What are pellets?

Pellets

are a granular type of solid fuel, cylindrical in shape, made from compressed waste from agricultural production and the woodworking industry. The main materials for the manufacture of fuel pellets are:

- sawdust, wood chips, bark, slabs of coniferous and deciduous (the best option) wood species;

- peat;

- sunflower husks (the most common solution), rapeseed (the best option), straw of various grain crops, corn, husks, cake and much more;

- charcoal;

- household waste.

The base binder is a substance of plant origin - lignin, a natural polymer contained in almost any plant, capable of being plasticized during granulation under the influence of a sufficiently high operating temperature.

Comparative characteristics of fuel types

First, about the price of energy resources. The table shows the cost of fuel at Moscow prices:

| Raw materials for pellets | Cost from 20 tons with shipment from warehouse | Price from 1 ton with shipment from warehouse |

| Sunflower husk pellets | From $50 (3300 rub.) per 1 ton | From $70 (4500 rub.) per 1 ton |

| Wood light pellets from 6 mm | From $100 (6500 rub.) per 1 ton | From $105 (6800 rub.) per 1 ton |

| Wood light pellets from 8 mm | From $95 (6000 rub.) per 1 ton | From $100 (6500 rub.) per 1 ton |

| Birch briquettes | From $90 (5800 rub.) per 1 ton | From $95 (6000 rub.) per 1 ton. |

Comparative characteristics of fuel costs:

The use of granular energy carriers is noticeably more profitable than the use of traditional types of raw materials. However, the costs of maintaining the equipment will be higher, but this figure is offset by savings when purchasing briquetted raw materials.

Pellet classification

The main regulatory document predetermining the production of pellets is the European Union standard EN 14961-2, adopted in January 2011, on its basis an international quality certificate EN Plus is issued. There are three classes of granular fuel:

- ENPlus-A1 – best premium quality, diameter up to 8.00 mm, ash content up to 0.70%, another name is “white granules”;

- ENPlus-A2 – with ash content up to 1.50%, also called industrial granules, can consist of mixed wood species;

- EN-B – standard quality, with ash content up to 3.00%, an alternative name for agropellets.

In terms of cost, the most expensive pellets are ENPlus-A1 class, the cheapest are EN-B class, it is better not to take substandard fuel.

Selection rules

Alas, not every manufacturer supplies good quality products to the consumer. Next - about the types of fuel and how to determine the quality of pellets by appearance.

Pellets consist of sawdust, shavings, and may include straw, peat, and seed shells.

In the Russian Federation, fuel standardization is poorly developed, so low-quality products are, unfortunately, quite common.

Typically, fuel is supplied in bags (packages) from 5 to 25 kg. It’s good if you can look inside and assess the condition of the granules. Some recommendations for choosing fuel:

- the less dust, fines, broken granules, the better;

- the color of high-quality pellets is brown or slightly lighter;

- the dark color of the fuel is a sign of a high concentration of bark, which impedes combustion;

- the lighter the granules, the more chemical impurities they contain.

The main criterion for classifying fuel by quality is moisture. There are three classes:

- first (minimum humidity, heat transfer up to 95%, high cost);

- second (intermediate option in terms of price and quality);

- third (the fuel is noticeably moist, smokes heavily, leaves a lot of ash, and is cheap).

The cost of pellets of classes I and III differs by 20-30%.

Typically, pellets are supplied in bags (packages) from 5 to 25 kg. It’s good if you can look inside and assess the condition of the granules.

Basic parameters of pellets

Pellets for heating are granules of white or shades of brown, with a length from 10.00 to 30.00 mm, a diameter of 6.00 and 8.00 mm, less common fuel with a diameter of 10.00 mm, the maximum diameter of the granules is 25.00 mm. The darkening of pellets is associated with the presence in the structure of the material of various non-combustible residues (dust, earth, and a number of others).

The main parameters of pellets are:

- ash content (the lower, the better and the less ash, so the boiler will have to be cleaned much less often);

- humidity;

- calorific value (ENPlus-A1 – 18.0 MJ/kg, ENPlus-A2 – 18.0 MJ/kg, EN-B – 15.0 MJ/kg).

- total length;

- degree of density;

- diameter;

- bulk mass;

- abrasion class.

Maintenance

Heating a home using pellet boilers requires little maintenance.

They usually have an open heating system, so you need to monitor the water level in the system. You can automatically supply water replenishment to the heating system. The boiler itself must be cleaned of soot, especially the heat exchanger jacket, as this affects the consumption of pellets. Smoke exhaust pipes need to be cleaned. This does not take much time, and the moment when cleaning is necessary can be determined visually by looking at the water jacket, or if the consumption of pellets has increased. The deadline is when the boiler begins to smoke into the room.

If pellets are supplied using a rigid auger, then it is necessary to periodically clean this system from dust that accumulates in the air supply channels.

Pellet manufacturing technology

The production of pellets consists of pressing waste that has been previously dried to a certain moisture content and crushed to a given fraction under a pressure of about 300 atmospheres. At the same time, the use of glue and other additives is prohibited (sometimes unscrupulous businessmen add sand and other non-combustible impurities to them to increase the weight of the granules, and synthetic polymers to ensure adhesive properties).

Main stages of pellet production:

- Grinding. The raw material enters the crusher and is crushed to a given fraction;

- Drying. The resulting raw material is dried to the moisture percentage specified by the technology (about 10% plus or minus 2%);

- Pressing. The dried raw material enters a press granulator, in which it is pressed into granules of a given length and diameter. As a result of compression, friction, and adiabatic processes, the temperature can reach 100°C Celsius, as a result, thermal energy is generated that softens lignin and the particles stick together into granules. This process is called pelletization;

- Cooling. To ensure the strength of the fuel granules, the pellets are cooled after pressing;

- Packing and sending to the consumer.

In some cases, water treatment and additional grinding are performed before pressing; everything directly depends on the type and quality of the raw materials from which the granules are made. Pressing is carried out in molds, ring-type dies using rotary rollers (rollers), which press the raw material into cone-shaped dies located on the matrix. On the other hand, the resulting granules are cut with special knives. After cooling, the pellets are sieved and small particles are sent for recycling. Closed cycle technology is virtually waste-free; only non-combustible impurities are removed. In order to make one ton of pellets, three to five cubes of wood waste are needed. The raw material is compacted approximately three times. To prepare one ton of pellets you need from 30.00 to 50.00 kW per hour.

Pellet boilers and fireplaces

Special equipment is produced for the combustion of granular briquettes; it is not recommended to burn fuel in conventional solid fuel boilers. Pellet boilers, like fireplaces, have their own characteristics and characteristics.

Fireplaces for burning pellets

They are used as an additional heating source for rooms with an area of no more than 25 m2.

The average power level is 6-15 kW, fireplaces differ:

- convection type, heating the air;

- supplemented with a DHW circuit, they heat the air and serve to distribute hot water;

- combined (universal) for heating water and air.

Advice! When choosing a combined fireplace, the owner can heat it not only with pellets, but also with wood, briquetted fuel of various types.

Solid fuel pellet boilers

These are pellet heating systems with a power of up to 100 kW, which can be installed in large houses equipped with water mains or underfloor heating circuits. Due to the high flammability of pellets, boilers are installed in a basement or a separate room - the boiler room must be equipped in accordance with safety requirements.

The thermal efficiency of boilers depends on the type of equipment; there are also devices on sale that can burn only granular fuel, firewood and briquettes, and universal units that burn any type of fuel.

Advice! All parameters of boilers are indicated in the technical data sheet of the device; universal types of equipment with a circuit for DHW distribution are more expensive, but are considered more economical and profitable.

Operating principle and design of pellet combustion boilers

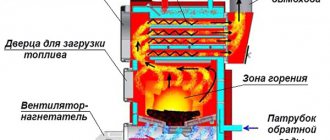

The difference between pellet boilers and standard solid fuel boilers is the small size of the combustion chamber. Reduced volumes are needed because all processes take place in the convection compartment of the equipment.

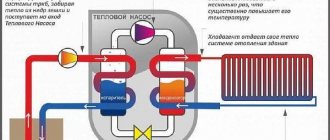

The principle of operation is standard - a special type of burner with increased efficiency ignites the fuel, during the combustion process heat is released, which warms up the water, the coolant is sent to heating appliances and pipes in the house, giving off energy to the air.

On a note! Pellet boilers last at least 20 years and are always equipped with an automatic control system that can completely eliminate human intervention. Boilers with a power of 20-100 kW are suitable for home systems; if you need less heat, it is more profitable to install a fireplace.

To calculate the boiler power rate, the formula is used for 10 m2 of area 1 kW of heat plus 15%. The additional reserve may be greater if the house is located in regions with a harsh climate, is not insufficiently insulated, or has large windows. Fireplaces with a power of 15 kW are used for heating houses up to 100 m2 only when the heating system circuit is connected. But most often, for houses from 25 m2, boilers are used, fireplaces are used for local heating of rooms or as an alternative heat source with the possibility of distributing hot water.

Types and production of pressed fuel briquettes from peat

Necessary machines for the production of pellets

Equipment for the production of sawdust pellets includes:

- crushers (chopping machines) for grinding the raw materials used to a given fraction;

- dryers to ensure the required percentage of humidity of the initial, base raw materials;

- hammer mills (in some cases they are replaced by flaring machines, disintegrators, everything depends directly on the characteristics of the feedstock), make it possible to obtain raw materials with a fraction of up to 4.00 mm;

- screw mixers (used when using overdried raw materials with a moisture content of less than 8.00%, by dosed supply of steam or water);

- presses (differ in the type of matrix used, which can be flat or round).

Dryers, in turn, are divided into:

- principle of operation (can be drum or belt (cost more, but are more productive and safer to use));

- drying technologies (using flue gases, water vapor or hot air);

- the fuel used (gas, wood waste, coal, etc.).

To burn pellets, special equipment is used - a pellet boiler.

.

The optimal solution in terms of price/quality/performance ratio on the Russian market is heating appliances from the Polish manufacturer Metal-Fach, including boilers from the SD DUO

,

SD DUO BIO

,

SMART

,

SMART EKO

,

SEG, SEG BIO

.

They have a steel heat exchanger (P265GH steel with a thickness of 4.00 to 6.00 mm is used for production), an efficiency of over 90%, an innovative, modern type controller FL 310LGRTC

, with continuous logic and PID control, as well as an upper combustion chamber and a retort type burner.

Also worthy offers are:

- domestic boilers created in Krasnoyarsk, ZOTA

Pellet

series ; - joint development of the Russian-Polish company Vulkan

, the

EKO

; - pellet boilers from the legendary Italian company FACI

Caldaie,

FACI SSL/SSP

.

You can purchase pellet boilers in a wide range, get the necessary advice, order installation, warranty and post-warranty service in Krasnoyarsk from the Kras-Kotel company.

Rating of quality pellets for heating 2021

Starting price category

Fuel pellets 2021 (oak)

As the name suggests, the fuel presented here is from a foreign manufacturer (Poland), based on oak wood. A distinctive feature of the product is its quality, the absence of third-party hazardous fractions, and a small release of waste after burning. The environmental friendliness of the product expands its possible applications. This makes it possible to heat a private home, heat a bathhouse, or use it as cat litter. The relatively low price, considering imported products, is considered a plus. Therefore, if the selection criteria are the optimal price-quality ratio, you should pay attention to Fuel pellets 2021 (oak).

Fuel pellets 2021 (oak)

Advantages:

- Wide functionality;

- Compliance with European environmental standards;

- Quality of composition;

- Heat dissipation.

Flaws:

- No.

Gardener's Empire (conifers)

By producing this fuel, the manufacturing company managed to achieve a high density of fractions, as a result of which the combustion process occurs slowly, measuredly, with high heat transfer. Coniferous wood is usually used to make furniture, and the waste is thrown away. Since they are not suitable for smoking products or frying over an open fire, being saturated with a large amount of resins. Therefore, the price of pine chips is quite low. Accordingly, the maximum cost of a package weighing 15 kilograms is 300 rubles. However, the spread of coniferous briquettes is limited by the high resin content. Therefore, “Gardener’s Empire” is suitable only for specialized heating systems designed for coniferous raw materials.

Gardener's Empire (conifers)

Advantages:

- Dense structure simplifies storage and transportation;

- Two types of packaging: 15, 30 kilograms;

- Burns out slowly;

- Good heat dissipation;

- The most inexpensive granules;

- No toxicity.

Flaws:

- Afraid of moisture.

Kuzmich 24 (pine)

The rating of inexpensive products is completed by a brand that occupies a mid-price position between the two brands mentioned above. It is more expensive than domestic analogs, being cheaper than the cheapest imported options. Using pine as a base, the fuel cylinders are the same size, structure, white in color with small inclusions. This indicates the quality of the product, worthy of the heat dissipation of the material, earning the best user reviews. Kuzmich 24 can be used for almost all types of solid fuel heating systems, baths, and fireplaces.

Kuzmich 24 (pine)

Advantages:

- Pressing quality;

- Price;

- Decent heat dissipation;

- No toxicity.

Flaws:

- Packed in 25 kilograms only.

Average price category

Wood technologies

When creating the presented fuel, the manufacturing company takes as a basis the material of trees, both coniferous and deciduous. Moreover, the manufacturer’s size varies from 6 to 10 millimeters, thereby allowing it to be used for different boiler room loading systems. Thanks to the combination of tree species, the resulting granulate has an ash content of about 0.5%, is not afraid of moisture and stress, facilitating transportation and storage.

Wood technology pellets

Advantages:

- Variety of packaging, sizes;

- Unpretentious to storage conditions;

- Ash percentage after combustion.

Flaws:

- Low heat transfer for this segment.

Gardener's Empire (hay)

The advantage of the Gardener's Empire is its versatility, which allows the presented product to be used as bedding, food for farm animals and some domestic animals, and fertilizer in gardening. The hay base burns long enough, as a result of which it can be used as a fuel corresponding to its status.

Gardener's Empire (hay)

Advantages:

- No toxic impurities;

- Multifunctionality of application;

- Decent burn time.

Flaws:

- Increased sensitivity to moisture.

Grillkoff Pellets (aspen, spruce, pine)

The vast majority of product components consist of coniferous waste, including tree bark, which determines the performance properties. Thus, the composition has an affordable price category, a specific smell (suitable for pine needle lovers), and a wide range of applications for private use for industrial purposes. The latter is possible thanks to packaging bags weighing 30 kilograms. For example, if a user is wondering which is the best cat litter to buy, then Grillkoff would be a good option. After all, 30 kilograms of jelly beans will last a long time, and the smell of pine needles will overpower the amber. Considering the price, about 600 rubles, the product is of interest to those who care about how much the filler costs.

Grillkoff Pellets (aspen, spruce, pine)

Advantages:

- Packaging size;

- Price;

- No toxic impurities.

Flaws:

- The smell of pine needles is not for everyone.

Highest price category

Mesquite BROIL KING

Reading the description of the products listed above, you can notice a purely economic predisposition - heating, filling cat litter, use as fertilizer. However, cooking food, grilling, barbecuing is impossible or not recommended. BROIL KING mesquite allows you to cook over an open fire without fear, because the company’s products have undergone strict environmental control. Moreover, Mesquite BROIL KING is not afraid of humidity, which is convenient when organizing picnics or grilling in an open kitchen. An undoubted advantage of BROIL KING Mesquite will be the spicy aroma it emits, which can give the prepared dishes a special taste.

Mesquite BROIL KING

Advantages:

- High environmental production standards;

- Multifunctional application.

Flaws:

- Price.

WEBER Hickory 190102

New products on the multifunctional pellet market are granules that have a pleasant pecan aroma. When preparing shish kebab or barbecue, WEBER Hickory 190102 will imbue dishes with an unobtrusive nutty aroma. It will be pleasant if you use pellets to heat a fireplace or open hearth. The European manufacturer guarantees compliance with quality standards and environmental friendliness, which justifies the cost of fuel.

WEBER Hickory 190102

Advantages:

- Pleasant pecan aroma;

- High environmental production standards;

- Multifunctional application.

Flaws:

- The packaging is opaque, it is impossible to judge the integrity of the granules.

Oklahoma Joe's

As the name implies, American-made pellets, which consist of a blend of sawdust from different tree species. The blend is based on cherry, maple and hickory. Accordingly, Oklahoma Joe's is used as fuel, grill ignition, barbecue, and even for smoking food. Moreover, smoking is more comfortable compared to using regular wood or gas. After all, Oklahoma Joe's energy efficiency is 5500 kW. This range of possibilities and product characteristics somewhat justify the price of about 2,000 rubles for a medium-sized package.

Oklahoma Joe's

Advantages:

- Wide functionality;

- Workmanship.

Flaws:

- Price;

- The packaging is opaque, it is impossible to judge the integrity of the granules.

How to distinguish high, premium quality pellets from substandard fuel?

When purchasing pellets, you need to pay attention to:

- the surface of the material must be smooth, shiny, without signs of deformation (swelling and microcracks);

- diameter (this parameter is established by the standards, the minimum value is 4.00 mm, the maximum is 10 mm, also standard are fuel pellets that have a diameter of 6.00 and 8.00 mm, please note that a pellet boiler operates on pellets of a certain fraction);

- length (this parameter should be about 20.00 - 30.00 mm, this is the optimal value, although the equipment can work on pellets with a length of over 50.00 mm);

- smell (the granules should have a slightly sweet smell of freshly prepared glue, this is a clear sign of excellent quality);

- color (it is important to remember that the highest quality pellets are white or slightly cream-colored, agropellets are predominantly dark, and in wood pellets, dark color indicates that bark, other impurities have been added, or wood species have been mixed);

- dust (there should be a minimum amount of dust on pellets, so it is better to buy fuel in sealed packaging);

- impurities (the presence of non-combustible impurities in the granules themselves can only be checked by burning them and determining the residue in the form of solid particles).

Rules for selecting and determining the quality of granular energy carriers

The quality of the pellets affects the cost of pellets; on average, pine fuel is estimated at $90 (6,200 rubles) per 1 ton, peat briquetted pellets from $85 (5,700 rubles) per thousand kilograms. Also, the cost may depend on the prevalence and availability of a particular raw material, but on average the difference does not amount to more than 500 rubles.

Selecting quality raw materials is the main task of the owner. The better the granular fuel, the higher the functionality of the heating system and all equipment.

To distinguish good fuel from bad, you need to pay attention to some nuances:

- Presence of dust. If there is a lot of dust in a bag of pellets, the pellets are overdried, so they crumble and crumble - this is a minus. Chips, defects and dents on briquettes also indicate poor quality of the product.

- Uneven color. The shade should be uniform without obvious areas of lightening or darkening. If the granules have taken on a gray tint, are swollen or cracked, they have been lying around for a long time and have lost some of their beneficial properties.

- Size. European standard length 25 mm. Small deviations in the direction of increase and decrease are allowed; this does not affect the overall quality of combustion.

- Smell. The fuel must have the aroma of raw materials with a hint of sweetness, which appears during the drying and processing process. The smells of rot, burning, chemicals are a minus.

You can check the purity of the raw materials just by smell - sunflower pellets smell like oil, wood - sawdust, peat - smoke.

Advantages and disadvantages of solid fuel in the form of fuel pellets

The main advantages of pellets:

- environmental cleanliness (when burning this type of solid fuel, carbon dioxide is released in volumes equal to the volumes formed during the natural decomposition of various wood wastes);

- fire safety (pellets are less susceptible to spontaneous combustion than other types of solid fuel);

- optimal humidity (8-10% versus 30-50% for logs) and density (one and a half times higher than that of firewood);

- remarkable calorific value, one ton of fuel pellets is enough to produce 3500 kW/h of thermal energy;

- constant and very high bulk density, which facilitates logistics, loading and transportation of pellets;

- the uniformity of the structure in shape and size makes it possible to automate all processes of loading and loading and combustion of fuel pellets in boilers.

Cons of pellets:

- high cost of solid fuel at the present stage;

- to burn pellets you need a special pellet boiler equipped with automation, which also costs more;

- the volume of supply on the market is low, the situation will improve over time, but pellets must be purchased in reserve and stored in warehouses, preventing excess moisture from entering.

Conditions of storage and use

When purchasing a large batch of pellets, you need to take care of where they are stored. When stored indoors, they should not be placed near open sources of fire. It is also necessary to protect the material from its worst enemy - dampness.

How to store pellets if there is no space in the house? Closed bags/packages can be placed outside under a canopy. However, this option is undesirable - when it rains, the risk of the packaging getting wet and irreversible damage to the fuel increases.

A few words about how to properly heat a solid fuel boiler with pellets. This requires a burner, which can be purchased separately and installed on the boiler literally within half an hour. The operation of such a tandem is extremely simple - the user will need to fill the hopper with fresh pellets from time to time and clean out the ash. The temperature balance is controlled using the control panel.

Fuel pellets are an economical, affordable, efficient solid fuel. And, although the cost of a special pellet burner is quite high, within no more than 1 year the investment in the equipment will fully pay off.

Pellet cost

Let's take the initial data:

- the average cost of industrial pellets in the Krasnoyarsk Territory as of December 2015 is 3,500 rubles per ton (3.50 per kilogram);

- the price of birch firewood is 1,300 rubles per cubic meter, in terms of tons (a cubic meter of dry birch firewood equals 650 kg of weight) is 1,846 rubles per ton (1.85 rubles per kilogram);

- the calorific value of birch firewood is 10 MJ/kg;

- The calorific value of wood industrial pellets is 18 MJ/kg.

In order to obtain 100 MJ of thermal energy, you need 10 kg of firewood (100/10), that is, 18.50 rubles, or 5.5 kg of pellets (100/18), that is, 19.44 rubles. The difference in cost is 1 ruble per 100 MJ. Moreover, it is necessary to note the undoubted advantages of pellets with an ash content of 1.5% over firewood with an ash content of 10%, the difference is obvious. It should be taken into account that the pellet market is growing dynamically, and with an increase in supply, the price will undoubtedly decrease. By the way, pellets can be made independently from agricultural or wood waste. Read below how.

Instead of an epilogue

An analysis of the Russian market for the goods in question has established that the middle and budget segments are completely occupied by domestic producers. However, such a product has a single and direct purpose - heating only. At the same time, reasonable prices and variability of supply indicate sufficient quality of products. The premium segment, as a rule, is entirely represented by foreign (primarily European and transatlantic manufacturers), is characterized by a high level of environmental friendliness and can be used in various fields. It is worth mentioning that the price of such quality and multitasking is very high, so the Russian consumer is unlikely to purchase premium samples for heating. They are ideal for grilling and other outdoor cooking tasks. In addition, it should be noted that the market for the goods in question in Russia is just beginning to develop and there is hope that domestic companies will soon begin producing multi-tasking granulates, and the prices for them will not be greatly inflated.

We make pellets with our own hands

You can make pellets with your own hands. To do this we need to assemble a granulator. It is necessary to take wood or agricultural waste, grind it to a particle fraction of 30.00-50.00 mm, dry it to a moisture content of 15.00%, grind it to particles with a fraction of 2.00 mm and place it in a granulator. In the case when you use agricultural waste, such as sunflower husks, rapeseed or sawdust, as the initial, basic raw material, you do not need to crush anything. But if branches, bark, or various substandard lumber are used, it is necessary to crush, although the use of a granulator allows you to omit this operation. The dryer is made from an ordinary metal barrel. It is better to use a granulator with a flat matrix (a cylindrical matrix in the shape of a perforated drum is a more complex solution) and a perforated disk with outlet holes in the shape of a cone with a diameter of 8.00-10.00 mm, this is the optimal solution. You need to buy a matrix and rollers (the production of spare parts is carried out by manufacturers of equipment for the production of animal feed). The matrix is also made independently, from steel with a thickness of at least 20.00 mm, and gears are used as rollers. You will also need a gearbox and an electric motor with a power equal to or greater than 15.00 kW. It is necessary to ensure rotation in the range of 60-120 revolutions per minute. The shaft can be installed both horizontally and vertically; the main thing is to make tanks for loading the raw materials and subsequent unloading of pellets.

Stages of making pellets:

- we take or make a matrix, make a hole in the center for the gearbox and always a groove intended for landing;

- gears (rollers can be used, the width of which must match the width of the working surface of the matrix used), are put on the shaft strictly perpendicular to the axis of the installed gearbox shaft using a conventional coupling;

- the cylindrical body is welded from sheet steel or steel pipe, taking into account the dimensions of the matrix, which should rotate easily and freely, providing holes for unloading pellets and a tray also made of sheet steel or steel pipe, the bottom and top of the structure can be made detachable to facilitate maintenance;

- the output shaft of the selected gearbox is strengthened in the lower part of the machine using a coupling and always bearings;

- the matrix, as well as the rollers, are installed in a cylindrical body;

- the resulting structure is mounted on a frame made of a channel or an ordinary angle and is rigidly fastened; all that remains is to install the engine and connect the output shaft to the installed gearbox.

The future belongs to pellets and pellet boilers. Kras-Kotel specialists will help you make the right choice of pellet boiler, taking into account all your wishes and the characteristics of your home.

Share on social media networks:

How to calculate pellet consumption

The calculation is carried out in several stages, although in general it is quite simple. Its result should be the average monthly fuel consumption of a pellet boiler during the heating season and the average cost of such heating. To do this, we will simultaneously consider an example for a house with an area of 100 m².

Stage one. First you need to understand how much heat actually enters the heating system when burning 1 kg of fuel pellets. After all, heating equipment is not so perfect as to direct all the energy received to heat the house; some of it still flies out into the chimney. To do this, the combustion heat of the granules should be multiplied by the efficiency of the heat generator, divided by 100:

5 kW/kg x 80% / 100 = 4 kW/kg.

Stage two. For ease of calculation, you need to do the opposite to find out how many pellets you need to burn to obtain 1 kW of thermal energy in real conditions:

1 kW / 4 kW/kg = 0.25 kg.

Stage three. Since the weather outside changes during the heating season and the temperature fluctuates from +10 °C to -30 °C, the average specific heat consumption for the entire season for a 100 m² dwelling will not be 10 kW, but half as much - 5 kW. Considering that power units are assigned to a time of 1 hour, the heat consumption per day will be:

5 kW/h x 24 hours = 120 kW.

The same, only for a month:

120 kW x 30 days = 3600 kW.

Stage four. Now it is easy to calculate the average consumption of pellets per month for a building of 100 m² during the entire heating season:

3600 kW x 0.25 kg/kW = 900 kg.

If the cold season lasts 7 months, as in Moscow, Russian Federation, then the total amount of fuel pellets for heating a private house with an area of 100 square meters will be 900 x 7 = 6.3 tons. The average monthly consumption of pellets for a house with an area of 150 and 200 m² is determined in the same way; it is equal to 1.35 and 1.8 tons, respectively. Since pellets are sold by weight and not by volume, there is no need to convert this quantity into volumetric units.

Those who are interested in the theoretical value of wood pellet consumption on average per day can calculate it in this way (for our example):

120 kW x 0.25 kg/kW = 30 kg.

Attention! The average calculated value should not be confused with actual fuel consumption on the coldest and warmest days. In a building of 100 m² it can vary between 15-60 kg of pellets per day

To get approximate costs for pellet heating in monetary terms, you need to multiply the obtained figures by the price per ton accepted in your region. At prices in the capitals of the Russian Federation and Ukraine, monthly heating costs for a private house of 100 square meters will be:

- for Moscow: 0.9 t x 7000 rub/t = 6300 rub;

- for Kyiv: 0.9 t x 2000 UAH/t = 1800 UAH.

It should be taken into account that we carried out an abstract calculation and in the conditions of Ukraine, financial costs for pellet heating will be less due to the milder climate.

Some pros and cons

- Combustion is supported by pellets, a fairly inexpensive type of fuel.

- They have a high level of efficiency, which brings their characteristics closer to gas boilers.

- Fuel is supplied to the burner and the temperature is maintained automatically.

- Storing pellets is not difficult, since they are packaged in bags (often thirty kilograms each) and only need a dry room.

- When burned, they leave behind small amounts of environmentally friendly ash.

- The pellet appliance provides the house with both hot water and a comfortable, constant temperature regime.

- They have a smart control system; some system models are designed for remote control.

- Pellet equipment for autonomous home heating is safe and does not require registration with regulatory authorities.

When deciding to buy a good pellet boiler, it is worth paying attention to some disadvantages

- Installation and connection to the home heating system must be carried out by qualified specialists.

- Pellet production is not yet well organized, which may result in fuel shortages.

Pallet boiler