What it is?

Hose couplings, called “connectors,” are a simple fitting. The product is presented in a fairly wide range. The main feature of all options is good waterproofing at high pressure inside the hose.

The modern hose connector is designed to suit every need. The devices are easily combined with popular hose diameters. In addition, they allow you to quickly connect and disconnect additional devices, such as a watering gun, pumping equipment, and plumbing fixtures. All quick connect couplings have an identical nipple outlet that connects the adapter to the faucet, sprinkler or sprinkler.

Alloys of various metals or PVC are used as materials for manufacturing parts. The product is selected in accordance with the tasks to be performed. It is clear that plastic connectors are cheaper in price, but they can withstand pressure up to 10 bar. Products made from metal alloys are stronger and can therefore withstand pressures of up to 15 bar. The most durable are brass options, which can withstand pressure from 15 bar.

Plastic connectors are well suited for watering beds, as a sprayer or water pressure amplifier. Brass connectors are of very high quality; they are used to create industrial lines, even in food factories. Couplings can be used to connect two hoses of the same or different diameters. A regular plumbing connector can be threaded or unthreaded, but both options will be reliable and will eliminate any leaks.

The connector can be useful if you need to mount a sprinkler head. For such purposes, special points called “aquastop” are provided. The water supply can be quickly shut off using a special valve on the connector without shutting off the water supply. In this case, the nozzle without thread is removed from the hose quite quickly: you need to pull the coupling with the nut towards you.

Putting on is also easy: the movable element of the connector is screwed in until it clicks.

Some useful installation tips

Despite all its advantages, plastic corrugation is not designed for heavy loads, so it cannot be mounted inside a wall. If the distance from the wall to the plumbing fixture is large, you should carefully select the length of the connector.

The corrugation stretches, but if this property is abused, the walls may become thinner and the strength of the structure will decrease. There is no need to stretch the corrugation before installing it - this will lead to sagging of the outlet.

Stretch it immediately before connecting to the sewer pipe. To avoid blockages, there is no need to allow sagging or counter-slope of the corrugation. When the sewer pipe and the outlet of the plumbing fixture are located relatively high, a support is built under the connector.

If the corrugation sag, a “pocket” will appear in it where deposits will accumulate. This may cause the connector walls to rupture. Stands or auxiliary clamps will help prevent this consequence.

When you decide to install a protective screen to mask communications, and use the fenced-off space as a place to store various small items, do not forget that a heavy object can damage the corrugation.

Before installing the plastic corrugation on the toilet, take into account that the product of standard sizes does not allow it to be installed flush against the wall. Here it is better to use an eccentric.

We must not forget about plumbing standards when choosing a slope. Do not turn the reinforced pipe at a right angle. If the device occupies a non-standard position, an offset connecting element is used.

Before you start work, you should make sure that the corrugation fits the parameters. You also need to check it for cracks. If, along with the corrugated pipe, it is also planned to replace the toilet, then it is put on before installing the plumbing

The corrugation can compensate for quite a significant displacement. Thanks to it, the device can be moved by a maximum of 200 mm. It can also be rotated to any angle you like. To do this, use an option such as a serial connection of two corrugated pipes.

You need to pay special attention to the angle at which the corrugation is bent. If the pressure is too high, draining cannot be carried out effectively. In addition to everything, the corrugation may crack at the point of pinching.

About connecting watering hoses

Published date 08/04/2011

Last modified date 01/17/2019

Perhaps I will tell you obvious things that have long been known to everyone, but for me personally it was a pleasant discovery. It turns out there is a technology that makes it easier to work with watering hoses in the country. Previously, when necessary, we simply pulled a 3/4″ rubber hose onto a 1/2″ bend and used it. Yes, sometimes the water leaked out, sometimes the hose was thrown off, but we didn’t know any other way. The hose was spliced with a 1/2″ barrel. Long-term connections were tightened with a clamp.

But while walking around OBI, I noticed interesting gizmos, namely hose connectors. They allow you to quickly connect hoses, connect various devices in one movement, and just as quickly disassemble everything back. Moreover, on one shelf there were branded gardena connectors with a wild price of about 230 rubles per piece. And next to it, which is not typical for OBI, are inexpensive and high-quality (!) Chinese plastic GardenCraft connectors. At a very reasonable price of 15-30 rubles per connector element.

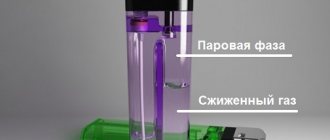

Hose attachments are available for hoses of different diameters. There is a bushing (in the middle) to connect the hoses to each other. There are different devices for mounting on a faucet, but in my case a simple 1/2″ plastic fitting is sufficient.

To attach it to the hose, simply cut it straight, put on the connector and tighten the nut by hand, it will evenly crimp the hose. There are options for a connector with a valve (“aquastop”), which will prevent water from flowing out of the free end of the hose if no nozzle is inserted into it. But the price for the valve will be an even greater narrowing of the lumen to the flow of water.

Two hoses are joined through an insert:

The connectors are put on the fitting with a click and fixed on it. To remove the connector, you need to pull off the orange ring.

A huge number of attachments are available - sprinklers, mechanical watering time relays, watering cans, nozzles, tees, valves.

The bright color allows you to quickly find the end of the hose in the grass. The strength is sufficient not to break if accidentally stepped on. Let's see how they survive the winter.

Everything comes together and disassembles very quickly:

The rubber ring prevents the connection from leaking. Over time, as it wears, of course water will ooze out a little, but not significantly.

UPD. Chinese connectors work well at pressures of 1-1.5 atm. at high pressures they begin to ooze. To connect the pressure washer to the water supply at work, we bought hozelock connectors with a metal fitting. Pressure 8 atm. withstands without leakage

Application area

PVC corrugation is mainly used as cable ducts when installing electrical, computer, telephone and television networks.

Corrugated products of larger diameter are used for:

- Cold water supply.

- Gravity sewer pipelines.

- Storm sewer.

Drainage systems are constructed from perforated elements.

Connecting and extending hoses

Hoses are very common and are often used in the private sector, especially in summer cottages and gardens in the summer (organization of water supply, hose irrigation of various vegetation, etc.). They are much easier and more convenient than pipes. If desired, the hose can be cut as well as extended; they are easy to carry; hose alignment does not require virtually any skills or expensive equipment. There are several solutions according to which high-quality hose matching can be performed: time-tested folk remedies and plastic connectors that have appeared recently. Modern plastic solutions (tees, adapters, crosses and other connectors) are offered by many manufacturers; solutions are available for literally any occasion. Such devices allow you to quickly and efficiently connect hoses; they can be used both indoors and in the garden. They are great for connecting any type of product for frequent switching between water points.

What else should you pay attention to?

If all installation operations are carried out carefully, then there will be no problems with the subsequent operation of the plumbing equipment. However, it is worth paying attention to a number of points.

A corrugated sleeve will last a long time if its length is chosen correctly. The product must not be installed in a fully extended or excessively compressed state, nor should it be allowed to bend sharply at turns. In the latter case, when space for the adapter is limited, a toilet eccentric can often be used instead.

The sleeve should not sag, otherwise a pocket will form in which deposits will begin to accumulate. This can lead to blockages in the drain or rapid rupture of its plastic walls. To avoid such consequences, you need to use auxiliary support clamps, stands, etc.- The corrugated plumbing adapter is a product intended for external installation only. It is not allowed to be walled up in the structure. This should be remembered, as well as the fact that sooner or later it will have to be changed, therefore, it is important to provide for the possibility of access to it.

Finally, it is worth recalling once again that when deciding how to choose a corrugated hose for connecting a toilet, you should initially consider the possibility of using any other rigid analogues from corners, swivel connectors or eccentrics. The strength of flexible adapters is quite limited, so the product can be damaged not only by hard sharp objects, but also gradually destroyed by natural wear and tear due to thinning of the walls.

Related posts:

Why do you need a vent pipe?

Water supply collector: what is it, how to choose and install it correctly?

- How to install a toilet: practical advice on installation and setup

Do-it-yourself methods for connecting hoses

If you do not want to buy modern plastic devices for connecting products, you can use one of the proven traditional methods: through an inexpensive adapter, through a piece of pipe and through a fitting (if the hose is connected to a pipe).

Today, hose fittings for any pipe and any hose are available for sale, and they are quite cheap.

For polypropylene pipes, you can use similar solutions with external threads, screwing them into the fitting. The only point that you need to pay attention to is the thickness and length of the fitting. You can grab the hose using a special clamp, or you can use a wire twist. There is absolutely no difference in the quality of the connection, but the cost is reduced several times when compared with factory-made plastic connectors.

It’s a common thing when there are many different hoses lying around in a garden plot or vegetable garden. Pieces of products can be connected using a piece of pipe of a suitable size and used on the farm. This is done very simply: hoses are put on a length of about 10 cm on both sides and grabbed, as mentioned earlier, with wire or clamps.

Drain hose connection diagram.

The adapter-connector, like the pipe mentioned in the previous example, connects both pieces of the hose, only it has special notches at the ends that make the process of joining the hose easier and more convenient if the diameters of the connections do not quite fit each other.

You can make your own hose connector from a coupling and polypropylene pieces. When assembled, such a homemade connector looks quite good and holds the hoses at ¾ length. A tee for connecting hoses can be made in a similar way. The closest store-bought analogue is a coupling (products are clamped using a union nut and petals on both sides).

For a high-quality and reliable connection of hoses, prepare the necessary tools and materials, namely:

- pipe cutters;

- Workbench;

- couplings;

- adapters;

- nuts;

- clamps;

- wire;

- spanners.

Technical characteristics of corrugated pipes for exhaust

The main technical characteristics of the corrugation used for hood are its dimensions - diameter and length. The length is determined by the manufacturer and can be of a standard size or sold in coils, which allows you to purchase an air duct of the required length.

Rectangular corrugation is used in ventilation systems at enterprises and technical facilities

The cross-sectional shape of the corrugation can be rectangular or round. Rectangular models are generally used only in production facilities. The diameter of the produced air ducts is standard: 10/12/12.5/15/20 cm, as well as 30 cm and more, but these are dimensions that do not relate to the standard of such products. For the manufacture of corrugated air ducts, plastic and aluminum, stainless and galvanized steel, as well as textiles and polyethylene are used. According to their design, such products are of frame and spiral-wound type.

High pressure hose connection

Connection diagram of the hose to the filter.

The service life of metal hoses depends mainly on the quality of the connection of the high-pressure hoses. Among other things, it is very important to choose the right couplings, fittings and other connecting elements of the structure. All elements must comply with the performance characteristics and technical parameters of the metal hose.

The modern market offers a very large range of products used to connect high-pressure hoses to the machinery and equipment in use. Offers from foreign and domestic manufacturers are available.

Basically, different connections differ from each other in the type of fitting (size or type of thread, method of sealing), as well as in the connection methods. Today, the most common type of end connection is the clamp type. This design is one-piece with a hose and is characterized by increased strength. Such a hose can only be disconnected by sawing the clamping sleeve, which, in turn, precludes further use of the fitting.

According to the design features, there are 3 main types of connecting end connections.

Thus, a connection of 2 elements consists of a sleeve and a separate fitting. During assembly, the fitting is inserted into the hose, after which the clamping sleeve is put on. This type of connection is most often used in Russia and the countries of the European Union. This is due, first of all, to the fact that the same sleeve design can be used for various types of fittings.

Connection diagram of the fitting with the fuel line.

The integral type of connection consists of one piece. In this design, the clamping sleeve and fitting are a single unit. When using this connection option, warehouse costs increase significantly, but the likelihood of making a mistake when choosing a clamping sleeve is noticeably reduced.

And the third type is a twist joint. It includes a clamping sleeve and a separate threaded fitting. During assembly, the sleeve is screwed onto the hose, after which the fitting is simultaneously screwed into the hose and the sleeve. With this type of connection, clamp fittings and bushings can be reused, but at the same time, this type of connection is slightly more expensive than others.

Air duct maintenance

When removing polluted air from the kitchen area, the air duct collects some of its contents on its walls. Fat and soot accumulate in the folds of the corrugation. Outside, the pipe is exposed to the same factors as all kitchen surfaces - evaporation, splashes, dust.

A smart solution is to regularly remove the hood and wash it with products you normally use to clean your kitchen, taking into account the type of pipe material.

Each time the air duct is completely dismantled and then reinstalled. In the process of removing and cleaning the corrugation, it is easy to damage it, break the seal, and leave dents. It is also unlikely that it will be possible to install it back the same way it was.

Many owners of flow hoods refuse to wash the inside of the air duct pipe, limiting themselves to wet cleaning from the outside. The outer surface is carefully wiped with water or a detergent approved for this type of coating.

Internal accumulations of dirt can become a serious obstacle to the operation of the device only towards the end of the corrugation service life declared by the manufacturer, on average after 8-10 years. After this time, the air duct pipe is dismantled and replaced with a new one.

Note ! If dirty streaks appear at the joints and joints of pipes, this indicates the need to replace the corrugation.

DIY instructions for connecting hoses

To connect products with your own hands, you will need a certain set of tools, as mentioned earlier. In most cases, you can do without a workbench, but it is much more convenient and faster. For plastic nuts you will need a gas wrench and fum tape. For polypropylene, special pipe cutters are required.

The hose is connected to the water source. This could be, for example, a collector. The ¾ hose is attached with a clamp directly to a section of pipe welded to the manifold. There is no need to install an extra valve so as not to increase the weight of the structure. The second end of the hose can be led to a steel pipe about 20 m across the site (it can be replaced with propylene, but taking into account the protection of pipes from rodents, it turns out to be very expensive). A tee-splitter with 2 mini-valves is put on the end of the pipe. It is connected to it on one side via a ¾ connector and an adapter. The second valve is a backup valve.

Advantages and disadvantages

This type of corrugated pipes has many advantages. These include:

- Absolute corrosion resistance.

- Wind and waterproof.

- Non-flammability. PVC does not ignite when exposed to open fire, but melts.

- Dielectric properties.

- Flexibility and lightness, allowing you to save on the number of connecting elements, supporting structures made of reinforcement and transportation.

- Inertness towards aggressive chemicals.

- Large selection of diameters.

- Low price. The cost of PVC corrugation is significantly lower than similar products made from other materials.

- Durability. PVC pipes can be used without losing their original properties for at least 50 years.

Disadvantages of PVC:

- Shows poor resistance to ultraviolet radiation.

- Releases harmful substances at operating temperatures above 45 ºС.

- Becomes brittle when exposed to low temperatures.

The procedure for connecting household hoses

Often there is a need to connect not only garden hoses, but also others, such as washing machine hoses. From time to time, many washing machine owners have to deal with the problem of damaged drain hose or its insufficient length. In this case, you can quickly extend the old hose with the same (or approximately the same) new hose.

You can make a reliable and high-quality connection by fixing the rubber tips using self-clamps through a durable tube (you can purchase a special connector). The most optimal size of clamps is no more than 27 mm. If you do not have a special connector, you can take a piece of durable plastic thin-walled pipe with an outer diameter of about 20 mm. In such cases, we can recommend using a fixing tie for clamps.

If the end of the supplied washing machine hose is plastic and not rubber, then you first need to insert a piece of tubing suitable for the outer diameter inside it. Then a rubber tip is put on top of it. The resulting structure is fixed using 1 auto clamp. If you wish, you can try to completely replace the old drain hose of the washing machine with a longer one, but there is not much point in this, because... the new hose may simply not fit the design, so it’s better not to take risks.

Stores sell hoses of various lengths, but 5-meter and longer ones are quite rare. However, extending the washing machine hose even by 5 m is already considered unacceptable, because... such a design would be unsafe.

Extension is carried out in different ways and depends on the required length of the hose. So, if you need to extend the hose to 1.5-2 m, then this can be done using a standard drain hose for washing machines; up to 3-3.5 m - using a metal-plastic pipe with a diameter of 20 mm (if necessary, the pipe can be recessed into the floor or sewn into the wall). For heating and pressure water supply, such a solution is unacceptable. If the distance is more than 3.5 m, the washing machine needs to be moved closer to the siphon (or the siphon should be moved to the machine).

When operating the washing machine, the drain and inlet hoses should not come into contact with sharp objects or rough surfaces. Otherwise, the hoses may rub through due to movements resulting from pressure changes.

Connection methods

There are three ways to connect corrugated PVC pipes:

- Coupling. For joining, fixed couplings with rubber seals are used. Suitable for connecting individual pipeline elements at turns or for joining elements made of different materials.

- Cold welding. A special chemical composition is applied to the joints of individual pipeline elements. The materials soften and the parts fit together. They are held motionless for 20 minutes so that the adhesive composition hardens.

- Bell-shaped A method used for the manufacture of sewer channels and cold water supply pipelines. The individual elements are connected using a special rubber gasket.

The choice of method for connecting the tubes depends on the purpose of the pipeline.

Coupling method of joining

What is it for?

Corrugated pipe provides protection and extends the life of electrical wiring.

Electrical cable and wires are laid in corrugation:

- for fire protection in case of fire of flammable walls made of wood or frame, lining or ceilings;

- for laying, for finishing materials: lining, drywall, PVC board, to ensure the safety of residents. When making repairs, owners drill or break through walls, which means they can damage products and suffer from electricity;

- under the floor to protect electrical wiring from the compressive effect of concrete poured into the base of the floor;

- under the floor so that the wires can be replaced if they become damaged or become outdated;

- for protection from external climatic and mechanical influences when installed outdoors.

For external installation, only durable shells are used that protect from moisture, sand, wind, snow and physical influences. On the street, corrugation is exposed to temperature, so its surface must be hard and resistant.

No matter how strong the corrugation is, it will not be able to stop the impact of the hammer drill if the user exerts sufficient physical force. The calculation is made for the timely stop of the drill if it fails during operation. You can warn the person who may be doing the repairs using photographs or a drawing.

For external installation, only durable shells are used that protect from moisture, sand, wind, snow and physical influences.

Common mistakes

The most common mistakes are made when installing corrugated or plastic air ducts. Thus, to install a plastic or corrugated pipe, it is important that its cross-section matches or exceeds in size the area of the air purifier outlet pipe. When purchasing hoses and exhaust equipment, you should pay attention to this.

The corrugated pipe must be installed as stretched as possible, which is not always observed. Its bends should not be less than the diameter of the corrugation itself.

When laying a plastic pipeline, the bend angles must be obtuse.

Types and types of corrugated pipes

Corrugated pipes are divided into categories based on strength. Therefore, when choosing a product, their thickness, material used and manufacturing technology are important.

Corrugated pipes are divided into:

- Lightweight, having a wall of 1-2 mm thickness and sufficient flexibility. Pipes are used when laying wires under the cladding of walls and ceilings. Protection against mechanical load is weak.

- Medium, having a wall of 2-3 mm, but made of more durable materials. Pipes are used when laying in walls and screeds. They protect wires and cables in walls, but are less effective when laid in the floor.

- Double-walled, with a 3-4 mm wall and a ribbed base. Suitable for laying under the floor, with the ability to change the cable in the future.

- Heavy, having a thick wall of 5-7 mm. They bend under force, but fit into the screed and are buried in the wall. The direction is changed by angles and special couplings. The degree of mechanical protection and moisture resistance is high.

- Reinforced, up to 5 mm thick. The plastic shell and twisted steel spiral are suitable for the ground. A reliable option for any use.

What materials?

Corrugation for cables and electrical wires is made of plastic and metal. Different materials are used, with different characteristics. They must be selected based on the tasks they must perform.

- Polypropylene (PPR). The color of this corrugation is usually blue, the material is self-extinguishing and does not support combustion. It is characterized by increased water resistance and can be used for laying cables outdoors or in rooms with high humidity.

- PVC (polyvinyl chloride). The color is gray pipes, self-extinguishing. PVC corrugation is not waterproof and can only be used in dry rooms.

Black cable corrugation is most often made of HDPE, but it can also be made of polypropylene (PPR)

If we talk about compliance with fire safety standards when installing gaskets in flammable walls, the ideal option is a metal pipe. It saves you from loads that may arise when the size of the building changes. Rodents cannot cope with it either. This is also the best option from a fire safety point of view: even if short-circuit currents occur and the circuit breaker does not operate, the probability of burning through a pipe with a wall thickness of 2 mm is very small. This means the fire will not start. If laying electrical cables in pipes does not appeal to you at all, then you can use metal cable ducts or corrugated stainless steel or galvanized steel.

Basic criteria for choosing corrugated pipes

The size of the hydraulic pipe that protects the electrical network varies from 1.5 to 6.5 cm. The calculation is based on the internal diameter, not the external one. When laying more than 2 wires and cables, the safe clearance size is 50%. Overheating of one or more cables is partially offset by air clearance.

Selection by size

The determining parameter when choosing the internal diameter of a product can be the cable section:

- to the lighting fixture - from 1.5 to 2 cm;

- to a socket or switch – up to 2 cm;

- from the distribution element to the box or panel – up to 2.5 mm;

- from one to another electrical panel - a cable with a diameter of 3.2 cm;

- between floors using rigid corrugation - 4 cm;

- low-current cables (telephone, Internet and antennas) – 2.5 cm.

The cost of corrugation for PVC cable will be the lowest. For a mid-range product - PP and HDPE, the builder will have to pay more, but not as much as for metal corrugated materials. The broaching element slightly increases the cost of the building material.

The protection is implemented in coils on which corrugations with a length of 50 to 100 meters are wound. The parameter that most influences the cost is the wall thickness and the material used. A budget option is PVC corrugation.

Methods for connecting corrugated pipes

Corrugated pipes have different diameters, configurations, materials of manufacture and other technical characteristics. So are the connecting elements that are used to create the system. They connect sections for pipelines into a utility system.

The system consists of:

- Connecting couplings.

- Heat shrinkable electric welded couplings.

- Troynikov.

- Taps.

- Fittings.

- O-rings.

- Tightening tapes.

The requirements that apply to pipes also apply to connecting elements. This increases the reliability and strength of the link and allows it to withstand aggressive environments, moisture, and mechanical stress. Connecting bands are popular. They reliably fasten the sections, provide rigidity, and resistance to temporary or permanent loads.

If desired, you can connect pipes of different types. For this purpose, special couplings and fittings are used. Thanks to these elements, the pipes acquire a flange connection. This way you can connect reinforced concrete, plastic, and polyvinyl chloride pipes.

Methods for connecting corrugated pipes.

Varieties of corrugation

What is a flexible adapter for the production of plumbing fixtures? The understanding of its design lies in the name itself.

A toilet corrugation is a sleeve, the walls of which are made of thermoplastic polymer with elastic cuffs at the ends, adapted to fit into a standard Ø 110 mm sewer and fixation on the outlet of the device.

Such products are offered by retail chains in two standard versions, distinguished by their reliability - these are reinforced and regular toilet corrugations. The only peculiarity of the reinforced modification is that it is reinforced with an insert made of a wire steel spring, which adds resistance to mechanical stress and increases its service life compared to its non-reinforced counterpart. Typical models of drainage fittings of both types are produced in lengths from 230 mm to 500 mm.

There are also product variations for special installation situations. For example, if a plumbing fixture has a direct outlet, then quite often the corner corrugation for the toilet fits better than a straight sleeve.

In small-sized combined bathrooms, a model of a flexible adapter (straight or angular) may be useful, which provides an outlet for connecting the siphon of a washbasin or washing machine.

Features of installation of corrugated pipes

To install the product externally, a plastic clip is used. It is selected according to the outer diameter. The clips are fastened at a distance of 20-30 cm from each other. Using self-tapping screws and dowels, the fastenings find their place. In order for the corrugation to fall into place, it is pressed against the mount until there is a characteristic click. Using homemade fasteners is not so much reliable as it is economical.

The pipeline route must be created according to certain rules. Firstly, there should be no sharp turns. This will allow you to tighten the cable a little if you need to do so.

Recommendations for creating a site:

- length should be no more than 25 meters;

- no more than 4 turns should be made along the entire length;

- areas where the angle of rotation changes should be located as far apart as possible: at least 4 meters;

- when rotating sections are located close together, special distribution boxes or inspection hatches should be used;

- Corrugated sleeves should be located at a distance of at least 20 cm if electrical wiring or low-current cable is laid in them.

Attaching a corrugated air duct to the hood

The air duct is connected to the hood as follows:

- They mark the route of the air duct, take measurements, and draw up a diagram.

- Prepare the corrugation of the required length and all the components for its fastening.

- The pipe is stretched to its full length, control measurements are taken, and if necessary, shortened.

- If the diameter of the air duct differs from the exhaust outlet hole, install a universal adapter coupling on the exhaust device. It will allow you to secure pipes of various sizes.

- The hood neck or coupling is treated with silicone sealant, and a corrugated pipe is installed. From the outside, secure the joint with a clamp, tightening it tightly.

- If the length of the air duct is more than 0.8 m, it is fixed to the wall or ceiling. This is done using clamps and brackets or corners. The distance between the clamps is 1 m.

- The ventilation opening is covered with a special grille with a hole for the corrugation. This will require dowels, screws or universal glue, depending on the wall material. Additionally, the cracks are treated with polyurethane foam or sealant.

- In the grille opening, the end of the air duct is secured with sealant. Install and tighten another clamp.

After these manipulations, the system is ready for operation. The hood is turned on and the correct installation of the air duct and its tightness are checked.

Advice . For additional strength and tightness of the connections, wrap them with aluminum tape.

How to connect corrugated elements together

If the configuration of the room does not allow the installation of an air duct from a single piece of corrugated pipe, you will have to assemble it from several parts.

There are two ways to fasten parts together:

- Use a special insert or adapter coupling if pipes of different diameters are connected. Each part is fixed with a clamp on the corresponding side of the connecting element.

- The edges of identical pipes can be secured with aluminum tape by cutting them straight and joining them.

How to install wiring in a corrugated

To ensure that the wiring remains protected during the installation of a house or apartment in all areas, the corrugation is installed between the distribution boxes, and then to switches with sockets and lighting fixtures. As a rule, there are no turns in these areas, so installation proceeds quickly.

When laying several cables in a protective pipe, they must be connected to each other using adhesive tape or electrical tape. To avoid the cables moving relative to each other, loops must be made at different ends.

What is corrugation and why is it needed for exhaust devices?

Corrugation is a corrugated pipe used in the installation of air ducts, installed between equipment that provides circulation and exhaust of air in the room where they are installed, into the building ventilation system or directly into the external environment.

The corrugated exhaust pipe is a flexible element, which is determined by its design and production technology. Due to its mobility, corrugation is used when installing air ducts in hard-to-reach places and in areas located in curved and perpendicular planes of space. In addition, due to their attractive appearance, certain brands of corrugated pipes made of stainless steel and aluminum are used throughout the entire length of the air duct without additional decoration or covering.

Connecting a kitchen hood to the building ventilation system using a corrugated air duct

Corrugated air ducts are used to connect kitchen hoods and axial fans installed in a bathroom or toilet, when installing geysers and heating boilers of various types.

In what cases can corrugation not be used?

The corrugation may not be used if the cable is laid through the wall rather than mounted into it. When working with a hammer drill, the user will be able to see where the wiring is, and he will not snag it. In addition, the use of corrugation can be abandoned if the wiring or cable has independent protection from various influences.

Laying is not necessary in cases where the cable will not be exposed to various influences in the cavity without moisture, dust and mechanical stress. These may be other protective elements or communications of the building.

Also read:

Requirements for materials for sealing pipes

The materials that cover the pipes must meet certain criteria:

- Be resistant to temperature and steam.

- Have good sound insulation properties.

- Do not lose color over time from exposure to sunlight.

- Easy to clean, withstands washing with chemicals.

- Fire safety.

Typically they use drywall, metal, plastic or wood. The characteristics of the materials should be taken into account.

Plastic pipes can fade when exposed to direct sunlight, are easily damaged by impacts, and are scratched. Pipes with a round cross-section create less resistance to air movement, so the efficiency of the hood will be higher. Rectangular pipes are less noticeable in the interior, but to create good traction they should not be more than 3 meters long, and the turns should not be at an acute angle. In addition, before purchasing, you should take accurate measurements, select all the parts (straight sections, sleeves for bends, fastenings) so that the assembled structure corresponds to the distance from the hood to the ventilation shaft.

The corrugation must be well stretched before installation, then there will be less noise during operation of the device and better conditions for air movement. Unlike plastic and steel products with a smooth surface, aluminum corrugations are more contaminated from the inside: particles of fat, dust, and fumes settle on the folds.

Wood is used to seal pipes if the kitchen has wooden furniture. To increase resistance to aggressive factors, it is coated with protective materials.

Each of the proposed options has its pros and cons. It’s better to plan what the kitchen will look like in advance, thinking through and taking into account all the details. Then it will be possible to realize most of your desires, optimally combine functionality and beauty of execution.

Direct connection of the corrugation to the sewer

As a rule, corrugated pipe is used to install a toilet. So this process will be described further. However, in the case of a sink and other plumbing fixtures, everything will look approximately the same.

So, at the first stage it will be necessary to prepare the plumbing equipment itself. If it's just from the store, you won't have to do anything. However, if it has been dismantled, then before connecting it is necessary to thoroughly clean the dismantled toilet from the old sealant. You can even additionally sand the edges of the outlet to remove any remaining sealant, cement, etc. After all, even the slightest roughness at the joints will lead to the seal being broken in this particular place.

Now you will need to apply a small amount of sealant to the outlet from the outside. The end of the corrugation where the membrane is located is put on the outlet. In this case, you also need to ensure that the outlet covers the edges of the outlet by approximately 50 - 60 millimeters. You must also carefully ensure that there are no distortions. The corrugation should be put on as evenly as possible.

Corrugated pipe is used for installing toilets, sinks, sinks and other plumbing fixtures.

Once the sealant has dried, you can install the toilet in place. And it will be possible to remove the corrugation to the sewer. To do this, the edge of the pipe with an external seal is inserted into the previously cleaned hole until it stops. In principle, sealing is not necessary here, but you can play it safe.

Now you can do a test run of water. Just turn on the water supply and perform several intensive flushes, or pour a bucket of water into the toilet a couple of times. If there are no leaks, then everything is in perfect order. The connection procedure can be considered complete.

Organization of a corrugated water seal

If it is not possible to purchase a separate siphon, then you can use the most ordinary corrugation for this. She will do an excellent job of organizing the hydraulic lock. However, it will be necessary to take into account a number of points.

- Firstly, you should not make too long horizontal sections from a corrugated pipe. Otherwise, under the influence of gravity, the pipe will sag - and it is in the place of sagging that stagnation of water and debris will form.

- Secondly, the pipe, bent in the shape of the letter S, will need to be held in this position using clamps or even using the most ordinary wire.

- Thirdly, you should avoid bending the corrugation too sharply. And of course, its kinks are unacceptable. Otherwise, the flow of water will be obstructed. Which, in turn, is fraught with the formation of congestion. Curves should be smooth, as close to natural as possible. However, they should not be too flat either. Otherwise, a water seal will not be formed.

To create a water seal - bend the corrugation in the shape of the letter S and secure it with clamps or regular wire.

Product Standards

The technical conditions for the production of PVC corrugation regulate:

- Electrical - GOST 32126.1-2013; GOST 50827-95 (IEC 670-89); EN 61386-1; EN 61386-22; TU2247-008-47022248-2002.

- Sewage and water supply - GOST R 54475-2011 and TU 2248-001—96467180-2008.

Dimensions

PVC corrugation with (and without probe) for electrical work is available in the following sizes:

| Outer diameter, mm | Inner diameter, mm | Quantity per bay, m |

| 16 | 10,7 | 100 |

| 20 | 14,1 | 100 |

| 25 | 18,3 | 50 |

| 32 | 24,3 | 25 |

| 40 | 31,2 | 15 |

| 50 | 39,6 | 15 |

| 63 | 50,6 | 15 |

A more rigid corrugated pipe, used for the installation of sewer and drainage systems, is produced in lengths of 2, 3, 6 and 12 m in the following diameter range:

- External - from 110 to 1135 mm.

- Internal - from 93 to 1000 mm.