When carrying out repair or construction work, the problem of accumulation of debris and dust very often arises, which cannot be eliminated using improvised means. In such cases, the easiest way is to use a special construction device, but it is worth considering that the prices for such devices are high, and the need for its use may not exceed several times. It is more advisable to assemble a construction vacuum cleaner with your own hands.

What is the difference between a construction vacuum cleaner and a regular one?

Conventional household models cannot serve as an alternative to industrial ones. To make a construction vacuum cleaner with your own hands, you need to heavily rework the device. Otherwise, there is a risk of constant oversaturation of the dust collector. In addition, the device will quickly break down.

Note! For normal operation of the product, you need to use components that create a significant vacuum at the input. The vacuum device is driven by a powerful motor.

Advantages and disadvantages

Understanding the principle of operation of a hydrocyclone makes the advantages of such water treatment obvious. In addition to obvious advantages, for example, simplicity of design, hydrocyclones are distinguished by the properties associated with them:

No moving mechanical parts;- Lack of need for consumables (colloids, filter media, etc.).

- Low cost of the device and ease of repair due to the low manufacturability of the product.

- Ease of arrangement in a sequential system of batteries that perform step-by-step cleaning.

- Possibility of work automation.

- Safe use of devices of any kind.

However, the scope of application of hydrocyclones is still limited mainly to industrial use. This fact is associated with few but significant disadvantages of the products:

- The need to maintain stable pressure and the resulting energy consumption, as well as depreciation of the pump;

- Mechanical wear of parts of the main body due to the abrasive effect of sludge;

- A decrease in pressure in the system, causing the use of a second pump.

In addition, it is extremely difficult to correctly calculate the parameters and select the elements of a hydrocyclone for a precise separation of fractions. There is no talk of automatic or simplified reconfiguration of the unit. For example, to catch coarse sand, install one sand attachment, for fine sand, another.

To remove sludge, in general, a GC of a different shape and size is required, operating at a different pressure. In any case, the separation will be only approximate, which is not particularly welcome in private water treatment. A primitive settling tank may work slower, but it has no other serious drawbacks.

Design Features

Homemade construction vacuum cleaners are characterized by certain design features.

Construction vacuum cleaner with water filter

The principle of operation of a device with a water filter is that the air flow with dust moves in a spiral and touches the surface of the water. Thus, the system additionally humidifies the air. Due to this, the dust becomes heavier and settles into the water.

A vacuum cleaner with an aqua filter can also be replaced by an ordinary household bucket, to which you need to attach the appropriate attachments. A barrel of suitable size is also suitable for this purpose.

Homemade chip sucker

This device helps to collect shavings that are constantly lying under your feet. To achieve a good result, you need to take a motor with a long shaft and a sheet of plywood. The motor must be powerful enough and have a speed of up to 3000.

Plywood is used to make an impeller, which is similar to a water mill. To avoid beating, it must be properly balanced.

To assemble the device, you must do the following:

- install the side of the case;

- place the impeller on the shaft;

- mount the top;

- install the second side panel.

Note! An additional container is required to collect chips. An ordinary box or bag is suitable for this.

Construction vacuum cleaner for cement dust

How to make a vacuum cleaner to collect construction waste? To collect cement dust, you need to use several high-quality filters. The fact is that it is extremely difficult to retain small fragments. In addition, they easily absorb moisture, acquiring a sticky consistency.

To make a high-quality device, you need to combine water and cyclone types in one. Sometimes a vacuum cleaner is added to a wall chaser.

In any case, the device must include the following:

- plastic cone;

- capacity;

- household vacuum cleaner.

Important! A synthetic mesh must be placed on the surface of the water layer. It will prevent liquid from spilling during operation of the device.

The device can be used to collect cement dust

Garden device

People with their own gardens periodically have to remove leaves and other debris. Garden devices are used for this. It's easy to make them yourself.

It is recommended to use an old Soviet vacuum cleaner as a basis. You need to install a plastic container in it and connect a wide corrugation, which has a dense piece of pipe at the other end.

It is noteworthy that among compatriots it is not customary to collect leaves with a vacuum cleaner. However, those who have already tried this option are completely delighted. With the help of a simple device, the speed of cleaning in the garden increases significantly.

You can make an effective device for the garden

Cyclone type device

This type of design is the simplest from the point of view of modernizing the selected donor. Before assembling a construction vacuum cleaner with a cyclone filter, you should immediately take into account that the power of the vacuum cleaner must exceed 1500 W.

Necessary materials

To assemble the structure, you will need an object that has a cylindrical shape or a ready-made cone. To do this, you can use the following materials:

- plastic;

- thick cardboard;

- tin plate.

Process of creation

Making homemade products depends on the available materials and tasks. In this case, different schemes can be used.

From improvised means

First of all, you need to make holes in the central part of the bucket lid and near the edge. Then you need to insert a tube into the center. However, first its edges must be processed with a file or sandpaper. This will help strengthen the adhesion of the surfaces. You should also prepare the lid. Then you need to lay the tube and apply glue.

When using a powerful vacuum cleaner, you should not use a plastic bucket, but a steel tank of a similar shape. Thanks to this, you don’t have to worry about the product being crushed.

From a household vacuum cleaner

Many craftsmen are interested in how to turn a regular vacuum cleaner into a construction one. To improve the properties of the device, you need to unscrew the wheels from it. Similar actions must be performed with the nameplate.

After removing all rivets and latches, you need to install the plug. To increase its reliability, it is necessary to wrap electrical tape and make a hole in the bottom. Its internal cross-section should be 3-4 cm. To seal the structure, you can use gaskets. You need to install a lid and a pipe in the waste container.

The cover must be secured with self-tapping screws. Then you can move on to working with the suction pipe. The hole into which it will be attached must be cut with metal scissors. Self-tapping screws can be used for fixation. To increase the tightness of the connection, gauze or a pharmaceutical bandage is suitable. Before winding, they should be soaked in glue.

An effective device can be made from a household vacuum cleaner

Operating principle of the dust collector

After turning on the electrostatic household appliance, the air begins to move, and dust particles with a negative charge are attracted to the ionizing plates. The plates themselves are oppositely charged, which is why dust is attracted and remains in the filter.

The operating principle of a photocatalytic dust collector is the formation of a substance with a high oxidation capacity as a result of ultraviolet light hitting the catalyst. When dust and contaminants enter the purifier, they turn into small particles.

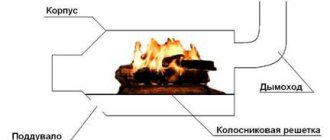

Cyclone dust collectors are simple and economical air purifiers. The components of the dust chamber are located on the axes of the cyclone. The exhaust pipe is used to remove dust particles and other solids in the air. The inlet pipe supplies gas.

The principle of operation of dust collectors, regardless of their type, in air circulation. Polluted air enters it, is retained in the filter, and subsequently the room is saturated with the purified product.

The effectiveness of homemade compared to store-bought analogues

Homemade devices cannot be compared with professional ones. They differ in the following parameters:

- motor and suction power;

- noise parameters;

- volume of waste collection container;

- air purification;

- additional functions;

- hull strength.

At the same time, a simple homemade vacuum cleaner will easily clean the room from small shavings and construction dust. Home devices are smaller in size. They help free the floor and walls from dust. However, they do not have an air purification function.

The manufacture of a construction vacuum cleaner has a number of features. To get a high-quality and reliable design, you should think it through to the smallest detail and prepare everything you need.

Criteria and characteristics that are important when selecting and ordering devices

The most important source of data when designing any water treatment plant is source water analysis . Its quality, quantity, as well as dimensions, hydraulic size and origin of particles affect all parameters of the hydrocyclone.

Including the following parameters:

- Diameter,

- Height,

- Diameters and number of pipes,

- Rotation speed (feed or suction pressure),

- Type of hydraulic mechanism (open or closed).

However, “approximate” use of hydrocyclones is also possible. An example of this is homemade devices. They are assembled practically without calculations, selecting the diameters of the inlet and outlet pipes experimentally.

A popular blank is a fire nozzle of the RS-70 type. However, when choosing a supplier, it is advisable to pay attention to the equipment of the structure. As standard, it may include:

- Water-filled pressure gauges;

- Cranes,

- Diaphragm valve for automatic flushing of the sludge collector;

- Electrically operated valves;

- Control system for gate valves and self-powered valves;

- Anti-corrosion protection;

- Lining and antistatic coating.

Of course, this list is not complete, because patents for inventions of various hydrocyclones are still being received. For example, the installation can optionally be supplemented with an expanded control system with operator display or an enlarged “sand collector”.

Also - for an additional fee - backup control mechanisms and bypass paths for water supply can be provided.

Service Features

Maintenance of hydrocyclone units consists of monitoring and cleaning. As a rule, the tightness of all components of the unit, as well as the fullness of the sludge collector, is subject to control. Cleaning and rinsing from time to time is generally necessary. However, sediment may also remain on the walls of pipes or taps.

If the design involves electromagnetic, electromechanical or electronic components, their elements require special care. As a rule, these responsibilities fall on the shoulders of the service organization servicing this treatment complex.

Disadvantages of cyclone vacuum cleaners

- The noise level of the vacuum cleaner, although it fluctuates within the normal range, is approaching its upper limit (80-85 dB). The noise is created by an air vortex and large particles that, when moving, hit the walls of the dust collector.

- Does not show the best results when cleaning fluff, wool and other thin and light particles (an additional attachment is required - a turbo brush, which is not always sold complete with a vacuum cleaner).

- The vacuum cleaner only works with a constant air flow. If the flow is interrupted for any reason, you will have to restart the device.

Nevertheless, an increasing number of buyers are paying attention to the advantages of cyclone-type vacuum cleaners. The best price-quality ratio, ease of use and reliability allow these vacuum cleaners to lead in comparison with other models on the Russian and foreign markets. Below is the rating of cyclone vacuum cleaners in 2021.

Special vacuum cleaner that handles hair

Negative qualities of the device

Any technique has not only pros, but also cons. The design mentioned above was no exception. The main problems during the operation of the vacuum cleaner were:

- Difficulty in collecting thin, light and long pieces of debris.

- Large debris falling into a plastic container can leave scratches on the walls of the tank.

- The ability of a vacuum cleaner to accumulate static electricity, which naturally falls on the body of the equipment.

- Dependent position before intake air speed. The moment the unit’s brush catches a curtain or other object, the air vortex inside the vacuum cleaner is destroyed, and dust and debris enter other filters. Restarting the device does not allow it to operate immediately at full speed.

Experts noted that the shortcomings identified by buyers are minor; they do not affect the deterioration of the quality of operation and cleaning. Unfortunately, the developers failed to eliminate the shortcomings. These defects relate to the design features of the vacuum cleaner

It is important to understand that cyclone-type devices are designed for cleaning dry rooms

Hydrocyclones PVO-GTsTO-S

Hydrocyclones made of carbon steel of our own production.

| Model | Productivity, m3/hour | Input/output, mm | Weight, kg | Dimensions (H/L/B) | Download passport (PDF) | Download (DWG) | Price |

| PVO-GTSTO-100-S | 18-19 | DN40 PN10/ DN50 PN10 | 25 | 1030x290x193 | DWG | from 80,000 ք | |

| PVO-GTSTO-25-S | 0,8-1,3 | G 1/2" | 0,71 | 280x100x41 | DWG | from 4 600 ք |

Hydrocyclones PVO-GTsTO-P

Hydrocyclones made of high-strength plastic of our own production.

| Model | Productivity, m3/hour | Input/output, inch | Weight, kg | Dimensions (H/L/B) | Download passport (PDF) | Download (DWG) | Price |

| PVO-GTSTO-25-P | 0,9-1,3 | 1/2 | 0,2 | 342x70x44 | DWG | from 18,000 ք | |

| PVO-GTSTO-40-P | 2,4-3,3 | 1 | 0,47 | 552x98x67 | DWG | from 24,000 ք |

Homemade cyclone from a household vacuum cleaner

The first method has been presented on the Internet and on YouTube for quite some time. You can easily find many videos with similar homemade cyclones.

However, they raise quite natural questions and skepticism among professional builders. Therefore, it should be noted right away that they are mostly suitable for removing wood chips.

But it is better not to work with cement dust with such devices. The second option is more tailored to it.

The main “trick” that will allow you to easily suck in kilograms of garbage, wood, and metal filings and not worry about frequently changing filter bags is a homemade “separator”.

It will then need to be constructed from several components. For the entire assembly you will need:

- regular vacuum cleaner

- thick plastic bucket with lid

A bucket of Shitrok putty is best suited here. It is harder to flatten it with a vacuum.

- plastic sewer pipe d-40mm

- polypropylene sewer outlet at 90 degrees with a diameter of 40mm

- 40mm crown or utility knife

First of all, drill or carefully cut a through hole for the tube in the center of the bucket lid.

Mark the third hole closer to the edges of the cover, where the stiffener is.

If you do not have a special crown, then first pierce the intended circle with an awl and carefully cut it with a stationery knife.

The edges will be uneven, but they can be processed with a round file.

Two sewer outlets are inserted into these holes. So that they hold securely and there is no additional air leakage, it is better to glue them.

To do this, first sand the edges of the tube with sandpaper or a file to create a rough surface.

Do the same operation with the lid.

After this, insert the tube into the inside of the cap and apply a thick layer of glue with a hot-melt gun.

Don't skimp on glue. This will help create a good seal in these places and tightly close all the cracks.

There is actually another option in which you can do without glue and fan pipes altogether. To do this, purchase rubber adapter couplings from Leroy Merlin.

They come in different diameters. Select according to the size of your hose.

For example, a tube from a 35mm hose is tightly inserted into a 40/32 coupling. But in a 40mm pipe it will dangle. We'll have to reel in something and collective farm.

On the tube that is located on the edge of the lid, place the sewer outlet at 90 degrees.

At this point, the separator design can be said to be almost ready. Install the lid with outlets on the bucket.

The air intake hose from the vacuum cleaner is inserted into the central hole.

And the piece that you will use to collect all the debris and dust is stuck into the corner joint.

It is desirable that the tubes contain sealing rings that match the size of the corrugated hoses of the vacuum cleaner.

This completes the entire assembly. You can plug in the vacuum cleaner and use it.

Here is a visual video of the inside of a bucket of a similar design. It clearly shows how sawdust is sucked into the separator, but cannot escape from it and get into the vacuum cleaner.

The operating principle here is as follows. Coarse dust sucked into the container falls to the bottom of the container. At the same time, it does not enter the area where air is pumped directly.

Three factors help in this matter:

- gravity

- friction

- centrifugal force

They then make the garbage rotate inside the bucket, pressing against its walls, and then fall to the bottom. And only the fine fraction goes directly into the dust collector of the vacuum cleaner.

Typically, such a cyclone in factory designs has the shape of a cone, but cylindrical specimens also often cope well with this task.

True, the higher the bucket, the better the installation will work. Much here depends on the correct combination of the design of the container and the power of the vacuum cleaner. Here is a sign from Chinese cyclones on the correct selection of hose diameter and unit power.

In cylindrical buckets, the tangential air flow enters not through the curved side wall, but through the flat lid. Assembling such a device is much easier.

Also, if you have several buckets, you can use them alternately. Just remove the lid from one and move it to the other. Moreover, this is even easier to do than in bulky cyclones.

Then, at the very end of the work, simply take out the filled containers at once. This is a great time saver.

If you have a powerful vacuum cleaner, instead of a plastic bucket for emulsion paint, it is better to use a metal tank of the same shape. Otherwise, the bucket will collapse and flatten it.

The power regulator helps in this matter. If, of course, it is present in your model.

Features of caring for a cyclone filter

There are no special recommendations for caring for the cyclone filter - all cleaning operations are carried out simply and intuitively.

With a slight movement, the container is taken out, and the garbage is just as easily poured in. After cleaning, there is no mandatory washing of all parts, as is provided for models with an aquafilter.

If there is little debris in the dust collector, then you can leave it until next time. The smell of room dust does not spread, and residents of the apartment do not experience any discomfort. It is better not to allow filling to the max mark.

If you still need to wash the tank, just rinse it with clean water. The filters can be washed with laundry soap, the sponges must be carefully wrung out and dried in natural conditions.

If water accidentally gets into the cyclone filter, it also needs to be dried, otherwise the remaining dust will be compressed and clog the holes - the vacuum cleaner will not work as usual or will simply turn off.

Degree of water purification using hydrocyclones

One of the important parameters when choosing equipment for water purification from mechanical impurities is the amount of suspended solids. If there are more than 100 mg/l in water, only hydrocyclones will have an efficiency of 80-90%. With this parameter of suspended substances, the efficiency of a disk, mesh, cartridge, backfill (quartz sand or activated carbon) filter is significantly lower, because the equipment will quickly become clogged - impurities get stuck in the disks/grids, in the pores, and settle on the sand load. Because of this, the equipment often has to be washed, and the backfill simply has to be changed.

Another important parameter when choosing a water filtration method is the size of mechanical impurities. When mechanical impurities in a wide size range of 50 microns - 5000 microns are present in the aquatic environment, then the use of disk/mesh, cartridge and bed filters is not a reasonable choice for filtration, because only hydrocyclones in this case will have higher efficiency compared to other water purification equipment.

Results of tests on hydrocyclones for suspended solids (using the example of air defense hydrocyclones):

Laboratory analyzes on the indicator of suspended substances in source and purified water demonstrate the high efficiency of water purification by hydrocyclone air defense systems (using the example of hydrocyclones of the air defense-GTsTO-P models). The source water contained 4000 mg/l of suspended solids; after the first stage of purification with the PVO-GTsTO-40-P hydrocyclone, there remained approx. 100 mg/l, after the second stage of purification with the hydrocyclone PVO-GTsTO-25-P there were approx. 25 mg/l., i.e. the content of suspended substances decreased by 160 times.

When concentrations of dense suspended solids exceed 10% of the total mass of the aquatic environment, the optimal solution is to connect hydrocyclones in series; in this case, the filtration efficiency increases significantly.

Results of tests on hydrocyclones by particle size (using the example of air defense hydrocyclones) :

A hydrocyclone for water purification is an option to remove mechanical impurities from water without the use of discs/grids, sand backfills and other consumables. We studied a water sample containing particles ranging in size from 1 micron to 300 microns. Below is the cumulative dependence (line) and the dependence of the particle size distribution (histogram) of the particle size distribution. On the left ordinate, the symbol Q denotes the proportion of particles with a diameter smaller than that plotted on the abscissa; on the right ordinate axis the symbol q is the relative number of particles of a given diameter. The studies were carried out using special research equipment.

The laser diffraction analyzer "SALD-2300" showed that in the water, before purification with the hydrocyclone PVO-GTsTO-40-P, there are particles ranging in size from 0.5 microns to 290 microns (99.8% of all particles fall into this range). The median particle diameter is 50 µm, the modal diameter is 100 µm. Median diameter is the size that divides the distribution curve in half, where 50% of all particles are smaller than the median and 50% are larger. Modal diameter is the size that has the largest number of particles (the maximum position on the distribution curve).

The ST-240-Omni analyzer, which is more sensitive to low concentrations of impurities, showed that only particles ranging in size from 0.2 µm to 30 µm remained in the water sample after purification with the PVO-GTsTO-40-P hydrocyclone. The median and modal particle diameters are the same - 3.3 µm. This means that the PVO-GTSTO-40-P hydrocyclone purifies water from mechanical impurities down to 30 microns.

Possibilities of hydrocyclones of our own production:

Hydrocyclones PVO-GC - filtration with a purification fineness of up to 150 microns and a suspended solids content of over 30 mg/l. Hydrocyclones PVO-GTsTO-P - filtration with a purification fineness of up to 100 microns and a content of up to 10-50 mg/l. Hydrocyclones PVO-GTsTO-S - filtration with a purification fineness of up to 50 microns and a content of up to 10-50 mg/l.

Degree of removal of mechanical impurities

| Water purification equipment | Degree of fur removal. impurities, % |

| Pressure hydrocyclone | 80-90 % |

| Hydrocyclone + strainer | 100 % |

How to choose?

When choosing a vacuum cleaner with an optimal filtration system, you should be guided by consumer reviews and information received from the brand manufacturer. The most effective filtration systems are 3M, Einhell, Type 2 and EIO. Models from such well-known brands as Siemens and Bosch are equipped with a dust collector of the Megafilt SuperTEX system. It has an additional fabric layer with micropores, which ensures maximum working suction power, even if the dust bag is completely full.

Products from the Thomas AIRTEC brand have a four-layer dust collector made of fabric, and products from the German manufacturer Melitta are a multi-layer bag made of thin paper that filters the smallest particles down to 0.3 microns in size, with each subsequent layer retaining increasingly smaller dust particles.

Many modern models are equipped with a Swirl MicroPor mechanical filtration system. Its advantage lies in the operation of three stages of cleaning - the first two levels act as a traditional dust collector, trapping fairly large dust particles up to 1 micron, and the third allows you to clean the air from microparticles and, notably, from bacteria, which often cause serious diseases. Thus, the first levels work as a coarse cleaning system, and the third as a fine cleaning system. In the most popular Philips units, the dust collectors are impregnated with a special antiseptic solution, which effectively destroys bacteria immediately after they enter the bag.

At the same time, every manufacturer to this day produces a line of vacuum cleaners with the usual reusable fabric bags. The reason here is simple - these vacuum cleaners are much cheaper, therefore, they are optimal for people with average and low incomes. In addition, a fabric bag can be used for several years, but a paper bag needs to be changed regularly, which entails a waste of money and time purchasing them.

In most modern models from Samsung, LG, Electrolux, Rowenta, as well as Hoover, Bosch and Siemens, the dust collector is a reservoir located in the middle of the product body - these are cyclone models. They are performed in two versions.

- In cyclones of the first type, air moves spirally, where, under the influence of centrifugal force, it sticks to the walls, loses speed and immediately settles, remaining in the tank itself. Then the treated air is passed through motor and foam filters and is pushed outside.

- In cyclones of the second type, the purified air moves into a container, where an immediate decrease in speed occurs. In this case, more than 95% of the particles settle to the bottom, and all fine dust is picked up by vortices and moves into a sponge motor cleaning filter impregnated with a fungicidal preparation, after which it enters the outlet compartment and is discharged outside. Such filters have their own advantages, among which the first priority is the consistently high operating power, which does not depend in any way on the degree of fullness of the dust collector, and the cleaning process itself is much more hygienic.

At the same time, it should be noted that the manufacturers of all of the above models have not been able to achieve 100% retention of dust particles, as a result - together with the exhaust, they again enter the living room, and from there they go straight to our mucous membranes and lungs. The consequences of all this can be the most unpredictable; as a result, in an effort to protect your family, you can, on the contrary, face irreparable damage.

An alternative to such filters are water filters, which cope with the task of retaining dust as efficiently as possible, but do not cause the slightest harm to the human body, but their cost is much higher than that of all other dry type vacuum cleaners.

Vacuum cleaners from the German brand Thomas are equipped with water filters - the dust particle retention process here is 99.998% and this is the highest result among all vacuum cleaners existing today. In these aquafilters, the incoming air is immediately irrigated with moisture, after which the air is subjected to three-stage purification in foam rubber and paper filters. It should be noted that models with an aquafilter also have pronounced hygienic advantages - they not only trap dust particles, but also humidify the air in the house.

In addition, the operating power in this case remains unchanged during all cleaning operations, and cleaning the filter itself comes down to timely pouring out the contaminated water.

Advantages:

- Own production in the Russian Federation

- Ease of use and compactness combined with high specific productivity.

- Increased separation efficiency due to optimized shape, dimensions and high quality flow path.

- Possibility of assembly into battery devices for any given performance.

The choice of a hydrocyclone as a basic device for a water treatment system is determined, first of all, by the high efficiency of filtration of aqueous media from large inclusions and productivity at a relatively small size and cost. In addition, as practice shows, the operation of hydrocyclones does not require large costs and additional personnel for maintenance. Hydrocyclones can be successfully used as clarifiers for water circulation equipment in the residential sector. In industrial production, single hydrocyclones are combined into complexes (batteries) to provide the necessary throughput for power supplied for finer filtration in many technological cycles of industrial production.

Conclusions and useful video on the topic

In the video below, the technician will demonstrate how to repair a hose containing a communication line inside:

Repairing a vacuum cleaner hose often does not cause any particular difficulties for the user. The main criteria for making independent hose repairs are the ability to hold a plumbing tool in your hands and, accordingly, a creative impulse to carry out repair work. Without both, the quality of the repair is not guaranteed.

Do you have anything to add or have questions about repairing a flexible corrugated hose? You can leave comments on the publication, participate in discussions and share your own experience of fixing this part of the vacuum cleaner. The contact form is located in the lower block.

Hydrocyclones PVO-GC

Hydrocyclones made of carbon and stainless steel of our own production.

| Model | Productivity, m3/hour | Input/output, mm | Weight, kg | Dimensions (H/L/B) | Download passport (PDF) | Download (DWG) | Price |

| PVO-GC-1025 | 3,5-7,5 | 25 | 8 | 527/312/150 | DWG | from 36,960 ք | |

| PV0-GC-1040 | 9.5-12 | 40 | 16 | 640/457/178 | DWG | from 51,920 ք | |

| PVO-GC-1050 | 14-18 | 50 | 40 | 964/505/245 | DWG | from 61,600 ք | |

| PVO-GC-1080 | 35-45 | 80 | 50 | 990/505/245 | DWG | from 73,040 ք | |

| PVO-GC-1090 | 50-62 | 100/80 | 80 | 1550/790/362 | DWG | from 177 540 ք | |

| PVO-GC-1100 | 86-120 | 100 | 100 | 1950/820/432 | DWG | from 193 160 ք | |

| PVO-GC-1150 | 150-190 | 150 | 175 | 1911/1085/700 | DWG | on request | |

| PVO-GC-1200 | 230-370 | 200 | 328 | 2897/1363/809 | DWG | on request |

Aytok hydrocyclones

Plastic hydrocyclones Aytok made in Türkiye.

| Model | Productivity, m3/h | Inlet/outlet diameter, inch | Net weight, kg | Price |

| P2020 | 20-30 | 2 | 9,5 | from 391$ |

| P2025 | 30-40 | 2½ | 9,5 | from 391$ |

| P203006 (tank 8 liters) | 40-60 | 3 | 19 | from 566$ |

| P203010 (tank 25 liters) | 40-60 | 3 | 19 | from 771$ |

Hydrocyclone made of Aytok steel made in Türkiye.

| Model | Productivity, m3/h | Inlet/outlet diameter, inch | Net weight, kg | Price |

| 2020 | 20 | 2 | 27 | from $656 |

| 2025 | 30 | 2½ | 33 | from 770$ |

| 2030 | 40 | 3 | 35 | from $798 |

| 2040 | 60 | 4 | 38 | from $1,017 |

| 2050 | 120-140 | 5 | 65 | from $1,895 |

| 2060 | 140-160 | 6 | 92 | from $2,486 |