The sewer pipe plays an important role throughout the entire drainage system, be it a private house or apartment. The sewerage system consists primarily of hollow interconnected pipelines.

They produce sewer gas (sometimes called biogas), which poses a serious danger - it adversely affects people's well-being, is flammable, and in some situations can become explosive. The removal of these gases is ensured by a sewer pipe, which must be installed in every private or public system. It is quite simply designed, works on the basis of natural physical processes and does not require the use of technical devices. The absence of a drain pipe has a very negative impact on the microclimate of residential premises, reduces the level of comfort and creates preconditions for deterioration of health.

What are fan pipes?

Many people have heard from friends and acquaintances that it is necessary to create a scheme for installing a vent pipe in a private house. This is due to high-quality ventilation of the toilet, bathroom, kitchen, and entire house, which can be built using a vent pipe.

What is a fan pipe, what can it be, how to install it?

The drain pipe is connected to the sewer system and is designed to perform a ventilation and water seal function with subsequent outlet to the roof. During operation of the sewer pipeline, gases accumulate in it. If you do not install a waterproof barrier, they will penetrate into the living space, which is dangerous for the lives of the inhabitants of the apartment. In addition, an unpleasant odor will spread throughout the house.

It can be of any length, shape, depending on the installation location and the size of the sewer line. This part of the exhaust system can be straight, angular, placed in horizontal, vertical directions.

To prevent unpleasant odors from entering your home, it is necessary to ensure high-quality ventilation of sewer risers. In such cases, a fan pipe, for the manufacture of which plastic is most often used, helps. However, plastic products have not completely replaced elements of metal origin. Today, many people use cast iron, less often copper, structures in their homes. Metal does not want to give up its positions.

Read with this article: How to bend and connect a brass pipe with your own hands.

Review from “A” to “Z” of this product.

What materials is it made from?

Both the wastewater pipe and the sewer pipe are the same type of pipes. This means that they are made from the same materials - plastic or cast iron:

- Plastic ones are cheaper, more convenient to install and use.

- Cast iron is stronger and more durable, but working with them due to its impressive weight and fragility is more difficult. In addition, cast iron ones become dirty faster during operation.

Possible schemes

Laying and replacing sewer risers does not allow mistakes in the process of planning and installing the system, otherwise the living space will be filled with an unpleasant odor. To prevent this from happening, in a private house you need to choose the right drain pipe design.

There are 2 installation schemes for exhaust systems:

- Horizontal. According to this scheme, the outlet of the vent pipe must be carried out through a hole in the wall, and not through the roof. This scheme can be used in private construction if it is impossible to make an exit through the roof. The final outlet is covered by a grille rather than a deflector.

- Vertical. With this design of the fan pipe in a private house, the riser goes out through the roof.

There are three types of vertical outlet of the riser to the atmosphere:

- output at an angle of 90⁰. It is necessary to make two branches from the riser, one after the other, at angles of 90⁰, after which it will come out vertically upward through the roof;

- output at a slope of 45⁰. To directly exit the riser through the roof, it is necessary to alternately make a branch from the main riser, first at 45 degrees, and then at 135 degrees;

- the usual vertical type outlet, which will immediately continue to the roof and exit through it to the outside.

Important! The ventilation installation scheme in a private house must be correct, that is, in accordance with the appropriate diameter and in the right place, provide for the presence of a check valve that blocks the overflow of feces.

Do I need to insulate and soundproof?

It is not at all necessary to insulate sewer pipelines passing through residential premises, as well as sewer pipelines. But in an unheated attic it is worth making at least minimal thermal insulation of the pipes so that during severe frosts the ice does not freeze inside, since water vapor is much lighter than air, and they will tend to rise up the pipe, where they will freeze on the cold walls.

Insulated pipe

Sound insulation of the drain pipe must be carried out only if it passes openly through residential premises. If this cannot be avoided, then the insulation work is quite simple and is carried out in the same way as for all sewer pipelines with the same ease. The only thing that complicates the process is the variety of acoustic processes in pipes, which directly depend on the materials from which the pipelines are made.

Thus, the sound insulation properties of cast iron pipes are much better than those of their plastic counterparts. This is due primarily to the properties of the granular structure of cast iron and the larger wall thickness, so such pipes, as a rule, do not require additional sound insulation.

Sound processes occurring in plastic pipes can be divided into four main components:

- Impact nature, when falling water and feces repeatedly hit the walls of the riser;

- Atmospheric nature is the penetration of wind and precipitation noise through the outer part of the pipeline;

- Resonant nature from the presence of extraneous noise in the pipes caused by the interaction of the sewer pipeline with the building structures;

- Vibrations that occur when there is contact with any operating equipment.

Sound insulation of a drain pipe

The main part of the work on sound insulation should be carried out at the design stage of a residential building, so that all sewer risers do not pass through residential premises and are installed exclusively in special boxes or sewer shafts, which themselves are shielding devices and prevent the spread of noise .

If, after all, the vent pipe is located open in a living room, then it can be easily soundproofed by wrapping the pipe with strips of inexpensive polyethylene foam in two or three layers.

Use of cast iron elements

For several decades, the installation of exhaust ducts took place using cast iron risers. Today, cast iron fan pipes are becoming increasingly rare. But in vain, because using risers made of this material you can be sure of the quality of the exhaust and ventilation ducts. Cast iron parts have a number of advantages.

They differ:

- strength. The rigidity and density of the alloy contribute to the safe operation of cast iron products, which can be purchased at a hardware store. They are used in the construction of private, multi-storey buildings;

- long service life. This is due to high wear resistance, which helps metal products maintain excellent technical characteristics for many years;

- resistance to mechanical impacts. They are not afraid of accidental impacts, damage, or heavy loads.

Minuses:

- tendency to corrosion processes;

- difficulty of transportation;

- heavy weight;

- high price.

When repairing or replacing old cast iron risers, it is necessary to dismantle the existing system. It is not easy to do this if the sewer or exhaust line is located in a hard-to-reach place. How to disassemble a cast iron pipe behind a toilet? It is difficult to carry out this procedure if tow with cement, aluminum or sulfur were used to connect the risers.

First you need to dismantle the parts that are located further from the riser. To do this, you should stock up on a chisel or a hammer with a plastic or rubber head. When you hit the chisel with an iron hammer, pieces of metal sharply bounce off the pipe and can fall into the riser, since cast iron is a very brittle alloy.

Having completed all the preparatory work, proceed to removing the cast iron drain or sewer riser:

- After destroying this element of the system, gradually approach the crosspiece, leaving 30-35 cm of an almost broken part.

- Using the remaining piece, gently loosen it. If this does not help, then use a chisel to start removing the packing, loosen it again, and then remove the remaining fragment.

- If the system is sealed with sulfur, then you need to take a blowtorch or gas torch and start heating the packing. Before doing this, you need to cover the furniture and walls with a screen so as not to damage them. It is advisable to carry out this work together, since one person must remove the heated, viscous sulfur.

- After removing a certain amount of the heated mass, remove the remainder of the unnecessary part of the part.

An option is possible when you can use a grinder to cut off the rest of the line right up to the socket. This procedure will ensure not only a neat cut, but also a quick, convenient joining of the new plastic sewer part with the old cast iron riser.

Important! The cast iron fan pipe can be used in any extreme situations. This means that such a system will function normally under conditions of a wide temperature range at elevated pressure.

Work with cast iron sewer or sewer pipes, including drilling them, must be carried out with the utmost care. This is due to the increased fragility of the metal.

Over a long period of operation, as a result of corrosion processes, cast iron sewer risers become unattractive. Therefore, they need to be refreshed. How to paint a cast iron pipe in a toilet?

For painting use acrylic, water-dispersion paint. The shade can be very diverse.

Some owners refresh cast iron risers with oil paints. Before painting, you need to get rid of rust, old peeling paint, unnecessary debris, and dirt. Only after such preparation can you begin painting. A painted, restored sewer line will last for many more years.

Installation rules and features

Fan pipes are made from sewer pipes of the required diameter. They serve as a continuation of the riser in the bathroom and end with an entry into a special channel equipped for ventilating the sewer system.

Concepts are often replaced, and the toilet drain pipe is the adapter (cuff, eccentric) connecting the plumbing fixture to the socket of the sewer pipe

Connecting a vent system allows you to successfully solve the current problem of unpleasant, pungent odors in the toilet when the sewer and ventilation systems are fully operational. This is due to the small size of siphons in modern plumbing fixtures, which can result in an insufficient supply of water (hydraulic seal).

If a shower drain or plumbing fixture is not used for more than 2 days, this can lead to the water seal drying out, which will cause the unimpeded penetration of air from the sewer into the bathroom. At the same time, the fan pipe not only effectively sucks in air, but also ventilates the sewerage pipeline.

When warm air rises through the riser, a vacuum occurs, due to which it partially enters the atmosphere through a previously dried siphon.

Installing a cast iron or plastic fan pipe in a private house reduces the unpleasant odor that arises when the siphon dries out

According to building codes, the fan pipe must be installed in a warm room; if necessary, the product must be insulated. If it freezes, the fumes will not dissipate quickly or efficiently. For this reason, after a year of use, the upper part of the element will be covered with a greenish coating.

Image gallery

Photo from

Connecting the toilet to the sewer riser

Outlet for connecting the toilet to the sewer

Part for connecting a toilet with an oblique outlet

Universal extension cord option

When installing a waste pipe, you must follow two basic rules:

- The diameter of the product must be greater than the diameter of the riser on which the sewer pipe is mounted (regardless of the material used in the manufacture of the pipe).

- It should end 40-50 cm from the edge of the roof ridge, so unpleasant odors will be quickly released into the atmosphere.

The system outlet must be located outside the residential area. More precisely, the drain pipe for the plumbing fixture (toilet) should extend beyond the bathroom and stretch through the attic to the roof of the building. Otherwise, the foul odors from your septic tank will permeate your living space.

What is required to install a toilet?

The connection diagram for a plumbing fixture to a general sewer system involves connecting the toilet to the pipeline using pipes, bends, corrugated or eccentric cuffs.

The elements that are necessary to connect the toilet in the bathroom are a rubber cuff (2), corrugation (3) and a plastic outlet (1). One is suitable, but sometimes you have to connect several

It should be taken into account that the installation of any toilet model using reliable and durable cuffs has a number of requirements:

- it is strictly forbidden to cut pipes and change their geometric shape;

- corrugated cuffs can be freely extended in length, as well as bent at the required angle;

- The eccentric cuffs must be rotated relative to the axis, this allows you to compensate for the deviation from the alignment of the plastic pipes connected to each other.

Making a pipeline connection using a corrugated cuff has its advantages. This is a unique opportunity to connect the toilet to the general sewer system in hard-to-reach places. In these cases, the sewerage system is equipped with various receiving sockets.

Instructions for installing the riser

When replacing a pipeline in a country house or apartment, you must first dismantle the sewer system. Products made of cast iron are considered obsolete, so they must be replaced with plastic counterparts, following certain rules.

Today, in old houses, old cast iron pipes are often dismantled. Plastic elements have better performance and durability

Dismantling is carried out by disconnecting the sewer riser and then disconnecting all structural elements. Before replacement, it is recommended to consult with specialists, which will allow you to find out whether replacing an element of a cast-iron riser with a plastic one will lead to unpleasant consequences, expressed in a decrease in the strength and reliability of the sewer system.

The new pipe is installed from the lower point of rigidity, located in the area of the main riser. Installation in a country house begins with the area where the building's foundation is located. It is necessary to drill holes in the supporting structures, after which a pipe with a diameter of 110 mm is installed and secured with clamps. After installing the plumbing fixture, a special outlet is connected to it.

When installing the riser, it is necessary to use exclusively metal clamps, which will ensure the reliability of the structure and will reduce deviations from the marking lines that arise during the assembly process.

Metal clamps, which are used when installing a drain pipe, ensure the strength of this structure and allow you to adjust the elements connected to each other

The pin on the metal clamp has a functional screw structure that allows you to accurately adjust the elements being connected.

Thermal insulation and sound insulation of pipes

When installing plastic elements, we must not forget about important measures to protect the system - noise insulation and thermal insulation of the pipe. Thermal insulation is carried out using a tubular cover made of foam insulation, which is worn from the outside.

To arrange the sound insulation of the system, the contact point between the interfloor slab and the pipes is filled with polyurethane foam or other sealed material.

The fan pipe is surrounded by a sealed material with excellent sound insulation properties. Due to this, vibration from movement through the sewage pipe does not transfer to the walls of the house

Sound insulation of a fan pipe can be carried out using a mineral slab or special polyurethane foam. Polyurethane foam is more often used, which is easier to use, however, if the structure is dismantled, it will not allow it to be put back together.

Check valve for vent systems

During the installation process, the fan pipe is inserted into the previously prepared ventilation duct. If the project provides for the presence of a minimum number of ventilation risers, then the outlet for the toilet is routed horizontally to the wall, without deteriorating the interior of the bathroom.

An important element of the system deserves special attention - the check valve, whose functions include:

- preventing waste from returning back into the toilet;

- the valve prevents rodents from entering the sewer system;

- correcting the situation in case of incorrect pipe slope;

- preventing mechanical impurities from returning to the toilet.

If the check valve is installed internally, the pipe should first be cleaned and thoroughly degreased. Then a special insert is installed - it must be purchased in advance, since it is not included with the check valve.

When installing the valve, it must be taken into account that its location should be opposite to the return flow, and the petals are bent towards the plumbing element.

Installation of a check valve can be carried out in various places in the sewer system. Internal installation requires preliminary preparation and some space

When installing the valve, do not use lubricants or silicone products, even if they are intended for sewer systems. The installation process must be carried out exclusively dry.

If the sewer pipe has a typical diameter of 110 mm, then installing the valve requires the use of a special adapter. If you plan to connect to a gray pipe with a sawn-off socket, the valve is installed in the pipe.

A cylindrical check valve with a cover must be installed in the outlet pipe immediately after installing the plumbing fixture in the bathroom

When the toilet flushes, the valve cover opens, after which it closes automatically using a spring made of stainless steel. Due to this design, the lid does not open from the outside with fecal matter, which prevents it from falling back into the toilet.

The tightness of the connection between the valve and the sewer pipes is achieved using rubber rings. The valve has a long service life (more than 50 years).

Application of plastic structures

In private homes, when installing systems for removing air and various types of odors, they mainly use plastic vent pipes. They can be round or rectangular.

Risers used as fan risers are produced in different sizes. When installing an exhaust or supply ventilation system, plastic fan pipes with a diameter of 50 to 110 mm and a length of 3-4 meters are in demand.

If the plastic fan pipe in the ceiling is cracked, it needs to be replaced. Repairing this part of the exhaust or ventilation line will not bring the desired result.

When carrying out this procedure, you should adhere to the sequence of work:

- using a hammer drill around the riser, expand the diameter of the hole (at least 2 times);

- use a grinder to cut the cracked element of the system approximately in the middle of the height so that it is convenient to remove both pieces;

- remove the cracked parts and put a new riser in their place;

- seal the hole around the installed exhaust ventilation element both from below in the ceiling and in the upper plane of the ceiling.

It must be said about the presence of flexible plastic fan pipes. To connect them to a solid part of the system, it is recommended to use rubber rings for sealing. For better fit into the socket and complete tightness, they must be coated with silicone before installation. When attaching such a section to the wall, metal clamps are used, which are characterized by increased reliability.

Important! Although silicone is an ideal substance for high-quality sealing, it should be remembered that the next time you dismantle it, you will have to put in a lot of effort to remove it.

Today, plastic risers can be purchased at any hardware store or store.

Which pipes are better to use: polymer or cast iron?

Modern consumers choose polymer materials

- Cast iron pipes in plumbing are giving way to more practical and cheaper materials. Yes, risers made of cast iron are considered strong and reliable and can last for decades. But the complexity of installation, as well as susceptibility to corrosion, forces modern consumers to abandon cast iron elements.

- Plastic pipes are a broad term that includes polyethylene (PE), polypropylene (PP) and polyvinyl chloride (PVC). They have different functional qualities and prices, but have one thing in common - ease of installation and durability.

Dimensions

There is no separate part called a fan pipe, regardless of size.

This design includes:

- regular tee;

- lid or grill;

- one or more pipes;

- safety valve.

The dimensions of drainage pipes for sewerage, as well as for toilets, depend on the specific conditions of their operation.

The following rules must be followed:

- You can use parts from any materials;

- The size of the pipes for the exhaust riser, including the length, may vary.

Today, the most popular are plastic fan pipes with diameters from 110 to 50 mm, regardless of other linear dimensions (length).

Using a 110x45 ani plast w4220 drain pipe, which can be of different sizes, it is convenient to connect the sewerage system to the toilet outlet. Such a detail will seem to glue the toilet bowl to the sewer riser, which will ensure that there are no leaks in the bathroom. The size of the toilet drain pipe depends on the diameters of the drain, sewer riser, and the distance of these elements to the wall or ceiling.

The diameter of the part must be such that the maximum possible sewer flows do not interfere with its normal functioning. Sometimes ventilation and sewage systems are constructed from risers of different diameters. Then you need to use a special adapter.

There is a catalog where you can select the necessary parameters of parts for arranging an exhaust system.

Important! The ideal location for the exhaust riser is the place where the internal and external sewers are connected.

Connecting a toilet without corrugation

If the owner decides not to use corrugation when connecting a plumbing fixture, it is necessary to adhere to the basic rules: it is necessary to use an adapter or pipe; connecting the toilet to the adapter is carried out in different ways, depending on the release of the plumbing fixture.

A smooth, rigid cuff is an important element that is used to connect a plumbing fixture of any modification without the use of corrugation

Depending on the internal design, toilets are classified into 3 types, which also differ in installation and connection features:

- Plumbing equipment with oblique outlet. The plumbing fixture is installed into the pipe at an angle of 90.

- Plumbing equipment with vertical outlet. Plumbing installation is carried out on the floor.

- Plumbing equipment with horizontal outlet. The products are installed into the sewer pipe horizontally or with a slight slope.

If the plumbing outlet and the sewer network inlet do not coincide, then you need to install adapter pipes bent at the desired angle or select the optimal toilet model.

Plumbing fixtures for the toilet room can have different types of outlet - oblique, horizontal (straight), vertical. The first option was widely used in the last century, but today the horizontal one is replacing it

Before choosing the optimal design, it is worth considering the installation features of each type of plumbing equipment.

Installation of a toilet with vertical outlet

Similar models of plumbing fixtures are widely used in European countries. This is due to the fact that a vertical outlet pipe and a siphon located in the plumbing bowl are built into the plumbing equipment. The convenient design allows the product to be installed at any distance relative to the wall.

Installation of plumbing fixtures with a vertical outlet is relatively simple:

- markings are made on the floor of the toilet room;

- According to the markings, a screw flange equipped with a special lock is installed;

- the sewer pipe is mounted in a round hole located in the center of the flange;

- The toilet is mounted on the previously installed flange, then it is turned until the equipment is completely fixed.

The outlet pipe is equipped with an O-ring. Thanks to the presence of this element, the pipe is automatically pressed tightly against the sewer pipe. Read on for more details on connecting a plumbing product with a vertical outlet.

Toilets with direct (vertical) outlet to the floor are installed using special spare parts. The sewerage junction is usually located under the ceilings, and the pipes do not require walls or partitions

Installation of plumbing fixtures with horizontal outlet

Connecting toilet models with direct (horizontal to the floor) outlet is relevant for the conditions in our country. This is due to the fact that the bathroom is tied to a specific wall of the toilet room due to the specific layout of sewer pipes in typical Russian houses.

Since the outlet in these models is directed backwards, it is located at the rear of the product. The outlet pipe is attached to the pipe using a sealing collar.

The connection diagram for a modern plumbing fixture with a horizontal outlet in the bathroom of an apartment or house includes six main stages

During installation, special attention should be paid to securing the plumbing equipment to the bathroom floor. The bowl legs of sanitary ware with a horizontal outlet have specially made holes designed to securely fix the toilet to the floor.

The connection of direct outlet plumbing equipment ends with the installation process, during which screws and dowels are used. Fastening must be done carefully, since if the screw is pulled too hard, the integrity of the sanitary ware surface can be damaged.

Installation of plumbing equipment with oblique outlet

The process of installing and connecting plumbing equipment with an oblique outlet is carried out in stages:

- Before connecting the plumbing to the sewer system, the outlet of the device with the grooves located inside should be lubricated with a mixture of red lead and drying oil (or sealant).

- A resin strand must be carefully wound on top. The tip of the 0.5 cm long shoot should remain free, since the ends of the strand can get into the hole and cause a blockage.

- The wrapped resin strand is lubricated with red lead.

Then the toilet is installed, during which the outlet branch is fixed in the socket of the sewer pipe.

Connecting a toilet equipped with an oblique outlet can serve as a visual aid for self-installation of the equipment. It can be embedded directly into the riser or connected to a sewer pipe

Installation of plumbing equipment with an oblique outlet is a simpler process due to the absence of a fixed connection point in a certain place. If, when installing a sewer system, the outlet socket is not positioned accurately, this is not considered a problem.

Fan pipe ventilation

Current building regulations state that it is not necessary to install ventilation in one-story houses, since in such dwellings the one-time drains are small. Buildings with two or more floors must be equipped with such systems. This is due to the fact that with the help of such risers there is a connection with the environment, which means ventilation processes occur.

Many people ask: “Can the waste pipe be vented? And if so, how to connect the vent pipe to the ventilation?” We will give detailed answers to these and other questions.

When installing a vent pipe, it can and simply must be vented, which is most often done. To carry out this procedure, you must first build a ventilation duct.

It is necessary to anticipate the installation of a check valve.

Its purpose:

- prevents the return of drain flows;

- prevents rodents from entering the sewer and into the premises;

- corrects a sewer pipeline with an incorrectly installed slope;

- limits the entry of mechanical impurities into the toilet.

The principle of operation of the device is simple: after water comes out of the drain tank, it is triggered and the liquid enters the sewer system. When the valve is closed, unpleasant odors from the toilet and sewerage do not spread throughout the rooms, since the device is completely sealed.

Important! Install a check valve immediately after the toilet.

Although everyone is trying to install the exhaust system correctly, you can still smell an unpleasant odor from the sewer system in our houses and apartments.

Sometimes odors from the exhaust pipe are blown into the ventilation, since these two channels are located next to each other. To get rid of unpleasant odors, you need to install an aerator at the upper end of the riser. Thanks to this vacuum valve, the system will function perfectly.

Design

To carry out the correct installation of this air duct, you first need to take care of drawing up the project. Such a project must meet two requirements that must be taken into account in all cases without exception:

- installation of the pipe is carried out in the direction of the removal of sewer gases using the force of the wind;

- the pipe for the ventilation riser should have a cross-sectional index no larger than that of the sewer riser.

Installing a vent riser is a necessary step in most cases and is carried out by connecting a pipe to the ventilation duct. In some cases, such installation cannot be performed and the outlet is made through the wall.

The system by which sewer vapors are removed includes the following structural elements:

- fan pipes;

- connecting pipes;

- ventilation ducts;

- connecting elements (fittings).

The future vent riser is attached to the drain pipe using adapter fittings

Output to the roof

Not everyone knows how to ventilate the roof. This must be done, since the ventilation system in the attic cannot end. The drainage pipe must have access to the roof so that there is a connection with the street and the atmosphere. If the sewer is led to the attic, then all the unpleasant odors will be concentrated there. When the hood does not reach the roof, mold will begin to appear in the attic as a result of increased humidity, which will cause a lot of harm to the entire home. The fan pipe is installed both on the roof of a multi-story building and a single-story building.

What to do when the drain pipe on the roof freezes? To prevent it from freezing on the roof, it is necessary to provide insulation around it. The cause of freezing is the formation of condensation, since warm air tends to rise. The result is freezing of the walls with ice, which can lead to the blocking of the exhaust lumen and the cessation of the functioning of the entire system.

The risers are insulated with rolled heat insulators or “shells”, which should be securely fastened.

In some cases, it is impossible to carry out the drainage pipe to the roof. This is not a problem, since you can use a horizontal mounting scheme for the exhaust system. The end of the ventilation system will not be located on the roof, but will be vented through the wall into the air.

You can buy a roof vent pipe at a construction supermarket.

Important! Regardless of how the drain pipe is routed - onto the roof or through the wall, the system requires a check valve.

In order for ventilation systems to function for a long time and efficiently, when laying pipelines, you must adhere to the above-mentioned norms and rules. Only then will your home not be filled with unpleasant odors, but will constantly feel the flow of fresh air.

Preparation for installation of the fan main

To install fan ventilation, you must use the same parts as for the drainage system, namely: fittings, pipes and fasteners. It is better to prepare all the necessary elements, materials and tools before starting all work. In most cases, plastic parts will do. The process can become more complicated if you need to replace an old metal structure with a new one. Let's discuss this process in detail.

Old cast iron fan lines that have been used for a long time fail. There is an opinion that it is impossible to replace metal lines with plastic elements, but this is nothing more than a misconception. Installing a plastic drain pipe instead of cast iron is possible, but only if all elements of the system are completely replaced.

Exit for drain pipe

According to experts, the fan line, which is assembled from elements of different materials, is not durable. It is best to work with similar materials. It is desirable that the material of the drain pipe matches the material from which the drainage system is made.

If the communication is made of cast iron, then the fan pipeline must also be made of this metal. If you have to combine different materials, it is better to first consult with an appropriate specialist and find out how such a pipe will behave. This can prevent significant reductions in ventilation performance.

The installation of a fan riser requires the use of the most ordinary pipes and parts for connection. Parts are made of metal or plastic. To install the system you will need the following parts:

- pipe with bends;

- rubber cuffs for a tight and airtight connection;

- adapters;

- clamps for securing the main line to the walls.

Dismantling the drain pipe

If you first need to dismantle the old pipe, you will also need a sledgehammer, a drill, and a grinder. The area where all work will take place must be cleared of all unnecessary things. If there are flammable items, it is better to remove them too. If they are stationary, then they should be covered with fireproof material. During installation, you should not use the sewer, so if you have neighbors, it is better to notify them in advance. After this, you can turn off the riser and dismantle the old ventilation system.

Return to content

About ventilation of concrete septic tanks

For sewerage on their territory, each owner tries to make a two-chamber concrete septic tank. These containers must be ventilated not only to eliminate unpleasant odors. If you correctly design and build a ventilation system in a septic tank, then you will make the living of your family and residents of neighboring houses safe, comfortable, and enjoyable. You need to take care not only of yourself, but also respect your neighbors.

Such a structure is a habitat for bacteria that can quickly process organic waste coming from the sewer system. As a result, dirty wastewater turns into clean water and sludge. This biological-chemical process is accompanied by the release of a large amount of gas, which not only smells unpleasant, but can cause an explosion if a spark hits it. Conclusion: high-quality ventilation of a two-chamber concrete septic tank without a drain pipe is impossible. For the full functioning of a conventional septic tank, it is also necessary to provide ventilation.

Installation of a new structure

Installation of a new product should start from the lowest sewer line or from the foundation if we are talking about a country house. It is necessary to drill holes in the wall to secure the clamps. You need to buy high-quality metal parts. Such elements give strength to the entire product. The line is installed and secured using clamps. Fan ventilation outlets are connected to the plumbing fixture and firmly fixed.

To achieve maximum tight and reliable contact of the riser with the fan device, it is necessary to use seals. Craftsmen recommend installing these elements using soap or silicone. In this case, the contact will be really reliable, but it will be difficult to remove it.

Fan pipe exit through the roof

It is also necessary to carry out soundproofing to protect residents from loud sounds from the sewer. The simplest, cheapest and at the same time reliable option is to apply polyurethane foam. The sewer pipe just needs to be filled with foam and allowed to dry. This building material perfectly absorbs all sounds. The only drawback of this method is the problematic maintenance of the sewer system.

A more acceptable option, which, by the way, is the only one when installing complex branches, is to use slabs and mineral wool for sound insulation. You can also purchase and install a box for sound insulation. This product is equipped with a window for checking the line.

Return to content

Natural and artificial type

According to the type of stimulation of the movement of air masses, ventilation systems are divided into natural and artificial:

- Natural, they are also gravitational. They operate due to the difference in density and temperature of the air mass outside the window and indoors. Warm exhaust air with a lower density rushes upward and is drawn out into the vents, and is replaced by a denser cold stream flowing from behind the window.

- Artificial, they are also mechanical. They work by continuously stimulating air flow with fans. They are installed on the exhaust or supply side; it happens that they are installed on both the supply and exhaust components, but only one direction is always involved.

The gravity type of ventilation directly depends on weather conditions. In the summer heat, its work spontaneously stops, because... the pressure between the air inside and outside is equalized. It happens that in hot weather the air flows in the opposite direction: from the house/apartment to the street.

Natural ventilation is energy independent. There are no expensive devices in its scheme. It is cheaper to assemble and maintain, but inferior to forced ones in terms of capabilities and efficiency

Fresh air enters naturally through leaks in window and door openings with frames, through open vents and periodically opened doors. Outflow is through barred ventilation openings located in kitchens and bathrooms.

Apartments in the old housing stock were ventilated according to a natural pattern. Nobody was going to mechanize it. Now in these apartments designed for natural influx, plastic sealed windows are installed. Because of them, the normal movement of air is disrupted, therefore, together with a plastic window in a high-rise building, a supply wall valve should be installed.

Supply or exhaust valves into the wall should be used in private houses in which the construction of mechanical supply and exhaust ventilation is not planned.

Using a valve, inflow or outflow will be ensured in the cheapest but most effective way. In this case, the entire system will receive the status of combined – i.e. partially mechanized.

The simplest options for combined ventilation systems, partially mechanized by local fans, include systems with supply or exhaust valves, as well as kitchen hoods without recirculation with an air duct connected to the ventilation shaft

Mechanical ventilation is the most expensive and difficult type of system to implement, requiring the inclusion of a recuperator or air heater, an air handling unit. Its air ducts are laid behind false walls, suspended or suspended ceilings, and laid out in building structures during the construction of a house.

Naturally, if the owner decides to install supply and exhaust ventilation, he will not skimp on material for the ventilation ducts. It is unlikely that he will buy sewer pipes. It is better to purchase plastic air ducts that can be connected to ventilation equipment without problems and unnecessary tricks.

A unit located in the attic of the house is responsible for the operation of supply and exhaust ventilation. It pumps in fresh air and removes waste material, regardless of weather conditions.

In private houses, exhaust ducts from bathrooms and kitchen hoods are either discharged separately into the attic or combined into a common shaft located in the middle of the building. This reduces the loss of usable area and the shaft reaches the roof at the highest point, which provides excellent traction.

The plastic sewer pipe passing through the attic must be lined with insulation. Otherwise, the pipe will collapse due to temperature changes. Hotter air will always come out of the kitchen than in the environment, which means that due to unstable expansion, deformation or violation of the tightness of the channel is possible.

A cap must be installed on top of the pipe - a ventilation deflector that protects from precipitation.

Basic issues related to the aeration plant

Most often, people living in private homes have concerns or questions about installing a ventilation system in the sewer system. The main topics are:

Will ventilation do its job in hot summers when organic waste is at its maximum decomposition?

Yes, it will be so. This is due to the difference in external and internal temperatures between the treatment plant and the surrounding air, which leads to a constant exchange of heat and air. The temperature of the wastewater will always differ from the ambient air temperature. This factor also contributes to the pressure drop in the installation and its effective ventilation.

Will the riser, which is an uninsulated part of the structure, freeze in winter?

In winter, wastewater is always warmer than the air, so with regular use of treatment facilities, the riser should not freeze. In some regions, the riser facing the street must be insulated (insulated). For this, a larger diameter pipe is used. For more detailed information, it is better to consult with specialists.

Some time after aeration was installed, foreign odors began to enter the premises. For what?

Traps filled with water tend to dry out, preventing odors. This happens when the sewer system is not used for a long time: diluted air collects in the riser. Solutions: changing (increasing) the volume of siphons, installing a drain pipeline or a ventilation valve on the riser. The valve will effectively conduct atmospheric air inside and prevent rarefaction of air in the pipes.

If the sewerage system in a private house is properly designed and installed, the ventilation system will be more comfortable for living. It is better if calculations and installation are performed by professionals. This prevents possible installation errors.

Construction and maintenance

The installation of ventilation ducts is carried out at the final stage of installation of the septic tank. There are many descriptions about what and how to make the latter. Ventilation of a septic tank made of concrete rings (this is one of the typical construction methods, characterized by reliability and accessibility) will become possible, on the one hand, due to the presence of a pipe diverted from its second (last) chamber (but not from the first), and on the other hand, account of risers provided at the starting point of the sewer system, providing vacuum compensation.

If there are filtration fields, drains should also be equipped with ventilation pipes. The latter will be able to additionally serve as inspection windows and places for washing. The diameter of the pipes in the general case is ~100 mm. As for air circulation, it goes according to the following scheme:

- inflow through the second (if there are more of them, the last) chamber;

- passing through the connecting pipes and riser upward (the appearance of gases is accompanied by abundant heat, and this contributes to precisely this direction of flow);

- exit through a riser located at some elevation above the roof of the building (fan).

What can interfere with the free flow of air? In order for gases to pass through the system unhindered, it is necessary to fill the pipes from 1/3 to 2/3 of the internal diameter, no more. To improve traction, as well as to prevent precipitation from getting inside, it is necessary to equip the upper ends of the risers with protective caps.

Scheme of treatment facilities

In this case, it is mandatory to comply with a number of safety precautions. Here they are:

- there must be at least two attendants;

- it is necessary to use personal fall protection equipment;

- Smoking is not allowed in work areas.

If you do not want the products sent from the toilet through the toilet and flush cistern to poison your life, returning in gaseous form, be sure to provide and ensure optimal operation of the ventilation system for your septic tank. This will not only save your nerves by getting rid of the stench, but may even save your life.

Adviсe

The outlet of sewer pipes is directed in such a way that accumulations of sewer gases are removed by the wind.

It is unacceptable to place the output in places where they will concentrate and stagnate, even if no one visits these places. If for some reason it is not possible to connect the sewer pipe to the ventilation system, then the outlet from the fan circuit can be routed through the wall. Decorative rosettes are an excellent way to cope with the negative aesthetic effects of such a solution. To connect several fan pipes, tees designed for angles of 45 or 135 degrees are used.

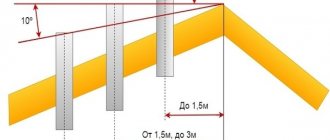

In the case when the attic of the house is used, it is necessary to increase the outlet height to 3 m. All vent risers going through unheated rooms must have a thermal protection layer.

Plastic pipes must be routed through the ceilings using metal sleeves. It is worth mounting a lid and a mesh on top - they will protect against small insects from entering the fan system. Instead of a fan pipe, an air valve can sometimes be used, installed above the inspection part of the riser. But such a solution is applicable only in houses where there is no more than one sanitary unit. Vacuum valves, regardless of their quality, quickly become clogged and cease to perform their main functions.

The problem with valves also occurs when the siphon (hydraulic seal) is deprived of water. In this situation, the entire system becomes useless. In addition, a hydraulic shutter, even in ideal mode, is not capable of 100% protection against unpleasant odors; it must be supplemented with supply and exhaust ventilation ducts. Only a full-fledged fan system can provide good air in houses with a toilet, bathroom, washing machines and dishwashers.

Fan pipes are mainly made of PVC. But it is much better to choose multilayer structures based on polypropylene, since they have an increased level of sound insulation due to the presence of special additives. The increased wall thickness and optimal design at the corners also help them dampen extraneous sounds. In order not to make a mistake with the selected dimensions of the fan pipes, it is recommended to carry out careful engineering calculations of the entire system.

It is advisable to make a minimum of turns, and if you resort to them, then only at an angle of 45 degrees. The connection is made mechanically: with a socket. Any docking point must be equipped with a rubber seal that makes the riser airtight. It is advisable to choose clamps with vibration-suppressing gaskets and install them at intervals of 700 mm. In houses made of natural or artificial stone, as well as when using reinforced concrete floors, pipes must be routed through them using fireproof cases.

Sufficient protection from fire and mechanical damage is guaranteed by cuttings of steel pipes. In most cases, such cases are installed directly during the installation of the ceiling. The key cut-off factors are the settlement of the house and thermal deformation of the pipe from the inside. The diameter of the sleeve should exceed the fan pipe by approximately 10 mm.

Most often such materials are:

- polyurethane foam;

- oiled rope;

- rope impregnated in bitumen;

- silicone based sealant.

To remove the fan system through the roof, it is allowed to use a special passage device. It is made both universal and adapted to a specific roofing material. Sometimes the fan pipe is pulled inside the chimney with a corresponding increase in its cross-section.

It is prohibited to install supply ventilation there.

It should also be taken into account that if there is a septic tank in the house, then ventilation will need to be removed openly. It is unacceptable to install valves in unheated rooms, where the accumulation of condensate can completely block their operation

It is very important to buy components exclusively from well-known manufacturers - products from anonymous and unfamiliar companies are rarely of high quality, and shortcomings are discovered only in a critical situation. You won’t be able to find any differences in appearance – even consulting a specialist when purchasing doesn’t always help

See the next video for more details.

SNiP rules

When ventilating the system, you should take into account the SNiP requirements for the internal plumbing system:

- The diameter of the ventilation system in the sewer network must match the diameter of the riser.

- It is necessary to bring the ventilation pipe to the roof and connect it to the top of the pipe.

- The instructions allow you to connect 4 or more risers to one exhaust device. In this case, the diameter of the finished ventilation and exhaust device must correspond to the diameter of the largest outlet in the combined group.

- When laying ventilation from prefabricated structures, a slope must be provided for condensate drainage.

- In unheated attics, ventilation ducts must be insulated, but their price increases slightly.

Tip: There is no need to install caps, guards or other deviations at the end of the chimney to increase its strength.

Route the sewer line through the home's ventilation shaft or through the roof.

At the same time, height from:

- flat unused roof – 200 mm,

- Sloping roof – 200 mm,

- cross-section of the assembly shaft – 100 mm,

- opening balconies and windows – from four meters,

- roof, when connecting 4 pipes - 3 m.

Note: Use an air valve at the end of each sewer hole if it is not possible to raise the hole to a height of 3 m.

The construction of unventilated wastewater risers in holiday homes is also permitted. However, it is necessary to ensure ventilation of the external sewer system (for example, a septic tank).

The principle of constructing a ventilation riser for sewerage in an apartment building

In apartment buildings, the problem of proper organization of ventilation of the sewer riser has always been acute. Because the main requirement of this system is 2 m above the apartment of the last top floor. It was not always possible to do this, but builders offer three options for solving this problem.

- The sewer riser is led outside the roof of the house. This is what they did a century ago, when the number of floors in buildings allowed this to be done.

- Boxes are installed on top of the risers in the attic, which in turn are connected to the ventilation shaft.

- The risers are led into the attic, and in it, in one or several places, pipes are brought out to the roof.

The second option has one drawback. There is a possibility that the volume of the box may not be enough to contain the simultaneous release of air from all sewer risers. Therefore, today the third option is most often adopted.

Ventilating a sewer riser using this method means increasing the riser in the attic by at least 1 m. At the same time, it is tilted towards the ventilation duct, which removes air from the attic itself. Plus, you have to take into account the diameter of the pipes used for the ventilation system. Their minimum size should be 140 mm. That is, these are the requirements that guarantee that sewerage ventilation will work in apartments on the top floor.

True, it should also be noted that if there are partitions with openings or doors inside the attic, this impairs the operation of the system. Due to the openings, drafts may occur, which weaken the movement of air towards the ventilation duct. This is why it is so important to keep attics locked and controlled by those living in upper apartments.

Possible elements of an autonomous system

There are several types of tanks for collecting liquid waste: absorbent, i.e. with an earthen bottom, sealed pits and septic tanks.

Absorbing

The most common ones are those that have as simple a design as possible - earthen pits, or actually bottomless pits. These tanks are cheaper, but they are the worst possible option. A mini-pit is dug into the ground, which is then gradually filled with wastewater. This allows dangerous liquid components to easily penetrate the soil, contaminating it, and this “fire radius” can be quite wide. Solid particles gradually sink to the bottom, where they are compacted into a heavy mass. Once the quarry is filled with wastewater, it is filled back in and new natural reservoirs are prepared.

Sealed

This option is much better for the environment. After excavating the soil, a concrete or metal (“light version” - made of plastic) container is placed in it, which completely prevents the possible leakage of harmful substances directly into the ground. There are no objections to these designs: they are reliable and hygienic. However, many are not satisfied with the fact that specialized equipment is needed to install such an ecological septic tank. Another “minus” is the regular cleaning of holes using a slurry machine.

Septic tanks

They are perfect. This is a plastic, completely sealed container. Its advantage over a septic tank is partial disinfection and wastewater treatment. Bacteria are added to the liquid substance, which accelerates the decomposition of solid substances. As a result, the water is purified by 50-60%. Filters are used to further purify the liquid. These structures, consisting of 2-3 containers, are often made themselves: for example, from concrete discs or bricks.

Any type of septic tank requires a ventilation system. Industrial septic tanks can be equipped with it. When constructing a ventilation system, the materials of the tanks, the characteristics of the structure, its location on the site and its depth are taken into account.

What is it used for?

At the point where the toilet and waste water drainage pipelines are connected to the sewer riser, there are water plugs or a water seal. This device prevents the smell from the sewer from entering the room. When water is drained into the riser, it moves sharply downward, creating a vacuum in the system, which causes the water plug to come off.

The drainage pipe for sewerage facilitates the rapid flow of air into the pressure reduction zone, which eliminates the possibility of water being sucked out of the hydraulic seals. The installation of such an element maintains constant pressure inside the system, prevents breakage of shut-off valves, blockage in pipes, stagnation of liquid waste and the possibility of its back penetration into the sewer.