The structure is first slid onto the beam and then into the wall niche. It must be taken into account that beams restored using prosthetics will last for a long time, however, the strength of the updated structure will certainly be lower than in the case of a new beam. Therefore, load the restored ones beams should be kept to a minimum.

Reinforcement of beams with carbon fiber

In addition to traditional technologies, innovative solutions are widely used when strengthening beams, one of which is the reinforcement of structures with carbon fiber reinforced plastics. Attention: this method is the only possible way to strengthen beams if, due to extreme cramped spaces or for some other reasons, increasing the cross-section of structures is impossible or extremely difficult. The undoubted advantage of carbon fiber reinforcing elements is the absence of the need to operate with large and heavy metal or wooden components, as well as minimal labor intensity of work in general. Modern carbon fiber reinforced plastics, like any composite materials, are characterized by high strength and low weight. Carbon fiber reinforcing elements cope well with significant mechanical loads. They are available in different modifications - in the form of tapes, fabric, threads, plates or sheets.

Reinforcement of a beam with composites is carried out by gluing carbon fiber onto it in several layers. The attached layers of carbon fiber are applied to the surface of the beam, one above the other and along its entire length. The edges of the glued strips must be covered with transverse layers.

The reinforcing components are glued until the reinforced beam becomes rigid enough to withstand the loads. Installation is carried out using epoxy glue. After hardening, the layer’s strength characteristics are sometimes not inferior to metal.

What to do if strengthening beams is impossible

If the floor beams are not damaged, but have difficulty withstanding the load and bend, and their strengthening is problematic or impractical, you need to consider the option of installing additional beams or placing supports under existing ones. In this case, the load-bearing capacity of the structures will be strengthened by redistributing the load onto additional beams or racks. The latter, naturally, will transfer the load to the floors of the lower room. New backup beams, just like the existing ones, are fixed in a socket arranged in a load-bearing wall. Installing racks, although a simpler task, is often associated with additional undesirable effect - such supports can clutter up the space and interfere with unhindered passage through the room. The visual component is also important - it is advisable to decorate the supports so that they fit harmoniously into the design of the room. So, we have looked at several basic, most common ways to strengthen beams. The choice of a specific method depends both on the degree of wear of structures and the load on them, as well as on the skills of the builder, the availability of the necessary tools, financial capabilities and free time of the craftsman.

The most common of them are the following three. There are other, very rare options for strengthening existing beams with additional wooden or metal elements.

How to cut a block diagonally with a circular saw.

- poor condition of the beam structure. The result is wood damage. High humidity, temperature changes, the activity of various pests (bark beetles), cracking - all this leads to deformation of the floor beam;

- reduction in load-bearing capacity. Under their own weight, constant and variable load, floor beams can bend. According to the standards, if the deflection is within 1:300, then there is nothing to worry about. For example, if a beam is 2500 mm long. bent by 10 mm. this corresponds to the normal deflection value. If the deflection is greater, it should be strengthened;

- the need to increase the load-bearing capacity of the beam. Associated, for example, with the reconstruction of an attic into an attic or living space. Such a restructuring will lead to an increase in constant and variable loads on the floors of the second floor, which automatically requires a change in the cross-section of the installed wooden beams.

Within the article, several common methods of strengthening the ceiling (repair, reconstruction) will be given. But only a professional can accurately answer the question of how to strengthen wooden floor beams and only after analyzing the condition of the structure. After all, in each case the decision will be individual. Using the table, you can get an idea of what cross-section a beam should have under a certain load.

Carbon fiber reinforcement

Carbon fiber reinforcement is a method of strengthening wooden floor beams, which is not entirely traditional, but is used in cases where the room has a small area or for other reasons when it is not possible to apply the above methods.

Carbon fiber is an innovative material that perfectly copes with any mechanical loads, including bending loads.

Carbon fiber elements are produced in various modifications, including plates, sheets, threads, tapes, or simply in the form of fabrics. The process of reinforcing beams with carbon fiber involves layering layers of glue (epoxy resin) on top of each other until the beam is sufficiently rigid.

After the glue hardens, the layers form a monolithic coating, with characteristics not inferior to metal.

Repair of wooden floor beams. How to repair a wooden floor beam yourself

In most old and some new houses, wooden beams were used to construct the attic (ceiling) or interfloor flooring. There are several reasons for this: wooden floor beams are lightweight, affordable, and easy to install. They can also be used in the construction of load-bearing walls from different materials. However, wooden floor beams have a significant drawback. Namely, an increase in humidity and operational load inevitably affect the quality of wood, and, as a result, its load-bearing capacity. In this case, repair work will be required.

Repair of wooden floor beams

Types of defects (damage) of floor beams

During a major renovation of a house, you need to inspect the floor beams for various types of defects. These include:

- rot and mold damage. It is especially common on attic floor beams. Mold on a ceiling beam is caused by a leak in the roof. The appearance of rotten areas is common where the beam is cut into the wall. The reason is insufficient waterproofing in this place;

Rotting and mold damage to wooden floor beams

- wormholes. The activity of wood beetles can significantly damage floor beams;

Wormholes on wooden floor beams

- cracking (delamination) - the formation of cracks. Initially, low-quality beams may, under the influence of temperature changes, delaminate along the length of the fibers.

Cracking of floor beams If any of the above are found, it is necessary to repair the wooden floor beams. In addition, it is necessary to eliminate the cause that led to the appearance of defects.

How to identify damage to wooden beams?

There are several ways to detect defects in beam floors:

- visual inspection of the beam. The simplest and most reliable way. Applicable if the beams are open. To make sure that the beam will last for many more decades, you need to run a screwdriver along it with pressure. If a slightly visible mark remains, then everything is fine. If the screwdriver leaves a groove, the beam needs repair. And the deeper the groove, the faster you need to start repair work;

- identification of external signs of deformation - subsidence (sagging) of the beam floor is noticeable even under the finishing;

- tapping. If a dull sound is heard from the impact, this means that the beam needs repair, i.e. it loses its load-bearing capacity. Suspicions can be confirmed by drilling a hole in the beam. Next, you can use it to evaluate the quality of the wooden floor.

It is especially important to assess the condition of wooden floors in areas adjacent to the wall. Most cases of damage occur in these areas.

Do-it-yourself repair of wooden floor beams

Restoration (restoration, strengthening) of beam floors can be performed in several ways:

- Repair of ceilings using wooden overlays.

A board or timber is used as an overlay. They should be equal in height to the height of the beam, and in width – equal to half the width of the beam. Since the linings are installed on both sides of the beam, it turns out that the linings are equal to the beam. The overlays are mounted close to the floor beam and secured with bolts. The length of the bolt is equal to the width of the beam and two overlays. To avoid damage to the overlays, they should be treated with an anti-fungal solution. It should be noted that it is better not to repair wooden floor beams at the junction with the wall using overlays. A steel prosthesis is more suitable for these purposes.

- Repair using a prosthesis - strips of steel sheet or steel rod. Their advantage is that they take up less space and are more durable. The steel plate should be treated with an anti-corrosion solution.

Important! The rotten part or the beam damaged by the bug should, if possible, be cut out and replaced with a whole one, and the cut points should be reinforced with overlays. Repair of wooden floors at the junction with the wall is carried out as follows: the damaged part is removed, and the remainder is extended using an overlay or prosthesis. Next, the beam is secured to the wall using bolts. If a significant portion of the beam is damaged (more than 2/3 of the length), the wooden floor beams are replaced. Otherwise, further use of the destroyed wooden floor may lead to the collapse of the house structure.

We recommend that you read a detailed description of the technology for strengthening wooden floor beams. All repair work must be carried out using dry wood. And the use of special protective solutions will significantly extend the operational period of the repaired floor beams.

Necessary clarifications

For all its positive qualities, wood still has a number of negative parameters. Of the most basic:

- relatively low endurance of both the floor beams and the entire structure as a whole. The maximum load is 500 kg/m2, and in most cases it does not exceed 200-300 kg/m2. Therefore, deflection is very likely;

- low sound insulation performance, which is typical for all wooden floors. They transmit the entire range of sounds, from airborne noise (conversation, music, murmur of water) to percussion, which occurs during repairs, moving furniture and even steps;

- fire hazard, to combat which it becomes necessary to treat wooden beams with special compounds;

- defenselessness against bioattacks. Wood is susceptible to rotting and woodworm damage, so wooden beams need additional impregnation not only from fire, but also from natural enemies.

Styrofoam

Foam plastic has become one of the most common materials for thermal insulation. It has earned its place in the top three thanks to its very attractive price.

The use of this insulation in an individual home provides the following advantages: high degree of protection; resistance to rotting and the occurrence of mold and mildew; low degree of water absorption; ease of installation and no need for complex tools and protective equipment; the low weight of the material does not allow excessive load on structures and allows carry out insulation from below. The material is suitable for insulating the ceiling of the upper floor due to its low vapor permeability. Disadvantages include low strength and the risk of falling apart into individual balls when simultaneously exposed to moisture and low temperatures. In addition, polystyrene foam is a flammable material, which is not very desirable when constructing a wooden building. More information about working with this type of material can be found in the article “Floor insulation with foam plastic.”

Timber laying algorithm

During the construction of walls intended for laying timber, they are covered with their own hands in several layers of roofing material. 1 day before laying, the timber is treated with a fire retardant solution to protect it from fire.

The ends of the wooden beams are wrapped in waterproofing material and placed in niches. The distance from the ends of the beam to the walls of the niche must remain at least 4 cm. This device is filled with foam plastic or mineral wool.

Do-it-yourself ceilings in a timber house

If the wall is brick and the thickness of the wall is less than two bricks, the space is filled with cement mortar. Every third beam is fixed with an anchor protruding from the wall by 20 cm, laid during the construction of the wall. First, a device for an anchor corresponding to the diameter and depth is drilled into the beam with your own hands.

The beams are laid from the walls to the center, checking the evenness of the laying with a level. Having discovered an unevenness, it is eliminated using tarred boards adjusted to the width. It is forbidden to cut the timber or place it under wood chips, as this will lose the strength of the structure.

Note

The outer beams are never placed close to the wall, leaving at least 10 cm. The beam is never installed directly next to the chimney pipe.