Nowadays you can see heated floors in almost every home, because they help create a special coziness in the room. In this article we will talk about independent calculation of warm water floors.

This procedure must be carried out before installation; you can measure everything by eye, but you can also use special programs or calculators. If you correctly carry out the calculations and perform the correct installation of heated floors, you can effectively and economically heat your home.

Below you will find information about how to calculate power, diameter, length, number of pipes and programs that can be used during the process.

Snake or snail?

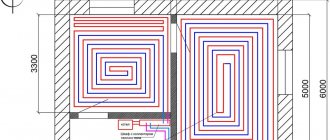

Types of laying heated floors: snake (left) and snail (right).

There are two main types of laying underfloor heating pipes - snake and snail (see figure). Although there is no fundamental difference between them in terms of pipe consumption.

A warm water floor laid in a snake pattern heats the room less evenly - the temperature of the floor in one part will be higher than in the other. Pipes are laid in this way when the room has a large window or a poorly insulated outer wall of the house.

The warmer part of the snake is placed where there is more heat loss. Sometimes the “corner snake” installation method is used (see figure).

The snail allows you to heat the entire room evenly. Heated floor pipes are laid in a snail pattern if the heat loss of the room is minimal - the walls are insulated, and the windows are at least two-chamber.

Determination of room heat loss

If heat loss exceeds the specified value, then you will need to choose a different heating system, or supplement the heated floors by installing radiators. Perhaps the house should be further insulated.

The resulting heat loss is divided by the area of the heated premises. This is the preliminary calculated power of water heated floors per square meter. The final calculation is performed in a special computer program.

If our heating system using floors of the specified design consisted only of it, then the calculations could be considered complete. But it is necessary to take into account the section from the collector to the boiler, taking into account, at the same time, the hydraulic resistance of the section.

Non-standard solutions

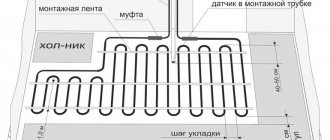

When laying heated floors, the “double snake” method can be used. It allows you to heat the entire room evenly. In terms of efficiency, this option is no different from the “snail”.

In large rooms, heated floors with one circuit are ineffective. Experts agree that the length of pipes should not exceed 100-120 linear meters (depending on the diameter of the pipe). This corresponds to a room with an area of 20-24 sq.m.

If you need to heat a larger room with warm floors, you need to make additional circuits (see photo). Moreover, they can be laid either like a snake or like a snail.

Warm water floor with two circuits in one room.

Determining the length of the contour for a heated floor

As mentioned above, in addition to the considered values, it is necessary to take into account the diameter of the pipes, as well as the material from which they are made.

If you opt for a metal-plastic structure, then with a diameter of 16 inches, the total length of the heating circuit should be less than 100 m . The ideal, from the point of view of such a scheme, is a pipe from 75 to 80 m.

Polyethylene products with a diameter of 18 mm should not exceed 120 m, but in fact the value varies from 90 to 100 m.

The best choice for purchase would be metal-plastic structures, which are characterized by high efficiency and durability.

Pipe length calculation

To calculate how much pipe is needed for a warm water floor, use the following formula:

S/ H x 1.1 + D x 2 = L

In this formula (all values in meters):

- L – Required length of pipes;

- S – Room area;

- H – Pipe spacing;

- D – Distance from the room to the collector.

The coefficient 1.1 in the formula is the required margin of 10%. When laying the floor, there may be unused scraps, incorrectly cut or incorrectly measured pieces of pipe. To take them into account you need to add this 10%.

The distance between the underfloor heating pipes depends on the diameter of the pipes and the heat demand. If you want to do the calculation yourself, you can use this table:

Table of heat transfer of a warm water floor depending on the diameter of the pipes and the laying pitch.

An example of calculating the length of pipes for heated floors

- Room length 4 meters;

- The width of the room is 3.5 meters;

- The distance between the pipes is 20 cm;

- The distance to the collector is 2.5 meters.

We calculate the area of the room: 4 x 3.5 = 14 sq.m.

We substitute the values into the formula and get: 14 / 0.2 x 1.1 + 2.5 x 2 = 82 linear meters of pipes.

Design of cable heating

The main differences between electric heated floors are heating elements consisting of cables or cable sections. Let's consider the varieties and calculation methods.

A resistive heating cable is a heating element made of a single or two-core cable in a protective screen, with a constant resistance, which is laid over the floor area.

The cable has standard lengths, and therefore resistance and heat generated. The cable length cannot be changed, this will lead to a change in current and malfunction.

Specific power and length

This is the capacity of one sq.m of heated floor. The length of the heating electric cable is selected based on this indicator.

For example, the power of the cable system for proper heating should be about 100-150 W/m2; if the heated floor is planned to be used as the main heating, then 150-200 W/m2 is needed. If we need to heat 10 m2, then we need a cable with a power of 10*100=1000 W.

How many meters of cable is this?

This will depend on its cross section. The thicker the wire, the greater its power, and the larger the installation step will be during installation. A thinner wire will have to be laid at a smaller pitch in order to maintain the selected power density, and accordingly the cable consumption will be greater.

For ease of calculation and installation, electrical transformer transformers are sold in the form of mats rolled into a roll. The cable in them is laid in a snake with a certain pitch and fixed. The width of such a “mat” cannot be changed; as a rule, it is 50 cm. It turns out that the specific power is set by the manufacturer, for example 130 W/m2. The buyer can only select the appropriate heating element area from those available for sale.

Calculation taking into account furniture

Experts recommend installing heated floors only where there will be no bulky pieces of furniture - cabinets, fireplaces, sofas, etc. Accordingly, you need to take into account when calculating the place where there will be no heated floor. To do this we use the formula:

(S – S1) / H x 1.1 + D x 2 = L

In this formula (all values in meters):

- L – Required length of pipes;

- S – Total area of the room;

- S1 – Total area of the room where there will be no heated floor (empty areas);

- H – Pipe spacing;

- D – Distance from the room to the collector.

An example of calculating the length of underfloor heating pipes with empty sections

- Room length 4 meters;

- The width of the room is 3.5 meters;

- The distance between the pipes is 20 cm;

- Distance to the collector – 2.5 meters;

The room contains:

- Sofa dimensions 0.8 x 1.8 meters;

- Wardrobe, dimensions 0.6 x 1.5 meters.

We calculate the area of the room: 4 x 3.5 = 14 sq.m.

We calculate the area of empty plots: 0.8 x 1.8 + 0.6 x 1.5 = 2.34 sq.m.

We substitute the values into the formula and get: (14 – 2.34) / 0.2 x 1.1 + 2.5 x 2 = 69.13 linear meters of pipes.

What is needed for the calculation

In order for the house to be warm, the heating system must compensate for all heat losses through the building envelope, windows and doors, and the ventilation system. Therefore, the main parameters that will be required for calculations are:

- house dimensions;

- wall and ceiling materials;

- sizes, number and designs of windows and doors;

- ventilation power (volume of air exchange), etc.

You also need to take into account the climate in the region (minimum winter temperature) and the desired air temperature in each room.

These data will allow you to calculate the required thermal power of the system, which is the main parameter for determining the pump power, coolant temperature, length and cross-section of pipes, etc.

A calculator located on the websites of many construction companies that provide installation services will help you perform a thermal calculation of a pipe for a heated floor.

Screenshot from the calculator program page Source www.apostroy.ru

Note! If a water heated floor is used as an additional, rather than the main source of heat, the resulting power values are reduced to a certain proportion.

Calculation for wrong rooms

It happens that rooms have complex geometry. To calculate the total area, you need to divide such a room into several zones. After this, calculate their area and sum them up (see figure).

Two options for calculating the area of an irregularly shaped room. The total area of the room is equal to the area of zones A + B + C.

After the area of each part of the room has been calculated, we sum them up. After this, we substitute the resulting value into the same formula:

S/H x 1.1 + D x 2 = L

Sometimes in one part of the room the heated floor is laid with a pipe pitch different from the other. In this case, it is necessary to calculate the pipe lengths for each part of the room separately. And the results are summed up.

How to calculate heat loss

The correctness of this calculation determines the amount of heat that needs to be supplied to the room so that it always has a comfortable temperature. The calculations performed will help determine the power of the heated floor, and will also help make the right choice of boiler and pump.

It is very difficult to perform such a calculation. We have to take into account quite a lot of different criteria:

- Season;

- Outside air temperature;

- Room type;

- Number and dimensions of the window;

- Floor covering.

- Insulation of walls;

- Where is the room located, below or on the upper floors;

- Alternative heat sources;

- Office equipment;

- Lighting.

To make this calculation more convenient, average values are taken. If a double-glazed window is installed in the house and good insulation is done, this parameter will be approximately equal to 40 W/m2.

Warm buildings with little thermal insulation constantly lose about 70–80 W/m2.

If you take an old house, heat loss increases sharply and approaches 100 W/m2.

In new cottages where the walls are not insulated and where panoramic windows are installed, losses can be about 300 W/m2.

Having chosen an approximate value for your room, you can begin calculating the replenishment of heat losses.

Online calculator

From this publication you learned about the different types of installation of underfloor heating. About how they differ and in what cases it is better to use one or another option. We also told you how to calculate the length of underfloor heating pipes. We hope that the article was useful to you. Don't forget to share it with your friends!

Do you want to get help from a master, a specialist in this field? Go to the professional search portal. This is a completely free service where you will find a professional who will solve your problem. You do not pay for posting an ad, views, or choosing a contractor. If you are a master of your craft, then register on Pro and receive a flow of clients. Your profit is just one click away!

How to install a heated floor?

The modern market offers a huge range of floor pipes. They all differ in length, diameter, and shape. In order for all measurements to be as accurate as possible, it is necessary to understand the design of this design.

The most popular installation methods are: flooring and concrete . In the first case, the floor is made of polystyrene or other material. Its advantage is its quick installation, since it does not require pouring and further drying.

As for the concrete option, it requires the presence of a screed, which takes a lot of time to apply and dry. In this case, the pipes are installed along the contour. The cost of purchasing pipes directly depends on the material you choose.

Recommendations

Experts say that when installing a heated floor, a heat map of the house is initially drawn up.

Based on the results of its compilation, you can see that the heat loss per 1 square meter will be 100 W, which means that it is advisable to insulate the house well and then install a heated floor, otherwise the power consumption will be high. There are also average power ratings:

- for rooms where people live and kitchens you need 150W per 1m2;

- bathroom – 140 W;

- veranda or loggia, glazed with high-quality double-glazed windows - 180 W.

You can also separately calculate the power of the pump that will be needed for heating. The pump must be selected with a power reserve and be guided by average speed indicators.

Calculation according to the scheme

To determine the required number of pipes, you can use another method. This requires:

- determine the scheme according to which the pipes will be laid. Pipes can be laid as follows:

- single snake. The circuit pipe enters the room and is then positioned in the shape of a sinusoid. This method is preferable for small rooms with a small contour. When laying out a “snake” in a large room, the floor will warm up unevenly;

- "double snake" The main difference from a regular snake is the laying of pipes alternately, which allows you to equalize the floor temperature over the entire surface;

Gasket shapes in the form of a simple and double snake

- "snails". The pipe is arranged in a spiral and heats the floor surface around the entire perimeter with the same intensity.

Laying pipes in a spiral

- draw on graph paper (for ease of calculation) the selected diagram with a selected step.

For correct calculations when developing a drawing, it is necessary to strictly adhere to the selected scale.

Floor installation steps

After you have chosen high-quality and reliable pipes, it is recommended to begin installing the heated floor. This needs to be done in several stages.

Installation of thermal insulation

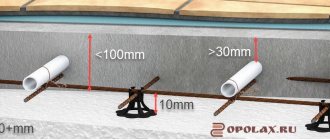

At this stage, preparatory work is carried out, the floor is cleared and a layer of thermal insulation is laid. Polystyrene foam can act as thermal insulation. Layers of foam plastic are laid on the subfloor. The thickness of the foam should not exceed 15 cm. It is recommended to calculate the thickness depending on the size of the room, its location in the apartment, as well as the individual preferences of the person.

Installation of waterproofing

After the foam has been laid, it is necessary to lay a layer of waterproofing. Polyethylene film is suitable as waterproofing. Polyethylene film is fixed to the walls (near the baseboard), and the floor is reinforced with mesh on top.

Laying and securing pipes

Next, you can lay the pipes for the heated floor. Once you have calculated and chosen a pipe laying scheme, this process will not take you much time. When laying pipes, they must be secured to the reinforcing mesh with special braces or clamps.

Crimping

Pressure testing is practically the last stage of installing a heated floor. Pressure testing must be carried out within 24 hours at operating pressure. Thanks to this stage, mechanical damage to pipes can be identified and eliminated.

Pouring concrete mortar

All floor pouring work is carried out under pressure. It is worth noting that the thickness of the concrete layer should not exceed 7 cm.

After the concrete has dried, you can lay the floor. It is recommended to use tiles or linoleum as flooring. If you choose parquet or any other natural surface, due to possible temperature changes, such a surface may become unusable.

Features of electrical floor systems

The technology for preparing and laying out electric heating elements differs from the design of water circuits and depends on the type of heating elements selected:

- resistive cables, carbon rods and cable mats can be laid “dry” (directly under the coating) and “wet” (under screed or tile adhesive);

- carbon infrared films shown in the photo are best used as a substrate under a coating without pouring a screed, although some manufacturers allow installation under tiles.

For reference. Self-regulating rod systems are carbon heating elements connected in parallel by two conductors. If one rod burns out, the remaining elements will increase the heating power and continue to heat the room.

Electric heating elements have 3 features:

- uniform heat transfer along the entire length;

- the heating intensity and surface temperature are controlled by a thermostat based on sensor readings;

- intolerance to overheating.

The last property is the most unpleasant. If in a section of the circuit the floors are filled with furniture without legs or stationary household appliances, heat exchange with the surrounding air will be disrupted. Cable and film systems will overheat and will not last long. All the nuances of this problem are covered in the next video:

Self-regulating rods easily tolerate such things, but another factor begins to influence here - it is irrational to buy and install expensive carbon heaters under furniture.

Manifold cabinet and its installation

Before calculating the pipe flow required for installation on the surface and underfloor heating, you need to prepare a place for the collector.

A manifold is a device that maintains pressure in pipes and heats used water. This device also allows you to maintain the required temperature in the room. It is worth noting that you need to buy a collector depending on the size of the room.

It is recommended to install and connect the collector with the help of professionals. If the manifold is not installed correctly, it may not work or may not function properly.

How and where should the manifold cabinet be installed?

There are no restrictions for installing a manifold cabinet; at the same time, there are several recommendations.

It is not recommended to install the cabinet too close to the floor. Calculate how many centimeters will be spent on screed, heat and waterproofing, as well as pipes, and only then plan the installation of the cabinet.

It is also not recommended to install the manifold cabinet too high, since ultimately the water circulation may occur unevenly. The optimal height for installing a cabinet is 20-30 cm above the bare floor.

Selection of cable and film heaters

In connection with the above points, the calculation of electric heating is somewhat simplified; the parameters of a cable heated floor are determined as follows:

- Calculate the amount of heat needed to heat a specific room (see section one).

- Draw the layout of the room with the location of stationary furniture and household appliances. Make the drawing to scale to the actual dimensions of cabinets, washing machines, and so on.

- Calculate the free area of the room by subtracting the square footage of the occupied areas.

- The previously found amount of heat should be distributed over the remaining area. Divide the required power by the square footage of the free area - get the heat transfer from 1 m².

- Resistive cables and mats with a thermal power of 9-25 W/m. items are sold in fixed lengths. Select a heating element from the manufacturer's catalog according to the required heat transfer.

- Divide the square footage of the free section by the length of the selected product - you will find out the cable layout pitch.

Scheme of underfloor electric heating of a bathroom

An example of calculating the bathroom of a one-story house with an area of 6 m², of which 2.5 m² are occupied by a bathtub, sink and cabinet. The square footage of the free area is 3.5 m², the required thermal power is 600 W. According to the catalog of the famous Devi brand, we select a two-core heating cable of the DEVIflex 18T brand, 37 meters long with a heat output of 622 W. We divide 3.5 m² by 37 m, we get a laying step of 0.095 m, rounded - 10 cm.

Note. It is even easier to select cable mats - the manufacturer indicates the area occupied by the heating element. For the bathroom, a product with a power of 635 W of the DEVImat 200T brand, designed for an area of 3.45 square meters, is suitable.

Film heaters placed under the floor covering are calculated and selected in a similar way. A small nuance: when installing carbon film or resistive cable in living rooms, a minimum distance of 150 mm is made from the partitions. These stripes along the walls will also have to be subtracted from the total square footage. On loggias, balconies and bathrooms, this indentation is taken to be equal to the laying step (in the example - 10 cm).

At what height is the collector mounted?

Manifold for water heated floors

As mentioned above, the amount of consumables increases by the length of the outlet section, that is, the section running from the floor to the manifold, which is placed on the wall, in close proximity to the floor. However, when placing it, it is necessary to calculate the height of the finished floor, including the future screed and finishing. In general, the shorter the length of the segment, the stiffer it is.

The optimal length of the outlet section from the surface of the finished floor is a height of 20-25 cm. However, if this somehow affects the design of the room, then the manifold cabinet can be placed taking into account the possibility of its unhindered opening. [ads-pc-2][ads-mob-2]

How to determine the optimal room temperature

In this case, no special difficulties arise. For orientation, you can use the recommended values, or come up with your own. Moreover, the floor covering must be taken into account.

The living room floor should be heated to 29 degrees. At a distance of more than half a meter from the external walls, the floor temperature should reach 35 degrees. If there is constantly high humidity in the room, you will need to heat the floor surface to 33 degrees.

If the house has wooden parquet, the floor should not be heated above 27 degrees, as the parquet may deteriorate.

Carpet is capable of retaining heat; it makes it possible to increase the temperature by about 4–5 degrees.

What room requirements must be met when installing the system?

During installation work, the most correct decision would be when the pipeline is installed at the initial stage of construction of the floors. This method is 30–40% more economical than the radiator method. It is also possible to install a water heating structure in a ready-made room, but to save the family budget, you should pay attention to the following requirements:

- The height of the ceilings should allow the installation of heated floors with a thickness of 8 to 20 centimeters.

- The height of doorways should not be less than 210 centimeters.

- To install a cement-sand screed, the floor must be more durable.

- To avoid airiness of the contours and high hydraulic resistance, the surface for the base of the structure must be flat and clean. The permissible level of unevenness is no more than 5 millimeters.

And also in the building itself or in individual rooms where the heating system will be installed, plastering work must be done and all windows must be installed.

Assessment of technical properties when choosing pipes

Due to non-standard operating conditions, high demands are placed on the material and size of the water floor coil:

- chemical inertness , resistance to corrosive processes;

- the presence of an absolutely smooth internal coating , not prone to the formation of limescale build-ups;

- strength - the walls are constantly exposed to the coolant from the inside, and the screed from the outside; the pipe must withstand a pressure of up to 10 bar.

It is desirable that the heating branch have a small specific gravity. The water floor pie already places a significant load on the ceiling, and a heavy pipeline will only aggravate the situation.

According to SNiP, the use of welded pipes in closed heating systems is prohibited, regardless of the type of seam: spiral or straight

Three categories of rolled pipes meet the listed requirements to one degree or another: cross-linked polyethylene, metal-plastic, and copper.

Option #1 – cross-linked polyethylene (PEX)

The material has a mesh wide-cell structure of molecular bonds. Modified polyethylene differs from conventional polyethylene in the presence of both longitudinal and transverse ligaments. This structure increases specific gravity, mechanical strength and chemical resistance.

A water circuit made of PEX pipes has a number of advantages:

- high elasticity , allowing the coil to be laid with a small bend radius;

- safety – when heated, the material does not emit harmful components;

- heat resistance : softening – from 150 °C, melting – 200 °C, combustion – 400 °C;

- maintains structure during temperature fluctuations;

- resistance to damage - biological destroyers and chemical reagents.

The pipeline retains its original throughput - no sediment is deposited on the walls. The estimated service life of a PEX circuit is 50 years.

The disadvantages of cross-linked polyethylene include: fear of sunlight, the negative effects of oxygen when it penetrates inside the structure, the need for rigid fixation of the coil during installation

There are four product groups:

- PEX-a – peroxide cross-linking . The most durable and uniform structure with a bond density of up to 75% is achieved.

- PEX-b – silane cross-linking . The technology uses silanides - toxic substances that are unacceptable for household use. Manufacturers of plumbing products replace it with a safe reagent. Pipes with a hygienic certificate are acceptable for installation. Crosslink density – 65-70%.

- PEX-c – radiation method . Polyethylene is irradiated with a stream of gamma rays or an electron. As a result, the bonds are compacted up to 60%. Disadvantages of PEX-c: unsafe use, uneven cross-linking.

- PEX-d – nitriding . The reaction to create a network occurs due to nitrogen radicals. The output is a material with a crosslink density of about 60-70%.

The strength characteristics of PEX pipes depend on the method of cross-linking polyethylene.

If you choose pipes made from cross-linked polyethylene, we recommend that you familiarize yourself with the rules for installing a heated floor system made from them.

Option #2 – metal-plastic

The leader in rolled pipes for installing heated floors is metal-plastic. Structurally, the material includes five layers.

The inner coating and outer shell are high-density polyethylene, which gives the pipe the necessary smoothness and heat resistance. Intermediate layer – aluminum spacer

The metal increases the strength of the line, reduces the rate of thermal expansion and acts as an anti-diffusion barrier - it blocks the flow of oxygen to the coolant.

Features of metal-plastic pipes:

- good thermal conductivity;

- ability to maintain a given configuration;

- operating temperature with preservation of properties – 110 °C;

- low specific gravity;

- noiseless movement of the coolant;

- safety of use;

- corrosion resistance;

- service life – up to 50 years.

The disadvantage of composite pipes is the inadmissibility of bending about the axis. Repeated twisting risks damaging the aluminum layer. We recommend that you familiarize yourself with the correct technology for installing metal-plastic pipes, which will help avoid damage.

Option #3 – copper pipes

In terms of technical and operational characteristics, yellow metal will be the best choice. However, its demand is limited by its high cost.

Compared to synthetic pipelines, the copper circuit wins on several points: thermal conductivity, thermal and physical strength, unlimited bending variability, absolute impermeability to gases

In addition to being expensive, copper piping has an additional disadvantage - the complexity of installation. To bend the contour you will need a press machine or pipe bender.

Option #4 – polypropylene and stainless steel

Sometimes a heating branch is created from polypropylene or stainless steel corrugated pipes. The first option is affordable, but quite rigid in bending - the minimum radius is eight times the diameter of the product.

This means that pipes with a standard size of 23 mm will have to be placed at a distance of 368 mm from each other - an increased laying step will not ensure uniform heating.

Stainless steel pipes have high thermal conductivity and good flexibility. Disadvantages: fragility of sealing rubber bands, creation of strong hydraulic resistance by corrugation

Calculation of the number of circuits

If you take into account all the rules, it becomes clear that one heated floor circuit is enough for small rooms. When the area of the room is much larger, you need to divide it into sections in a ratio of 1: 2. In other words, the width of the section will be less than its length, exactly half. To determine the number of sections, you need to know the following parameters:

- Step 15 cm - plot area 12 square meters. meters;

- 20 cm – 16 sq. meters;

- 25 cm - 20 sq. meters;

- 30 cm – 24 sq. meters.

Sometimes the supply section is made longer than 15 meters. Experts advise increasing the indicated values by another 2 square meters. meters.

Determining the temperature of the water floor coolant

According to design standards, the calculation of the heat of a heated floor (on the surface of the auxiliary heating system) should be based on the following values:

- 290С-310С - residential premises (long-term presence of people);

- up to 350C - non-residential premises (corridors);

- 320С-340С - sanitary and hygienic premises (toilet, bathroom).

If the temperature on the floor surface is maintained within the specified limits, then optimally comfortable living conditions are achieved in the premises of the house. The limits can be shifted downward by 2-30C. With a greater shift, it makes no sense to install a water heating system for heating air masses from below the room.

Now we will answer the question of how to calculate a warm water floor without using an online calculator. Having checked the purpose of the room and determined the required optimal temperature on the surface of the system, you need to evaluate the quality and physical and technical characteristics of the future floor covering. Namely, its resistance to temperatures. For example, tiles are not afraid of them, but parquet can quickly lose its qualities. It is these features that calculators for calculating heated floors on websites do not take into account.

Experts have calculated that the coolant temperature should be in the range of 43-550C. The more intricate the flooring, the lower the temperature, but not lower than 370C.

How to control and regulate the temperature of the coolant?

To avoid heat loss, it is recommended to install two thermometers:

- on the coolant supply;

- on the coolant return circuit (return).

It doesn’t matter which calculator was used to calculate the warm water floor, the main thing is to create such a project so that the difference in the readings of the measuring instruments does not go beyond the range of 5-100C. These parameters indicate that the heating system is working correctly. To do this, when drawing up a project and determining the optimal temperature of the coolant, the following are taken into account:

- climatic zone (the lower the temperature outside the window, the higher the temperature of the coolant);

- quality of insulation of ceilings and walls of the house. It will influence the calculation of the power of a water-heated floor - the better the thermal insulation system, the less productive the system can be;

- power and characteristics of forced ventilation;

- total area of the heated room. When calculating a heated floor by area, only the area useful for laying pipes is taken into account. The more common, the more useful. The same parameter is also involved when choosing the method of laying elements;

- the number of doors, window openings, as well as the quality of double-glazed windows. All these are bridges of cold. The more there are, the more accurate the calculation of the power of a warm water floor should be, so it is better to choose a calculator with the maximum number of parameters;

- the presence of a main heating system or other heating devices in the house.

The listed parameters affect the individual calculation of the heat transfer of a heated floor, and the online calculator does not take it into account. The expert tables below accurately calculate heat transfer coefficients for different floor installation conditions.