Electric boilers are the easiest to install and connect; they do not require a chimney, supply and exhaust ventilation, or a separate room for the boiler room. Since standard heating element models already contain all the necessary elements and components (circulation pump, expansion tank, safety group, etc.), when organizing a simple heating system, communications around the electric boiler are minimal.

All these factors allow you, having basic skills and knowledge, to install and connect an electric boiler yourself, without the involvement of specialists. But please note that the condition for providing a warranty from most manufacturers is that installation is carried out by a specialized service organization. However, the ease of installation also has a positive effect on the cost of the work of the craftsmen.

Features of operation and connection of the electric boiler

If we talk about the operating features of this type of boiler unit, the main thing is the connection to the electrical supply network. There are strict requirements here:

- separately laid cable from the distribution board;

- installation of a serious security system on site: automatic machines, RCDs, etc.;

- accurate calculation of all connection elements taking into account power consumption;

- installation of an electric boiler taking into account the requirements and provisions of the PUE.

The operating principle of the unit is simple. The design contains a container, inside of which an electric heater is installed. This could be a heating element, electrodes or an induction coil. Two pipes are connected to the tank. One is where water flows in, while the other is where it flows out, already heated.

Electric boiler wiring

There are models on the market without circulation pumps and with them. The first make it possible to simplify the strapping. But if the second ones are installed, then you can additionally purchase a circulation pump and install it in the boiler piping.

Useful tips

In order for systems with electric boilers to operate efficiently and have high efficiency, pumping equipment is installed in them to circulate the coolant.

Thanks to good circulation, the coolant will warm up evenly. It is recommended to install the circulation pump on the bypass so that you can switch to natural circulation of water in the system. When installing circuits with a gravitational carrier current, the return pipeline is laid with a slope towards the heating boiler. Thanks to this, the cooled liquid will quickly flow into the boiler.

What is electric boiler piping

In the context of the topic, the word “piping” has one meaning - connecting an electric boiler to the heating system of a house using pipes. The installation of other elements that affect the efficiency of the boiler unit is also taken into account, such as:

- expansion tank;

- circulation pump;

- heating process monitoring and control system.

The piping of boilers of different types, that is, those operating on different types of fuel, is the same. Because a boiler is just a heating element. And it doesn’t matter what fuel it runs on. But there are nuances. For example, the piping of solid fuel and electric boilers differs from each other in that in the first, steel pipes are used in the process of connecting to pipelines.

The entire heating pipe system can be assembled from polypropylene, but the connection areas to the boiler must be steel. In this case, the length of each such segment should not be less than 1 m. This is done for one reason - the high heating temperature of the boiler unit. Polypropylene pipes in the boiler piping may become deformed. Everything else is the same.

How to connect a circulation pump to electricity

The electrical circuit for connecting the heating pump can be implemented as follows:

- Using a differential machine. The simplest option that can be implemented independently without any problems.

- Thermostat control. Makes it possible to automatically stop the movement of the coolant if its temperature drops below a certain level.

- Combined use of network and uninterruptible power supply unit. Connecting power via the UPS is a snap thanks to special connectors. The same cannot be said about the procedure for connecting the pump to the distribution panel: for this it is better to call a specialist.

- Powered by built-in automation. The organization of such an electrical circuit for a circulation pump will require some knowledge in the field of electrical engineering.

It is not recommended to use a simple socket without automation or grounding to switch the device.

Materials used

Previously, steel pipes were mainly installed. They quickly failed due to corrosion. Also, their internal diameter during operation decreased over time due to salt build-up. This reduced the efficiency of the heating system and electric boiler.

Polypropylene pipe piping

Tying with polypropylene pipes

Steel has been replaced by plastic in the form of polypropylene, which not only has a service life of 50 years, but is also several times cheaper. Piping with such pipes is easy. This means that prices for installation work are reduced.

Positive characteristics of polypropylene pipes:

- the inner diameter never changes;

- the inner surface is always smooth, which does not reduce the speed of water flow;

- speed of installation;

- withstand pressure up to 25 bar and temperature up to +95 ℃;

- high quality connections between pipes and other elements of the heating system.

There is only one drawback - linear deformation with increasing coolant temperature.

Pipe connections are made in two ways: using special fittings or soldering. The second option is more reliable in terms of not causing leaks at the joints.

Copper piping

An excellent option, but expensive in all respects:

- the price of copper pipes is higher even than steel pipes;

- the cost of the services of a welder and installer will be more expensive, because joining requires knowledge of the technology, the availability of a welding machine and consumables, and extensive experience in carrying out this type of work.

The advantages of using copper pipes in piping include:

- their long-term operation, not inferior to polypropylene. Copper does not react corrosively with hot water;

- high heat transfer. Copper products themselves will give off heat well into the room, thereby acting as additional heating elements for the house.

Piping an electric boiler with copper pipes

Sequence of work

It all starts with the installation of an electric boiler. It can be mounted either on the wall (wall-mounted model) or on the floor (floor-standing). Further according to the following scheme:

- The pipes of the heating system are connected to the pipes.

- The latter include the required additional network elements: expansion tank, circulation pump, temperature, pressure sensors and others.

It makes no difference what needs to be done first: the heating network or the installation of the boiler. The main thing is to choose the right location for installing the boiler unit. It should be convenient for servicing the equipment.

Piping diagram of a natural circulation system

There is no pump here. Such boilers are often used in heating networks with natural coolant movement. When hot water heats up, according to the laws of physics, it tends to rise. It passes along the upper section of the piping and goes down to the heating radiators, because it is supported by cold water moving along the opposite section.

Here the coolant transfers heat to the premises, cooling down. From here it enters the return line and, flowing through the pipes, moves back to the electric boiler. The cycle repeats again.

The entire process of coolant movement occurs under the influence of the physical laws of heating liquids. A convenient and effective option for small homes. Plus - it is partially non-volatile. That is, apart from the electric boiler itself, there are no other electrical devices in the system.

But in such a piping system it is necessary to take into account the location of the expansion tank. It is usually installed on the coolant supply pipe section at the highest point of the heating system. It's all about the air that comes with the water. If it is not removed, a plug may form, which will negate all the heating work.

The air with the coolant moves upward, entering the expansion tank. The latter is an open type device. It has full connection with atmospheric air, allowing air pockets to be removed.

Pay attention to the picture below. It clearly shows where the expansion tank is located. This is the highest place.

Boiler piping diagram with natural water circulation

Another point is the coolant supply section. It should be located on a slope. This does not in any way affect the wiring diagram of the electric boiler, but this is an important nuance in installing heating with natural coolant circulation.

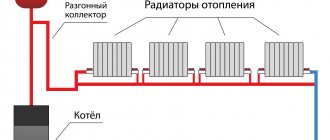

Forced circulation piping

The pump forcibly pumps water, creating a slight pressure inside the system. This device is installed for one purpose - to evenly distribute the coolant over the radiators. Forced circulation is not used in all heating schemes.

If the house is small, then you can install the “Leningradka” scheme (it is also called one-pipe), in which the supply and return networks are mounted parallel to each other and next to each other. Radiators crash into them - only into the coolant supply network, in series.

Another option is called a two-pipe. This is when pipes are laid in the same way, but radiators are inserted into two flows at once: supply and return. The battery is connected to the supply section with one pipe, and the return pipe with the other. In the photo below the two options are clearly visible.

Heating system diagrams

Both schemes are closed. A hermetically sealed expansion tank is installed in them. Air cannot be vented through it. Therefore, the tank can be installed anywhere in the heating system. More often this is the return pipe next to the electric boiler. A circulation pump is also installed here if it is not included in the boiler unit design.

It turns out that the piping is two pipes that are connected to the boiler pipes. If heating is used with natural circulation of water inside, then an expansion tank is connected to the upper section through a pipe. If it is forced, then a circulation pump is additionally mounted on the return circuit. When the pump is already present in the electric boiler, then no other devices are installed except the expansion tank.

The only thing that is always present in the harness are two required elements:

- Supply pipe with a ball valve at the end. It is cut into the return line through a tee and connected to the water supply network. Purpose – to fill the heating system with water. You can additionally install a coarse filter here, which is usually done.

- Pipe for draining coolant from heating. It is equipped with a ball valve and connected to the house sewer. Purpose – draining water to free the heating network from the coolant for repair or dismantling.

Types of electric boilers

Returning to the choice of electric boilers, I would like to dwell in more detail on power. The larger the heating area, the higher the power of the equipment should be. For example, for a house with an area of 150 square meters, a 14 kW boiler will be sufficient. Such a boiler can easily cope with two radiator heating circuits on the first and second floors and heated floors on the first. The boiler will have a power reserve, which is important in case of critical frosts.

Speaking of power, it is worth noting that this value depends on current and voltage. The greater the power set on the boiler, the higher the current in the power circuit. In turn, the current depends on the voltage: the higher it is, the lower the current will be in the circuit. Therefore, it is best to connect the boiler via a three-phase line.

It remains to figure out the cable cross-section. For example, with a power consumption of 14 kW and a voltage of 380 V at peak load, a current equal to 22 A will flow in the circuit. Such a current can easily be handled by a cable made in accordance with GOST, with a core cross-section of 4 mm square. Typically, such a cable is installed based on 5 full cores (three phases, neutral and ground).

As for the types of electric boilers used by private individuals, here are:

- ten varieties;

- induction options;

- electrode boilers.

Attention. To understand, you need to say a few words about each of the proposed options.

Heating elements new boilers

Such boilers are the most common, have a low cost and are equipped with all important operating components. This includes an expansion tank, a boiling water discharge system, a circulation pump, an automation unit and other components. Based on the name, it is clear that the water is heated by heating elements in special tanks. Depending on the power, the boiler is equipped with one or three heating elements. The greater the power, the faster the water in the circuit heats up.

This system is wall mounted, has a simple and intuitive control interface, and is easy to maintain. As for the disadvantages, thanks to heating due to heating elements, scale inside the container is not excluded. Years later, it can cause the boiler to fail. Although modern models have protective coatings on heating elements against scale, breakdown of the system cannot be ruled out.

Induction electric boilers

Such a system can be called the most modern in its class. Here, induction heating of the core is implemented, which heats the coolant in a very short time. During operation, microwaves (vibrations) are generated, which eliminates the possibility of scale formation. Hence the service life of such systems is 30 years, without the need to replace the heating element. The disadvantages of such boilers include high cost and operation only with coolant under high pressure.

Attention. These are modern models that have been introduced to the market relatively recently, which causes distrust among buyers. Boilers are characterized by heavy weight.

Electrode electric boilers

An electrode boiler is compact, high efficiency, and also reliable. Models with power from 1 to 16 kW are available on sale. The boilers are not sensitive to voltage changes in the network, and, therefore, are more suitable for operation in places with active use of electric heating devices.

Increased danger is the main disadvantage of such a system. To reduce the danger factor, experts recommend installing a grounding circuit. A closed system requires the use of only special liquids as a coolant, the cost of which is high. The system requires attention to itself, and also does not have the ability to smoothly regulate the current.