When an old gas stove loses its beautiful appearance, it is taken to the pantry or barn, hoping that someday it will be useful again.

You can take it to a scrap metal collection point, but the fee for it does not always compensate for the cost of delivery, especially if the slab is large and cannot be carried away alone.

Therefore, it is much more practical to give an old stove a new life by turning it into some beautiful or useful craft, and in this article we will tell you what exactly can be made from an old stove.

Free heating, sir!?

Greetings to all blog readers!

Today it’s cool outside, it’s raining, and therefore the weather itself makes me think about talking about how to heat an apartment or house. At the same time, preferably with significant cost savings. People have special warm feelings for everything free. And if we talk about saving money on heating, then on the eve of the coming winter these feelings stimulate the brain, and this topic becomes extremely relevant. The Internet has already overheated from the number of requests on this topic. Some are interested in ideas on how to steal more electricity from the state and pay less for it, others are inventing ways to circumvent the law of conservation of energy. If the first group implements this idea successfully, but with the risk of meeting with an Energonadzor inspector, then for the other group of Kulibins things are, to put it mildly, unimportant. One can only be amazed at the ideas that are born in the heads of our inventors. Take, for example, an electric induction cooker. This thing in the kitchen is very useful in all respects. It combines the advantages of an electric and gas stove. It seems to me that the inventor himself and the manufacturers of these products could never have imagined that someone in Russia would have the idea of using an induction stove to heat an apartment.

And the idea is the following. Electric induction cooker is used as a heater for a water boiler. The boiler fits into an existing water heating system. Everything is as usual here. The whole trick, according to the author of the invention, is to convert energy to power the induction cooker.

The stove is not plugged into an electrical outlet directly, but through a charger, a pair of batteries, and an inverter. An induction cooker with a capacity of 2000 W is used, which can be purchased for 1500 rubles. There is no need to invent anything here. The current power in it can be changed on the control panel, and the built-in timer automatically regulates the heating. For stable operation, you will need a 4000 W and 12 V inverter, two 250 Ah batteries.

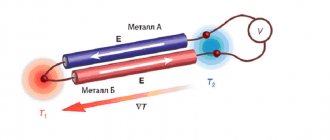

The sequence of assembling the electrical circuit is clear from the figure. The question is how “free” the heat received in such an apartment heating system will be. Judge for yourself: energy losses from the outlet to the stove are inevitable, which means that the efficiency of the heating system decreases. It is more efficient, in my opinion, to plug the stove directly into an outlet. As for frequent power outages, this system is indeed capable of operating autonomously for some time. Or am I wrong?

But that is not all. Here is another option for “warm floor” heating, which uses this connection diagram for an electric induction cooker.

It is unlikely that an electric induction cooker alone will be able to effectively heat an apartment. It would be interesting to know the opinion of those who have already experienced such a heating system in practice. Write and share your ideas. I think that the problem of home heating with the annual increase in energy tariffs worries the majority of Russians.

Judging by this sunset, which looks like a huge glow, there will be frosts at night, which means that the solution to this problem is urgent.

Author of the article: Alexander Kharin

iddeas.ru

Typical causes of heating boiler breakdowns

The main reason is the destruction of electro-automatic devices, including the “safety unit” and the control unit. Flame, draft and temperature are controlled by bimetallic sensors. If the integrity of the protective fuses or the rules of use are violated, the servomotor will block gas access to the boiler and an error will appear on the information panel. To resume operation, use a multimeter to detect a break in the circuit or a burnt-out temperature sensor.

Low pressure in the expansion tank is the second reason. For correct operation, a pressure of 0.8-1 bar is required. At 0.7 bar the condensing boiler will not turn on. To increase it, remove the water from the boiler and pump up the air with a bicycle pump. The flexible hose connects to a built-in nipple, the pressure is controlled by a mechanical pressure gauge.

The electronic board of the boiler is faulty. An incorrectly selected voltage stabilizer, lack of grounding in the socket and lack of power supply protection unit increase the risk of board burnout. It is impossible to repair the electronics yourself; dismantling and diagnostics by a master electronics engineer will be required. A burnt-out circuit is difficult to restore after moisture has entered; you should order and install a new circuit board according to the model of the electric boiler.

The spark clicks and the burner does not start - the ignition electrode or the boiler ionization sensor is faulty. If the electro-automatic ignition constantly clicks, and upon completion of the start-up the red LED flashes (go into emergency mode), you should inspect the spark plug and high-voltage wires for cracks. If the insulation is broken and the spark strikes away from the main burner, the ceramic spark plug must be replaced.

Insufficient water pressure is reason number five. If the pressure in the heating system drops below 0.5 bar, the boiler will turn off. To resume operation, the system must be recharged with water. Open the feed tap until the pressure stabilizes. For control, a pressure gauge is installed on the front panel. If the fall continues, invite our technician to your home to check the tightness of the pipe welds and threaded connections of the batteries.

DHW or hot water supply does not turn on - the three-way valve of the boiler is faulty. The electric valve is dismantled, disassembled and washed from rust. Then they check the power button, visually it sticks in one position. After assembly, apply voltage to the motor to check the rod. If after repair the boiler does not start, the 3-way valve must be replaced.

Lack of annual preventive surveillance is the seventh reason. We offer qualified cleaning assistance from experienced craftsmen. Write in the chat window or submit a request by phone. An engineer will remotely diagnose a defective device and advise the owner on the cost of services. We will draw up a defective work report and provide a guarantee for equipment repairs for up to 1 year.

Is it harmful to heat the room including the oven?

Whether or not to heat a room using a conventional oven is a question that regularly appears on various forums dedicated to home economics. This is due to the fact that the heating season does not always begin in accordance with the weather, and many houses are simply not suitable for living in cold conditions (damp, moldy with thin walls). Many craftsmen prefer at such moments to open the oven door, turn on the fire at full power, and thus warm the room and kitchen. Experts assure us that this is absolutely impossible to do. Heating a room with an appliance that is not designed for this purpose can be deadly. Short circuits in houses where electricity is used, gas leaks - this is not a complete list of problems that can arise and lead to great difficulties. Experts say that owners of gas stoves need to be especially careful. It just seems that an open fire heats better. In fact, it significantly spoils the air, making the situation even worse.

What to consider

Heating a room with an oven is quite easy. However, it is worth considering that if you open an electric oven, your stove will immediately start working harder, because. it will have to heat a much larger surface than the one for which it is designed. And this leads to increased energy consumption, faster wear of the furnace, and the likelihood of a short circuit. After all, if the wiring is old and weak, it simply may not withstand such abuse. Putting something in an open oven for cooking (so that the oven supposedly works as intended) is not an option. After all, she does not have enough power to perform her direct duties. As for gas stoves, the situation is even more serious. After all, such furnaces emit nitrogen dioxide into the atmosphere, and at a fairly high level. And this is a rather dangerous carcinogen, leading to very unexpected consequences. For example, it can worsen asthma in children prone to this disease. Preschool children are especially affected. If the ventilation system in the house also does not work well, you risk getting serious poisoning with the help of such heating of the premises. And no amount of ventilation will help and you can’t heat the room with an oven. Moreover, by opening the window and turning on the gas oven, you do not provide the proper level of heating. And as a result, you poison yourself more than you insulate your room.

What to do

The only sensible option that can be offered to those who like to warm themselves by the stove is the purchase of an air conditioner or heater.

Electrical appliances create a comfortable room temperature in a matter of minutes. Moreover, they are completely safe for humans and do not cause the development of serious diseases such as asthma or other respiratory problems. If possible, it is better to make a fireplace in the room. Let it be small, but real. Firewood does not emit toxic substances when burned, as a result of which the room is heated and does not cause harm to health. And be sure to contact your housing office to resolve the issue with the room temperature. Perhaps your housing office will reconsider the conditions for supplying heat if the whole house is suffering just like you.

With the arrival of autumn, the apartment is filled with dampness and cold, and there is still a long wait for heating. And, as you know, the normal and comfortable state of a person in most cases depends on the air temperature in the room in which he resides. So in what ways can you heat a room so that you don’t have to freeze? With the arrival of cold weather, it is necessary to insulate windows and doors, especially if they have cracks. Of course, the ideal option would be to change the doors and windows, but this method is not suitable for everyone, since you will have to shell out a large sum of money. You can use paper, foam or self-adhesive insulation. If there are large gaps between the frame and the glass, the seal will allow cold air to pass through. In this case, you can cover it with a special putty-sealant. And to seal large gaps, prepare a paste of chalk paste (1 part water, 2 parts chalk and 1 part flour glue). Insulate the doors using a hollow polymer cord; it must be glued on the inside along the entire perimeter of the door. Often central heating is not able to maintain the desired and optimal temperature. Therefore, you need to purchase an additional heat source in advance - a heater. When choosing it, consider the area of the heated room. The greater the power of the heater, the correspondingly greater its heat output will be. You can purchase a fan heater; it consists of a heating element and a fan, which distributes heat throughout the room. The body of this device is mainly plastic, but ceramic models have also appeared on sale. The fan heater is compact in size and lightweight; it quickly heats the air in the room. Its main disadvantage is considered to be noise during operation and the fact that it drives dust around the room. Therefore, it is not recommended to use such a device in a child’s room, especially if the baby has allergies. If you live in a private house, then the ideal option would be to build a fireplace. It will not only create an atmosphere of comfort and warmth, but also decorate the interior of the house. However, such a fireplace can heat only one room, and not the entire room, as we would like. It can be a real one that needs to be heated with wood. Or you can buy a decorative one - electric, it also emits heat and creates the effect of a real fire, and besides, you will not have problems installing it. Do not heat the room under any circumstances using a gas stove. With the burners turned on and the windows closed, there is a possibility of becoming oversaturated with carbon dioxide, which is life-threatening. Do not plug multiple high-power electrical appliances into one outlet. Keep children away from heating appliances. Electric and induction stoves, which are gaining popularity, are replacing a familiar element of everyday life for many residents of our country - the gas stove. In some cities, however, such stoves still continue to be used due to the relatively inexpensive opportunity to supply natural gas to a residential building or apartment. Turning on a gas oven is a little more complicated than simply turning the temperature knob on an electric or induction oven. Buy matches if your oven does not have a built-in igniter and only has a narrow tube removed from the inner burner. This tube allows you to light the oven in one and only way: turn the knob (turn on the gas) and bring the lit match to the very edge of the tube. After this, if the flame is not blown out by a stream of gas, or the match simply does not go out, the burner lights up. Use an external piezo igniter if the burner is easily accessible or the bottom of the stove is raised, allowing access to the burner. The process is similar to the first option: turn the oven knob and press the piezo lighter button, releasing a spark. Remember that initially you need to turn the handle a short distance when lighting matches, otherwise the light will go out; When using a piezo igniter, the handle can be immediately unscrewed to the required position. If the stove is equipped with built-in electric/piezo igniters, then you can turn on the oven by turning the gas supply control knob to the required mark and pressing the piezo igniter button - the burner will start working. Most often, the resource of the built-in piezo igniter is limited and after several months of operation it stops working; You will have to light the oven manually. The stove can also be equipped with automatic electric ignitors that are activated when the regulator knob is turned to any distance different from the start. The automation is designed to start a spark immediately after turning on the gas on the oven burner. The mechanism for turning on the burner will look different: the knob must be turned sharply in order for the igniter spark to fire while the gas is being supplied, and not a second earlier (housewives often, out of fear, turn the knob slowly, thereby only releasing gas and exposing themselves to danger). Is it harmful to heat the room including the oven?

www.kakprosto.ru

How to deal with problems

If the boiler goes out and does not light up again, check the quality of ventilation in the room. This is a common cause of problems for atmospheric models “Proterm”, “Navien”, “Ariston”, “Bosch” with an open combustion chamber, because they take combustion air from the room.

- Organize high-quality ventilation in the room;

- Install ventilation valves on sealed window packages;

- Open the window in the boiler room for air flow.

Check the presence of draft in the boiler chamber. To do this, light a match and bring it to the control window or chimney outlet. If there is draft, the flame will deviate to the side. If not present, it will burn evenly. In the latter case, a chimney inspection is required.

This is excess, deficiency or backdraft. All this leads to the fading of the wick and automatic shutdown of the equipment.

Backdraft or blowing out occurs due to weather conditions: strong winds, pressure changes lead to the burner extinguishing. During installation, take into account the requirements for the height of the chimney:

- The height of the pipe on a flat roof is at least 50 cm;

- With a distance from the roof ridge of 1.5 meters - from 50 cm above the ridge;

- At a distance of 1.5–3 meters - level with the ridge.

Compliance with these parameters will help to avoid blowing and backdraft.

Excess air flow occurs with a powerful kitchen hood or ventilation. The solution is to turn off the hood while the boiler is operating.

Lack or absence of traction provokes:

- Blockages. Occurs in stationary chimneys. Clear the mine of leaves, debris, and construction debris. Fixed and coaxial pipes can become covered with ice in winter. Along with combustion products, hot steam escapes into the street, condensation forms, which freezes on surfaces. Insulate the chimney.

- Damage, burnout of the pipe. Only replacing the chimney will help.

Does the dual-circuit device “AOGV”, “Beretta” or “Vailant” turn off and not turn on? This is possible when the fuel supply is unstable. For the same reason, the burner does not light the first time. First of all, check:

- Pipes and joints for gas leaks. To do this, lubricate them with soap foam. If bubbles appear, there is a leak. Then turn off the valves, open the window and call the gas workers.

- Counter. If there is a breakdown, the meter readings do not change; noise and crackling are heard. You can’t fix the problem yourself—you need a specialist.

If everything is fine, wait until the gas supply is restored.

Does your equipment not start after a long shutdown? It may be worth using antifreeze as a coolant. It does not freeze when the temperature drops and allows you to safely start the system after a long period of inactivity.

All boilers with a closed combustion chamber - such as Buderus, Wolf, Danko, Lemax - are equipped with fans. They forcibly discharge combustion products into the street. If you hear strong noises when the blades rotate or do not hear operating sounds at all, carry out diagnostics and replace the element if it breaks.

To find other problems, it will be useful to know the structure of the boiler you are going to repair. “Aton”, “Siberia”, “Buderus”, “Ferolli” or another brand may have their own characteristics. But the following sensors and components often break down:

- Circulation pump. If it fails, the boiler may make noise and the flame in the burner goes out. In such cases, the equipment will not work for heating and hot water supply. The only solution is to replace the pump.

- Igniter. Incorrect pressure adjustment results in flame failure. The protection is triggered and the operation stops. Set the correct fuel supply.

- Burner. The appliance has switched off and will not re-ignite. Check the burner nozzles for blockages. Clean them from soot and dust. Also clean the sensor photocell and try ignition again.

Diagnostics and replacement are also carried out in case of breakdown of the thermocouple, pressure and draft sensors.

Does the device not start after turning off? Check the remote control, replace the batteries. Examine the display. If it does not work, diagnose the controller.

Heating equipment that is additionally connected to the network suffers from power surges. If the values are lower or higher than the nominal value, the unit will not work. It is recommended to connect a voltage stabilizer.

It is important to understand that a boiler emergency stop can happen for a variety of reasons. It's good if a code appears on the display. For example, the display of the Proterm model may display error A6. This means that the temperature in the room has dropped and you need to connect an additional heater. So, thanks to symbolic codes, it is easier for the user to detect the problem. In other cases, you will have to check all boiler systems.

It is always easier to prevent a breakdown than to repair it. Therefore, monitor the operation of the boiler and carry out maintenance once a year.

To understand the reasons why a gas boiler does not light up or goes out, it is important to understand the principle of operation of the system. An analysis of the most common practical situations - why the boiler does not turn on or light up, and recommendations for repairs - is presented in the material.

Heating a kitchen with gas - Tips for all occasions

Do you think it is dangerous or not to heat the kitchen with a gas stove? Those. It’s very cold in my kitchen in winter, and I periodically turn on all the burners to warm up the air in the kitchen. After some time I turn it off. And then everything starts all over again. From time to time I go and monitor the process... Do you do this at home?

I think there’s nothing wrong with that - everyone does it)) how else can I increase the temperature? We rarely do this, but in our kitchen there is a gas boiler and it’s constantly working... it seems like we’re still alive))

What a horror. It’s better to buy a heater than to set up a gas chamber with your own hands in this way. After all, you can easily get burned - using gas for heating is not as safe as is usually thought. But a gas boiler is completely different.

I also warm myself this way in winter. I don’t know how you can get so upset if the kitchen is equipped according to all the rules. In addition, the heater can also be dangerous. And regarding the gas chamber, in order to avoid this they came up with gas control.

Yeah, gas control was invented. They also came up with ventilation shafts. But both do not always work correctly - devices, as you correctly noted, tend to break down, and ventilation shafts do not always provide sufficient ventilation. So you can easily get poisoned by the carbon monoxide that is released.

How do you feel after such heating? As far as I know, when the gas or oven is on and the windows are closed, the oxygen that is in a closed room is burned, it becomes difficult to breathe, and dizziness occurs. That's exactly how it is for me. Even when I’m cooking or baking, I open the window wide, otherwise I’ll just crawl out of the kitchen.

I have the same situation. I immediately begin to choke. In addition, some kind of fragrance is probably added to the gas, because in addition to just heavy air, there is also a very specific smell in the apartment right away. So I prefer to turn on fireplaces and fan heaters when it’s cold.

My grandmother used to like to warm up with gas, too. But now it's really smelly. So it might be better to dress warmly or buy a heater. Gas won’t heat up your kitchen quickly, but a heater will handle it in a few minutes. The only downside is that it takes a lot of electricity, but you don’t have to breathe harmful gas.

Why warm up in this way - firstly, oxygen burns out, and secondly, there is still an open flame, God forbid it goes out and you get gas poisoning (((

Why warm up in this way - firstly, oxygen burns out, and secondly, there is still an open flame, God forbid it goes out and you get gas poisoning (((

They heated the room with gas for so long that I had already forgotten that this is how it is done. But in general, of course, it’s scary because God forbid the flame goes out... I don’t even want to think about the possible consequences (((My advice to you is to find a safer way to heat the house.

Good for those who have questions about why heat up. And I understand those who heat with gas. Year after year, not only do the heating turn on late and turn off early, but also in cold weather the radiators are barely warm. But you can’t heat up much with a fireplace - the meter is spinning, and you have to pay a lot for electricity. So we heat with gas.

this is dangerous and harmful... oxygen is burned, it is better to buy a good heater, now there is a choice for every taste and budget

uborka-doma.net

Possible startup problems

The gas boiler slams when the main burner starts

The most common problem, the cause of which is most often clogging of the igniter (dust, combustion products, etc.). It is recommended to call a specialist to clean it.

The reason may also be that the pilot flame is too low: below the main burner. When using electrode ignition, the electrode may be clogged or faulty. In rare cases, the cause may be excess gas pressure in the line. It is important to understand that slight, barely audible pops are characteristic of most models of gas boilers that do not have a sound insulation layer.

Only the wick burns and cannot light the main burner.

The reason may be the same clogging of the igniter or its incorrect installation, when the flame simply does not reach the main burner. Clean the pilot nozzle (it is advisable to entrust this to a specialist) and check the operation: its flame should reach the main burner and simultaneously “wash” the thermocouple. Sometimes the reason lies in a malfunction of the thermocouple, which does not open the gas supply.

How to use an old gas stove in the country?

What can be made from old things in the country? We communicated on this topic several times and provided our readers with many interesting ideas, for which we received positive feedback. Today we decided to delve even deeper into the topic, since it seems quite interesting to us!

Our previous article, in which we looked at the life of old things in the country, received several positive reviews and personal letters, and therefore we decided that we were doing a really useful thing. Today DachaDecor.ru presents a kind of continuation of this article, and offers you to get acquainted with even more exclusive ideas for using old things in the country.

Country tea coasters

Simple wooden coasters can be cut from any log using a circular saw or chainsaw. This is exactly how they turn out, cute and original stands, on which, by the way, you can place not only hot cups, but also the kettle itself, pots and pans. You just have to remember that it is better to choose hardwood for them.

Criterias of choice

It is important to choose a gas stove for a garage taking into account the main characteristics. Let's look at them in more detail

Power

This characteristic will allow you to save not only on the purchase of the optimal stove option, but also during operation. A powerful stove will heat the room faster, but gas consumption will also be higher. A low-power stove will not be able to heat the room

Therefore, it is important to know even approximately the required power of the equipment to heat your garage

You can calculate this characteristic yourself. To do this, you will need to determine the volume of the entire room and the cubic capacity of the gate. Multiply these values by the coefficients for the materials from which the garage itself and the gate are made. The resulting result will be the approximate power of the heating unit.

Material

This characteristic affects the longevity of your stove. When purchasing, you will need to familiarize yourself with the thickness and grade of steel of the body and firebox. When using structural steel, the thickness of the firebox sheet should be from 6 mm. It is better if heat-resistant steel or alloys were used in heat guns or convectors for the production of the body and grilles.

Alloy steels with a high content of chromium, silicon, and molybdenum are the best option for the production of parts exposed to high temperatures. Another option for a material that is not exposed to aggressive environments is stainless steel.

Winter summer

If the use of heaters is planned to be short-term and during the warm season, there is no point in buying expensive, powerful equipment. Small heat guns or convectors or a homemade stove that burns gas in a closed chamber will help here.

For winter and low temperatures, you will need to purchase a powerful gun or several infrared heaters and install them throughout the room. At this time, the efficiency of technology is an important factor.

In this matter one should not go to extremes. You can’t try to save money and buy low-quality Chinese equipment for pennies and throw it away after a short time. But you shouldn’t buy an expensive, powerful heat gun from leading manufacturers to heat a small garage during short visits.

Design and principle of operation

Regardless of the manufacturer and model, the IR heater consists of the following main parts:

- metal case coated with a layer of heat-resistant enamel;

- heating element (heating element);

- a radiating plate made of aluminum and coated with a layer of thermal insulation;

- fastenings (if the selected model is designed for mounting to a wall or ceiling).

IR heater device

The principle of operation is as follows: electrical energy is converted into heat rays, which heat all objects encountered in the path of infrared radiation. And the heated objects then share heat with the air space (for more details, see the article on the principle of operation of a heater with infrared radiation).

Operating principle of the IR heater

Reviews of gas heaters

Victor, Chelyabinsk:

“I purchased a fairly solid device for heating rooms with gas - Timberk TGH 4200 SM1 . I use it most often in the garage, but I have also warmed rooms in the house several times.

Any room heats up very quickly, I didn’t even expect such an effect. The only thing that sometimes bothers me is the very high sensitivity of the sensors. Any push from the heater causes it to turn off .”

Sergey, Kirov:

“To heat the garage, I chose an infrared heater NeoClima UK-02 , designed for an area of 25 meters. I liked not only the heating speed and compactness of the device, but also the ability to heat up and even cook food on it when traveling.”

Ilya, Zelenograd:

“I purchased a Ballu BIGH-3 for the utility room. Works great. The temperature even at sub-zero temperatures rises in an hour to an hour and a half. Lights up easily on the first try. I liked the opportunity to connect to natural gas.”

With complete objectivity, gas heaters with infrared radiation can be called an extremely useful . Therefore, some home craftsmen have already started making such devices, making them from improvised means.

Having a small gas cylinder, a reflector made of stainless steel and a mesh diffuser, they assemble a small heater that can warm its owner while fishing. It is worth noting that in the absence of safety sensors, such devices are not recommended .

Operating principle of a gas ceramic heater for a summer residence Timberk 4200 M1

For an overview and characteristics of the MASTER 450CR gas heater, see the video below:

Infrared heaters have gained immense popularity among the population due to their cost-effectiveness. But what to do if the device breaks down? Let's look at how you can repair an infrared heater yourself.

Why does a gas boiler go out? Causes and solutions

Today, gas boilers are used everywhere, especially in winter. They act as the main part of an autonomous heating system. It happens that the boiler refuses to work correctly, for example, the flame may go out. When a consumer has a question about why a gas boiler goes out, it is necessary to analyze whether the device is working differently. Therefore, wind noise may be heard. It is important to pay attention to the display, which may show an emergency sign. In this situation, diagnostics should be performed to identify the causes that led to the problem. Otherwise, the temperature in the home may drop significantly, as a result, the system will defrost, which will then become unusable.

Do-it-yourself gas heater repair

Even the most reliable device can fail Therefore, each owner of a heater is interested in the opportunity to bring it back to life independently, without resorting to the services of specialists.

Knowing the structure of the unit, it is quite possible to solve the problem that has arisen. It is clear that the designs of different models have differences, but repairs always begin in the same way. First of all you need :

- find out the cause of the malfunction;

- determine whether parts need to be replaced;

- make sure that the repair can be done yourself;

- begin the necessary repairs.

For infrared gas heaters equipped with a ceramic plate, repair most often comes down to replacing low-quality plates that are unable to provide the level of heat declared by the manufacturers.

Since the device runs on gas, you need to make sure that there is no fuel leakage . To eliminate it, it may be necessary to tighten the fasteners, and sometimes replace the cylinder.

The malfunction may also be hidden in the power regulator , so you need to make sure that there are no fuel leaks through it, and if necessary, replace this part.

Even minor gas heater repairs require experience in this area. For people who do not have such experience, it is better to contact a specialized workshop .

Do-it-yourself gas ceramic heater repair: features

As a rule, repairing a gas heater with your own hands comes down to replacing low-quality plates that cannot provide the required level of heat. In addition, you need to make sure that there is no fuel leakage in the device. To eliminate a leak, you have to tighten the fasteners, and sometimes replace the cylinder.

When relaxing in nature, people often face the need to warm up .

The same problem arises for those whose work involves spending a long time outdoors, especially if this happens during bad weather .

It is not always possible to make a fire, and for heating this heat source does not always provide the necessary effect. In modern conditions, the best way to heat , autonomous and compact, is an infrared ceramic heater running on gas.

Preventive recommendations

Each user manual supplied to the heating boiler by the manufacturer must contain a section describing the mandatory periodic maintenance of the device.

The owner can call service center employees for this, or can perform maintenance work independently.

Before starting work, be sure to turn off the gas supply and power supply to the device.

To carry out maintenance you will need:

- wire brush;

- a toothbrush with hard bristles;

- fine grain skin;

- air compressor or enema;

- thin awl or needle;

- vacuum cleaner;

- soap solution;

- rags.

To carry out maintenance, you will need to remove the device housing. On some boilers you will have to unscrew several screws to do this, while other models are equipped with quick-release fasteners.

For maintenance you will have to remove the body of the gas boiler

After removing the casing, you can begin to remove carbon deposits from various parts and components. These include:

- heat exchanger radiators;

- gas-burners;

- igniter;

- security sensors.

Using the tools listed above and without applying excessive force, you need to carefully clean off the carbon deposits. After this, you need to blow out dust and carbon deposits from the cavities and openings of the unit using compressed air.

The next stage is cleaning the holes of the burner nozzles and igniter. For this, a needle or thin awl is used. After cleaning, they also need to be blown with compressed air.

The sensor electrodes and contacts of the electric ignition system are cleaned with careful, gentle movements using sandpaper and wiped with a rag.

At the end of the service, the unit should be vacuumed and, where possible, wiped with damp wipes or rags.

After installing the housing in place, you should check the draft force of the chimney and the absence of gas leaks in the connections.

Despite the fact that a gas boiler is a rather complex device, in some cases it can be repaired with your own hands. It is enough to follow the above repair instructions, and in difficult cases contact a workshop. Regular maintenance extends the useful life of a gas boiler and several times reduces the likelihood of its unexpected failure.

Ceramic

The operation of this heating device is based on forced convection. The heating element of the device is made of ceramics. Since the heating element consists of many plates, the device has a significant heat transfer area. This is its undoubted advantage.

Important! The advantages include practical “indestructibility”, safety of operation and preservation of the original volume of oxygen in the room. Some models are additionally equipped with a device for air ionization.

Repair issues

The “weak link” of ceramic structures is the fan heater. Sometimes it simply won't turn on. The reasons for this can be completely different:

- When diagnosing, check the serviceability of the fuse and its contacts, as well as the resistance of the transformer windings. If these components turn out to be serviceable, check the voltage of the stabilizer.

- A typical malfunction for “ceramics” is the lack of response to commands from the control panel. As a rule, the breakdown is associated with a quartz resonator. Repair consists of replacing this component.

Material

The base and walls are usually made of enameled metal or stainless steel.

For the buyer, it is much more important what the hob is made of. After all, this not only determines the appearance, but also how difficult it will be to get rid of the stains.

Enamel

The most popular coating. It looks harmonious, and is available in many color options: white, gray, brown, beige, red and others. If you don't let dirt and grease dry out and burn, it's easy to care for.

The use of abrasive cleaners and hard sponges leads to scratches and thinning of the enamel. The impact may cause a piece of the coating to break off or a crack to appear, so you should be careful when handling it.

Stainless steel

It looks very impressive, is more resistant to mechanical damage, and dirt is easier to remove from it. At the same time, it is more labor-intensive to maintain its appearance: all stains, drops and prints are clearly visible on it. To make the unit look decent, you will have to make a lot of effort and buy special household chemicals.

Glass ceramics

It appeared relatively recently, but is rapidly gaining the love of housewives. This is due to the wide possibilities of design solutions: colors, patterns, shape.

And also with relative ease of maintenance - it is easier to wash off dirt from glass than from other coatings. It is difficult to break, but still possible, so you should be careful. Another disadvantage is the high cost.

Rules for dismantling and disassembling the gearbox

Regardless of the modification of the geyser, before starting repairs or preventive maintenance, turn off the supply of gas and cold water to the unit.

To drain water from the system, open the hot water tap, located below all water taps powered from the column. We place a wide container (basin or bucket) under the dismantled water unit, where the remaining water from the gearbox will be drained.

Removing the gearbox from the column

Often the frog can be removed separately. But in some columns this is impossible, so you will have to dismantle both blocks together. There are models of instantaneous water heaters in which, in order to gain access to the insides of the frog, it is not at all necessary to dismantle it - just remove the cover.

Dismantling the frog of the Neva 3208 water heater

In the Neva 3208 column, it is easy to dismantle the gearbox, as in other similar devices. To do this, you need to unscrew the union nuts on the inlet and outlet pipes of the housing, and also unscrew the three screws that secure the frog to the gas unit. When unscrewing the nuts and screws securing the water regulator, hold the unit being removed with your hand so as not to accidentally deform the parts of the gas unit.

When dismantling the water regulator, use a wrench to unscrew the 2 union nuts of the pipes in the indicated order, then unscrew the 3 screws with a screwdriver

The procedure for removing the Neva-Transit gearbox

To repair the water reducer, it must be removed from the column housing. Let's look at how to do this using the example of dismantling the Neva-Transit dispenser, since the fastening of gas-water units in many modern models is very similar. First, remove the adjusting knobs on the front panel. They are simply put on stock.

After that, unscrew the screws and remove the front panel

Please note that the digital display on the front panel is connected using detachable terminals to the electronic devices of the column. Therefore, by pulling the panel towards you, disconnect the terminals and only after that remove the panel completely

Do you have a Neva gas water heater? We recommend reading in more detail about typical faults and how to fix them.

Disassembling the water regulator

Having freed the frog and drained the last water from it, unscrew the lid. Often the screws are soured. To make the work easier and to avoid tearing off the splines, we use the special tool WD-40. After unscrewing the screws, remove the cover, remove the membrane and inspect the condition inside.

We replace parts that have become unusable, clean and rinse the insides (surfaces, channels, if necessary, clean the outside of the body), install the parts in place and reassemble the frog in the reverse order.

Reassembling the frog

It is especially important to set the aperture correctly. The bypass hole must exactly coincide with the holes of the same name in the cover and base

If the channel connecting the cavities of the base and cover is blocked, the column will not work.

After installing the cover on the base, tighten the screws. We install the assembled gearbox in place (also in reverse order), not forgetting about the sealing gaskets on the pipes and on the connection of the water-gas unit with the gas burner leg platform.

The screws should be tightened and tightened without any misalignment. To do this, they are installed and baited in pairs, crosswise, and similarly screwed in until it stops.

A gasket is installed in this place (between the burner and the gas unit). Be careful - the safety of the gas water heater is ensured by the tightness of this unit

Testing a repaired unit

After installing the repaired frog, we check the operation of the water part without connecting the gas by opening the hot water tap.

We observe:

- whether drops have appeared on the connections;

- Is the flow rate the same when turning on hot and cold water separately;

- does the burner igniter click?

- Does the rod move normally when opening and closing the tap?

If not everything is going as it should, you should double-check your work. However, sometimes the reason may lie not only in the water node.

Only after the mounted frog has passed the test can gas be supplied to the column. But do not forget about the safety rules when using the speaker. And if you smell gas, you should immediately turn off its supply, arrange ventilation and call the gas workers.

Pipe system

The system itself consists of correctly selected and laid heating pipes, which connect your radiators and boiler to each other. There are two types of such pipeline laying systems: one-pipe and two-pipe.

When a heating system is being designed, a two-pipe supply scheme involves installing two pipes on each of the batteries, the so-called “supply and return”. Through one of them (supply), the coolant (water) enters the heating device, through the other (return), having already cooled, it returns to the boiler. The use of such a wiring diagram makes it possible to achieve the same degree of heating of the coolant in all radiators in the house. Two-pipe type wiring is divided into two main types:

- Connecting radiators in parallel-series (one closed ring).

- Using a collector, to which all radiators are connected with separate hoses (pipes).

The second type of connecting radiators makes it possible to regulate the temperature of each battery. But it also has a noticeable financial disadvantage, this is the need to install a large number of metal-plastic or other pipes for heating to provide connections to radiators. A single-pipe heating circuit made of metal-plastic pipes functions like this: the heated coolant (water) simply flows through the pipes from one radiator to another. Simply put, such a system is sequential, and this leads to a gradual cooling of the coolant along its route. This means that the last radiator in the chain will always be significantly cooler than the first battery. The main advantage of a single-pipe heating system made of metal-plastic pipes is the low cost of its arrangement.

Also very important is the degree of thermal insulation of your home. If you have taken all measures and insulated the walls, ceilings, floors, installed new good windows, and you have a modern, high-quality entrance door (doors). Then the heat loss of your heating system will be minimal and during the season, you will spend much less money than you planned.

Necessary equipment

If you decide to connect a tabletop or built-in gas stove yourself, then first of all you need to prepare all the equipment. To complete the work you will need:

- flexible hose connecting the stove and the central gas pipe. Instead of a hose, you can use metal pipes, but in this situation the installation process will be more difficult and will require special skills. Since pipes can be connected to each other in the case of gas supply only by welding;

- a ball valve that allows you to shut off the gas supply, for example, in the event of a leak or other emergency, as well as for carrying out repair/preventative work;

In accordance with safety requirements, the tap must be made of brass and have a nickel coating.

- tools: adjustable wrench, screwdriver;

- gaskets and sealing tape for sealing threaded connections;

- dielectric coupling. The equipment is required if it is necessary to connect the stove to the electrical network, for example, if there is an electric ignition;

- soap solution and sponge to check the tightness of the system.

Choosing a flexible liner

What kind of hose is needed? The first thing you need to pay attention to when preparing the equipment necessary to complete the job is the choice of flexible gas supply. Flexible connection of a stove or oven can be done using:

Flexible connection of a stove or oven can be done using:

rubber reinforced hose. The eyeliner is made of vulcanized rubber. Reinforcement with textile thread gives the product additional strength. The hose is durable and has minimal cost. The equipment can operate in the temperature range from -35°C to +50°C. The average service life is 5 – 7 years;

Rubber gas hose with thread braid

rubber hose with metal braiding, which gives the product additional strength and durability. The equipment can operate properly for 8 – 10 years;

Rubber liner with durable metal braid

bellows hose made of metal. The product is distinguished by its high cost and large margin of safety, as well as a long period of use (over 10 years).

Metal gas line

To increase strength and service life, the bellows liner can be protected with a plastic braid.

Metal gas hose with additional protective braiding

When choosing eyeliner you should also consider:

- hose length. According to safety regulations, the hose must not be stretched. The maximum length of the gas hose is 1.5 m;

- type and size of thread. If the thread on the flexible connection does not match the size or type of thread on the gas pipe or gas stove, then the installation of additional equipment - adapters - will be required, which can reduce the level of tightness of the gas supply system.

Selecting a seal

The rules for connecting a new slab require sealing of threaded connections. To seal connections in the gas supply system, it is recommended to use:

FUM tape. The sealing material is laid in a thin film, which facilitates the method of application. Average service life – 10 – 12 years;

Sealing tape for threaded connections

Loctite 55 thread is a sealing material made from high-strength threads. In most cases, it is supplied in special plastic containers. The period of use of the material is no more than 10 years.

Sealing thread for gas system