The comfort of people staying indoors, especially in the winter, largely depends on the temperature of the air around them. Therefore, among the utilities installed in residential premises, the heating system takes first place. In urban environments, issues of heating apartments are most often resolved centrally, but in private buildings their owners have to install autonomous heating systems, the main element of which is a hot water boiler. The efficiency of the entire system depends on the technical and economic characteristics of the latter.

VALTEC.PRG.3.1.3. Program for thermal and hydraulic calculations

The VALTEC.PRG program is publicly available and makes it possible to calculate water radiator, floor and wall heating, determine the heat demand of premises, the required flow of cold and hot water, the volume of sewage, and obtain hydraulic calculations of the internal heating and water supply networks of the facility. In addition, the user has a conveniently arranged selection of reference materials at his disposal. Thanks to its clear interface, you can master the program even without having the qualifications of a design engineer. The program meets the requirements of Russian regulatory documents governing the design and installation of engineering systems (certificate of conformity).

- Difference between version 3.1.3 and version 3.1.2:

- added module for calculating pipe capacity;

- amendments have been made to the module for calculating water demand according to SNiP - it is possible to continue the calculation if the probability is more than one (insufficient number of devices);

- the “Pipes” reference table has been expanded;

- The User's Guide has been updated.

Training videos:

Calculation of heat loss of a cottage. Part 1 Calculation of heat loss in a cottage. Part 2 Calculation of underfloor heating Part 1 Calculation of underfloor heating Part 2

Varieties of boiler models

Boilers can be divided into two types depending on the purpose of application:

- Single-circuit – used only for heating;

- Double-circuit – used for heating, as well as in hot water supply systems.

Units with one circuit have a simple structure, consisting of a burner and a single heat exchanger.

Single-circuit wall-mounted gas boiler Source ideahome.pp.ua

In dual-circuit systems, the water heating function is primarily provided. When using hot water, the heating is automatically turned off while hot water is being used so that the system is not overloaded. The advantage of a dual-circuit system is its compactness. Such a heating complex takes up much less space than if the hot water supply and heating systems were used separately.

Boiler models are often divided by placement method.

Depending on their type, boilers can be installed in different ways. You can choose a wall-mounted or floor-mounted model. It all depends on the preferences of the owner of the house, the capacity and functionality of the room in which the boiler will be located. The installation method of the boiler is also affected by its power. For example, floor-standing boilers have more power compared to wall-mounted models.

In addition to fundamental differences in purpose of use and placement methods, gas boilers also differ in control methods. There are models with electronic and mechanical control. Electronic systems can only operate in homes with constant access to the power grid.

Double-circuit gas boiler with indirect heating boiler Source norogum.am

See also: Catalog of companies that specialize in home insulation services.

Valtec “Sputnik” software package

The Valtec “Sputnik” software package is intended for use in the housing and communal services sector (management companies, homeowners' associations) and industry. The intuitive interface makes it easy for users to quickly learn. A number of special reports for management companies (homeowners associations, resource supply organizations) and integration with accounting programs (1C) make it easy to generate payment receipts. The control center includes reports that allow you to track emergency situations, unauthorized access to resources, and requests from subscribers from your personal account.

Integration into the Housing and Public Utilities GIS has been introduced to simplify reporting in organizations.

- Main features:

- Collection of readings from metering devices, event sensors, remote resource limitation

- Online emergency monitoring

- Data storage

- Generating special reports

- Integration with related software products used in the organization’s business processes (1C, video surveillance, POS, etc.)

- Open API

- Recommendations for saving resources

To familiarize yourself with the program's capabilities: Login: demo Password: demo

In the case of a comprehensive supply of metering devices and dispatch systems, a license file that allows you to fully work with the program is issued free of charge. The server is formed on the customer's side.

As an additional paid service, it is possible to use a Valtec remote cloud server.

For commissioning, commissioning of a facility or testing of dispatch system equipment, a free test license file valid for 1 month is provided.

For details on obtaining a test license, please contact the managers working in your region.

Typical device power calculations

There is no single algorithm for calculating both single- and double-circuit boilers - each system must be selected separately.

Formula for a typical project

When calculating the required power for heating a house built according to a standard design, that is, with a room height of no more than 3 meters, the volume of the premises is not taken into account, and the power indicator is calculated as follows:

- Determine the specific thermal power: Um = 1 kW/10 m2;

- Next, calculate the required power to heat the house.

Rm = Mind * P * Kr, where

P – a value equal to the sum of the areas of heated premises,

Kr is a correction factor that is taken in accordance with the climatic zone in which the building is located.

Some coefficient values for different regions of Russia:

- Southern – 0.9;

- Located in the middle zone – 1.2;

- Northern – 2.0.

- For the Moscow region, a coefficient value of 1.5 is taken.

This technique does not reflect the main factors influencing the microclimate in the house, and only approximately shows how to calculate the power of a gas boiler for a private home.

Some manufacturers issue recommendations, but for accurate calculations they still recommend contacting specialists Source parki48.ru

Example calculation for a single-circuit device installed in a room with an area of 100 m2, located in the Moscow region:

Рм = 1/10 * 100 * 1.5 = 15 (kW)

Calculations for dual-circuit devices

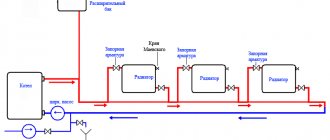

Double-circuit devices have the following operating principle. For heating, water is heated and supplied through the heating system to radiators, which release heat to the environment, thereby heating the rooms and cooling them. When cooling, the water flows back to be heated. Thus, water circulates along the heating system circuit, and goes through heating cycles and transfer to the radiators. At the moment when the ambient temperature becomes equal to the set one, the boiler goes into standby mode for some time, i.e. Temporarily stops heating the water, then starts heating again.

For domestic needs, the boiler heats water and supplies it to the taps, and not to the heating system.

Double-circuit heating system Source idn37.ru

When calculating the power of a device with two circuits, another 20% of the calculated value is usually added to the resulting power.

An example of calculation for a two-circuit device that is installed in a room with an area of 100 m2; the coefficient is taken for the Moscow region:

- Рм = 1/10 * 100 * 1.5 = 15 (kW)

- Ritogovaya = 15 + 15*20% = 18 (kW)

VALTEC CO 3.8. Heating system design software

VALTEC CO is a calculation and graphic program for designing radiator and underfloor heating systems using VALTEC equipment, developed by the Polish company SANKOM Sp. z oo based on the latest version of the Audytor CO program – 3.8. The product allows you to design and regulate heating systems, and perform a full range of hydraulic and thermal calculations. The program is certified for compliance with the current construction standards of the Russian Federation and the requirements of the Voluntary Certification System of NP "ABOK" (

).

Heat loss accounting

Without taking into account heat loss, it is difficult to correctly calculate the boiler power

. When starting to develop an autonomous heating system, you must first find out how much heat is lost to the street during the most severe frosts through the so-called enclosing structures. These include walls, windows, floors and roofs. Only after determining the amount of heat loss will it be possible to worry about selecting a heat source of appropriate power. It should be taken into account that the loss of heat from a building in the winter season occurs not only through the enclosing structures. A significant part of the generated heat (up to 30%) is spent on heating cold air coming from the street due to natural ventilation.

The total amount of heat required to heat the room is determined by the formula:

Q = Qdesign + Qair, where:

- Qconstruct – the amount of heat lost through a similar structure, W;

- Qair – the amount of heat consumed to heat the air coming from the street, W.

By summing up the values obtained as a result of calculations, the total heat load on the heating system of the entire building is determined.

All measurements are carried out on the outside of the building, necessarily taking into account its corners. Otherwise, the calculation of heat loss will be inaccurate.

There are other ways of heat leakage in rooms, for example, through a kitchen hood, open doors and windows, cracks in structures, etc. However, the amount of heat lost for these reasons practically does not exceed 5% of the total heat loss and is therefore not taken into account in calculations .

Calculation of heat loss through building envelopes

The complexity of the calculation lies in the fact that it must be carried out for each room separately, carefully inspecting, measuring and assessing the condition of each of its elements adjacent to the environment. Only in this case can you take into account all the heat leaving the house.

Based on the results of the measurements, the area S of each element of the enclosing structure is determined, which is then inserted into the basic formula for calculating the amount of lost thermal energy:

Qconstruct = 1/R*(Tv-Tn)*S*(1+Σβ), R = δ/λ; Where:

- R – thermal resistance of the construction material, m sq.°C/W;

- δ – thermal conductivity of the construction material, W/m°C);

- λ – thickness of the construction material, m;

- S – area of the external fence, sq. m.;

- Tb – indoor air temperature, °C;

- Tn – lowest air temperature in winter, °C;

- β – heat loss, which depends on the orientation of the building.

If the structure consists of several materials, for example, a brick wall with insulation, the value of thermal resistance R is calculated separately for each of these materials and then summed up.

Heat losses, depending on the orientation of the building, are selected based on where the enclosing element is oriented:

- to the north side – β = 0.1;

- to the west or southeast – β = 0.05;

- to the south or southwest – β = 0.

The calculation of heat losses through the elements of the building envelope is carried out for each room in the building, and then summing them up, the predicted value of the total heat losses in it is obtained. After this, they proceed to the calculation in the next room. As a result of the work carried out, the home owner will be able to identify ways of maximum heat leakage and eliminate the causes of their occurrence.

Calculation of heat consumed to heat ventilation air

The amount of heat that is spent on heating ventilation air reaches, in some cases, 30% of the total thermal energy losses. This is a fairly large value that is inappropriate to ignore. To calculate the amount of heat that will be forced to be spent on heating the supply air, the formula is used:

Qair = c*m* (Tv-Tn), where:

- c is the heat capacity of the air mixture, the value of which is 0.28 W/kg°C;

- m – mass flow of air entering the room from the street, kg.

The mass flow of air entering the room from the outside is determined by assuming that the air is renewed throughout the entire house once every hour. In this case, by adding up the volumes of all rooms, the volumetric air flow rate is obtained. Then, using the air density value, its volume is converted to mass. Here you need to take into account the fact that the density of air depends on its temperature.

| Supply air temperature ºС | — 25 | — 20 | — 15 | — 10 | -5 | 0 | + 5 | + 10 |

| Density, kg/m3 | 1,422 | 1,394 | 1,367 | 1,341 | 1,316 | 1,290 | 1,269 | 1,247 |

Substituting all known quantities into the above formula, the amount of heat required to heat the supply air is determined.

Common mistakes

Calculation of an autonomous heating system is a complex process consisting of several interrelated, step-by-step procedures:

- Calculation of heat losses of an object.

- Determination of the temperature regime of individual rooms and the building as a whole.

- Calculation of the power of heating radiator batteries.

- Hydraulic calculation of the heating system.

- Calculation of heating boiler power.

- Determination of the total volume of the autonomous heating system.

Thermal calculation of a heating system is not theoretical research, but an accurate and well-founded result, the practical implementation of which will allow you to correctly select all the necessary components and set up an effective heating system that functions without problems for many years.

The main mistake that many owners of private houses make is ignoring some stages of the calculation. They believe that to solve the problem it is enough to choose a more powerful boiler, focusing only on the data of the approximate calculation of its power based on the area of the room. This approach threatens with unnecessary operating costs and often leads to the fact that the boiler will work constantly, the radiator batteries will be hot, and the room will be cold. In this case, it is necessary to return to the original state and perform a full calculation of the heating system. Only after this can we begin to eliminate the shortcomings caused by critical errors in calculations.

VALTEC H2O 1.6. Software for designing water supply systems

VALTEC H2O is a program for designing cold and hot water supply systems using VALTEC plumbing engineering, developed by the Polish company SANKOM Sp. z oo based on the calculation and graphic program Audytor H2O 1.6. Allows you to perform a complete calculation and design of a hydraulically balanced water supply system. The program meets the requirements of the Voluntary Certification System of NP “ABOK” and SNiP 2.04.01-85* “Internal water supply and sewerage of buildings” ().

What happens if you incorrectly calculate the required power

It is still worth choosing a boiler so that it matches the power required to heat the building. This will be the best option, since first of all, purchasing a boiler that does not match the power level can lead to two types of problems:

- A low-power boiler will always work at the limit, trying to heat the room to the set temperature, and can quickly fail;

- A device with an excessively high power level costs more and, even in economy mode, consumes more gas than a less powerful device.

Valtec “Sputnik” equipment configurator

Configurator software is a modular configurator for various metering devices and equipment. Allows commissioning of the Valtec “Sputnik” automated energy metering system.

- The configurator includes the following modules:

- polling of metering devices via radio channel using radio modem VT.WRM.MASTER.0

- module for reading data from VT.WRM hubs

- module for configuring wireless pulse counter-recorder GSM/GPRS VT.WLR.GSM

- module for configuring a wireless pulse counter-recorder with a radio channel (LoRAWAN 868 MHz) VT.LR

- module for configuring pulse counter-recorder SIPU (RS485/M-Bus) VT.MB/ VT.RS

Advantages of using gas boilers

Gas equipment has a number of advantages and disadvantages. The advantages include:

- possibility of partial automation of the boiler operation process;

- unlike other energy sources, natural gas has a low cost;

- The devices do not require frequent maintenance.

The disadvantages of gas systems include the high risk of gas explosion, however, with proper storage of gas cylinders and timely maintenance, this risk is minimal.

VHM-T Service. Program for working with VALTEC heat meters

- The VHM-T Service program is designed to work with VALTEC VHM-T heat meters in terms of:

- reading current meter readings and characteristics;

- working with daily, monthly and annual archives;

- generation of thermal energy consumption accounting sheets;

- settings of date, time and automatic transition to summer/winter time (if necessary);

- counter settings for operation in automated data accounting systems.

Work computer software requirements

- operating system Windows XP Service Pack 3 (32/64 bit) or higher;

- Visual C++ Redistributable Packages for Visual Studio 2013 (free download available from microsoft.com). As a rule, these packages are already present in versions of Windows 7 and higher with the latest updates.

The interaction of the working computer with the heat meter is carried out through an optoelectronic sensor with the appropriate drivers installed in the system.

Setting up communication between the program and the meter

- Connect the optoelectronic sensor to the computer.

- On the front panel of the heat meter, press and hold the button (about 8 seconds) until the “=” symbol appears in the lower right corner of the screen.

- Bring the optoelectronic sensor to the opto-receiver of the meter on the front panel.

- Give a command to establish a connection in the program.

— Windows XP/Server 2003/Vista/7/8/8.1 (v6.7)

To activate the program, you must register again. The activation key is sent to the user's email address within 1-2 days.

If you have any questions about working with the program, you can ask them at:

Programs for old-style counters

Additional factors taken into account when installing the boiler

In construction, there is also the concept of energy efficiency of a building, that is, how much heat a building releases to the environment.

One of the indicators of heat transfer is the dissipation coefficient (Kp). This value is a constant, i.e. constant and does not change when calculating the level of heat transfer of structures made of the same materials.

It is necessary to take into account not only the power of the boiler, but also the possible heat loss of the building itself Source pechiudachi.ru

For calculations, a coefficient is taken, which, depending on the building, can be equal to different values and the use of which will help you understand how to calculate the power of a gas boiler for a home more accurately:

- The lowest level of heat transfer, corresponding to a K value from 0.6 to 0.9, is assigned to buildings made of modern materials, with insulated floors, walls and roofs;

- Kr is equal to from 1.0 to 1.9, if the external walls of the building are insulated and the roof is insulated;

- Kr is equal to from 2.0 to 2.9 in houses without insulation, for example, brick houses with single masonry;

- Kr is equal to from 3.0 to 4.0 in non-insulated rooms, in which the level of thermal insulation is low.

The level of heat loss Qt is calculated in accordance with the formula:

Q t = V * P t * k / 860, where

V is the volume of the room,

Pt – temperature difference, calculated by subtracting the minimum possible air temperature in the region from the desired room temperature,

k – safety factor.

Modern gas boiler Source tr.decorexpro.com

The boiler power, when taking into account the dissipation coefficient, is calculated by multiplying the calculated level of heat loss by the safety factor (usually from 15% to 20%, then multiply by 1.15 and 1.20, respectively)

This technique allows you to more accurately determine productivity and, therefore, approach the issue of choosing a boiler as efficiently as possible.

Radiator calculations

In our case, we will use standard aluminum radiators with a height of 0.6 m. The power of each fin of such a radiator at a temperature of 70 ° C is 150 W. Next, we will calculate the power of each radiator and the number of conventional fins:

- room 1: 28 m3 · 40 W · 1.2 = 1344 W. We round up to 1500 and get 10 conventional fins, but since we have two radiators, both under the windows, we will take one with 6 fins, the second with 4.

- room 2: 28 m3 · 40 W · 1.2 = 1344 W. We round up to 1500 and get one radiator with 10 fins.

- room 3: 56 m3 · 40 W · 1.2 = 2688 W We round up to 2700 and get three radiators: 1st and 2nd with 5 fins each, 3rd (side) with 8 fins.

- hallway: 22.4 m3 · 40 W · 1.2 = 1075.2 W. We round up to 1200 and get two radiators with 4 fins each.

- bathroom: 11.2 m3 · 45 W · 1.2 = 600 W. Here the temperature should be a little higher, you get 1 radiator with 4 fins.

- toilet: 8.4 m3 · 40 W · 1.2 = 403.2 W. Round up to 450 and get three edges.

- kitchen: 43.4 m3 · 40 W · 1.2 = 2083.2 W. We round up to 2100 and get two radiators with 7 fins each.

As a final result, we see that we need 12 radiators with a total capacity:

900 + 600 + 1500 + 750 + 750 + 1200 + 600 + 600 + 600 + 450 + 1050 + 1050 = 10.05 kW

Based on the latest calculations, it is clear that our individual heating system can cope with the load placed on it without any problems.

How heat-saving film is used for windows - pros and cons of use

In search of energy savings, consumers are looking for new building materials that will help save heat in their home or apartment. A special place in this series is occupied by heat-reflecting film for windows, which can reduce energy consumption by up to 30 percent.

How advisable is it to use this material and what properties, besides heat conservation, does the film have?

How much heat should the pipeline supply?

Let's take a closer look at the example of how much heat is usually supplied through pipes, and select the optimal pipeline diameters.

There is a house with an area of 250 sq. m., which is well insulated (as required by the SNiP standard), so it loses heat in the winter by 1 kW per 10 sq. m. To heat the entire house, 25 kW of energy is required (maximum power). For the first floor - 15 kW. For the second floor - 10 kW.

Our heating scheme is two-pipe. One pipe supplies hot coolant, and the other pipe cools it to the boiler. Radiators are connected in parallel between the pipes.

On each floor, the pipes branch into two wings with the same thermal power, for the first floor - 7.5 kW, for the second floor - 5 kW.

So, 25 kW comes from the boiler to the interfloor branch. Therefore, we will need main pipes with an internal diameter of at least 26.6 mm so that the speed does not exceed 0.6 m/s. A 40mm polypropylene pipe is suitable.

From the interfloor branching - along the first floor to the branching on the wings - 15 kW is supplied. Here, according to the table, for a speed of less than 0.6 m/s, a diameter of 21.2 mm is suitable, therefore, we use a pipe with an outer diameter of 32 mm.

7.5 kW goes to the wing of the 1st floor - an internal diameter of 16.6 mm is suitable, - polypropylene with an outer diameter of 25 mm.

Accordingly, we use a 32mm pipe on the second floor before branching, a 25mm pipe on the wing, and we also connect the radiators on the second floor with a 20mm pipe.

As you can see, it all comes down to a simple choice among the standard diameters of commercially available pipes. In small home systems, up to a dozen radiators, in dead-end distribution circuits, 25 mm polypropylene pipes are mainly used - “per wing”, 20 mm - “per device”. and 32 mm “to the main line from the boiler”.

Types of batteries

There are several types of batteries, and we will list the characteristics of each to make it easier for you to choose the right option.

Steel

Not the most common option. The reason for their low popularity is their heat transfer characteristics. Advantages: reasonable price, light weight and easy installation. However, the walls have insufficient heat capacity - they quickly warm up and cool down quickly. In addition, water hammer can cause leaks in the places where the sheets are connected. At the same time, inexpensive models (without a protective coating) may rust. Such options last much less than others and their warranty period is more limited.

It is often difficult to determine the number of steel radiators for one room, since their solid design does not allow adding or removing sections. Thermal power must first be taken into account. It all depends on the width and length of the space in which you are going to install them. Some tubular models allow you to add segments. The craftsmen do it to order when they make them.

Cast iron

Each of us has seen such products: standard accordions. Even though their design was extremely simple, the design made it possible to effectively heat houses and apartments. The heat output of one accordion is 160 W. The calculation of sections of prefabricated cast iron radiators is simple, since their number could be unlimited. Modern proposals have become improved; they fit into different interiors. There are also exclusive models with relief patterns. Advantages of cast iron pipes:

- heat is retained for a long time at high output;

- resistance to water hammer and sudden temperature changes;

- Corrosion resistant.

You can use different coolants, as they are suitable for autonomous and central heating systems. Disadvantages include the fragility of the material (it cannot withstand direct impacts), the complexity of installation (due to its large size). In addition, not every wall will support their weight. Before starting the boiler in winter, test the system, fill the pipes with water to determine if there are any problems.

Aluminum

They appeared not so long ago, but quickly became popular. They are relatively inexpensive, minimalistically designed, and their material has good heat transfer. Aluminum models can withstand high pressure and temperature. The heat output of each section is up to 200 W, but at the same time its weight is small - no more than 2 kg. They do not require large coolants. They are stackable, so you can add or remove radiator sections based on the area of the room. There are also solid models.

Flaws:

- Aluminum is susceptible to corrosion. There is also a high probability of gas formation, so aluminum pipes are more suitable for an autonomous heating system.

- Non-separable models may leak at the joints; they cannot be repaired and will have to be completely replaced.

The most durable options are made from anodized metal. They remain resistant to corrosion for a long time

Their designs are roughly similar, and when you make your choice, pay attention to the documents. How to correctly calculate the number of radiator sections per room according to the instructions.

Bimetallic

The bimetallic radiator model is no less reliable than the cast iron one. Good thermal output makes them better than aluminum ones. This is facilitated by the features of their design. One segment consists of steel manifolds. They are connected by a metal channel. Craftsmen assemble them using threaded couplings. Due to the aluminum coating, good thermal output can be obtained. Pipes do not rust. High strength and wear resistance are combined with excellent heat dissipation.

Eventually

As you can see, calculating the heating capacity comes down to calculating the total value of the four above elements.

Not everyone can determine the required capacity of the working fluid in a system with mathematical accuracy. Therefore, not wanting to perform the calculation, some users act as follows. To begin with, fill the system to approximately 90%, after which the functionality is checked. Next, the accumulated air is released and filling continues.

During operation of the heating system, a natural decline in the coolant level occurs as a result of convection processes.

In this case, there is a loss of power and productivity of the boiler. This implies the need to have a reserve tank with working fluid, from where it will be possible to monitor the loss of coolant and, if necessary, replenish it. Date: September 25, 2021