Gas heating equipment is the most profitable in terms of operating investments. Natural fuel is an order of magnitude cheaper than electricity and is easier to accumulate compared to solid combustible materials. Small heating boilers can be used in an apartment or in a private house. They are distinguished by their modest size, convenient operation and quiet operation. In the wide range of this segment, Daewoo gas boilers occupy far from the first positions. These products are more likely to belong to the middle class, which means a relatively affordable price, acceptable quality and certain technological innovations.

Installation of gas boilers

The manufacturer produces gas boilers in the format of so-called boilers. These are units whose function is performed in the process of heating water circulating through the circuits. Mainly on the market are Daewoo wall-mounted gas boilers, which take up little space and at the same time do not limit the owner’s options for laying circuit heating networks for the room.

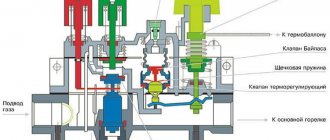

The structure is formed by several component groups. The basics are the burner, which serves the gas and then transfers the energy to the heat exchanger. The latter is interfaced with circulation pumps - two or one. The workflow is carried out over this infrastructure. However, for monitoring and control, measuring instruments are also provided in the form of a thermostat, pressure gauge and thermometer. These devices allow you to use a gas boiler with optimal heat transfer. The price of equipment varies on average from 15 to 25 thousand rubles. Again, these are average price standards that determine the appropriate quality of the units.

Kinds

The Daewoo company produces the most popular and convenient wall-mounted gas boilers for use in a private home.

There are no floor-standing models in the company’s arsenal, which is not a drawback, but demonstrates the approach of the company’s engineers to creating the most compact and multifunctional models.

According to the type of combustion chamber, two options are available:

- Atmospheric boilers. The combustion chamber is open type, and the air required for combustion and smoke removal is taken directly from the room in which the boiler is installed. They are connected to a common house chimney and require the creation of certain conditions for operation. DO NOT tolerate drafts or sharp gusts of wind outside - the flame may go out.

- Turbocharged boilers. The air supply occurs under the action of a turbocharging fan. This design makes the boiler completely independent of external factors, and the operating mode is stable and sustainable. Connecting the boiler to a common chimney is not required; special chimneys of the coaxial type (“pipe in pipe”) of the horizontal type are used, which can be led directly out of the room through the wall. Forced air units are stable and in higher demand.

By type of heat transfer there are:

- Convection boilers. They work on the usual principle - heating the coolant in a burner flame.

- Condensation models. A new type of design that uses two-stage heating of the coolant. First, the thermal energy obtained by condensing water vapor from the exhaust smoke is used. Then the coolant, which has received some heating, is sent to the primary heat exchanger, where it is finally heated to a given temperature.

The use of condensing boilers began recently, but statistics have already been collected. They provide significant fuel savings due to the recycling of thermal energy.

It becomes possible to reduce the heating intensity of the heat exchanger, which saves gas and increases the service life of boiler components that are not subject to too much load.

NOTE! Condensing boilers require specific operating conditions. The temperature difference between the outside and inside the building should not exceed 20°, otherwise the condensation process will become impossible

Because of this feature, the use of condensing boilers in Russia does not make sense. When purchasing such installations, you should know in advance about the existing restrictions so as not to pay extra money.

Main characteristics of Daewoo boilers

The key parameter in choosing a boiler is power. Typical models from the Daewoo line for domestic use operate with potentials of 20-25 kW. Thermal power varies in the same range and can reach 30 kW. These data are typical for models designed for use for private needs. Equipment performance largely depends on gas consumption. In standard members of the family it is approximately 2.5-3 m3/h. As for the design, Daewoo gas boilers are small in size, which allows installation even in a small kitchen. Do not forget that these are mainly wall-mounted units that practically do not occupy the housewife’s work space. Another thing is that experts recommend assessing the possibility of installing a chimney. The diameter of the canal varies from 100 to 120 mm on average.

Reviews of the DGB-160 MSC model

Models of the DGB line are suitable for use in the engineering structure of private houses and apartments. According to users, the 160 MSC option, the power potential of which reaches 18.6 kW, may be optimal for the needs of the average family. Practice shows that this power is sufficient for hot water supply and heating functions. Another thing is that achieving high operating efficiency in different modes is only possible with high-quality installation and proper use of the control system. Those who use a Daewoo gas boiler in this modification also point to an improved security system. For example, the developers have optimized the stabilization system when supplying gas. At the same time, ergonomics could not be improved. The heating process is carried out in an accelerated mode, which saves time both on cooking food and on bringing the air to the required temperature.

Other faults

During operation of a Daewoo boiler, error codes cannot always help with malfunctions.

The following problems may occur:

- The room remote control power buttons do not work when the power cord is connected. You should measure the voltage at the signal end of the remote control and at the blue CN terminals. It should be equal to 12 volts. The solution is to replace the defective controls and configure the terminal unit.

- If overheating is detected, check whether the circulation pump is working correctly, check the pressure in the heating pipe and the cleanliness of the distribution pipe.

- If a pump failure occurs during testing, the mains voltage is measured between the two black-and-white and white-black terminals on the CN pump

- When ignition does not occur, the locking condition and operation of the control panel are inspected. The operation of the main board is also checked. Diagnostic points for this are indicated in a special table in the operating instructions.

Reviews about the boiler DGB-160 MES

The version of the gas boiler is similar in general characteristics, but the MES series has its own features that are highlighted by users. This modification has a significantly improved control system. For example, we can note the presence of a weekly programmer of operating modes, autonomy of the control panel, as well as simplified connection of the chimney. In other words, the model design saves space for loop integration and maintains high control reliability. In addition, the Daewoo gas boilers in this series, according to the owners, are distinguished by the presence of a built-in pulse stabilization module for energy supply SMPS. Together with the durable materials of the technical components of this version, the latest control systems make it almost ideal for private needs. True, you still have to forget about high power. This option is good primarily for its environmental friendliness, safety and ergonomics.

Feedback about DWB-201 GOM

If previous models are focused on the common requirements of the average owner of a small house or apartment, then this option is usually used by private owners who require more powerful equipment. According to the manufacturer’s calculations, the Daewoo gas boiler version 201 GOM is capable of serving an area of up to 250 m2. And the opinions of the majority of cottage users confirm this. At the same time, high-quality assembly based on modern element base is noted.

Compared to traditional boilers equipped with a combustion chamber, this option is also advantageous due to the lower placement of the turbine. The fact is that Daewoo gas boilers in the latest versions create adjustable air pressure, which increases operating efficiency. To this, users add the advantages of electronic ignition, which eliminates routine operator actions.

Price range

The cost of Daewoo gas boilers is in the conventional range of 34-59 thousand rubles. The price difference depends on the model, power and other factors.

If the region is located far from large populated areas, the price of the boiler will increase due to logistics costs. Before purchasing, you should find out in what configuration the equipment is supplied and what needs to be purchased in addition for optimal and safe operation of the boiler.

In addition, you need to take care of concluding a warranty agreement, which will also cost a certain amount.

IMPORTANT!

Some users do without warranty service, but this approach is only possible for specialists who can independently repair and configure the boiler. For mass users, it is strongly recommended to use the services of warranty workshops.

User manual

While using the equipment, the user will have to deal with several groups of parameters. In the future, you can completely rely on automation, but at first the boiler needs to be tested according to operating modes to ensure it meets specific needs. So, you should initially determine the heating modes by indicating the temperature limits through the control display. The same applies to the water supply regime, but in this part the volumes of coolant along the circuits that serve Daewoo gas boilers are also determined. The instructions note that protecting equipment from freezing in automatic mode will only work when switching to the appropriate mode. This nuance is taken into account when operating indicators are switched from winter to summer use and vice versa.

Installation

Installation of Daewoo equipment does not cause any difficulties for experts in their field, while an inexperienced user may have questions and problems during operation. Dealers who sell Korean equipment may well refuse repairs under warranty if the buyer did the installation himself. It is worth remembering that when tying, you need to connect to electrical networks and connect thermostats. To carry out similar work, you need special permission and knowledge of the rules of electrical installations.

During installation work, it is important to strictly follow the manufacturer's recommendations. Look at the instructions and read about the wiring diagram

Maintenance instructions

Once again, the user will be required to carefully configure automatic functions. For example, most Korean gas boilers support options for air removal, tank disinfection, fault detection, etc. As for physical maintenance, it is important to prepare for some repair operations, which a Daewoo gas boiler can undergo at home. Spare parts are supplied separately - a typical list of main components includes heat exchangers, expansion tanks, fans, pipes, pipes and accessories for the loop infrastructure.

It is important to note that regular maintenance can significantly increase the cost of maintaining equipment. This depends on the gas consumed and on the use of new consumables and components. For example, a gas boiler, the price of which is no more than 20 thousand, on average every six months requires an investment of up to 2-3 thousand to update pipes and fittings.