Advantages of beams made from lvl timber

LVL timber has been used for decades in the construction of frame houses in the USA and Europe.

LVL timber in Russia is a new material, but rapidly gaining popularity. In terms of its performance characteristics, it is superior to other types of construction wood. This type of timber and slabs are produced by gluing at least 7 layers of three-millimeter veneer. The wood then goes through pressing under pressure and at high temperatures.

More and more companies are producing material in Russia. You can purchase it from official distributors. In the online store Recons Eco LVL timber is in stock.

Manufacturers of LVL timber

There are two large manufacturers of construction products in Russia that produce LVL timber. The first has been in production since April 2009. the Talion Terra enterprise The scale of production reaches 150 thousand m³ per year . The plant uses a continuous pressing method with preheating in a microwave oven. Ultralam slabs and timber are high-quality building materials produced using an innovative deep processing method.

The second Russian enterprise "Yugra" for the production of LVL has launched production in the Tyumen region, Khanty-Mansiysk district (Nyagan) . Production processes are automated, laser control technologies are used, so the products correspond to the declared quality and are not inferior to imported goods.

the Kerto (Finland) trademark are supplied to Russia . The material is in demand for prefabricated buildings for its impeccable quality.

Advantages of beams made from laminated timber

Coniferous trees are used to produce LVL materials. The basis of beams, beams, slabs is pine, larch, and less often spruce.

LVL timber and laminated veneer lumber are often confused; the difference between them lies in the production technology and final performance characteristics. In the first case, thin veneer is glued together. Its plates are offset relative to each other. What makes the building material almost monolithic.

Regular laminated timber is made from lamellas (planed boards). As a result, its performance characteristics are lower. LVL and laminated veneer lumber of the same section can withstand loads at least 2 times greater.

Advantages of LVL materials:

- High strength that does not change over time.

- Uniformity of properties; a beam or slab reacts equally to external influences at any point.

- Beams made from LVL timber allow you to design houses with almost any layout.

- The geometry of the material changes minimally during operation. It does not shrink and is not hygroscopic when used correctly.

The cost of LVL timber is comparable to the cost of laminated timber and provides reliable thermal insulation. Beams placed outside the outer wall do not become cold bridges.

What is LVL timber and where did it come from on the market?

The three-letter abbreviation “LVL” (Laminated Veneer Lumber) in its commercial name indicates that this is multi-layer lumber made from softwood veneer. As sad as it is for us Russians to state this fact, American engineers came up with it. This happened after the Great Depression of 1929, which marked the transition of the United States to a new stage of economic development. The first batch of timber, which is the subject of today’s article, rolled off the conveyor belt of the Weyerhaeuser factory six years later, after the events mentioned above, which drove the Americans into a certain framework, but let’s not talk about that.

Serial production of LVL timber for the construction of residential buildings, bathhouses, cottages, townhouses and even bungalows was established thirty years later - in the 1960s. This begs the question. What happened between '35 and '60? The material has been tested. He was tested and researched. Changes were made to technology. Thanks to numerous experiences and improvements, LVL timber currently occupies a leading position in the international ranking of materials for the construction of the already listed structures and buildings. Read further about the scope of its application, as well as the advantages and disadvantages in comparison with competing analogues.

Release form or what LVL timber looks like

Unsurpassed strength allows LVL load-bearing elements to withstand extreme loads in the horizontal plane. Along with frame beams, ridge strips, legs for the rafter system, and interfloor ceilings are made from it. With its help, reinforced spans are created in agricultural buildings, retail outlets, commercial pavilions, and equipment warehouses. Due to its homogeneous structure, as well as resistance to aggressive environments, LVL timber is allowed for use in the construction of baths, saunas, swimming pools, that is, where high air humidity prevails.

The timber supplied by foreign and Russian LVL factories differs in marking. The letters "R" and "S" in the trade name indicate maximum density veneer with grains running parallel to each other. The alphabetical signs “X” and “Q” inform the consumer interested in it about the perpendicular position of the wood threads relative to adjacent sheets. The letter “T” with the additions “G3” and “G4” indicates that the fibers are directed in different directions. The English alphabet symbol “I” describes a combined material, which, due to the mixing of different types of wood, is of the lowest quality.

Two words about production - how LVL timber is made

The technology for obtaining the advertised material is brilliantly simple and straightforward. Sawmill employees take spruce, larch or pine. They make a cut and select the part of the tree with the highest density for production. The beams, cleared of thick bark and excess resin, are immersed in a container of hot water, where they soak for 24 hours. A day later they are sorted. Sent to the air workshop. They are loaded onto a special CNC machine, where they are cut into thin-leaf veneer with a density of 1.5 to 3 millimeters. At the final stage, the sheets undergo a secondary drying process so that upon completion they have a moisture level of approximately ten (10%) percent.

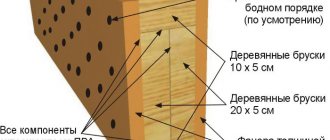

Sheet products are laid systematically, but so that the main edges do not coincide with each other. This feature gives the manufacturer the opportunity to obtain an elongated workpiece. At the final stage, the pieces are glued together with formaldehyde resin and sent under a hydraulic press. Then they are compacted, cut using special equipment, marked and sent to a long-term storage warehouse. See what LVL timber looks like ready for transportation to a construction site or a hardware store.

Advantages of LVL timber over analogues

- natural humidity of 8-12% and resistance to penetrating moisture allows it to be used in construction, exterior and interior decoration of Russian baths and Finnish saunas;

- the unlimited service life, according to manufacturers, is dictated by the fact that carefully selected wood is used in production;

- immunity to horizontal deformations, lighter weight compared to solid timber, rounded logs, and other building materials;

- the bending strength of a multilayer but homogeneous material along the ribs and layers is 48.0 and 50.0 n/mm2;

- fire resistance in accordance with class “E” is dictated by the presence of formaldehyde resin, which inhibits fire and damage to integrity;

- the relatively light weight of the beams reduces the list of requirements for constructing a concrete foundation for a frame cottage under construction;

- bioresistance to fungal deposits, shingles mold, small insects, rodents and other pests.

A few words about the negative sides

The fundamental disadvantage of timber, according to wealthy Russian consumers, is the exorbitant price tag. The cost of the material announced in the current article is one and a half, or even two times higher than competing products. Considering this fact, 9 out of 10 of our fellow citizens build houses from double timber, which we told you about in reviews and videos on the YouTube channel. Another quality that frightens some people is its poor environmental friendliness. The technological composition requires the presence of alloying additives based on a harmful substance called formaldehyde.

The weak heat-saving ability of LVL timber obliges homeowners to pay additional costs for insulation with mineral wool, polystyrene foam, PIR boards, sawdust or eco-wool made from cellulose. Considering the negative qualities briefly listed in this paragraph, we do not recommend using it in the interior design of a townhouse, country house, or villa. But for the construction of load-bearing structures it is perfect. Returning to the price, which Russians consider the main negative side, let’s say that it ranges from 32 to 45 thousand Russian rubles per cubic meter.

Beams made of laminated timber: characteristics

The high strength and durability of the material is ensured by its production technology. Veneer, varying in density, is evenly distributed in LVL timber. This ensures the absence of warping and stability of the beam or slab.

LVL timber can withstand bending loads that exceed the characteristics of solid timber timber. The material also demonstrates better performance in resisting tensile loads.

A special adhesive composition and pre-treatment of the veneer makes the material non-hygroscopic. Operation at high humidity does not lead to changes in the geometry and weight of the LAN timber.

LVL timber is also resistant to chemically aggressive influences.

LVL timber can be bought in Moscow from the manufacturer at affordable prices in the Recons Eco online store.

Advantages and disadvantages

LVL timber is suitable for construction in any weather because it does not deform under the influence of external factors. The material has the following advantages:

- the level of strength is higher compared to ordinary wood;

- not afraid of aggressive substances and humidity;

- it is not affected by rot, fungus and other bacteria;

- does not ignite in case of fire;

- high heat and sound insulation;

- lightweight and easy to build;

- does not load the foundation;

- wide range of sizes;

- absence of defects and cracks;

- allows you to implement unusual architectural solutions.

Serious disadvantages include airtightness and environmental issues. Despite meeting the standards, substances in the bonding resin may adversely affect the body. The downside is the high cost of the panels compared to other wood materials.

Properties and characteristics of laminated timber LVL

Initially, this material was intended for the construction of houses, so one of the main properties that was paid attention to was the ability to withstand loads acting on the ends of LVL beams. It is for this purpose that during the manufacture of products, the fibers in adjacent rows are arranged in parallel.

For your information! LVL timber is one of the most durable materials made from wood. Its strength is several times greater than that of a simple glued bursa.

Using LVL timber in the manufacture of staircases

The operational and main technical characteristics of LVL timber are given in the table below:

| Indicator/characteristic | Values |

| Bending resistance along the fibers, MPa | 22,5 – 27,5 |

| Tensile strength, MPa | 16,5 – 22,5 |

| Fire resistance class | "E" |

| Density, kg/m3 | 480 |

| Humidity, % | 8-12 |

| Roughness, microns | ≤ 320 |

| Wear resistance | 4 |

| Charring speed, mm/minute | 0,7 |

| Class for the release of harmful substances (formaldehyde) | "E1" |

Using LVL timber in the manufacture of rafter systems of complex design

Prices for wooden I-beams

Beam with wooden shelfShelf size, mmLength, mHeight (H), mmOSB thickness, mm Price, rub./linear mBeam CM-14070x45 up to 61409350 rub.Beam CM-24070x45 up to 62409385 RURBeam CM-30070x45 up to 63009400 rubBeam CM-36070x45 up to 63609415 RURBeam CM-40070x45do 64009430 rub.Beam CM-46070x45 up to 64609450 rub. Beam with wooden shelf, length up to 12 metersShelf size, mmLength, mHeight (H), mmOSB thickness, mm Price, rub./linear mBeam CM-140LT72x48 up to 121409485 RURBeam CM-240LT72x48 up to 122409515 RURBeam CM-300LT72x48 up to 123009530 rub.Beam CM-360LT72x48 up to 123609545 rubBeam CM-400LT72x48 up to 124009560 rubBeam CM-460LT72x48 up to 124609575 rub Beam with shelf made of LVL barsShelf size, mmLength, mHeight (H), mmOSB thickness, mm Price, rub./linear mBeam SM-240L64x39do 122409505 RURBeam SM-300L64x39do 123009525 RURBeam SM-360L64x39do 123609535 RURBeam SM-400L64x39do 124009555 rubBeam SM-240L with wide flange 89x39 up to 122409615 RURBeam SM-300L with wide flange 89x39 up to 123009635 RURBeam SM-360L with wide flange 89x39 up to 123609645 RURBeam SM-400L with wide flange 89x39 up to 124009665 RURBeam SM-460L with wide flange 89x39 up to 124609685 RURFree layout and calculation of beams + 7 495 797 05 60

I-beam rafters

I-beam rafters

I-beam floors

I-beam ceiling

I-beams for floors

Dimensional grid of standard thicknesses and sections

Table 1

| Width(mm) / Height(mm) | 200 | 225 | 260 | 300 | 360 | 400 | 450 | 500 | 600 |

| 27 | • | • | |||||||

| 33 | • | • | • | ||||||

| 39 | • | • | • | • | |||||

| 45 | • | • | • | • | • | ||||

| 51 | • | • | • | • | • | • | |||

| 57 | • | • | • | • | • | • | • | ||

| 63 | • | • | • | • | • | • | • | • | |

| 75 | • | • | • | • | • | • | • | • | • |

table 2

| Width(mm) / Height(mm) | 900 | 1200 | 1800 | 2500 | 1800 | 2500 |

| 27 | • | • | • | • | • | • |

| 33 | • | • | • | • | • | • |

| 39 | • | • | • | • | • | • |

| 45 | • | • | • | • | • | • |

| 51 | • | • | • | • | • | • |

| 57 | • | • | • | • | • | • |

| 63 | • | • | • | • | • | • |

| 69 | • | • | • | • | • | • |

| 75 | • | • | • | • | • | • |

| 78 | • | • | • | • | • | • |

table 3

| Thickness | standard 39-45 mm. |

| Width | standard < 200 mm. |

| Height | standard < 8.5 mm. |

Ceiling beams usually belong to the first type of product. It is often used in rafter systems and ceilings. of beam may have higher rigidity. In addition, it is usually much wider. That is why such a wooden LVL beam is often used to create floor slabs and cladding facades. It is worth noting that, if necessary, it can be supplied with the same geometric parameters as the first type of building materials. buying an LVL beam made of light veneer to create a building frame when forming load-bearing partitions.

Where can I buy such products?

You can select suitable building materials in our company. Our for LVL beams In addition, we have a huge range of such products. Our specialists will help you select the cross-section of LVL beams . We guarantee the high quality of our products and their compliance with the stated characteristics. They are easy to install and have increased load-bearing capacity. We help you calculate LVL beams , which are necessary for the construction of any building. This allows our clients to plan their costs in advance. It is worth noting that with a large order for LVL beams, our price can be significantly reduced.