Alkyd-urethane-based varnish is a composition that includes alkyd-based resins, urethane compounds, and organic thinners are also added.

This material is used to cover various wood coverings, even furniture, floors, yachts, and so on.

Also, this alkyd-urethane product can be used for new products, as well as for those that have previously been coated with paints and varnishes.

Compositions of the alkyd-urethane group cannot be used in saunas, baths and other places where the level of moisture is too high.

Description

Alkyd-urethane compositions include various resins, polyurethane material, driers and solvents. These solutions are used to coat wooden products, parquet floors, ships, yachts, boats, stairs, railings, and other wood surfaces. In addition, they have found their application in the field of protecting metal products and stone surfaces. Three types of varnishes are produced, which belong to alkyd-urethane products:

- water-based polyurethane. These compounds do not emit any unpleasant odor and are resistant to high temperatures. These mixtures are available in liquid form and aerosol cans;

- two-component. They have a pungent odor; before application, two components are mixed with each other - varnish and hardener. Such mixtures are among the most stable, durable and durable;

- single-component. These solutions are very popular today and do not require any prior preparation before use.

Important! Alkyd and urethane varnish should not be used on wood located in damp areas. These compounds are not used for baths and saunas.

Dilute, dilute or dissolve

At first glance, there is no difference. Using a special tool, we bring the varnish substance into “working condition”. A solvent is a liquid that dissolves dried varnish, bringing it from a solid to a liquid state. We use a thinner if we need to change (reduce) the viscosity of paints.

Some types of organic eluents perform both roles, but some may be effective in one task and completely useless in another. For example, white spirit can be used to dilute compositions of polyurethane, alkyd and oil groups. But if the varnish has dried, it will not be possible to dissolve it with white spirit.

White spirit can be used to thin some varnishes.

But shellacs, on the contrary, are equally dissolved and diluted with denatured alcohols. But let's not go into such subtle details.

If you need advice on what to thin varnish or what to use for thinning paints, it is better to consult with specialists in this field.

We propose to consider in detail which solvents need to be used in specific cases.

Advantages and disadvantages

The advantages of alkyd-urethane products include the following characteristics:

- dry quite quickly, this requires from 5 to 11 hours;

- have a high level of strength and wear resistance;

- have good adhesion to various materials, easy to lay on various substrates;

- have excellent resistance to moisture, water and chemicals;

- provide reliable protection to the base from dust, dirt and debris;

- practically odorless;

- do not make the surface slippery;

- highlight and emphasize the natural grain of wood;

- protects wood from mold and fungi, and provides metal with reliable protection from corrosion and rust;

- do not have adhesive properties;

- resistant to temperature changes;

- have a long service life.

Despite all the above advantages, alkyd and urethane varnishes also have negative properties:

- unpleasant, pungent odor if the varnish contains organic solvents;

- fire hazard; only those varnishes that contain water as a solvent do not ignite.

Old alkyd varnishes took quite a long time to dry. In order for the varnish film to harden, it was necessary to wait a day or more. But alkyd-urethane varnish no longer has this drawback, since it contains toluene diisocyanate, which gives the solution additional molecular weight. Thanks to this substance, the solvent from the varnish evaporates very quickly, so the drying process takes only 6-16 hours, however, the cost of alkyd-urethane compositions is higher than the price of alkyd products.

Bitumen mixtures

Bituminous varnish is a mixture of a special grade of bitumen, various resins and oils. After drying, a durable black film is formed on the surface, moisture-resistant and impervious to chemical attack. It is considered a fairly new material in household use. Belongs to the inexpensive category. It is often used as an anti-corrosion protective layer.

For wooden surfaces it is used when there is no need to emphasize the natural texture of the base (instead of paints). Bituminous material has found application as a decorative coating for the effect of aging surfaces (patina). Another unique feature of bitumen mixtures is cold gluing. The bitumen solution is diluted with white spirit.

To prevent it from thickening during storage, the container must be airtight. The storage location should be dark (without direct sunlight), with moderate temperature and humidity.

Bituminous varnish protects the surface very well from moisture and chemical influences, diluted with white spirit

Characteristics

These varnishes have the following technical characteristics:

- the volume of volatile substances, that is, solvents, is about 50%;

- when applied, wood moisture content should not exceed 18%;

- a suitable temperature for using varnish should be in the range from 9 to 25 degrees, and humidity from 35 to 75%;

- one liter of varnish is usually enough to treat 9-12 square meters of wooden surface, in the case of a single layer application;

- The drying period to degree 3 is approximately 3 hours;

- Warranty storage period – 5 years.

Selection rules

High-quality material will last longer and provide better decorative and protective properties. When choosing, you need to be guided by the following points:

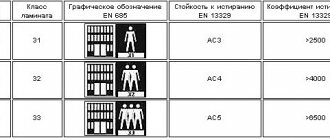

- Wear resistance. If the level of load on the base is regularly high, you need to buy a product with excellent resistance to wear, friction, and mechanical damage.

- Fire safety. Wood ignites quickly and burns well, so the varnish must increase the heat resistance of the material and prevent fire.

- Compound. There are two-pack formulations that must be mixed before application, and there are also ready-to-use products. When purchasing, it is important to take into account convenience and the fact that after mixing it will not be possible to store the varnish for a long time.

- Type of varnish. Some materials traditionally give a shiny, glossy sheen, but there are also varnishes that have a matte effect.

- Drying time. Varnishes diluted with water dry quite quickly, but the drying period may vary depending on the composition.

- Moisture resistance. Not all varnishes can protect wood from water. It is better to buy polyurethane compounds if you need to use the product for wet areas.

Odorless varnishes can be used to cover windows, doors, and other wooden products. The products are universal and last for a long time.

Varieties

Typically, mixtures containing alkyd resins and polyurethane are used to coat wooden products. There are two types of these solutions:

- alkyd-urethane “yacht” varnish. This composition is used for painting boats and yachts above the waterline;

- parquet composition. It is usually used for the protection and decorative treatment of wooden and parquet floors.

Each of these varieties can be applied to any wood surface. Yacht varnishes are used to protect wooden buildings outdoors. Yacht varnish compositions are usually used to treat verandas, gazebos, terraces, garden buildings, fences, and wood fences. And parquet varnishes are applied to any wooden products during interior work. In addition to the floor, parquet solutions can be applied to staircase railings, window frames, furniture, doors, baseboards, etc.

Both yacht and parquet varnish solutions are available in one-component and two-component versions. Although two-component ones are more expensive, they have better wear resistance and durability. Varnishes can also be classified according to the type of gloss; there are glossy, semi-gloss and matte mixtures. Matte solutions are usually used in very dirty areas and in high traffic areas. The matte layer is easy to clean and shows much less damage. Glossy mixtures strongly reflect light, so they are more often used in rooms with poor lighting or on decorative, elegant products and details.

Alkyd mixtures

Alkyd compounds have good adhesion, moisture resistance, insensitivity to ultraviolet radiation, and strength. They can be used for external and internal work. Alkyd mixtures contain a main component, organic solvents, driers (for faster drying), and additives. The main component may be:

- pentaphthalic resin,

- glyphthalic resin with cotton oil,

- a mixture of melamine-formaldehyde and alkyd resins.

To enhance the properties of materials, elements of alkyd resins are often included in multicomponent varnishes, paints, and enamels. The traditional thinner here is white spirit.

Additional Applications

In addition to processing internal and external wooden surfaces, alkyd-urethane varnishes are used for processing metal surfaces and stone - natural and artificial. In addition, they are sometimes used to protect glass products.

Before you begin applying this varnish to stone or metal, be sure to carefully read the instructions to ensure that the varnish mixture is compatible with the specific material. Some types of alkyd and urethane solutions are intended only for wood treatment.

Safety

Such paint and varnish compositions can be stored and transported at temperatures up to 30 degrees Celsius.

Do not allow ultraviolet light to come into contact with the varnish.

It is important to take precautions when storing and transporting alkyd-urethane coatings, because they contain butanone oxime and cobalt bis. They can cause allergies, which manifest as cracked skin and dryness.

Such mixtures should not be poured down the drain. It is also unacceptable to throw such material into the environment.

Manufacturers

The following alkyd-polyurethane varnish products are very popular in our country:

- Parade;

- White house;

- "Boron";

- parquet varnish luxens.

Parade has a high elasticity rate. The protective layer does not crack after many years, and for a long time practically does not wear off. In addition, Parade varnishes highlight the natural grain and texture of wood well. These varnish products are made for use both indoors and outdoors.

White house products have a relatively low cost and almost no perceptible odor. Varnish mixtures from this manufacturer are highly wear-resistant, quickly polymerize and retain the natural shade of wood. White house varnish solutions can be applied both outdoors and indoors.

Russian paints and varnishes "Bor" have good performance properties. The varnishes of this company dry in about 4 hours, after which the protective layer becomes resistant to adverse factors and chemical detergents.

Popular and high-quality parquet varnish luxens is used for external and internal finishing works. It can be applied both to the old varnish layer and to new wood. Parquet varnish solutions are made on a water basis and dry quickly enough, thanks to which repair and finishing work is carried out very quickly. The products have increased strength and wear resistance, have an attractive price, and are manufactured in France.

Advantages

Alkyd-urethane mixtures have a number of positive characteristics:

- Attractive appearance.

- Quick drying (average waiting time is shorter than in the case of alkyd varnishes, and if technological procedures are followed, does not exceed 6-12 hours).

- High wear resistance and increased hardness of the coating (in this regard, the alkyd-urethane group is also preferable to alkyd compounds).

- The mixture is easily applied and evenly distributed over the surface, after which the wood becomes matte or semi-matte.

- Resistant to humidity and household chemicals.

- Protecting the floor from dirt.

- Almost complete absence of odor (the mixture is produced on the basis of slightly aromatic solvents).

- High elasticity of the coating, due to which the material is not subject to cracking when the size of the wooden product changes.

- There is no gluing of the end parts of the parquet. In this way, material stresses are avoided.

- There is no need to prime the surface before applying varnish to a previously varnished surface.

- Parquet treated with an alkyd-urethane mixture is not slippery when walking on it.

- Varnishes of this group allow you to intensify the natural color of wood, making the surface pattern more accentuated.

Surface preparation before varnishing

Before you start applying varnish, you need to do the following procedures:

- clean the base from any contaminants, for example, dirt, dust, grease stains, old paints, etc.;

- if hardwood is to be varnished, you need to treat it with white spirit;

- sand the wood with sandpaper, clear it of fibers;

- if a metal surface is to be varnished, it must be cleaned of rust, scale and traces of corrosion; for this you can use sandpaper;

- perform test varnishing, for this a small layer of varnish is applied to wood or metal;

- the surface is primed with a mixture of varnish solution and white spirit, in a ratio of 1 to 5;

- The base is wiped with a damp cloth, after which it should dry.

Consumption

Many people are interested in how much alkyd varnish costs. This indicator depends on the type of mixture and your talent. Experts advise applying 2-3 layers of varnish. Each level should be applied only after the previous one has dried. Thus, it will take you at least 3 days to treat the surface.

The consumption of alkyd products is 50-75 grams per square meter. If you use more varnish than required, the polymerization time will increase. You also risk getting a less durable surface.

Before use, some brands should be diluted to a working consistency with xylene or solvent. You can mix one of these drugs with white spirit in a 1:1 ratio.

Varnishing rules

You can varnish the surface using a spray gun, brush or roller. Applying varnish is allowed at an air temperature of at least 5 degrees. It is necessary to work in a respirator, gloves and goggles to protect the respiratory system, skin and eyes. If the varnish mixture gets on the skin, it should be washed off immediately with warm soapy water. Nearby objects must be protected with cellophane film to prevent splashes of varnish from getting on them, because if they dry out, it will be quite problematic to remove them.

Before applying the composition, it must be mixed thoroughly. If a two-component solution is to be applied, you need to mix both components in the required proportions specified in the instructions. After mixing, the two-component composition must be applied within 3-5 hours, so when treating large areas it is advisable to mix it in small portions.

The process of applying the varnish mixture must be carried out in thin layers so that there are no sagging, drips, and so that the protective layer does not wrinkle. If you are treating floors, you need to start varnishing from the window, moving in the direction of the wood fibers. After the first coat has dried, it is recommended to apply a second coat of varnish in a direction perpendicular to the previous coating.

After the second layer has dried, it is advisable to sand it with fine-grained sandpaper, then apply the third and final layer. If the windows are open in the room, the varnished surface will dry much faster. The varnish layer will become as durable as possible only after a couple of weeks; during this time it is not recommended to walk on it or bring furniture into the room.

How to get rid of the smell of varnish on wood?

Some types of varnish contain toxic substances, so fumes can cause headaches and allergies. To eliminate the problem, it is recommended to neutralize the pronounced aroma after the paintwork has completely dried.

You can remove the smell of varnish from wood by repeatedly wiping the surface with a cloth soaked in a vinegar solution. 2 tbsp is enough. l. Dilute vinegar in 6-8 liters of water to remove the chemical aroma. Before wiping the wood, it is recommended to squeeze the rag well to remove excess liquid.

Alternative odor control options:

- adding mint or vanilla essence (a few drops) to a jar of varnish;

- reducing indoor humidity;

- thorough ventilation of the room;

- using an air purifier or ozonizer.

Receipt

Alkyds are synthesized in two ways: alcoholysis and the fatty acid method.

In the first case, the process takes place in 3 stages:

Transesterification of vegetable oil or triglycerides of its fatty acids with polyhydric alcohols. The chemical reaction takes place at a temperature of 240-260 °C and in the presence of a catalyst. To produce glyphthalic resins from alcohols, glycerin is used, for ethphthalic resins - etriol, for pentaphthalic resins - pentaerythritol.

Esterification of partial esters with phthalic anhydride, resulting in the formation of an acid ester.

Polyesterification with release of water and formation of alkyd.

The second method of producing resins involves esterification and polyesterification of fatty acid esters and polyhydric alcohols.

Working with varnish indoors

Before applying varnish, the surface must be thoroughly sanded, then cleaned of remaining particles and dust, otherwise unsightly bumps will remain on it. All holes (for example, from nails) are first filled with putty and then sanded.

The next step is applying primer varnish. This operation is especially important before varnishing the parquet. The primer will provide better adhesion of the base material to the surface, remove remaining dust particles, and additionally protect the wood from moisture. In order for the choice to be correct, you must follow several rules.

- The first stage before priming work is to check the composition on a small area of the floor covering. This way you can determine how the composition acts on wood.

- Equally important is the compatibility of the primer varnish with the base varnish. For example, if you decide to use a water-soluble varnish, then the primer material should be the same.

- Drying the primer takes anywhere from 15 minutes to 3 hours, so this process won't take much time anyway since most base coats take much longer to dry.

- Apply primer varnish to the cleaned material along the grain, evenly. The main recommendation is full compliance. The primer and base material must be from the same manufacturer. In this case, there is a guarantee that there will be no unpleasant “surprises” (for example, dried bubbles).

The primer and base varnish are applied either manually - with a roller, wide brush, or spray. Different compositions need their own drying time. The fastest varnishes (alcohol-based) require speed from the master, as they begin to set after 10-15 minutes. “Slow” compositions (water-based) dry from several hours to several days. The period indicated on the product packaging is the time that must be waited before applying the next layer.

To improve the appearance of wood, add tone or enhance the pattern, use tinted varnish or stain. The latter liquid is produced on a water, wax, organic or alcohol basis. Its task is to make the drawing more expressive and contrasting.

The best polyurethane parquet varnish

It is characterized by such properties as heat and light resistance, elasticity, adhesion. The top layer is abrasion resistant and can withstand significant loads.

LobaDur WS 2K DUO

Loba parquet varnish is a two-component coating, the main component of which is polyurethane. It is considered the most popular in the manufacturer’s series due to the possibility of use in industrial and residential buildings with high mechanical load on the base.

LobaDur WS 2K DUO

Product consumption does not exceed 130 g/m2 provided that it is applied in one layer. The composition is packaged in containers of 5 and 1 liters. Costs 2000 rubles. and a 5 liter canister. It comes in matte, semi-matte, glossy and extra-matte.

Pros:

- suitable for public buildings;

- Resistant to scratches, impacts, heavy furniture.

Minuses:

after wet cleaning the surface is very slippery.

Dufa Expert D333

Polyurethane material is consumed quite economically - 1 liter per 8 m2. For interior work only. The acrylic composition forms a wear-resistant and durable coating with a silky shine.

Dufa Expert D333

The consistency is applied to a previously prepared surface. Easy to clean, even with detergents. Waterproof, colorless material is diluted with water. One coat requires 24 hours to dry completely. Price for 2.5 liters – 2850 rubles.

Pros:

- can even be washed with abrasives;

- silky finish;

- wear resistance

Minus:

It takes a very long time to dry - for hours, and you need at least 3 of them.

Luxens Heavy Duty

This parquet varnish is two-component, so it needs to be diluted with a solvent, but oddly enough, reviews say that it has absolutely no smell. The company produces it in a wide palette, everyone will find something in the line.

Luxens Heavy Duty

Specifications:

| Consumption, sq.m/l | |

| Time for complete drying, h | |

| Time between layers, h | 2-3 |

2 liters will cost 758 rubles.

Plus:

- a budget option;

- designed for intensive operating loads;

- for finishing plank floors, parquet, lining, wooden walls.

Minus:

takes a long time to dry, sticky.

Marshall Protex Parke Cila 90

Marshall is an alkyd urethane parquet varnish that gives a glossy finish. Complete drying takes as much as 96 hours, but in the end you will get a wear-resistant coating. Application is easy and leaves no streaks from the brush. It must be diluted according to the instructions with white spirit.

Marshall Protex Parke Cila 90

Specifications:

| Consumption, sq.m/l | |

| Time for complete drying, h | |

| Time between layers, h | 2-3 |

| Temperature during application, °C | 5-30 |

Price 932 rub.

Plus:

There are options with different finishes;

Minuses:

- there will be an odor due to the thinner;

- not suitable for kitchens and balconies, laminated surfaces;

- manual application only.

Eurotex Yacht

Eurotex is created on the basis of alkyd-urethane oils. Can be diluted with solvent. Application is carried out both mechanically and manually. A perfectly glossy sheen is guaranteed. Since this parquet varnish is also for yachts, it is suitable for wet operating conditions. There is a semi-matte option.

Eurotex Yacht

Specifications:

| Consumption, sq.m/l | 8-17 |

| Time for complete drying, h | |

| Time between layers, h |

A 2-liter container costs 790 rubles.

Pros:

- indoors and outdoors;

- does not burn out.

Minus:

The smell is from the solvent, but it dissipates quickly.

Lakra PF 231

Alkyd-urethane parquet varnish, which can be applied to metal and wood in rooms with moderate and high humidity. Complete hardening takes two days. Bring in furniture only after 5 days.

Lakra PF 231

Specifications:

| Consumption, sq.m/l | 13,5-16,5 |

| Time for complete drying, h | |

| Time between layers, h |

Price 0.8 l 140 rub.

Pros:

- apply with a roller, spray, brush;

- waterproof;

- Can be applied to oil based bases

Minuses:

- there is an odor;

- Internal use only.

Popular car polishes in spray form

There are many known brands of car varnishes in aerosol cans, we suggest you get acquainted with some of them.

Mobihel 1K

This varnish has excellent viscosity and adheres clearly to the car surface being treated, which makes it possible to form a dense layer without traces of leakage. It has excellent adhesion properties to the Mobihel metallic base coat. This spray is clear and is intended as a final coat over base paint. Two layers of applied aerosol give a total thickness of about 50–60 microns, which is a decent parameter for the consumer.

At standard 20 °C drying time is 5 minutes. (from dust), 12–15 min. (touch-free), complete drying lasts 60–90 minutes. The torch is unregulated, 7–8 cm in size. The main advantages are short drying time and excellent shine for this type of product.

Brulex

Transparent acrylic spray is designed to form a protective layer, as well as create a decorative shiny coating on the surface of metal, plastic and other materials. The product is one-component, for various types of work, air-dried. Brulex, released in the form of an aerosol, protects the base paint, does not turn yellow over time, and is resistant to abrasion, damage, and atmospheric conditions.

Holex

Car Acrylic Spray HAS-2559 is a 1K high quality product and air dry quickly. This composition is used to organize a transparent protective layer as part of a two-layer base-varnish paint coating. The advantages of the Holex composition are durability, strength, gloss. Can be applied to various surfaces that are properly prepared. It dries quickly, does not become cloudy over time, and is used for interior and exterior work.

Carfit

The varnish is used to form the finishing layer in car repair painting together with metallic paints. Aerosol can with a volume of 520 ml. The coating is shiny, well-adhesive to the surface, resistant to external influences, including mechanical damage. Before using the spray, shake vigorously for 1-2 minutes. The spray varnish is applied to a completely dry base paint, but it is permissible to apply it to an old coating that has been previously matted with a suitable abrasive.

Body clear coat

Excellent material, acrylic spray. Often used for urgent painting due to the fact that it dries very quickly. Used exclusively for local repairs, filling minor surface imperfections, scratches and pores. Fast drying and hardening makes it possible to save time and consumables.

Characteristics in the rating

| 1 | BRULEX 2K-HS | High quality material |

| 2 | Bosny VG | Best shine |

| 3 | PPG D800 | The best ratio of price and quality |

| 4 | Mobihel Anti-Scratch HS | Resistant to minor scratches |

| 5 | Motip Clear Varnish | Buyer's choice |

To complete the final treatment of the car body, a layer of varnish is applied several times to protect the paint from minor scratches, chips and fading in the sun. Polyurethane is considered the most modern and practical car varnish. A product based on this substance with the addition of acrylates is considered a more affordable material with excellent properties. Today it is the undisputed leader in sales, because it forms on the surface a film with excellent gloss and resistance to external influences that is the best.

Our review presents varnishes from different brands that occupy leading positions on the market. The place of each model in the rating is based on the properties, recommendations of professional car painting specialists and assessments of owners who have experience in the practical use of these products.

Which brand of yacht varnish should I choose?

Today, many paint and varnish manufacturers have expanded their range with varnishes of increased moisture resistance.

And to make it clearer to customers what properties the new products have, they added a loud inscription “yacht varnish” to the product names. There is no big deception here - the proposed coatings really reliably protect wooden structures from water and sun. So if you don’t plan to go out to sea on your summer gazebo, it’s quite possible to paint it with just such a varnish. Moreover, its cost will be relatively low.

Good coating materials with a moisture-proof function are offered by the following companies:

1. Poli-R

2. LLC Taganrog Paint and Varnish

3. Symphony

4. Polisan LLC (TM Maxima)

5. Private enterprise "Emal" (TM Rolax)

But if you want maximum water resistance or are really looking for a boat protection varnish, you'll need real "navy" grades:

1. Caparol (TM Alpina)

2. Belinka

3. Yaroslavl paints

4.Johnstones

5. Eskaro