Different materials are used to insulate the ceiling surface. In some cases, not only the thermal conductivity of the thermal insulation layer is important, but also its thickness. This is especially important when installing insulation on the residential side. Insulating the ceiling with foil insulation provides many advantages, but the main one is maintaining the height of the room. Let's consider the features, advantages and disadvantages of foil heat insulators, as well as the nuances of their installation on the ceiling surface.

Comparison of insulation for balconies and loggias

A balcony, according to Wikipedia, is “an unheated room in the form of a fenced area protruding from the plane of the façade of a building.” It's nice and cool in the summer, but in the winter? There comes a time when there is a desire for the balcony to please even during the long winter months of our harsh winter.

A modern balcony, if you apply a little imagination, desire, materials and material investments, is an additional room that can be used at any time of the year. This is also a room for receiving friends, where you can drink a cup of tea or a glass of wine and chat.

This is a study room with a small bookcase and computer accessories, and a relaxation room. where you can read, knit, daydream, or a playroom for children. This means that in order to use the balcony in winter, you need to insulate it.

Which insulation material to choose

There is a large selection of thermal insulation materials on the modern market. How to understand them and make a decision in favor of a certain material? What parameters are important?

Parameters of thermal insulation materials

Weight . The less weight of the insulation, the less weight the balcony structure will take after installation.

Material thickness . The thinner the material used, the more free internal space the balcony has.

Thermal conductivity . The lower the thermal conductivity, the higher the retention of internal heat in the room.

Moisture permeability . The lower the moisture permeability, the lower the effect of moisture on the material and the lower the thermal conductivity.

Soundproofing. Protection of the interior space from excessive noise from the street.

Fire safety. The material must be non-flammable and, when exposed to elevated temperatures, must not emit toxic fumes.

Environmental friendliness. The material used must be environmentally friendly for both human health and the health of the environment.

Economical. Must be economically accessible to a wide range of consumers.

Durability. The longer the period of use of the material, the cheaper it costs the consumer.

Easy to use during installation. This point is important for people who like to do their own repairs.

About the material

Foil Penofol is produced on the basis of foamed polyethylene and aluminum foil. It can be two-layer, when the thinnest aluminum sheet is glued on one side, or three-layer, when the foil is fixed on both sides. The connection of metal and plastic is carried out using a thermal method - heat welding.

The base, polyethylene foam, can have different thicknesses and densities, which affects the technical parameters of the product. The thickness of the foil is 12-30 microns, it only affects the strength under mechanical stress or compression.

Important: there are many fakes on sale. Instead of foil, metallized film is used. You can tell the difference with a lighter: foil does not burn.

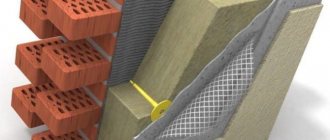

The main purpose is an additional heat insulator with sound, heat, steam and waterproofing properties. Can be used as a vapor and wind insulation material when insulating facades.

Kinds

Penofol foil insulation is used in many sectors of the national economy. The requirements for the material are different. Manufacturers took into account the wishes of users and offered the building materials market several types of insulation. To designate varieties, a classification by type with a letter designation from the Latin alphabet was used.

Type A. This type of foil material is considered classic - foil is only on one side of the insulation (one-sided). The main purpose is additional insulation using mineral wool with simultaneous vapor barrier.

Type B. In construction, situations often arise when thermal insulation is needed on one side of a building’s structural element, and vapor barrier or wind protection is needed on the other side. In these cases, an additional sheathing is installed and a vapor barrier membrane is attached to it. I solved the problem by applying a layer of foil to the second side of the material.

The result was insulation with double-sided foil. It is used on all structural elements of a house or apartment: floor, wall, roof. You can most clearly see how type B insulation works using the example of a roof. From the attic side it prevents heat from escaping. And from the outside it protects the insulation and the interior space from steam and wind.

Type C. Foil insulation is secured with staples or screws, which is very difficult to do on reinforced concrete walls. Applying a layer of glue to the foil-free side made the task easier. The type of insulation is designated “C”, which means self-adhesive. The structure of such “Penofol” is shown in the photo below.

These are the basic types of insulation. The insulation of individual objects and structures with foil Penofol gave birth to several more varieties of the material.

Type R. To give a more beautiful appearance, with open insulation inside buildings, the surface of the polyethylene foam on the foil side is embossed. The relief pattern does not affect the technical and operational characteristics, but protects the insulation from the outside from mechanical damage. Therefore, type R is similar to type A.

Type M. Hidden under this marking is foil insulation with a relief on the side opposite to the foil.

Type A-LP. Aluminum is afraid of aggressive environments. For example, when insulating calf barns and barns with foil material, the foil is corroded within 3-5 years. They found a simple way out of the situation: they covered the aluminum with plastic film. Pasted.

Features and main differences

There are several methods involved in heat transfer:

- convection - heat is transferred by air currents. If there is no wind, then the heated air simply rises, giving way to cold air. By the way, central heating works on this principle;

- heat transfer. All materials, without exception, have thermal conductivity. Thanks to this, heat is transferred from one object to another or, if there is no direct contact, to air;

- radiation. All heated bodies emit infrared waves. When they encounter an obstacle on their way, they give it their energy, heating them up.

The task of any insulation is, if not to completely break the heat transfer chains, then at least to reduce their strength. A preventative method is used for this. In this case, the effectiveness of thermal insulation is affected by the thermal conductivity and thickness of the material. The lower the first indicator and the higher the second, the warmer the house will be.

In the case of Penofol, the principle of operation of a thermos is used - heat rays are reflected back into the room by a layer of foil. This method of insulation is called reflective.

Don’t forget the porous structure of polyethylene foam - it works as insulation using the preventive method. The complex method of thermal insulation makes any comparisons of Penofol with other types of insulation incorrect.

The only indicator that will allow you to more or less objectively evaluate and then compare foil-coated Penofol with other insulation materials is the heat transfer resistance coefficient. So, for “Penofol” foil-coated on both sides with a polyethylene foam thickness of 4 mm, the heat transfer resistance indicator is 1.2-1.23 m2*oC/W. The given parameter corresponds to a layer of basalt wool 8-8.5 cm thick.

What is the difference between penofol and isolon?

Penofol and the like Teplofol, Energofol (foil insulator based on foamed polyethylene)

This insulation consists of several layers of polyethylene foam, having unequal density, thickness and different porous structure. The insulation also has a layer of foil for a reflective insulation effect.

Penofol has a thickness of only a few millimeters, which is on average 10 times thinner than conventional mineral wool insulation. It reflects about 97% of thermal energy and is very light and thin. Penofol is used for internal and external thermal insulation, vapor barrier, sound insulation, waterproofing, has a long service life, is not particularly difficult to install and is relatively inexpensive.

Izolon, Penolon (foil insulator based on foamed polyethylene)

This material has the structure of foamed cross-linked (physically and chemically) polyethylene and is used for thermal insulation, sound insulation, vapor barrier, and moisture insulation. Penolon (izolon) is an ideal option for insulating balconies and loggias. It does not compact after a long time, does not create dust and does not emit substances harmful to the body.

Externally, Penolon is an elastic, mostly white, sometimes with a yellowish or grayish tint. The canvas is produced in rolls and sheets. The surface of Penolon has a slight roughness. It is used for both internal and external thermal insulation, sound insulation, waterproofing, vapor barrier, is not subject to wear, and is easy to use. The price is affordable.

This thermal insulation insulation is made using steam foaming of polystyrene. Polystyrene foam has very low weight and low thermal conductivity, is resistant to dampness, is easy to cut with a sharp knife, has low compressibility, and is easy to use during installation. Due to its low cost, it is in priority demand for insulating balconies.

Areas of application of foil penofol

Penofol is available in rolls. The thickness of the material is 2-40 mm. At the same time, the same indicator of foil varies between 12-30 microns, which ensures good heat-reflecting qualities of the material. The thickness of the foil layer directly affects the price of penofol per m2. The thinner the thermal insulation material, the lower its price. The most popular insulation is 5 mm thick. The price of foil penofol is 120 rubles/m².

Foil penofol is used for steam, sound, moisture and heat insulation

This material has a wide range of uses. It is used for thermal insulation of residential single- and multi-storey buildings, industrial and administrative buildings, saunas and baths, cold and heated hangars, warehouses, refrigerators, permanent, stationary and mobile trade kiosks and shops, railway cars, refrigerators, vans, pipelines of various types. purpose, heating, air conditioning, ventilation and water supply systems, and is also intended for technical insulation of equipment.

It can be safely used for waterproofing attics, basements, attics and basements. This is reliable heat and sound protection for loggias and balconies. Penofol can be used for finishing external and internal surfaces of walls, ceilings, floors, and ceilings above cold rooms in basements. The material is used to shield heating radiators, insulate and seal window and door systems.

Foil penofol is in great demand among motorists. Using this material, you can perform high-quality noise and sound insulation of the body of a car and truck.

Penofol: what is it and why is it needed?

Various building materials are used to insulate residential and non-residential buildings. Penofol is also used as insulation. Let's consider what this material is, what its advantages and disadvantages are.

How to lay it correctly

When using foil-coated Penofol there are many nuances that can negate all the work done.

- Only when the house is insulated from the inside with foil-coated Penofol, as well as the roof from the attic space, does the insulation perform a direct function: it reduces heat loss. In all other cases, it is useless as a heat insulator. But it copes well with the functions of steam and wind protection. Therefore, you need to assume that it is cheaper to buy a vapor barrier membrane (film) or use foil with a polyethylene foam backing.

- Reflective heat shielding only works if there is free space above the foil shield. Therefore, pouring screed directly onto the insulation is excluded. This has been written about more than once on our website. In addition, you need to remember that the alkaline environment of the CPR destroys a layer of aluminum 14 microns in 5 weeks. Thicker foil will take a little longer.

- When using the material as insulation, the foil side should be placed towards the heat source, and when used as steam and wind protection - towards the street. In short, polyethylene foam without foil should always look at the main insulation.

- Despite the fact that, in terms of heat transfer resistance coefficient, Penofol is equal to 8 cm thick mineral wool, it cannot retain heat at the same level. It is necessary either to additionally insulate the structural elements with preventive insulation materials or to use them when the estimated thickness of the insulating layer does not exceed 3 cm, i.e. in the case when the walls themselves retain heat well enough.

- The material is laid end to end, tightly to each other. No overlaps or gaps.

- All seams are taped with metallized tape or tape.

- In frame houses, it is prohibited to lay electrical wiring directly over the foil, because aluminum is a good conductor.

- It is recommended to fasten to the wall or insulation using glue or staples from a construction stapler, which should preferably be carefully sealed with metallized tape. Nails, screws and other illegal hardware damage the integrity of the foil. This is especially important when using material for vapor barrier of the base insulation.

What it is?

Penofol is a two-layer heat-insulating building material, which can be made from one or 2 layers of foil applied to a base layer of polyethylene foam. Depending on the type of product, the density and thickness of the foam may vary. Utilitarian and inexpensive insulation is in great demand among buyers, because it has high performance characteristics.

A layer of foil, the thickness of which is 20 microns, provides penofol with excellent heat-reflecting qualities.

This insulation is used in everyday life and industry as the main insulating material or as an auxiliary thermal insulation layer.

Penofol is used as the main insulating material in cases where it is necessary to insulate a room with normal heat loss and where there is a powerful heating source (bathhouse, sauna, underfloor heating system in a wooden house). As an additional insulating building material, penofol is used to create complex heat insulation in residential and industrial premises, and such premises must be equipped with vapor barrier and waterproofing.

Insulation technology

Now let's talk about how foil thermal insulation is attached to the ceiling in a private house. If self-adhesive material is used, then there is no need to construct a sheathing. In this case, the base ceiling surface is cleared of the remnants of the old finish. All defects, irregularities and cracks are eliminated with putty. After this, the base is primed. Then the protective film is removed from the insulation, applied with the adhesive side to the ceiling and pressed tightly.

If a material without a self-adhesive coating is used, installation is carried out between two layers of sheathing. In this case, first a thin layer of penofol is fixed to the ceiling surface, and then the main layer of insulation is installed. With two-layer installation, the thermal insulation efficiency is much higher. This is facilitated by the resulting air gap. It also prevents condensation from accumulating and settling on surfaces.

Tools and materials for work

If the ceiling is insulated with isolon (penofol) from the inside, then the following materials and tools will be needed for the work:

- wooden slats for lathing;

- drill or hammer drill;

- screws and dowels;

- wood screws;

- hacksaw;

- laser level;

- Ruler and pencil;

- roulette;

- foil insulator (material of the smallest thickness and a product of primary purpose);

- reinforced tape;

- ceiling primer;

- roller;

- putty;

- putty knife;

- containers for mixing solutions;

- scissors or a stationery knife for cutting insulation;

- construction stapler and staples;

- ladder.

Installation of insulation on the ceiling

Installation of penofol (isolon) on the ceiling is carried out in the following sequence:

- First, the base ceiling surface is prepared. The old finish is removed, preliminary leveling is carried out, and defects are puttied. After the putty has dried, the ceiling is primed.

- Next, the thinnest layer of foil insulator is installed. It is fixed to the ceiling surface with wooden slats, which will subsequently be used to attach the main insulation. The installation pitch of the slats is approximately 50 cm. The joints of the material are glued with tape.

- The main insulator is laid from foamed polyethylene. It is secured to the sheathing with staplers. The joints must be taped with tape.

- Afterwards, the insulating layer is pressed against the first sheathing with another row of wooden slats.

- We attach the finishing ceiling trim (plastic or wooden lining, MDF panels, etc.) to the outer sheathing.

Advantages and disadvantages

The use of penofol has its advantages:

- The small thickness of the material allows you to create reliable thermal insulation of the room.

- Installation of building materials does not require special skills or special tools. Working with this material is much easier than with other types of insulation.

- The material is environmentally friendly, which makes it possible to use it for storing food.

- Fire safety. This building material belongs to the class of fire-resistant materials.

- Ease of transportation. The thickness of the product allows the insulation to be rolled up, which allows it to be transported in the luggage compartment of a car.

- Excellent sound insulation. Mounting penofol on top of the frame of building structures provides good insulation of extraneous sounds.

Penofol has not only positive qualities. There are also disadvantages to using this building material:

- The insulation is soft. Because of this, this product is not used for finishing plastered walls. When lightly pressed, the material bends.

- To fix the insulation you will need special adhesives. It is not recommended to nail it to the surface, because in this way penofol loses its thermal insulation qualities.

Unique characteristics of Penofol

Penofol is an insulation material defined as a heat-noise-moisture-insulating material. It is made from environmentally friendly substances, and is thin and light in weight. In industrial and civil construction it is used for:

- basement insulation;

- wall insulation;

- attic insulation;

- ceiling insulation;

- roof insulation;

- floor insulation;

- hydrothermal insulation of pipes;

- thermal insulation of air conditioner;

- hydrothermal insulation of external walls;

- strengthening waterproofing and massive insulation;

- dust protection;

- repair of ceiling covering;

- strengthening walls;

- door insulation;

- insulation of water heating elements.

In the automotive industry, Penofol is used as a material for sound insulation and insulation of vehicle interiors.

Which material is better?

As you know, heat is transferred from product to product in 3 ways:

- heated air;

- thermal conductivity of materials;

- radiation - heat transfer from one product to another occurs using electromagnetic waves in the infrared spectrum.

Let's look at some differences between penofol and other thermal insulation materials.

Most thermal insulation building materials (mineral wool, isolon, penoplex, tepofol) interfere with one type of heat transfer. A distinctive feature of foil material from other types of insulation is that it has a complex effect: foamed polyethylene is an obstacle to convection, and thanks to aluminum foil, the thermal reflection rate reaches 97%.

Penofol can be compared with only one group of thermal insulation materials - isolon. Comparing isolon and penofol, there is no significant difference in the quality and method of their use. To determine the winner, you need to look at the availability and price category of a particular building material. The only advantage of Izolon is that the range has been expanded with sheet building materials, the thickness of which ranges from 15 to 50 mm.

Penofol is mounted using glue, and the penoplex is fixed using fungal screws. Also, foil insulation does not accumulate heat, but rather reflects it.

Mineral wool is attached only to vertical slats. The price category of penofol is significantly lower than that of mineral wool.

The principle of operation of foil insulation called “penofol”

Having decided on the question of what foam rubber with foil is called, it is necessary to understand the principle of operation of foil penofol. It is based on the functioning mechanism of a simple thermos. This development is associated with the name of the Scottish scientist in the field of chemistry and physics James Dewar, who conducted a series of experiments at the beginning of the twentieth century.

Penofol first accumulates thermal energy and then slowly releases it

Scientists have found that any substance can resist the transfer of heat. It accumulates heat waves, while accumulating energy. After some time, oversaturation is observed, leading to the fact that the material begins to give off heat.

The scientist then identified a number of materials that could reflect thermal energy rather than store it. These substances include polished aluminum. When thermal waves reach the surface, they are reflected from it by 99%, which indicates excellent thermal conductivity. Such substances must be supplemented with other materials that perform the function of “thermal barriers,” which can be foamed polyethylene.

From the above, it becomes clear what penofol is and how it works. Due to the fact that the air cushion in the form of foamed polyethylene is covered with a reflective element (foil), the material is able to retain the heat it receives from it for a long time. This is because polished aluminum does not store heat, but rather transfers it to another material that can store it. Thanks to its unique features, foamed penofol copes with this task in the best way.

Penofol

About the manufacturer

Penofol is a brand produced by LIT Plant, which was founded in 1979. The company was the first in Russia to begin applying a reflective layer of foil to the surface of foamed polyethylene. Thanks to this fact, the Penofol trademark is widely known in the Russian market.

Very often, the consumer calls penofol any insulation made of foamed polyethylene with a reflective surface. And this despite the fact that in Russia there are about 30 similar manufacturers with their own brands.

The main activities of the enterprise are:

- production of energy-saving materials based on polished aluminum foil, operating on the principle of reflecting heat flow (reflective thermal insulation), intended for insulation of enclosing structures of residential and industrial buildings;

- production of materials from foamed polyethylene intended for technical thermal insulation of heating and water supply, ventilation and air conditioning systems, for use in “warm floor” systems, as well as for protecting thermal insulation from mechanical damage, atmospheric influences and ultraviolet radiation.

The company is successfully developing and producing products for various purposes under the trademarks: PENOFOL®, TILIT®, ARMOFOL®, TITANFLEKS®, used in construction.

About products

A distinctive feature of Penofol is its blue color. In principle, only foil is used as a reflective layer. Excellent quality material with an adhesive layer, one of the best on the market, if not the best.

Since 2015, LIT Plant began producing the updated Penofol material with additional protection against counterfeiting - a hologram, which is printed on both sides on polished aluminum foil.

Common mistakes and installation tips

The main mistakes when insulating a wooden ceiling with isolon from the inside are in laying the material with an overlap. There is no air gap between the two layers, so condensation accumulates there, which then flows into the room and leads to damage to the finish. Correctly lay the foil insulator only end-to-end. After this, all joints are insulated with silicone sealant or sealed with tape. Joints should not be left unprotected because moisture can penetrate through the seams.

Reflective insulation is placed on the walls of the room to a height of 150 mm, and is not adjacent to the wall. It is also forbidden to attach electrical wires to the foil layer, because it conducts electricity well. The wiring must be well insulated, for example, using a special corrugated pipe.

When using foil insulation as the only insulation, the type with the greatest thickness is used. In this case, the foil layer should be on both sides. If there is an unheated attic behind the ceiling, then foam polyethylene insulation is used only in combination with another reliable heat insulator.

Tepofol

About the manufacturer

Tepofol is a brand, a registered trademark also belongs to Tepofol LLC. The manufacturing company was founded in 2004 and began its activities by designing and putting into practice a laminator for applying a reflective layer to a polyethylene foam surface.

“Tepofol” is the founder of a completely new thermal insulation material made of non-crosslinked polyethylene foam and seamless insulation technology based on it. Currently, Tepofol is not only the first and leading domestic manufacturer, but also the only company in Russia and in the world in the segment of production of insulation in rolls (thickness over 50 mm) with a patented technology for interlocking the material.

Unlike Penofol, the production company specializes only in foamed polyethylene and products made from it.

About products

A distinctive feature of Tepofol is the edge of the locking connection at the top and bottom of the roll.

Foil or metallized Mylar film is used as a reflective layer. Tepofol is used for basic (20-150 mm) thermal insulation of residential premises and construction sites. Tepofol for additional thermal insulation

Additional thermal insulation (2-10 mm) is used as a supplement to the main insulation when insulating a house structure, as well as in other design solutions for vibration, hydro, and noise insulation of residential premises and construction sites.

Tepofol for basic thermal insulation

Tepofol (20-150 mm) is widely used as the main and only (without insulating membranes) thermal insulation instead of traditional types of insulation (foam plastic, mineral wool, expanded polystyrene, etc.). Insulation of an object based on Tepofol and seamless technology is simple, easy to install, reliable, and does not require replacement for many years. Not only foil is used as a reflective layer, but also metallized lavsan film is used for use in a humid environment to avoid corrosion of the foil.

In addition to the production of thermal insulation material, we have extensive practical experience in insulating various objects, on the basis of which unique technologies have been developed and patented that guarantee high insulation results for many years, namely:

- insulation of industrial buildings, warehouses, hangars (frame, frameless, tent);

- insulation of private residential premises (walls, roofs, floors, foundations, attics) and frame houses;

- insulation of balconies, loggias;

- thermal insulation of sports facilities, including facilities where it is necessary to maintain snow or ice cover;

- insulation of objects in the Arctic zone;

- and others.

Penofol parameters

What is Penofol?

Nowadays a lot of materials are produced under the brand name PENOFOL. Perhaps it is worth listing those that are most in demand. Among them we can highlight the classic Penofol, covered with aluminum foil on only one side. This Penofol is type “A”.

Penofol foiled on one side - type A.

Penofol, which is foiled on both sides, is type “B”. Penofol of both these types is quite dense and also resistant to physical stress.

Foiled penofol on both sides - type B

Penofol type C belongs to the category of self-adhesive materials. In it, a polished aluminum coating is applied to a layer of foamed polyethylene on one side, and on the other, a layer of moisture-resistant glue and a film that prevents the adhesion of materials. This type of insulation is used where regular Penofol is not suitable or is too expensive, because no additional devices are needed to attach it.

Self-adhesive Penofol - type C.

There is also Penofol, which has perforation. It can also be single-sided or double-sided and was produced not so long ago, and is used for thermal insulation of facades from the outside. Perforation allows moisture to escape from the material. In other words, walls insulated with such material can “breathe”.

About the thickness of Penofol

The thicker the insulation, the more expensive it is. And the price and technical characteristics of foil Penofol are influenced by the number of layers of aluminum foil: there can be one or two. As for thickness, its standard sizes are: 10, 8, 5, 4 and 3 millimeters. You can understand that centimeter-thick material with a double layer of foil will be the most expensive. By the way, it not only stores heat better than anyone else, but also protects well from noise.

In terms of optimal price-quality ratio, Penofol with a thickness of 0.5 centimeters came out on top. If maximum thermal insulation, as well as protection from noise and moisture, is required, then it is better to opt for a centimeter layer of Penofol. As for the other parameters of the insulation, they also depend on the thickness of its layer, as well as on its type.

About Penofol's heat conductivity

Since this insulation is combined, combining heat reflection and absorption, it is difficult to compare it with traditional heat insulators. Penofol insulation helps reduce convection due to the polyethylene foam layer, and the foil layer on the outside can reflect up to 97% of heat rays. The result is comprehensive insulation.

And yet, let’s try to compare, if not the thermal conductivity coefficient, but the heat transfer resistance of Penofol and other insulation materials. If we take this material with a thickness of 4 to 5 millimeters, covered on both sides with aluminum foil, we get a heat transfer resistance of 1.2 to 1.23 square meters-degrees Celsius per watt. To achieve the same result, the layer of mineral wool should be no less than 8 or 8.5 centimeters. Data are calculated according to SNIP II-3-79.

About the material's absorption of water

Penofol almost does not absorb moisture, and it does not matter what humidity the air has indoors and outdoors. This does not depend on the change of season and temperature conditions.

This distinguishes this insulation from most modern heat insulators.

About the vapor permeability of Penofol

There is no need to lay a vapor barrier film when using Penofol. After all, its vapor permeability coefficient does not even reach 0.001 milligrams per meter-hour-Pascal. We can say that this insulation is an excellent barrier to fumes.

Sound resistance

Speaking about the sound absorption of Penofol, we can name the following number: 32 decibels. This is precisely the sound absorption that class “A” material has. It is mounted not inside the frame of the building structure, but on top of it, with no seams. Therefore, it allows you to protect yourself from various noises: both acoustic and structural. This versatility is a definite plus.

Fire protection

According to the standards, this material is classified as substances that are difficult to burn and do not support combustion. The Research Institute of Construction Physics issued Penofol a certificate of conformity confirming that the material is not a fire hazard. When burned, polyethylene releases water and carbon dioxide. True, if there is not enough oxygen, carbon monoxide may appear.

Service life and safety

One of the cleanest materials in terms of ecology is polyethylene foam. Therefore, it is this that underlies Penofol. By the way, in terms of durability (200 years) this substance can be given the highest score. At the same time, you will be able to protect yourself from the harmful effects of electromagnetic radiation. They can be reduced by two or even ten times.

Insulation Penofol

In the insulation department of any construction supermarket there is a place allocated for penofol. Thin rolled material with a foil surface attracts attention, but its appearance does not always answer the question of where it can be used.

However, it successfully occupies a whole niche in the field of home insulation, where conventional insulation materials, such as mineral wool or expanded polystyrene, will not help adequately cope with the task.

Differences between Isolon PPE and NPE

The differences between these two types of Izolon are visible to the naked eye, and they also have different areas of application. Externally, Izolon NPE has larger cells and is less elastic to the touch. It is undesirable to use it under point loads, since air-filled cells can burst, depriving the material of its noise-absorbing and heat-insulating properties. Large cells contribute to the formation of a rather uneven surface of the material, which can complicate the process of gluing it and subsequent leveling of the surface.

Most often, this type of Isolon is used when carrying out packaging work, as well as when it is necessary to create a shock-absorbing pad. Thanks to a simpler production method, NPE is an order of magnitude cheaper than polyethylene foam with a cross-linked molecular base.

PPE costs a little more, but its technical characteristics benefit in many ways. It is stronger and more elastic, better adapted to changes in ambient temperatures and mechanical stress, and it is also more durable. This material has a perfectly smooth surface, making it easier to install. When gluing the material, several times less glue is used than when installing NPE.

What is Penofol

Penofol is a practical and inexpensive insulation made of non-crosslinked polyethylene foam with aluminum foil applied on one or both sides of the material. Gas-filled cells are sealed and closed, which provides high compressive strength, but does not interfere with the bending of the material. The cell size is usually from 0.5 to 2 mm.

Its advantage is its dielectric properties - it does not allow electric current to pass through , which is especially important when installing electric heated floors.

The insulation stands out from the rest due to its affordable price and simple installation method, however, due to thickness limitations, it is used in a fairly narrow number of cases where it is only necessary to supplement the existing enclosing structures, increasing the overall resistance to heat loss.

Penofol has found its main area of application in air conditioning and thermal insulation systems, where the bulk of the heat is transferred using infrared radiation.

Three types of penofol are produced:

- Type A - with one-sided foiling;

- Type B – with double-sided foil;

- Type C – foil on one side and self-adhesive surface on the other side.

The choice of a suitable option is determined by the direction of propagation of the target thermal radiation. For example, one-sided penofol, when installed on the wall of a living space, when the foil surface is facing inward, protects against heat loss from inside the house to the outside. This means the house will be warmer in winter.

Double-sided penofol can not only prevent heat loss from the house to the street, but also the flow of heat from outside. So it will be warm in winter and not hot in summer, since the heat from the walls irradiated by sunlight will not overheat the air inside the room.

Varieties

See also

: Washing facades: the most affordable ways to wash them yourself

In addition to the type of coating made of foil or sprayed metal, tepofol is divided into several categories.

- Type

A. This is a rolled material made of foamed stitched polyethylene. On one side it is covered with a metallized film. Suitable for pitched roofs, ceilings, walls, floors and attics. Can be used as a reflector for heating radiators. Tepofol type A is also used to insulate pipes; - Type

B. There is a double-sided reflective layer in the form of aluminum foil. There is polyethylene foam between them. This structure provides maximum protection against heat loss. Used for insulation of floors, walls, pipelines. They also install air ducts, an attic, and a roof. And not only for heat protection, but also for noise and moisture protection; - Type

C. The structure includes a metallized film, polyethylene foam, an adhesive layer and a protective coating. Can be used on roofs and attics. It insulates well and protects walls from noise and moisture. Can be used in baths and saunas.

Based on what needs to be isolated and where, you can select the appropriate type of tepofol.

Specifications

A significant part of the thermal energy is distributed in the form of radiation, and therefore the heat-reflecting surface of penofol allows not only to slow down heat loss, but to turn the heat back into the room in winter or prevent it from coming from outside in the hot summer.

The layer of foamed polyethylene acts as a strong and durable base for the aluminum screen, and at the same time copes with thermal insulation in the usual way, increasing the thermal resistance of the fences. That is why it is difficult to compare penofol with traditional insulation using a simple calculation.

Aluminum, even of this thickness , does an excellent job of reflecting up to 97% of thermal radiation , while foamed polyethylene provides thermal insulation in the classical way, preventing convection heat transfer.

| Characteristic | Unit. | Type A | Type B | Type C |

| Operating temperature | ºС | -60..+100ºС | ||

| Thermal reflection coefficient | % | 95-97 | ||

| Coefficient of thermal conductivity | W/m*K | 0,037-0,049 | 0,038-0,051 | 0,038-0,051 |

| Water absorption by volume | % | 0,7 | 0,6 | 0,35 |

| Specific gravity at 4 mm thickness | Kg/m3 | 44 | 54 | 74 |

| Dynamic modulus of elasticity under load 2kPa | IPA | 0,26 | 0,39 | 0,26 |

| Vapor permeability | Mg/m*h*Pa | 0,001 | ||

| Compressive strength | MPa | 0,035 | ||

| Specific heat | J/kg*K | 1,95 | ||

To compare penofol with other materials, it is more clear to use the value of the total heat transfer resistance R under equal operating conditions and a difference between external and internal temperatures of 40ºС.

For example, penofol 3 mm thick Type B (double-sided foil) according to tests creates a resistance equal to 1.173-1.064. Similar resistance is provided by:

- 1.7 m of concrete;

- 77.40 cm of expanded clay concrete;

- 11.70 cm wooden beam (oak);

- 55.0 mm mineral wool (stone);

- 42.2 mm EPS;

- 36.0 mm polystyrene foam;

- 31.7 mm polyurethane foam.

The numbers are impressive, but such results can only be achieved if operating rules are followed and provided that the main source of heat transfer is radiation. Simply put, in the absence of active convection air flows in a heated room.

Why choose Tepofol: customer opinions

“Tepofol”, reviews of experts about which you can read in the article, can be used in heated buildings and houses without heating. Thanks to the opinions of professionals, we can conclude that the material is characterized by high thermal insulation properties. And the foamed structure of polyethylene increases the sound insulation ability, which is expressed in noise absorption of 32 dB. Due to the fact that the water absorption of the product described is only two percent, this makes it possible to use it as thermal insulation and a waterproofing layer.

Among other things, if you insulate surfaces, they will not lose their ability to breathe. Also for this reason, according to buyers, this thermal insulation can act as a vapor barrier. If you do the calculations, it turns out that the consumer saves three times. The use of Tepofol has a positive effect on the internal microclimate of the room. The optimal temperature is maintained in the building, a person does not experience the effect of suffocation, because the penetrating ability of the material is quite high. "Tepofol" foil has a small thickness. That is why he is not able to take away the volume of the room. Due to the thermal insulation properties, the thickness of the wall can be reduced and the costs of work can be reduced.

What is it needed for

The main feature of penofol is the presence of a heat-reflecting screen. It is indispensable for insulation:

- walls and ceilings as part of multilayer enclosing structures;

- balconies and loggias;

- pitched roofs, attics and attics;

- utility rooms and outbuildings;

- greenhouses;

- heat-reflecting screen as part of a heated floor system;

- niches with an installed heating radiator;

- air conditioning systems for freezing units;

- pipes and lines with refrigerant or coolant within the permissible operating temperatures.

Covering all the advantages, penofol is ideal for arranging insulated heat-efficient rooms: greenhouses, incubators, vegetable stores, for protecting basements and semi-basements.

Thanks to the hermetic closed structure of polyethylene foam, penofol has good soundproofing properties. Basically, it absorbs shock sound and vibration well, but is less resistant to high-frequency sounds and noise.

As an underlay for flooring, as well as under a thin screed, it will absorb the sound of footsteps or impacts on the floor.

Floor insulation. Under the screed

When insulating floors, penofol is used as a substrate for all types of screeds, wet, semi-dry, dry, bulk or made with any sheet material, as well as as a substrate for all types of floor coverings.

This is facilitated by the high compressive strength of the material and the dynamic modulus of elasticity is much higher than that of any other insulation.

Floor insulation scheme

Polyethylene ensures the strength of air bubbles, which in turn provides uniform shock absorption to any distributed loads.

Taking into account the horizontal distribution of penofol, it is not necessary to attach it additionally to the base.

Balcony insulation

For insulating a balcony, penofol is an ideal thermal insulation material. In conditions of extremely limited space, it will be necessary to subtract only 20 mm from each fence in order to insulate the room with penofol, taking into account the required gap between the insulation and the finishing to form a closed air chamber.

Two installation options are used:

- Uniform laying of the material end-to-end over the entire insulated surface and installation of sheathing for further finishing on top of it;

- First, a sheathing made of 40x40 mm timber is attached, and then insulation is distributed in each cell, extending onto the sheathing elements.

Balcony insulation scheme

In both options, there is no need to use adhesives or a large number of fasteners. In the first case, the insulation will be securely pressed to the base by the sheathing, and in the second case, it is enough to attach the penofol under the very base with a stapler to the same sheathing.

The choice of the optimal option is determined based on the required load capacity of the sheathing and the weight of further finishing.

How to properly lay foil insulation on the floor

To lay foil insulation on the floor, you must first prepare the base, on which all irregularities, defects and cracks must be eliminated. Then the surface is treated with a soil solution.

Helpful advice! To achieve better thermal insulation properties, many experts recommend laying foam plastic 7-12 cm thick under foil insulation on a concrete floor.

When using a type A heat insulator, a thin, uniform layer of penofol adhesive is applied to the base. Particular attention is paid to the edges of the material, which must be carefully treated with adhesive. Next you should wait 10-60 seconds. for the glue to dry, which will contribute to its better adhesion. After this, the insulation is fixed with little force, performing careful smoothing.

For indoor floor insulation, a more convenient option is penofol C 10 mm. To install the material, it is enough to remove the protective polyethylene film from its inner surface. The insulation must be laid in such a way as to ensure that it overlaps the walls by 5 cm. Penofol strips should also not overlap. Protruding areas should be removed using a construction knife. The joints must be sealed with insulating aluminum tape.

Foiled penofol is suitable for the “warm floor” system

Important! When deciding which side to lay the foil insulation on, you should remember that the foil part of the insulation should face the inside of the room, while the opposite side is glued to the floor. In this case, reliable vapor and noise insulation is ensured.

How to lay insulation for a “warm floor” system and on the ceiling

To install a “warm floor” system, two methods of laying penofol are used. The first involves installing joists on the insulation. This option is advisable to use if a wooden floor is mounted on a heat-insulating material. The logs should be laid along such a base on top of the heating elements.

When installing a heated floor under the tiles, the base is covered with foil foam, which is fixed to the concrete surface with glue. Heating elements are mounted on it, which are covered with reinforced mesh and then filled with concrete mixture. For this option, it is recommended to use foil penofol "Leroy Merlin" type ALP.

The laying of electrical cables over foil foam is carried out in a protective corrugation. This also applies to radio cable and telephone wire. This safety measure is explained by the fact that foil is a good conductor.

Foil penofol types A and B are suitable for insulating ceilings

Let's consider how the ceiling is insulated using such material. First of all, self-adhesive foil penofol 5 mm is fixed to the base surface. Wooden slats are screwed onto it to create a frame for type B insulation. It is attached to the bars using screws or a construction stapler. If it is necessary to install a third layer, the process is performed in a similar way.

How to attach

The basis for penofol is polyethylene, which, unfortunately, has very weak adhesion to construction adhesive solutions.

Mechanical methods are used for fastening: self-tapping screws with a press washer, stapler brackets, clamping strips, fixation under the sheathing. When laying on a horizontal surface under a screed, fastening is not necessary at all.

All joints and fastening points where the material has been stitched through are sealed with special tape made from thick aluminum foil or a polymer base coated with aluminum. This will restore the tightness of the insulation layer and give additional strength to the insulation.

Foil self-adhesive

As an additional fastening, double-sided tape can be used along the edges of the penofol strip.

However, manufacturers provide an even better option. The self-adhesive surface of foam foam “type C” makes installation on any clean, prepared surface extremely simple. One side of the material is completely covered with an adhesive composition with the same properties as regular tape, covered with a protective film.

It is enough to prepare the surface, clean, degrease and, if necessary , prime it so that it does not accumulate dust.

Kinds

Depending on the intended use of the material, manufacturers produce the following types:

- type A , covered with foil on one side only. It is also called one-sided;

- type B , presented in the form of a double-sided foil coating. Used for autonomous type of insulation;

- type C, self-adhesive penofol, which at its base consists of foil, polyethylene and a layer of moisture-resistant glue. This option is convenient for installation and does not require additional installation tools.

In addition to the three main types, manufacturers also produce the following options:

- type ALP , which is additionally covered with polyethylene film. This film is designed to protect the material from aggressive environments;

- type M and R , presented in the form of one-sided insulation with a relief base;

- type AIR , special materials used to install air vents.

Izolon or penofol: which is better?

Penofol can be compared with only one group of thermal insulation materials of the Izolon brand, namely “heat-reflecting insulation IZOLON”.

The ISOLON company offers insulating materials based on polyethylene foam (ISOLON 100) or cross-linked polyethylene foam (ISOLON 500) with aluminum foil or lavsan applied on one side.

When comparing Isolon 100 and penofol, there is no significant difference in properties and method of application, so the final winner will have to be determined by availability and cost. The only advantage of Izolon is that the range has been expanded with sheet material with a thickness of 15 to 50 mm.

Thermal reflective insulation based on Isolon 500 is made from cross-linked polyethylene foam, which gives it much greater strength and a slightly lower thermal conductivity coefficient. Depending on the frequency of foaming (5-40 times), the compressive strength at 10% deformation ranges from 0.011 to 0.15 MPa.

In most cases, it is enough to use penofol, however, Izolon makes it possible to use heat-reflecting screens in cases where the performance characteristics go beyond the limits permitted for penofol.

Reviews about sizes

It is important not only to install the insulation correctly, but also to select the thickness and length of the material. The first parameter varies from 2 to 10 mm. This, according to buyers, is very convenient, since you can choose the thickness depending on your goals. But the length of the roll can be 15 or 25 m. As for the width, it is 1.2 or 1.05 m. Buyers claim that these parameters make it easier to carry out work on preparing and strengthening the material to the surface.