Look. If you are not going to make a room in the attic yet, then you can insulate the attic floor. And then the same wool will be used to insulate areas 1-2, 3-5, 6-7. That is, now, put a vapor barrier film on the attic floor, with insulation 150-200mm thick on it. You can roll, the softest positions of mineral wool or fiberglass wool. Mineral wool density 20-30 kgm3, fiberglass 14-17 kgm3. You don't have to cover it with anything. And let it lie there until you get ready to make the room. Then reinstall it, and the vapor barrier too.

In your case, the slope (the slope itself, sections 1-4, 4-7) does not need to be touched with insulation. If you insulate a slope, you will need to disassemble the slate, remove the roofing material, replace it with another waterproofing, etc. There is no point in this :-). With an insulated attic floor, the rooms of the house will be warm. And when you finish the room, just redo the insulation.

Do-it-yourself roof insulation from the inside

Preface . Insulating the roof from the inside with foam plastic or mineral wool is a beneficial activity for the owner who wants to do something in the house on his own. Add to the desire the ability to be precise and careful in detail, and insulating a gable roof from the inside will go like clockwork. You just need to select the insulation, read the recommendations in this article and watch the video instructions for carrying out the work.

Insulation of a private house

Warming a cold floor

How to insulate walls in a house

How to insulate the attic of a house

Internal wall insulation

Processes inside

In order to properly insulate a private house and make the roof a full-fledged protective mechanism for both the main room and the attic, you need to be able to choose the right material for insulation. Usually the selection is based on the physical processes occurring inside, under the roof.

There are several of the most important ones.

- Heat exchange , which occurs due to different temperatures in the house and outside it. If the roof is not insulated, then some of the heat escapes through the roof, and the insulation prevents this process and maintains optimal temperature in the room.

- Moisture exchange , which occurs from the person himself, his breath, evaporation from body temperature to the cooking processes, when vapor rises to the ceiling, carrying particles of moisture that are removed through the roof. If the roof is insulated, the humidity level remains optimal, and unnecessary odors can be removed using ventilation.

Materials for insulating a pitched roof from the inside

We will show a video on insulating a roof with mineral wool at the end of the article, but now it’s worth talking about the materials used to insulate a pitched and gable roof. It’s really not difficult to insulate from the inside, anyone can solve this problem, the main thing is to choose the right material and follow the rules of use.

Materials for insulating the roof from the inside If you purchased a country house with an old, uninsulated roof, or you decided to make a warm attic and equip the attic for a room, then the task of “insulating a gable roof from the inside” simply begs to be done by you. The main rule here is good theoretical preparation.

Regardless of the material used to insulate the roof of a house from the inside, it is possible to achieve an equally effective result - a warm and cozy attic. The roofing material can be any on an old roof: tiles, metal tiles, corrugated sheets, slate, etc. Initially, everything under the roof looks simple - rafters and sheathing.

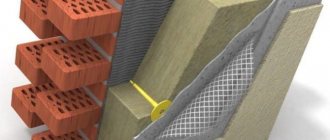

Insulation is the main element, but it must be covered with waterproofing on both sides. Often, after the insulation, a second sheathing is installed to additionally secure the insulation. Let's first consider a popular insulation option - mineral wool, and then how to insulate the roof from the inside with polystyrene foam.

What do you put under the slate?

There is a need to replace the iron roof on the roof of a house in the village and we are planning to make a slate roof ourselves, but we have no experience in this matter. Please tell me what they put under the slate?

When changing the roof covering from metal sheets to slate, you must first check the safety of the sheathing, which very often fails in places where the roof covering leaks.

Places of the sheathing with defects should be removed and a new sheathing should be laid, for which unedged sanded boards can be used. After the sheathing is completed, sheets of roofing material are laid on it. The cheapest is glassine, but it is short-lived. Basically, roofing felt was laid earlier. Now more modern materials have appeared, for example, bipole, which is more durable, but it is somewhat more expensive.

Sheets of slate are laid on the roofing roll material, which are attached to the sheathing boards using special roofing nails. Nails must be driven into the top wave of slate.

Insulation of an attic roof from the inside with mineral wool

This is the most common type of insulation among builders, and if you use basalt-based mineral wool, then you can say that it is recommended by everyone. A wide variety of composition options will allow you to find what you need, which corresponds to the required characteristics and pitch of the sloping roof rafters. When purchasing any mineral insulation, you must ask the seller for a material safety certificate.

Often, even on inclined roof planes, additional fixation of the insulation is not required; the main thing is to accurately select the dimensions of the sheets. Glass wool has been used very widely for a long time. But today it is losing its popularity due to the emergence of environmentally friendly materials. If you decide to use glass wool, then carry out the work in overalls, cover your face and eyes from falling crumbs.

Asbestos slate

There are three types of slate covering: metal, Euro-standard and asbestos. Metal is made of thin galvanized steel coated with a protective layer of polymer. The composition of Euro slate includes cellulose and basalt fibers, fiberglass, and jute. The last type is the most popular. The material is characterized by very high rigidity, because asbestos fibers are stronger than even steel. They are connected by cement. Asbestos threads are evenly distributed over the sheet, which creates a good reinforcing mesh. This helps to increase the impact strength and strength of the coating.

Asbestos slate is highly durable Source rmnt.mirtesen.ru

There are different types of corrugated asbestos slate:

- VU

is a wavy slate with a reinforced profile. This material is used for roofing work in the construction of industrial buildings.

- IN

- slate with a regular profile, having a rectangular shape. Not only the sheets themselves can be made from it, but also other roofing elements, for example, a slate roof ridge.

- UV

- This is a wavy unified slate. It has a good wave width and sheet size. All this allows you to significantly reduce the number of joints.

Roof insulation from the inside with foam plastic

Using slabs of expanded polystyrene or polystyrene foam to insulate a pitched roof is a tempting solution, but the fact is that the materials are flammable, and when burned, polymers emit smoke and compounds hazardous to the body. Therefore, the use of polymers is justified in non-residential premises; for example, insulating a garage roof from the inside with polystyrene foam will be cheaper than with mineral wool and polyurethane foam.

Expanded clay is better suited for flat roofs.

Expanded clay is well known to everyone as an excellent heat insulator, but insulating a sloping roof from the inside is inconvenient for them.

After all, expanded clay is a lot of small fired fractions that will simply roll down. The use of expanded clay is justified when insulating flat and pitched roofs and when insulating floors and attic floors.

Among all the insulation materials known today, polyurethane foam has the lowest thermal conductivity coefficient. Therefore, we will devote the next section to this insulation. Let us immediately note that this is also the most expensive insulation option today.

Selection of tools

If you ask a professional roofer what tools you need to have to insulate the roof, he will probably answer that a knife, a hammer, a clear head and skillful hands. Essentially, this is the case, but there are subtleties and secrets that not everyone wants to divulge.

Roofing tools

The most important detail and, accordingly, the trick is choosing a knife . If you take a regular mounting knife, you will be able to work, but throughout the entire time you will suffer from unevenly cutting off pieces of insulation. Such a construction tool has a blade that is too short and is unable to cut through a thick layer of heat-insulating material. In addition to all this, a standard knife will quickly become dull on polystyrene foam or mineral wool.

If you don’t have a knife, then you can use improvised means for cutting - a hacksaw for wood or a wide kitchen bread cleaver with a lumpy sharpening.

The ideal option would be to purchase a special professional long knife . It is made taking into account the requirements placed on it - made of carbon steel with a length of 35 cm and a comfortable handle made of high-quality plastic.

Professional knife

In addition to a good cutting tool, you will definitely need a hammer, a screwdriver, self-tapping screws of different lengths, a long strong cord, reliable protective clothing, glasses to preserve your vision and a respirator.

It would also be a good idea to listen to the following recommendations:

- the place where thermal insulation materials are to be cut must be well ventilated;

- carefully protect your hands, head area and, especially, the respiratory tract with your eyes - they are most susceptible to damage from flying fibers;

- after work, immediately take a shower, thoroughly washing your hands, face and other areas of the skin;

- before cutting, make sure that the size is correct - the pieces should fit freely between the rafters, without falling out or being squeezed;

- It is advisable to cut mineral wool across the fibers - this minimizes the release of flying particles.

Cutting mineral wool

Insulation of the attic roof from the inside with polyurethane foam

Insulating the roof from the inside can be done in a matter of hours. Polyurethane foam (PPU) appeared recently and instantly took a leading position among insulation materials. It is convenient to apply to any surface. Polyurethane foam is convenient to apply to any surface. PPU can be used to insulate the roof of a house from the outside and inside. Using portable units, even an untrained person can carry out the treatment.

Before applying polyurethane foam, you need to read the instructions:

– polyurethane foam can be applied without prior preparation; – during work, good ventilation of the room must be ensured; – insulation cannot be applied during the cold season; – the sprayed mixture quickly increases in volume and hardens instantly.

The only disadvantage of polyurethane foam insulation is its high cost. Roof insulation costs much more than sheet or roll insulation. However, polyurethane foam is extremely resistant to negative influences and does not require additional waterproofing. After insulating the PPU roof, there are no drafts, so the attic will be comfortable and warm. Insects and rodents will not enter the room.

Choice of insulation

Having dealt with the protection of heat-retaining material, it is necessary to move on to one of the most important issues - the choice of insulation. It must be selected in accordance with the requirements that are placed on it. At the same time, in different cases these will be different requirements.

- For houses where residence is not permanent, a thin layer of material is sufficient - from 50 millimeters. It will retain heat while the house is being heated and will allow it to escape fairly quickly after the heaters are turned off or the furnace goes out.

- Permanent housing requires a different approach - you need to retain heat as efficiently as possible and the insulation layer should be at least 100 millimeters.

These data are true for a layer of mineral wool - the most popular and popular insulation. However, there are other options for insulating materials. For example - polystyrene foam. It is lightweight, easy to install and retains heat well. But, it also has enough disadvantages that will outweigh the advantages in the form of cheapness and lightness. This is a very flammable material that releases harmful substances when melting and burning. In addition, many people are allergic to the smell of polystyrene foam. So, it is suitable for technical structures, but it is better not to use it for housing.

Spray polyurethane foam can be an ideal solution for slate roofs. This is essentially a sprayed insulation that covers the entire treated surface with a dense layer, without cracks or gaps. When using it, it will only be necessary to ensure that there are no through cracks and holes in the roof and on the side of the gables. Its only drawback is the lack of air exchange between the external environment and the treated room. You'll have to think about good ventilation.

Another option for how to insulate a slate roof from the inside would be to use bulk insulation materials such as expanded clay, which are laid on the side of the ceiling that is external to the premises. This solution will not make the attic warm, but the insulation of living spaces will be very effective. The most modern material in this category will be ecowool, which can simply be scattered over the surface of the ceiling and covered from the outside with a waterproofing film.

Do-it-yourself insulation of an attic roof from the inside

Insulating the roof of a balcony or attic from the inside is a responsible task; if the electrical wiring has not yet been laid, we advise you to move it away from the insulation. If changing the lighting scheme on the balcony is impossible, then insulate all the wires into cable channels and do not confuse the stages of repairing the balcony.

1. installation of a counter-lattice so that the under-roof space is blown from the bottom up; 2. installation of waterproofing on the sheathing (do not confuse which side to attach the vapor barrier); 3. installation of insulation adjusted to the dimensions of the rafters, but additional cross members can be made; 4. The insulation is covered with a vapor barrier film to prevent the material from getting wet.

The final stage is finishing - installing the frame and covering it with clapboard, plasterboard or other materials. Insulating the attic means paying attention to every detail, including insulating the windows for the winter, as well as insulating the attic hatch with your own hands.

The cost of insulating the roof from the inside is high, and companies charge even more for roof insulation, because it is through the attic that a large loss of heat occurs in the house. Treat your work with the utmost conscientiousness, calculate the required material carefully and draw up for yourself an algorithm for all the work on self-insulation.

How to insulate a roof without removing slate: a simple method

Slate

- one of the most popular roofing materials, it has been used successfully for a long time and is not going to lose ground. Slate roofs are easy to insulate without removing the slate, but there are a few key points to be aware of.

The easiest way to insulate a residential building, if there is no task of insulating the attic, is to pour expanded clay into the attic

. This will not make the attic warm, but if they are used for housing, then this method is suitable. Instead of expanded clay, you can also use ecowool. It should be scattered over the surface and covered with waterproofing.

If you need to insulate the attic itself, then you need to keep the following in mind. Slate has a wavy shape, so it is impossible to install insulation under it. Ideally, before laying the slate, the builders at one time made waterproofing, for example, with roofing felt. After all, moisture always accumulates under the slate.

If this is not done, then you must first lay waterproofing: a vapor barrier waterproofing membrane or just a piece of polyethylene.

The insulation should not be laid close to the roof, but with a gap for ventilation

When installing the film, be careful not to tear it

Next, the insulation is selected. If you do not plan to live in the house permanently, then a thickness of 50 mm

, and for year-round use

100 millimeters

.

What to choose as insulation

The classic material is mineral wool,

suitable in most cases. It is inconvenient for transportation, as it stains the car interior, can generate dust and cause coughing. However, there are other materials, such as polystyrene foam. It is cheap, easy to transport and install. It is very light, so it is easy to work with in the attic, it is easy to lift such panels up and fasten them.

Expanded polystyrene panels can be transported on the roof or trunk of a car. There are also disadvantages: the material causes allergies, so it is not suitable for everyone. In case of fire, it releases toxic substances and is itself very flammable and flammable. It is usually used for offices and industrial premises, but is not recommended for apartments.

You can also find other types of insulation on sale, which are more expensive, but have their own advantages.

Recently, an advanced method has appeared - sprayed polyurethane foam

. This is a sprayable material that fills all the cracks and reliably seals the roof. The disadvantage is that it interferes with ventilation, and the owners of the premises will have to think about how to ventilate the room and remove moisture from it.

Helpful information?

Don't forget to like and subscribe to the “ Facade Expert ” channel!

Types of roof according to attic parameters: “cold” and “warm”

Conventionally, roof insulation in the construction world is divided into attic, when the roof slopes are insulated, and attic, when the ceiling is thermally insulated.

Like this? We can say that attics also have their own attic - this is a ventilation gap between the internal insulation and the laid roofing. The fact is that heat, according to all the laws of physics, always rises and seeks its release into the atmosphere. It passes through both the insulation and the vapor barrier, and together with water vapor. And here the external air is pulled in at the eaves plumb, which passes to the ridge and along the way picks up both vapors and excess heat. Through aerators or the same ridge, all this is safely removed and does not cause any problems.

Those. in an ordinary, unused roof, the attic occupies the entire space from the ridge to the attic floor, and in the attic, the attic is just a small space under the slopes between the insulation and the roofing. And in insulating both, the type of roof has its own approach, which we will now study.

Main difficulties

Slate has a wavy shape and it will not be possible to lay the insulation close to its surface. This is one of the main problems, since creating a dense heat-insulating layer in this case will be difficult, especially when using fibrous insulating materials. It will be necessary to install a special system of cranial bars and sheathing so that the insulation has something to rest against during installation.

The second difficulty is waterproofing the heat-retaining material. The slate waves run along the entire plane of the roof and moist air easily enters them, which can render any fibrous insulation unusable - moisture can accumulate in them and the effectiveness of the material will decrease. Therefore, it is necessary to ensure high-quality waterproofing.

Previously, roofing felt was used as a water insulator, nailed directly to the roof sheathing before laying the slate. However, over time it very quickly becomes unusable and cannot serve as full protection against water. You will have to attach another layer of waterproofing materials to the rafters. It could even be a simple plastic film.

However, the question immediately arises of removing excess moisture from the insulating layer. It is necessary to secure the vapor barrier and waterproofing membrane in such a way that small ventilation channels are maintained between it and the roof, through which moist air will escape outside. Moreover, this must be done extremely carefully so as not to damage the protective film.

Cold roof insulation technology

If your roof is cold, then the heat-insulating layer should not be on the slopes, but on the floor of the attic. This is where it stops the heat flow coming from below and prevents the cold from the roof from descending into the living space below. As a result, the temperature in the attic is kept within +1-2 degrees, the roofing material is not heated. In fact, such an attic serves as the necessary air gap between the living rooms of the house and the thin roof covering.

All roll, slab and bulk insulation materials are suitable for attic floors. Because the ceiling does not have a slope, it does not have any special requirements for the heat-insulating material used: nothing will crumble or be exposed.

Please ensure that, after insulating the roof, there remains properly organized ventilation: there should be dormer windows located opposite each other, ventilation ridges and aerators, and in the eaves there should be round-the-clock access to suck in outside air. As a result, the temperature in a non-residential attic should be as close as possible to the street temperature, and the living space below is already separated from it by proper thermal insulation of the floor.

Now let's take a closer look at insulating a cold roof.

Insulation with mineral wool

When insulating the attic floor with mineral wool, first of all pay attention to the distance between the slats or joists - it should be slightly less than the roll or mat of insulation.

Typically, thermal insulation of the internal space of the roof is complicated by the uneven surface of the attic floor, differences in its height, a large number of slats and bars, not to mention ventilation pipes and electrical wiring:

Ecowool insulation

If you want the house to breathe and steam to escape easily, then insulate the attic floor with modern eco-wool:

Insulation with blown-in cotton wool

Recently, blowing - roof insulation with blown-in cotton wool has become increasingly popular. The Japanese “insulation” Esbro-Vul II is used here, which does not emit dust and therefore does not create problems. And the blowing method itself is actually quite simple:

- Step 1. Place a vertical ruler on the floor and mark the required height of mineral wool spraying.

- Step 2. Apply insulation in an even layer to the desired level.

- Step 3. We lay the insulation so tightly that it weighs 25 kg per cubic meter.

Note that this type of insulation is the most popular in Japan, and has already found many supporters in Russia.

Glass wool insulation

And finally, glass wool - if you will not use the attic at all. The fact is that even glass wool closed under the sheathing sometimes causes irritation to the ENT organs. This is why you have to wear a respirator and goggles when working with it:

Insulation with sawdust

When insulating a roof with sawdust, follow these instructions:

- Step 1. First of all, you need to protect the wooden structure. To do this, we first apply an antiseptic composition, then fire-bioprotective mixtures, and on top - water-repellent agents.

- Step 2. The next step is to place a backing (cardboard is possible) and close the seams and cracks, if any, with foam (large) or sealant (small). When finished, we trim off the foam that has come out and level it with the beams.

- Step 3. Now we fill in the sawdust in two layers: first the larger fraction, as well as shavings, and then the fine ones, so that dust does not form in the room.

- Step 4. To prevent rodents from growing on the attic floor, add dry lime and small broken glass to the sawdust.

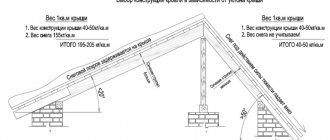

Physical factors: impact

Any house that is used for housing must meet certain requirements to make living in it cozy and comfortable. It is important to lay the foundation correctly so that the house does not shrink or crack, insulate it and build a roof. The choice of covering is very important because it determines the weight that is applied to the house, the time it takes to complete the covering work and the cost. In addition to all this, it is necessary to take care of insulating the inside of the roof so that the structure of the house remains as reliable as possible and the residents feel comfortable at any time of the year.

In different climatic conditions, buildings are affected by various factors.

Our latitudes will be characterized by:

- precipitation in the form of rain;

- snow, cereals and similar phenomena;

- hail;

- roof icing;

- active sun;

- strong wind.

To withstand all these negative factors, the roof must be covered with sufficiently dense materials that can reliably protect the house for many years.

A private house is a structure that consists of a main floor and an attic. If the roof is not insulated, then up to 15% of the heat from the room escapes through the ceiling in cold weather, which makes it necessary to intensively heat the rooms. In addition, having an insulated attic, this space can, if desired, be made residential and used as rooms for a specific purpose. For a large family this is an ideal option.

Warm roof insulation technology

The mansard roof is a special design. There is also a cold attic here, only it is very small, because... the insulated attic ceiling is pulled almost flush against it using additional sheathing. In fact, there is only space for ventilation, and nothing more. And ventilation serves to ensure that the heat from the attic does not touch the roofing, on which the snow in winter should remain as a heat insulator and not melt.

Here is a striking example of the most standard situation of improper insulation of an attic: they install the cheapest rafters of 15 cm, put fluffy mineral wool in two layers of 5 cm and cover it all with a roofing covering. Ventilation - only 5 cm, without inflow and outlet, because... There was no specialist nearby to advise. As a result, in the summer there is unbearable heat, from which even air conditioners cannot help, and in the winter there is a generous amount of ice on the roof. And all because in this circuit it is the street air that heats up the most. In other words, that very small attic that we talked about must definitely be there, and far from 5 cm.

And in such a roof you need to think through the vapor barrier especially carefully:

And further. The material used to make rafters is always designed for a certain weight. Thus, a roof under soft tiles can also be built from plasterboard profiles, but it cannot be insulated with heavy basalt wool. Also, the attic roof needs good forced ventilation so that the insulation does not rot or deteriorate. Therefore, carefully read all the points of the master classes we prepared:

Insulation with mineral wool

Follow these simple instructions:

- Step 1. Install hydro and wind protection. If possible, use modern membranes - they are stronger and more durable. In any case, fasten the material with an overlap, and seal all joints with construction tape.

- Step 2. Now measure the distance between adjacent rafters.

- Step 3. Using a regular or stationery knife, easily cut the insulation into the required pieces and insert it between the rafters.

- Step 4. We install additional lathing between the membrane and the inner lining.

For this purpose, we recommend using hard slabs, or even better, basalt slabs.

Please note that you need to attach the vapor barrier membrane with the smooth side to the insulation, and the fleecy side - inside the room.

If the distance between the beams is no more than 60 centimeters, it will be more convenient for you to use square insulation mats:

- Step 1. It is advisable to add rough sheathing inside, under the rafters, so that the insulation has something to rest on. Make the distance between the bars about 20-30 cm. Ordinary uncut wood with medium-sized nails is also quite suitable for this purpose, it is only important that the bars are of the same thickness.

- Step 2. After installing the rough sheathing inside the structure, remove all dust and dirt using a construction vacuum cleaner.

- Step 3. Next, we treat all wood with a special agent against fungus, rot and mold. Just use for this purpose not a spray gun, which is less effective, but a regular paint brush. With its help, you can achieve deep penetration of the product into the wood, and this is important.

- Step 4. Allow the product to completely absorb and dry for two to three days.

As a result, all your sheets should lie tightly - a little tighter than you need at first glance. This is the only way to avoid the presence of cracks and subsequent freezing of the roof.

And one more point: ordinary mineral wool slabs are not particularly suitable for insulating roof slopes, because... They don’t stick well between the rafters, but they can be used to insulate gables.

Glass wool insulation

To insulate roof slopes, purchase the best glass wool from well-known manufacturers. Such glass wool practically does not contain dangerous glass dust, which is what annoys workers the most. Also, even after installation it does not emit harmful substances, which is even confirmed by the Finnish Institute of Health. After all, it’s one thing to throw this “thorn” onto the ceiling of an unused attic, and another thing to cover it with clapboard in a billiard room or private office on the attic floor.

Features of the roofing system for slate covering

How to make a plywood ceiling with your own hands

1. Rafter system. 2. Sheathing with a 60x60 mm block with a pitch of 750 mm. 3. Skate support board. 4. Frontal board. 5. Stop board for laying the first row of slate; after laying the slate it is dismantled

Slate does not accept movement in the substructure, so all the trusses are strengthened with each other by a common ridge beam, under which supports are mounted when the length of the slope is more than 10–12 m.

All wood used in the roofing system must be naturally dried within six months in a properly stacked pile. Minor holes that appear as a result of warping are directed into the attic. Careful culling is also necessary: lumber with defects is set aside and subsequently unraveled for lathing.

The sheathing is done with an unedged board with a clearance of 10–15 cm if it is planned to cover it with flat slate. For the wave format, a rare sheathing made of 60x60 mm timber, packed with a pitch of 45 to 60 cm depending on the number of waves and, accordingly, the size of the sheet, is better suited. After installing the sheathing, it is recommended to immediately nail the frontal and wind boards, along the edge of which the direction of the wave is set.

The presence of cross lathing is most important for slopes with a large area, where it is necessary to compensate for shrinkage and thermal expansion, avoiding overstress in the slate. In general, destruction of the coating most often occurs due to the use of low-quality or poorly dried wood.

Video description

How to properly make hydro- and vapor barrier insulation of a cold attic floor, see the following video:

If you do the opposite, then water vapor from warm air will penetrate into the pores of the wood, but will not be able to erode - there is a vapor-proof barrier on top. This will lead to wetness of the wooden elements of the supporting structure, and no treatment with antiseptics will save the wood from waterlogging and rotting.

The scheme for insulating the wooden floor of a cold attic looks like this:

- On the side of the room there is a vapor barrier, on top of which there is lathing for decorative finishing of the ceiling. Vapor barrier can be of several types: simple film, with an anti-condensation surface, with a reflective (reflective) surface. In addition to protecting the thermal insulation from getting wet, it protects the room from insulation particles getting inside.

- Thermal insulation between beams is stone wool mats or expanded clay.

- A layer of waterproofing superdiffusion membrane.

- Distance bar.

- Attic flooring.

Typical scheme for insulating a wooden floor in a cold attic